Self-leveling mortar problems can quickly turn your construction project into a costly nightmare. Cracks, uneven surfaces, and slow drying times frustrate even the most experienced contractors and delay project completion.

WH® E401 is a specialized cellulose ether2 designed to enhance self-leveling mortar3 performance by improving flow properties, extending working time, and preventing segregation. It creates a smooth, level surface with excellent water retention and adhesion properties, making it ideal for both residential and commercial flooring applications.

As a manufacturer with over 15 years in the cellulose ether industry, I've seen countless formulation issues that could have been avoided with the right HPMC product. Let me share how our WH® E40 can transform your self-leveling mortar performance and help you deliver superior results to your customers.

What Makes WH® E40 Essential for Quality Self-Leveling Screeds?

Every contractor knows the pain of dealing with self-leveling compounds that crack, shrink, or simply don't flow properly. These issues waste time and damage professional reputation when customers see imperfect floors.

WH® E40 is a premium hydroxypropyl methylcellulose4 (HPMC) specifically formulated for self-leveling applications. It provides exceptional water retention, controls rheology, prevents material segregation, and ensures consistent flow properties throughout the entire application and curing process.

The science behind WH® E40's performance lies in its carefully engineered molecular structure. Our product has been developed through extensive research and testing specifically for demanding self-leveling applications. The methoxyl content and hydroxypropyl substitution are precisely balanced to deliver optimal performance in cement-based systems.

When incorporated into your self-leveling formulation, WH® E40 forms a protective colloid that suspends cement and aggregate particles, preventing material segregation. This is crucial for maintaining consistent flow and ensuring the final surface is smooth and uniform. Additionally, the water retention properties help control the hydration rate of cement, reducing the risk of shrinkage cracks and ensuring proper strength development.

In my experience working with major mortar manufacturers across Saudi Arabia, UAE and other Middle Eastern markets, those who switch to WH® E40 consistently report fewer customer complaints and higher satisfaction rates with their self-leveling products.

What Technical Specifications Make WH® E401 Superior for Self-Leveling Applications?

Construction material manufacturers often struggle with inconsistent cellulose ethers that perform differently from batch to batch, causing production headaches and quality control issues that damage brand reputation.

WH® E40 maintains strict technical specifications with viscosity of 380-400 mPa·s (2% solution), methoxyl content of 28-30%, hydroxypropyl content of 7-12%, and gel temperature of 65-81°C. These parameters ensure consistent performance in self-leveling mortars across all production batches.

The technical excellence of WH® E40 comes from our advanced production process and rigorous quality control system. Each batch undergoes multiple testing phases to verify it meets our strict specifications before reaching your facility. Our production line in China utilizes the latest technology to ensure molecular weight distribution is tightly controlled – a key factor in providing consistent workability and water retention.

Beyond the standard specifications, WH® E40 offers additional technical benefits that make it particularly suitable for self-leveling applications. Its particle size distribution is optimized for easy dispersion in dry-mix formulations, reducing mixing time and energy consumption during production. The ash content is kept below 5%, minimizing any interference with cement hydration.

We also conduct application-specific testing that simulates real-world conditions. This includes flow testing under various temperature and humidity conditions, ensuring WH® E40 performs reliably regardless of the environmental challenges at the job site. This comprehensive approach to product development and quality assurance is why major mortar manufacturers across developing markets trust our products for their premium self-leveling formulations.

| Property | WH® E40 Specification | Benefit in Self-Leveling Applications |

|---|---|---|

| Viscosity (2% solution) | 380-400 mPa·s | Optimal flow control and water retention |

| Methoxyl content | 28-30% | Balanced dissolution rate and workability |

| Hydroxypropyl content | 7-12% | Enhanced water retention and open time |

| Gel temperature | 65-81°C | Thermal stability in various climates |

| Particle size | 100 mesh (≥95%) | Easy dispersion in dry mixes |

| Ash content | ≤5% | Minimal interference with cement hydration |

What is the Recommended Self-Leveling Mortar Formulation With WH® E40?

Formulating a balanced self-leveling mortar often becomes a frustrating trial-and-error process, wasting valuable R&D time and resources while competitors move ahead with better products.

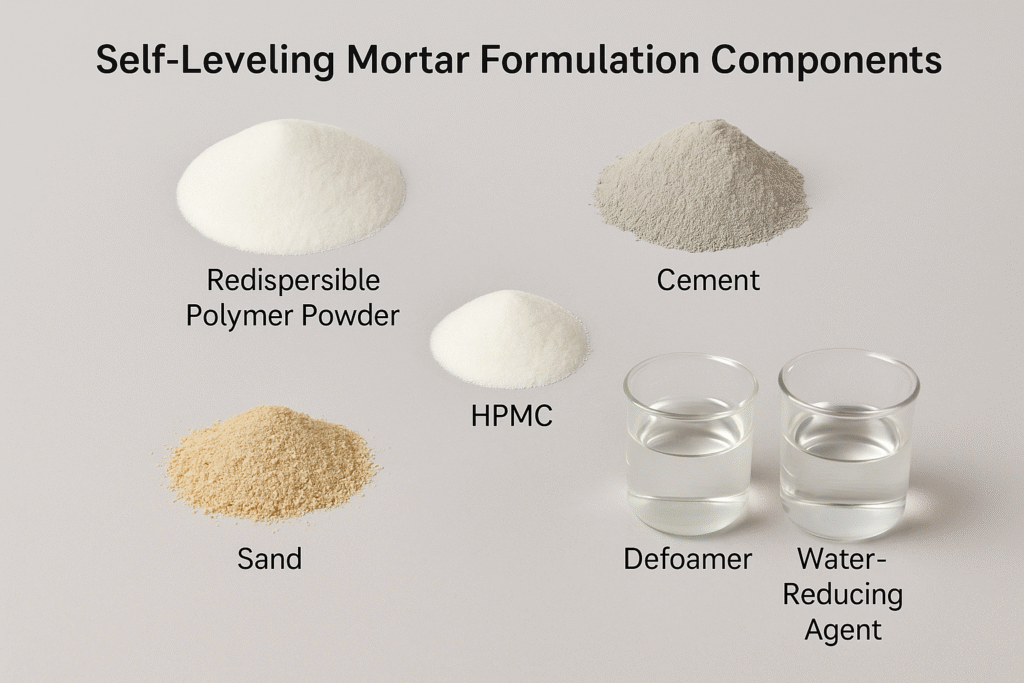

A balanced self-leveling mortar3 formulation with WH® E40 typically contains: Portland cement (25-30%), calcium aluminate cement (3-5%), WH® E40 (0.15-0.25%), redispersible polymer powder (1-2%), calcium carbonate (50-60%), and other additives like accelerators and defoamers (2-3%).

Through years of collaborative work with our technical partners and customers, we've refined this formulation to deliver exceptional performance across diverse environmental conditions. The key to success lies not just in the percentages but in understanding how each component interacts with WH® E40 to create a synergistic effect.

The double cement system (Portland and calcium aluminate) provides both early strength and long-term durability, while WH® E40 at the recommended dosage ensures proper water retention without overly delaying setting time. The precise amount of redispersible polymer powder enhances adhesion to the substrate and improves flexibility of the cured mortar.

When implementing this formulation, particle size distribution of the calcium carbonate filler is crucial – we recommend using a blend of fine, medium, and coarse particles to optimize packing density and minimize water demand. This approach, combined with WH® E40's excellent water retention properties, creates a self-leveling mortar that flows easily without segregation while maintaining dimensional stability during drying.

I've personally worked with customers in Saudi Arabia and the UAE to adapt this formulation to local raw materials and climate conditions. One large mortar factory in Riyadh was able to reduce setting time variation by 40% after implementing our recommended formulation with WH® E40, significantly improving their production efficiency and customer satisfaction.

How Long Does Self-Leveling Mortar Take to Dry With WH® E40?

Unpredictable drying times can throw off project schedules, frustrate customers, and lead to callbacks when floors are sealed or covered too soon, resulting in bubbling, delamination, or other failures.

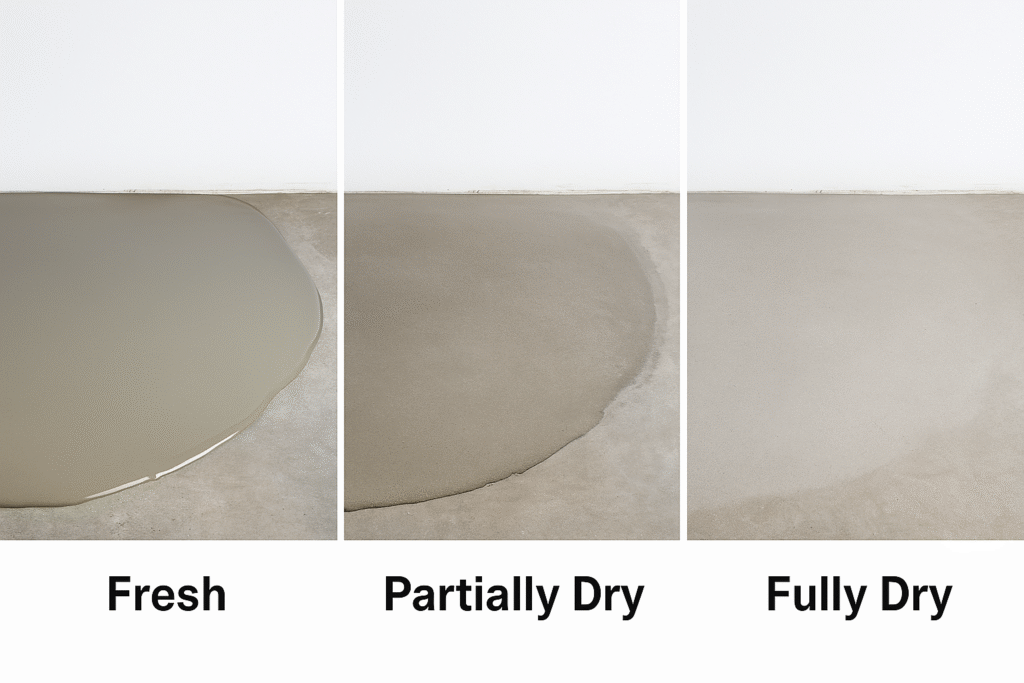

Self-leveling mortar made with WH® E40 typically becomes walkable in 3-4 hours and achieves sufficient dryness for most floor coverings in 24-48 hours. The controlled water retention properties of WH® E40 ensure consistent drying times even in varying humidity conditions.

The drying time of self-leveling mortar depends on multiple factors, but WH® E40 helps create predictable results through its engineered water retention profile. Unlike generic HPMC products that might excessively delay drying, WH® E40 releases moisture at an optimal rate that balances proper cement hydration with practical drying times.

Our laboratory testing has shown that the moisture content in self-leveling mortars formulated with WH® E40 follows a more consistent drying curve compared to formulations using standard cellulose ethers. This predictability is especially valuable in commercial projects with tight scheduling requirements.

Temperature and humidity naturally affect drying times, but WH® E40's performance remains more stable across varying conditions than generic alternatives. In extreme environments, minor adjustments to the formulation can be made without compromising the core benefits. For instance, in high humidity tropical regions like Singapore or Vietnam, reducing the WH® E40 dosage by 0.05% can maintain optimal drying times without sacrificing flow properties.

It's worth noting that thickness significantly impacts drying time. While a 3mm layer might be ready for covering in 24 hours, a 10mm application could require 48-72 hours. WH® E40's consistent performance helps make these timeframes reliable, allowing contractors to plan subsequent work with confidence. This predictability is one reason why our product has gained popularity among large mortar factories supplying time-sensitive commercial construction projects.

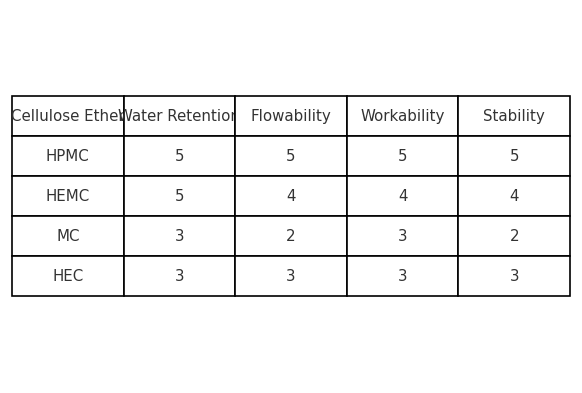

Why Choose WH® E40 Over Other Cellulose Ethers for Self-Leveling Applications?

Generic cellulose ethers often create inconsistent results in self-leveling applications, leading to quality control issues, customer complaints, and damage to your brand reputation when floors don't meet expectations.

WH® E40 is specifically engineered for self-leveling mortars with precise viscosity control, optimal water retention, and controlled rheology modification. Unlike generic HPMCs, it provides consistent batch-to-batch performance, enhances flow characteristics without segregation, and creates smooth, defect-free surfaces.

The difference between WH® E40 and standard cellulose ethers becomes evident immediately during application. While general-purpose HPMCs might initially provide acceptable flow, they often fail to maintain consistent rheology throughout the working time. WH® E40, by contrast, is designed with a specific molecular structure that provides sustained performance from mixing through leveling and curing.

Our commitment to quality extends beyond the product itself. When you choose WH® E40, you gain access to our technical support5 team with extensive experience in self-leveling applications. We don't just sell a chemical – we provide a complete solution that includes formulation assistance, troubleshooting support, and ongoing optimization as your market demands evolve.

The stability of WH® E40's performance across temperature variations is particularly valuable for manufacturers selling across multiple climate zones. One of our customers supplies self-leveling products throughout the Middle East, facing temperature variations from 10°C to 45°C depending on season and location. After switching to WH® E40, they were able to maintain a single formulation year-round with only minor adjustments, simplifying their production and inventory management.

Cost-effectiveness must be evaluated beyond the initial price per kilogram. When accounting for reduced waste, fewer customer complaints, and enhanced product performance, WH® E40 delivers superior value despite its premium positioning. A major mortar manufacturer in Mexico calculated that switching to WH® E40 increased their raw material cost by just 3% while reducing returns and complaints by over 30%, resulting in significant net savings.

Frequently Asked Questions (FAQ)

Is WH® E40 compatible with all cement types?

Yes, WH® E40 works well with Portland cement, calcium aluminate cement, and blended cements. However, minor dosage adjustments may be needed depending on the specific cement chemistry.

Can WH® E40 be used in gypsum-based self-leveling compounds?

Absolutely. WH® E40 performs excellently in gypsum systems, providing similar benefits of water retention and flow control as in cement-based formulations.

What packaging options are available for WH® E40?

We offer WH® E40 in 25kg paper bags with PE inner liner as standard. Bulk bags (500-1000kg) are available for high-volume customers, and custom packaging with your branding is available upon request.

How should WH® E40 be stored?

Store in a cool, dry place away from direct sunlight. When properly stored, WH® E40 maintains its properties for at least 24 months from the production date.

Is technical support available for formulation development?

Yes, our technical team provides comprehensive support including starter formulations, troubleshooting assistance, and on-site optimization services for qualified customers.

Conclusion

WH® E40 transforms ordinary self-leveling mortars into premium products with exceptional flow, consistent drying times, and superior surface quality. Try our professionally engineered cellulose ether and experience the difference in your next project.

-

Explore how WH® E40 can enhance your construction projects with superior performance. ↩ ↩

-

Learn about cellulose ether's role in improving construction materials and their performance. ↩

-

Understanding common issues can help you avoid costly mistakes in your projects. ↩ ↩

-

Discover the benefits of HPMC in construction and how it can improve your projects. ↩

-

Explore the benefits of having technical support for your construction projects. ↩