Tile installation nightmares keep contractors awake at night. Adhesives dry too quickly, tiles slip, and soon you're facing expensive rework and unhappy clients. These challenges directly impact your bottom line and reputation.

HPMC (Hydroxypropyl Methylcellulose)1 transforms tile adhesives by enhancing water retention and controlling viscosity. It extends open time allowing proper tile placement while improving workability. The right HPMC grade is crucial - higher viscosity types provide longer open times for premium adhesives, while standard grades suit basic applications.

As a manufacturer with six production lines dedicated to construction chemicals2, I've seen firsthand how the right additive makes all the difference in tile installation success. Let me share what I've learned about HPMC's crucial role in creating high-performance tile adhesives.

Why Do Tile Adhesives Need HPMC?

Contractors frequently struggle with inconsistent adhesive performance. Tiles fail to bond properly, slide down vertical surfaces, or the adhesive dries before proper positioning. These issues waste time, materials, and damage professional reputations.

Tile adhesives need HPMC because it acts as a water retention agent and rheology modifier. It prevents premature water loss to porous substrates and evaporation, while simultaneously providing the right consistency for easy application and strong tile bonding.

HPMC transforms ordinary cement-based adhesives into high-performance products. The chemistry behind this transformation is fascinating and directly impacts everyday installation work. When HPMC dissolves in water, it forms a protective colloid that significantly slows water movement out of the adhesive.

How HPMC Impacts Different Adhesive Properties

| Property | HPMC Effect | Benefit to Installer |

|---|---|---|

| Viscosity | Increases thickness | Prevents tile slippage on vertical surfaces |

| Water Retention | Slows water evaporation | Extended working time |

| Sagging Resistance | Improves structural stability | Tiles stay in place during installation |

| Bonding Strength | Enhances cement hydration | More durable installation, fewer callbacks |

| Workability | Creates smoother consistency | Easier spreading and troweling |

I once visited a major construction project in Dubai where the contractor switched to our HPMC-enhanced adhesive mid-project. The difference was immediately noticeable - installation speed increased by nearly 30% because workers spent less time fighting against quick-setting adhesives in the hot climate.

How to Speed Up Tile Adhesive Drying Time?

Balancing adequate working time with reasonable drying can be frustrating. Too slow, and projects fall behind schedule. Too fast, and proper tile placement becomes impossible. This timing challenge costs professionals money and client satisfaction.

To speed up tile adhesive drying time, use lower viscosity HPMC grades (15,000-30,000 mPa·s), reduce HPMC content slightly, ensure proper ventilation, maintain moderate room temperature, and consider adding small amounts of accelerator compounds like calcium formats if compatible with your adhesive system.

Finding the perfect balance between workability and drying time is an art mastered through proper HPMC selection and formulation adjustments. I regularly work with customers to find this sweet spot for their specific applications.

The molecular weight of HPMC dramatically impacts drying characteristics. Lower molecular weight HPMC (identified by lower viscosity numbers) retains less water, allowing faster moisture release and quicker setting. This is particularly important in humid environments or cooler temperatures where drying can otherwise be significantly delayed.

When formulating for specific climate conditions, we recommend different HPMC specifications:

HPMC Selection Guide for Different Drying Requirements

| Climate Condition | Recommended HPMC Viscosity | Recommended Dosage | Expected Drying Benefit |

|---|---|---|---|

| Hot, dry (40°C+) | 40,000-60,000 mPa·s | 0.3-0.4% | Prevents premature drying |

| Moderate (20-30°C) | 30,000-40,000 mPa·s | 0.2-0.3% | Balanced drying time |

| Cool, humid (<20°C) | 15,000-30,000 mPa·s | 0.1-0.2% | Accelerated drying |

I remember consulting with a large tile installation3 company in Saudi Arabia that was struggling with excessive drying times despite the hot climate. Upon investigation, we discovered they were using an excessively high-viscosity HPMC. By adjusting to a moderate viscosity product, they achieved the perfect balance between workability and drying speed.

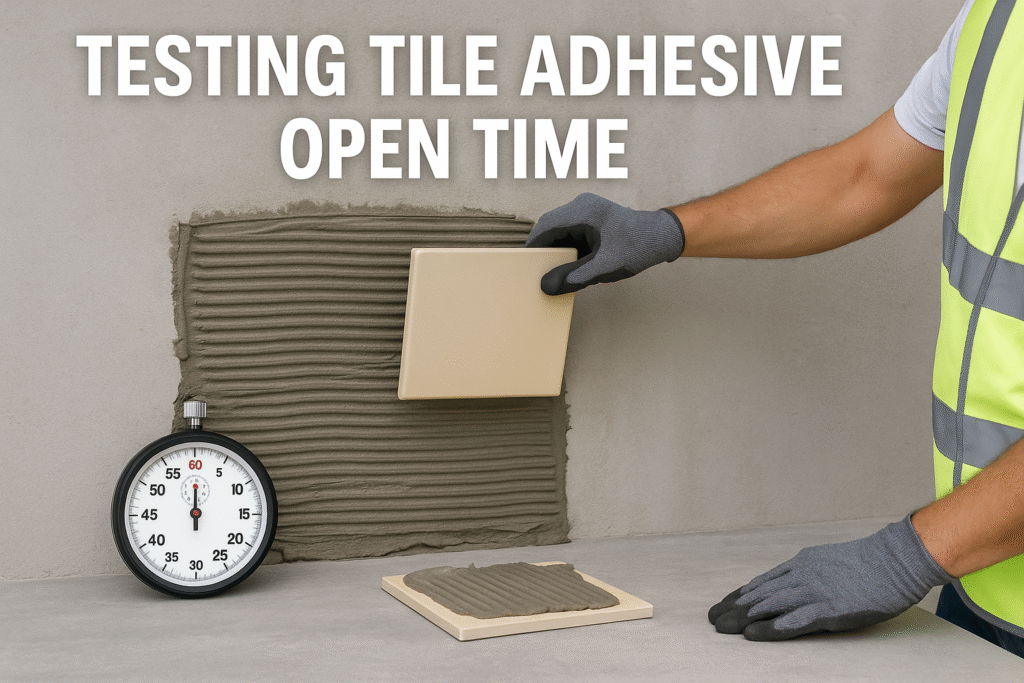

What is the Open Time for Tile Adhesive?

Time pressure creates anxiety for installers. The clock starts ticking once adhesive is applied, and exceeding open time means wasted product, poor bonding, and failed installations. Professionals need reliable open times to plan large-scale projects effectively.

Open time for tile adhesive refers to the period after application during which tiles can be properly placed and adjusted while maintaining full bonding strength4. Standard tile adhesives typically offer 15-20 minutes, while premium HPMC-enhanced versions can extend this to 30+ minutes, critical for complex installations.

Open time is perhaps the most crucial performance parameter for professional tile installers. It directly impacts workflow efficiency, installation quality, and ultimately, the durability of the finished project.

HPMC creates this extended open time through its unique water retention mechanism. When incorporated into adhesive formulations, HPMC molecules form a protective network around water molecules, dramatically slowing evaporation and absorption into porous substrates like concrete or drywall.

The grade of HPMC used significantly impacts open time5 performance:

HPMC Impact on Open Time Performance

| HPMC Grade | Typical Viscosity | Open Time | Best Application |

|---|---|---|---|

| Economy | 15,000-30,000 mPa·s | 10-15 minutes | Small residential projects |

| Standard | 30,000-50,000 mPa·s | 15-20 minutes | General tiling work |

| Premium | 50,000-100,000 mPa·s | 20-30+ minutes | Large format tiles, complex patterns |

| Ultra-Premium | 100,000+ mPa·s | 30-40+ minutes | Commercial projects, extreme conditions |

During my visit to a major hotel renovation in Singapore, I observed installers using our premium-grade HPMC in their adhesive. They were able to spread adhesive across a significantly larger area before beginning tile placement, dramatically increasing installation efficiency while maintaining perfect alignment. The project manager estimated they saved nearly two weeks on the overall schedule.

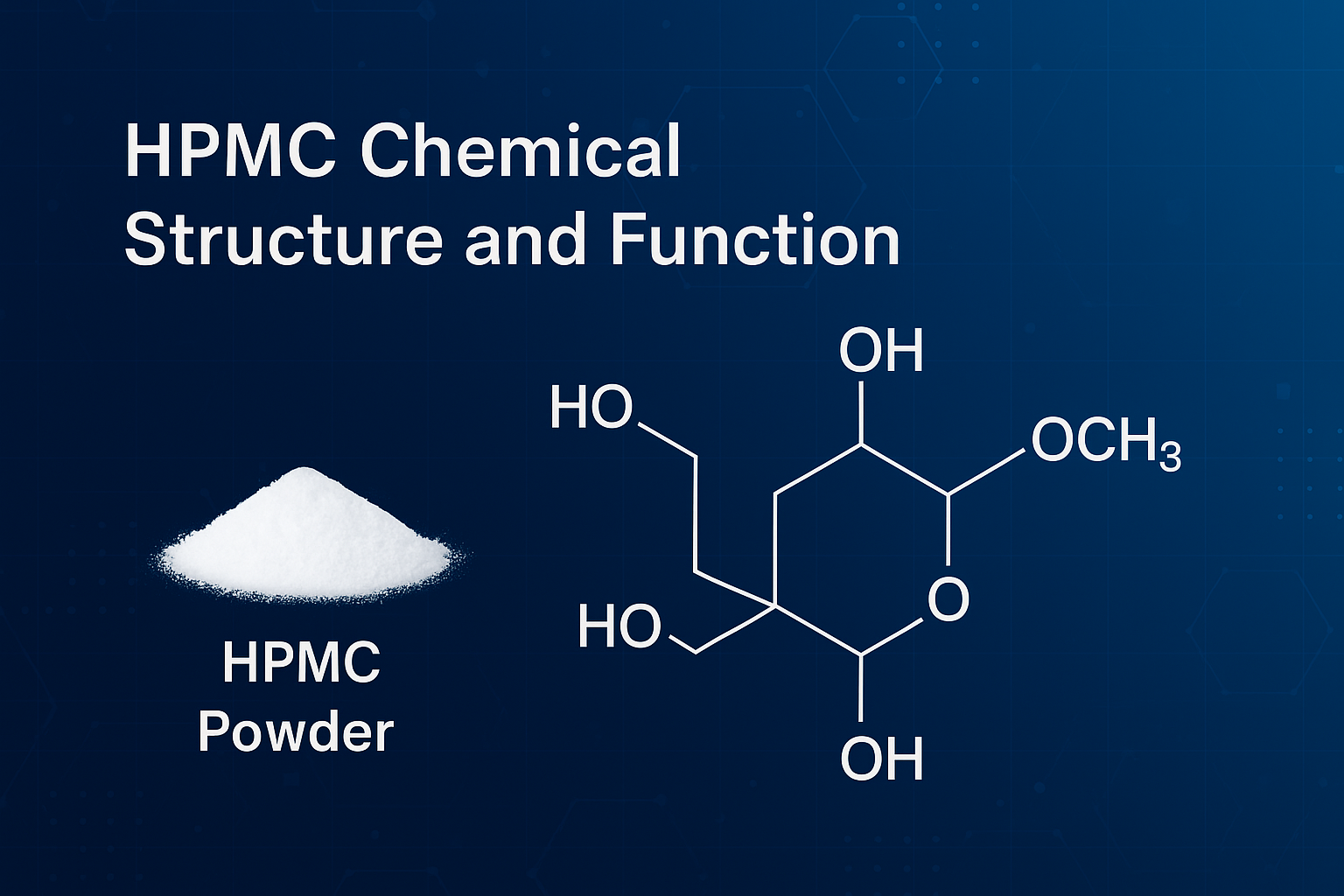

What is HPMC Chemical for Tiles?

Confusion about chemical additives creates hesitation. Construction professionals worry about using unfamiliar products, concerned about compatibility issues or performance failures. This uncertainty leads to resistance in adopting advanced technologies.

HPMC chemical for tiles is a cellulose ether derivative produced by reacting alkali cellulose with propylene oxide and methyl chloride. It functions as a thickener, binder, film-former, and water retention agent in tile adhesives, available in different viscosity grades (15,000-200,000 mPa·s) to suit various application requirements.

HPMC's chemical structure gives it unique properties that directly benefit tile installation work. The hydroxypropyl groups provide water retention capabilities while the methyl groups control solubility and surface activity. This combination creates the perfect additive for cement-based adhesives.

At our factory, we produce HPMC through a sophisticated process that allows precise control over molecular weight and substitution patterns. This enables us to create specialized grades for specific tile adhesive applications.

HPMC Chemical Properties and Benefits

| Chemical Property | Technical Description | Practical Benefit |

|---|---|---|

| Methoxyl Content | 19-30% | Controls dissolution temperature and water retention |

| Hydroxypropyl Content | 7-12% | Influences compatibility with cement and other additives |

| Molecular Weight | 22,000-250,000 | Determines viscosity and water retention capacity |

| Particle Size | 100-150 mesh | Affects dissolution speed during mixing |

| Gel Temperature | 58-65°C | Impacts performance in different climate conditions |

I often explain to customers that HPMC is one of the few additives that simultaneously improves both the application properties and the final performance of tile adhesives. In a recent consultation with a major mortar manufacturer in Brazil, I demonstrated how changing from a generic HPMC to our specialized tile-grade product improved open time by 40% while maintaining the same mixing and application characteristics their installers were accustomed to.

Conclusion

HPMC transforms ordinary tile adhesives into high-performance products6 by controlling water retention and viscosity. Select the right grade for your specific application—higher viscosity for premium adhesives requiring longer open times, and standard grades for basic applications.

-

Explore how HPMC enhances tile adhesives, improving performance and installation efficiency. ↩

-

Explore the broader category of construction chemicals and their significance in the industry. ↩

-

Identify the challenges faced during tile installation and how to overcome them. ↩

-

Find out why bonding strength is crucial for durable tile installations and fewer callbacks. ↩

-

Discover the importance of open time for tile installers and how it affects project success. ↩

-

Discover the characteristics that make tile adhesives high-performance and reliable. ↩