Many industries face challenges with product stability, performance, and safety. Without proper binding and thickening agents, products may fail to meet quality standards, leading to significant financial losses.

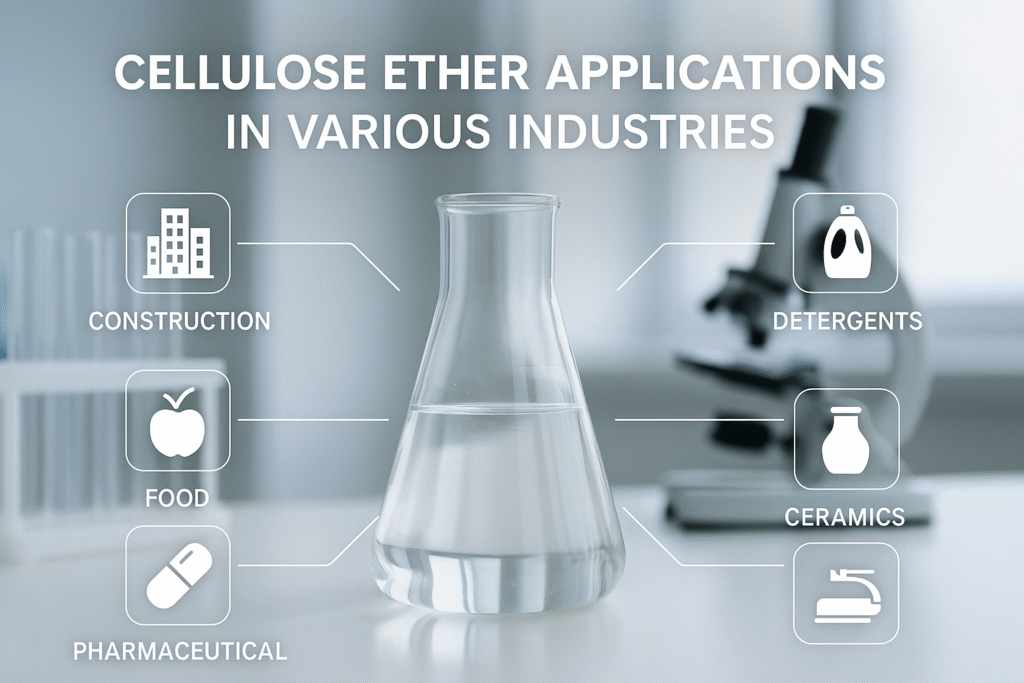

Cellulose ether1 serves as a versatile additive across multiple industries, functioning as a thickener, binder, film-former, and water-retention agent. It's derived from natural cellulose and modified to create compounds that enhance product performance in food, pharmaceuticals, construction, and scientific research.

I've spent years working with cellulose ethers at our production facility, and I've seen firsthand how these remarkable compounds can transform product formulations. The versatility of these modified natural polymers makes them indispensable across numerous sectors. Let me show you how this incredible material works in different applications.

How Does Cellulose Ether Enhance Food Safety and Quality?

Food manufacturers struggle with texture consistency, shelf-life, and maintaining product integrity. Without proper stabilizers, food products can separate, degrade, or develop unpleasant textures.

Food-grade cellulose ethers like methylcellulose2 (MC) and hydroxypropyl methylcellulose3 (HPMC) function as thickeners, emulsifiers, and stabilizers in food products. They improve texture, prevent syneresis, enhance freeze-thaw stability, and maintain product quality without affecting taste.

https://placehold.co/600x400 "Cellulose ether used in food products")

https://placehold.co/600x400 "Cellulose ether used in food products")

When I first started working with cellulose ethers in food applications, I was amazed by their versatility. These compounds have transformed how we approach food formulation across numerous categories. The key benefit lies in their ability to maintain food structure while being completely safe for consumption.

Cellulose ether1s play crucial roles in various food products. In ice creams and frozen desserts, they prevent ice crystal formation, creating smoother textures. For baked goods, they improve moisture retention and extend shelf life. In sauces and dressings, they provide stable viscosity even under varying temperature conditions.

What makes food-grade cellulose ethers particularly valuable is their resistance to enzymatic degradation in the digestive system. This means they pass through the body without being absorbed, qualifying them as dietary fiber. For consumers seeking reduced-calorie options, cellulose ethers can replace fat while maintaining pleasant mouthfeel.

Types of Food-Grade Cellulose Ethers

| Type | Primary Functions | Common Applications |

|---|---|---|

| Methylcellulose (MC) | Gelling agent, emulsifier | Vegetarian meat alternatives, baked goods |

| Hydroxypropyl Methylcellulose (HPMC) | Foam stabilizer, film former | Gluten-free products, fried foods |

| Carboxymethyl Cellulose4 (CMC) | Water binder, thickener | Dairy products, frozen desserts |

The food industry continues to find new applications for these versatile compounds, particularly as consumer demand for clean-label, plant-based, and reduced-calorie options grows. Our factory has seen increasing requests for customized cellulose ether formulations5 specifically designed for novel food applications.

How Do Pharmaceutical Products Benefit From Cellulose Ether?

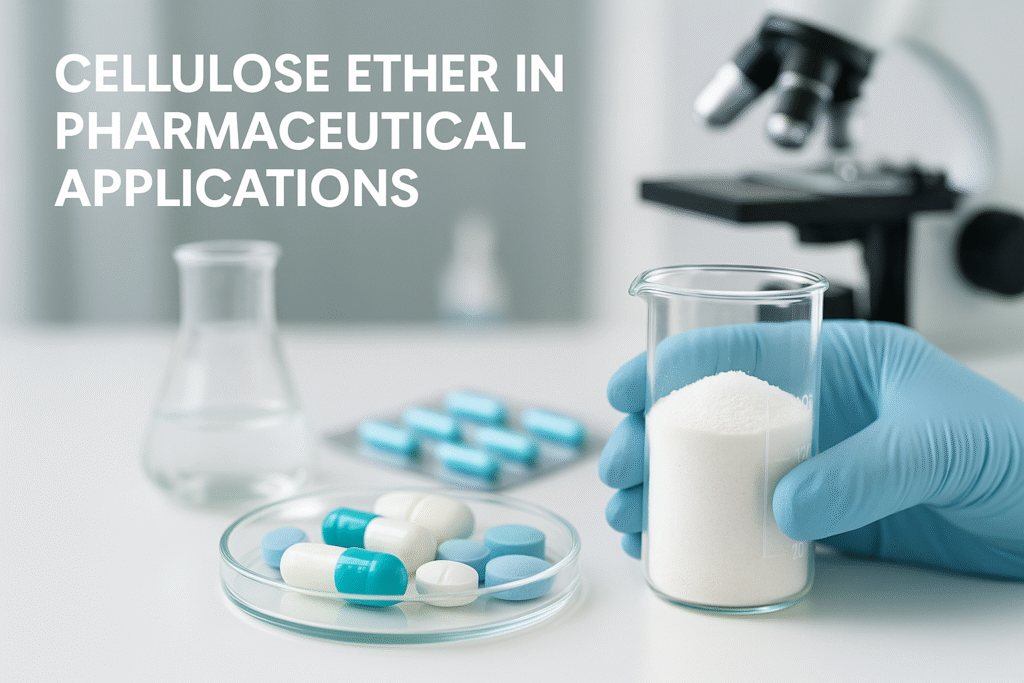

Pharmaceutical companies face challenges in drug delivery, controlled release, and tablet formation. Without effective excipients, medications may release too quickly, degrade prematurely, or fail to dissolve properly.

Pharmaceutical-grade cellulose ethers provide controlled drug release, tablet binding, film coating, and increased bioavailability. Types like HPMC, HEC, and CMC create matrices that regulate medication release rates, helping maintain therapeutic drug levels over extended periods.

In our work with pharmaceutical manufacturers, I've observed how cellulose ethers have revolutionized drug delivery systems. These compounds have become essential components in modern medication formulation, addressing many challenges that previously limited treatment efficacy.

Controlled-release formulations represent perhaps the most significant pharmaceutical application. By creating a hydrophilic matrix system, cellulose ethers like HPMC can regulate how quickly a drug dissolves and enters the bloodstream. This technology allows patients to take medications less frequently while maintaining consistent therapeutic effects.

For tablet manufacturing, cellulose ethers serve multiple functions simultaneously. They act as binders during the granulation process, helping to form sturdy tablets that won't crumble during packaging and transport. They also function as disintegrants, ensuring the tablet breaks apart appropriately when ingested. Additionally, they can form protective films around tablets, masking bitter tastes, protecting from moisture, or ensuring the medication reaches the intended part of the digestive tract before releasing.

Pharmaceutical Applications by Cellulose Ether Type

| Type | Viscosity Range | Primary Applications |

|---|---|---|

| HPMC | Low to High | Extended-release tablets, film coating |

| CMC | Medium to High | Tablet binder, suspending agent |

| HEC | Low to Medium | Thickener for liquid medications |

| MC | Variable | Coating agent, controlled release |

The pharmaceutical industry's continuing shift toward personalized medicine and complex delivery systems has only increased demand for specialized cellulose ether grades. Our factory has invested in additional quality control measures to meet the stringent requirements for pharmaceutical-grade materials.

How Can Cellulose Ether Improve Construction Materials?

Construction material manufacturers struggle with workability, water retention, and final product durability. Without effective additives, mortars and plasters can crack, lose strength, or fail to adhere properly.

In construction applications, cellulose ethers like HPMC and CMC improve water retention in cement-based materials, enhance workability, prevent sagging, and increase open time for application. These properties result in stronger, more durable finished structures.

Having supplied cellulose ethers to the construction industry for years, I've witnessed their transformative impact on modern building materials. What once required complex formulations with multiple additives can now be achieved more efficiently with properly selected cellulose ethers.

Water retention is perhaps the most critical function in construction applications. When cement-based materials lose water too quickly, proper hydration doesn't occur, resulting in reduced strength and durability. Cellulose ethers create a water-retaining gel structure that slows evaporation and prevents water from being absorbed too quickly by porous substrates. This ensures complete cement hydration and significantly improves the final material strength.

Another key benefit is improved workability. Cellulose ethers give mortars, plasters, and tile adhesives a creamier consistency that makes them easier to apply. This reduces mason fatigue and increases productivity. They also prevent sagging of freshly applied materials, which is especially important for ceiling applications and when using larger, heavier tiles.

For self-leveling compounds6, cellulose ethers control flow properties to create perfectly smooth surfaces without manual intervention. In exterior insulation and finish systems (EIFS), they improve freeze-thaw resistance and reduce cracking. In tile adhesives, they extend open time, allowing more material to be applied before setting begins.

Construction Applications by Cellulose Ether Grade

| Grade | Viscosity | Key Construction Applications |

|---|---|---|

| HPMC E40 | Low | Self-leveling compounds |

| HPMC P200 | Medium | Tile adhesives, renders |

| HPMC P150 | High | Plasters, stuccos |

| RDP Enhanced | Variable | Exterior insulation systems |

Our factory has developed specialized cellulose ether grades with optimized particle size distribution specifically for construction applications. These materials dissolve quickly during mixing while providing excellent water retention and workability properties.

How Does Cellulose Ether Advance Scientific Research?

Scientific researchers face challenges in sample preparation, analysis methodology, and experiment reproducibility. Without effective separation media and stabilizers, research results may be inconsistent or inaccurate.

In scientific research, cellulose ethers serve as separation media for chromatography, stabilizers for biological samples, and components in tissue engineering scaffolds. Their biocompatibility, consistent performance, and customizable properties make them valuable tools across various scientific disciplines.

Through our collaborations with research institutions, I've gained insight into how cellulose ethers facilitate scientific advancement. These materials have become fundamental components in numerous laboratory techniques and innovative research applications.

Chromatographic separations represent one of the oldest scientific applications for cellulose derivatives. Modified cellulose creates stationary phases that can separate complex mixtures based on molecular size, charge, or hydrophobicity. This enables researchers to isolate specific compounds from natural products, identify contaminants in environmental samples, or purify synthetic products.

In biotechnology, cellulose ethers help stabilize proteins and enzymes, preserving their activity during storage or analysis. They also serve as cryoprotectants for preserving biological samples at extremely low temperatures without damaging cellular structures. For tissue engineering, certain cellulose ether types can be formulated into hydrogels that mimic natural tissue environments, providing scaffolds for cell growth and tissue development.

Another emerging application is in 3D bioprinting7, where cellulose-based bioinks provide structural support while maintaining cell viability. These materials offer excellent printability and can be formulated to degrade at controlled rates as natural tissue forms.

Scientific Applications of Specialized Cellulose Ethers

| Type | Modification | Research Application |

|---|---|---|

| HPMC | Photocrosslinkable | 3D bioprinting materials |

| CMC | Ionic | Drug delivery research |

| HEC | Thermoresponsive | Controlled release studies |

| Specialized Derivatives | Various | Chromatographic media |

The growing interest in sustainable materials has also led researchers to explore new applications for cellulose ethers in fields like environmental remediation, sustainable packaging, and green chemistry. Our R&D team actively collaborates with university partners to develop novel cellulose ether derivatives for these emerging applications.

Conclusion

Cellulose ether1s transform multiple industries through their versatile functionality as stabilizers, thickeners, binders, and film-formers. Their natural origin and extensive modification possibilities ensure they'll continue meeting evolving needs across food, pharmaceutical, construction, and scientific applications.

-

Explore how cellulose ether enhances product formulations across multiple sectors. ↩ ↩ ↩

-

Explore the versatile uses of methylcellulose in enhancing food quality. ↩

-

Learn about the critical applications of HPMC in drug delivery systems. ↩

-

Discover how CMC enhances texture and stability in various food items. ↩

-

Discover how tailored cellulose ether formulations meet specific industry needs. ↩

-

Find out how self-leveling compounds improve the application of construction materials. ↩

-

Learn about the innovative uses of cellulose ethers in bioprinting technologies. ↩