Paint application problems frustrate even experienced contractors. Drips, sags, poor coverage, and extended drying times waste time and money. The right HPMC viscosity selection can solve these issues from the start.

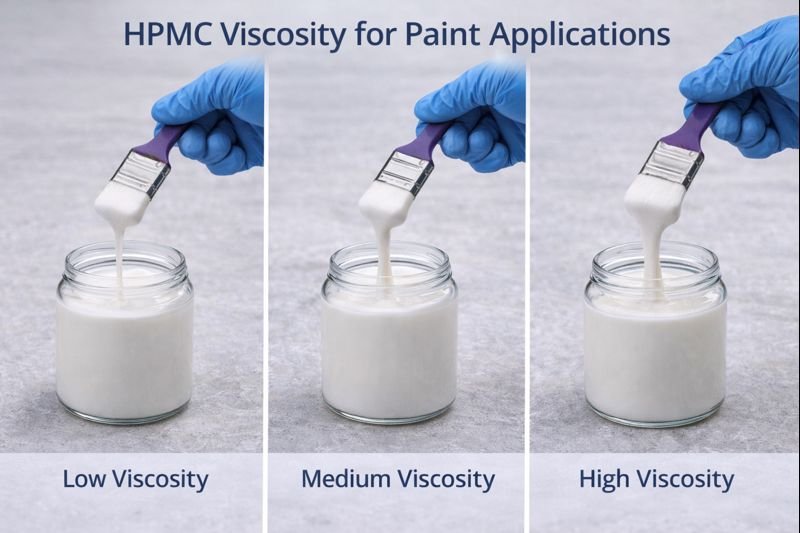

HPMC viscosity1 directly impacts paint application by controlling flowability and film formation. Low viscosity HPMC (5,000-15,000cps) creates easily spreadable paint but may drip, while high viscosity types (50,000+cps) provide sag resistance but may leave brush marks.

After 15 years supplying HPMC to major paint manufacturers across Asia and the Middle East, I've seen firsthand how this seemingly small formulation detail can make or break a product's market success. Let's examine exactly how viscosity impacts your paint performance.

How Does Viscosity Affect Paint?

Paint that's too thin runs off surfaces wastefully. Paint that's too thick becomes impossible to apply evenly. This viscosity balancing act costs manufacturers millions in reformulation.

Paint viscosity determines application method suitability and final appearance. Low viscosity paints (60-80 KU) work well for spraying but may drip, medium viscosity (85-95 KU) suits rolling and brushing, while high viscosity (100+ KU) prevents sagging but requires more effort to apply.

The viscosity profile of paint isn't just about its thickness - it's about how that thickness changes during application. This is where HPMC truly shines compared to other thickeners.

Shear-Thinning Behavior: The Key to Smooth Application

HPMC creates a unique rheological profile in paint that makes application easier while maintaining good film properties. At high shear rates (during brushing or rolling), HPMC-thickened paint becomes temporarily thinner, allowing easier application. Once applied, at rest, the paint quickly recovers its higher viscosity, preventing sags and drips.

I once visited a customer in Saudi Arabia who switched from a generic cellulose thickener to our Kehao HPMC K75M grade. The difference was immediately noticeable - painters completed walls 30% faster with fewer touch-ups needed. This shear-thinning behavior is particularly important for brush and roller applications where the balance between ease of application and sag resistance is critical.

To quantify this property, we measure viscosity at different shear rates (usually 0.1-100 s⁻¹) using a rotational viscometer according to ISO 2555 standards. The ratio between low-shear and high-shear viscosity (thixotropic index) should ideally be between 3-5 for optimal application properties.

What Is The Viscosity Of HPMC?

Selecting the wrong HPMC viscosity grade leads to costly paint formulation failures. Many manufacturers struggle with inconsistent product performance due to poor viscosity selection.

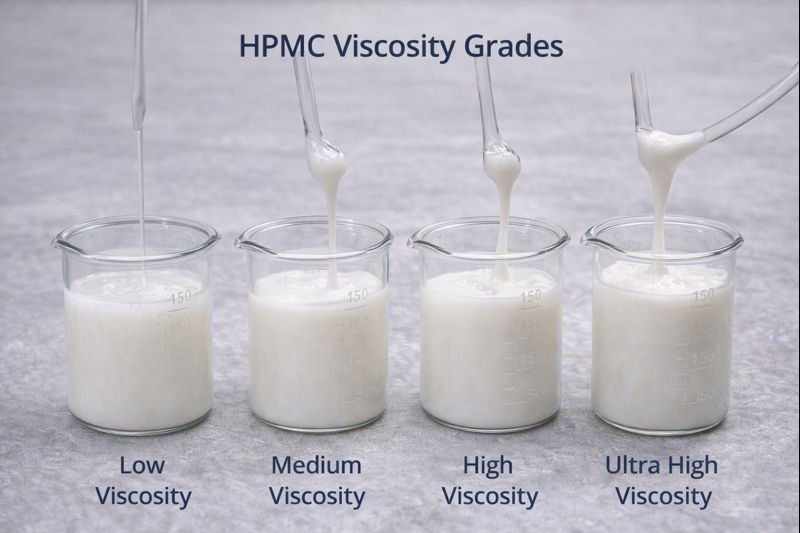

HPMC viscosity1 typically ranges from 5 to 100,000 mPa·s (2% solution at 20°C), with grades classified as low (5-15,000 mPa·s), medium (15,000-50,000 mPa·s), or high (50,000-100,000 mPa·s). The viscosity depends on the degree of substitution and molecular weight.

Understanding HPMC viscosity measurement is crucial for proper grade selection. Standard test methods involve preparing a 2% aqueous solution and measuring viscosity at 20°C using a rotational viscometer.

Viscosity Designation Systems: Decoding the Numbers

HPMC products often use different naming conventions that can be confusing to formulators. Most manufacturers use a letter-number system where the letter indicates viscosity range and the number provides more specific information.

For example, in our Kehao product line:

- K5M: 5,000 mPa·s

- K15M: 15,000 mPa·s

- K50M: 50,000 mPa·s

- K100M: 100,000 mPa·s

The viscosity of HPMC is influenced by several factors during manufacturing:

- Molecular weight - controlled by the degree of polymerization

- Methoxyl content - affects water solubility and thermal gelation

- Hydroxypropyl content - impacts surface activity and compatibility with other ingredients

Temperature significantly affects HPMC viscosity. Most grades exhibit inverse solubility, forming gels at higher temperatures (thermal gelation). This property can be advantageous in paints applied in hot weather, as it can prevent excessive sag when applied to sun-heated surfaces.

During my visits to paint manufacturers in the UAE, I've noticed that many don't account for the temperature effects on HPMC viscosity, leading to seasonal performance variations in their products. Testing at application temperatures rather than just standard laboratory conditions is essential.

What Is A Good Viscosity For Paint?

Incorrect paint viscosity causes application headaches, customer complaints, and project delays. Finding the optimal viscosity balance prevents these costly problems.

A good viscosity for water-based architectural paint typically falls between 85-95 Krebs Units (KU). Interior paints often perform best at 85-90 KU, while exterior paints may require 90-95 KU for better sag resistance on vertical surfaces.

The "right" viscosity depends heavily on the application method and environmental conditions. I've developed a comprehensive guide based on our work with major paint manufacturers.

Viscosity Requirements by Application Method

Different application methods demand different viscosity profiles for optimal results. Here's a detailed breakdown:

| Application Method | Ideal Viscosity Range (KU) | Required HPMC Grade | Benefits |

|---|---|---|---|

| Spray application | 60-80 KU | Low viscosity (5,000-10,000 mPa·s) | Prevents clogging, ensures fine atomization |

| Roller application | 85-95 KU | Medium viscosity (15,000-30,000 mPa·s) | Good transfer, minimal splatter |

| Brush application | 90-100 KU | Medium to high viscosity (25,000-50,000 mPa·s) | Good pick-up, less dripping |

| Texture coatings | 100-120 KU | High viscosity (50,000+ mPa·s) | Pattern retention, sag resistance |

Environmental conditions also significantly impact optimal viscosity. In hot, dry climates like Saudi Arabia, slightly higher viscosity helps compensate for faster drying. In humid regions like Vietnam or the Philippines, lower viscosity improves flow and leveling as drying times are naturally extended.

One crucial factor often overlooked is the substrate porosity. Highly porous surfaces like new drywall or concrete require paint with higher viscosity to prevent excessive absorption. I recommend increasing HPMC dosage by 10-15% for these applications to maintain proper film build.

What Is The Role Of HPMC In Coating?

Poor coating performance often stems from inadequate understanding of HPMC's multifunctional role. Many formulators see it merely as a thickener, missing its broader benefits.

HPMC serves multiple functions in coatings: primary thickener controlling application properties, water retention agent preventing premature drying, protective colloid stabilizing emulsions, and film formation enhancer improving durability and appearance.

From my experience working with coating formulators across different markets, I've observed that HPMC's role extends far beyond simple viscosity control.

Beyond Viscosity: HPMC's Critical Functions

While viscosity modification is HPMC's most obvious function, its other roles significantly impact coating performance:

-

Water Retention

HPMC forms a protective hydrogel network that slows water evaporation during film formation. This is particularly crucial for exterior applications in hot, dry climates. I've seen dramatic improvements in film quality when proper water retention is achieved. -

Protective Colloid Properties

HPMC surrounds pigment and latex particles, preventing agglomeration during storage and application. This ensures consistent color development and prevents settling in the can. The methoxyl substitution level directly affects this stabilizing ability. -

Enhanced Adhesion

The hydroxypropyl groups in HPMC create hydrogen bonding with substrates, particularly porous ones. This improves wet adhesion and reduces the risk of peeling or flaking over time. -

Open Time Extension

By controlling water evaporation rate, HPMC extends the paint's workable time, allowing better leveling and touch-up. Our K15M grade typically extends open time by 5-7 minutes compared to unmodified formulations.

The optimal HPMC grade for coating applications depends on the balance needed between these functions. For example, external masonry paints benefit from higher molecular weight grades (K30M-K50M) for better water retention, while interior paints often work better with medium grades (K15M-K25M) for better flow and leveling.

What Happens When Viscosity Is Too High?

Excessively high paint viscosity creates application nightmares: poor atomization, brush marks, roller stipple, and inadequate leveling that frustrates professional painters and homeowners alike.

When paint viscosity is too high, it causes several application problems: difficult brushing and rolling requiring excessive force, poor leveling leading to visible brush marks, inadequate substrate wetting causing adhesion issues, and spray application clogging equipment.

I've witnessed numerous projects compromised by overly thick paint. One large commercial job in Dubai required complete repainting when an incorrectly formulated high-viscosity paint left unsightly roller marks throughout a hotel lobby.

Detecting and Resolving High Viscosity Issues

High viscosity problems often manifest during application, but careful laboratory testing can identify issues before field problems occur:

-

Viscosity Stability Testing

HPMC continues to hydrate over time, sometimes causing viscosity to increase during storage. We recommend monitoring viscosity changes over 30 days of storage at elevated temperatures (40°C) to predict shelf stability. -

Temperature Response Curves

Mapping viscosity changes across application temperature ranges (5-40°C) helps identify potential seasonal application issues. Some HPMC grades show dramatic viscosity increases at lower temperatures. -

Shear Recovery Testing

High viscosity paints often exhibit poor flow after high-shear application. Measuring viscosity recovery time after shearing helps predict leveling performance.

When viscosity is too high, adjustment options include:

- Reducing HPMC dosage by 10-15%

- Switching to a lower viscosity HPMC grade

- Incorporating a small amount (0.1-0.3%) of non-ionic surfactant to modify the HPMC's thickening efficiency

- Using a combination of HPMC with other rheology modifiers like HEC for a more balanced rheology profile

In one case study with a customer in Pakistan, we helped reformulate their exterior masonry paint using a combination of our K15M HPMC with a small amount of associative thickener. This hybrid approach maintained the necessary sag resistance while dramatically improving application properties and eliminating complaints about excessive thickness.

What Is The Difference Between High Viscosity And Low Viscosity Paint?

Choosing between high and low viscosity paints creates a difficult tradeoff. High viscosity prevents drips but may compromise finish quality. Low viscosity flows better but risks sagging and poor coverage.

High viscosity paints (95+ KU) resist sagging on vertical surfaces and provide better hiding power but require more effort to apply. Low viscosity paints (60-85 KU) offer superior leveling and atomization for spray applications but may drip and require multiple coats.

The choice between high and low viscosity formulations fundamentally affects application method compatibility and final appearance. Let me break down the key differences I've observed:

Key Performance Differences: High vs. Low Viscosity

The viscosity of paint directly impacts numerous performance attributes that matter to end-users:

| Performance Factor | High Viscosity Paint | Low Viscosity Paint |

|---|---|---|

| Application Method | Best for brush and roller | Best for spray application |

| Film Build | Thicker single coat | Thinner, may require multiple coats |

| Sag Resistance | Excellent on vertical surfaces | Poor to moderate, can drip |

| Leveling | May show brush/roller marks | Excellent self-leveling |

| Splatter Resistance | Good, less droplet formation | Poor, can cause overspray issues |

| Substrate Penetration | Minimal, stays on surface | Good, especially on porous surfaces |

| Drying Time | Typically longer | Generally faster |

HPMC selection greatly influences the formulator's ability to achieve the right balance. For high-build systems like texture coatings, our K75M high-viscosity grade provides excellent sag resistance. For trim paints requiring excellent flow, our K5M low-viscosity grade creates smoother finishes.

One interesting innovation we've developed is "dual viscosity" systems using a combination of fast-dissolving and slow-dissolving HPMC grades. These provide high initial viscosity for good application properties, followed by a viscosity reduction during leveling for superior finish quality.

Temperature effects also differ significantly between high and low viscosity paints. High viscosity formulations typically show more dramatic viscosity increases at lower temperatures, sometimes becoming unusable below 10°C. Low viscosity formulations generally maintain more consistent application properties across temperature ranges.

Conclusion

HPMC viscosity1 directly determines paint application success. The optimal viscosity (20,000-30,000 mPa·s) balances workability with sag resistance. For best results, match HPMC grade to application method, climate conditions, and desired finish quality.

FAQ

Can I mix different HPMC viscosity grades?

Yes, blending different viscosity grades can create customized rheology profiles. Start with an 80:20 ratio of your primary grade to the secondary grade.

How does temperature affect HPMC viscosity in paint?

HPMC viscosity typically increases as temperature decreases. At higher temperatures (above 32-40°C depending on grade), thermal gelation may occur.

How can I prevent HPMC lumps during paint manufacturing?

Pre-disperse HPMC in cold water (10-15°C) before adding to the main batch, or use specially modified "rapid-dissolving" HPMC grades.

Why does my paint develop higher viscosity during storage?

HPMC continues to hydrate slowly over time, especially at higher storage temperatures. Add 0.1-0.2% enzyme-based stabilizer to prevent viscosity drift or slightly under-dose HPMC initially to accommodate the expected increase.

How does HPMC molecular weight affect paint performance?

Higher molecular weight HPMC provides better water retention and sag resistance but may compromise leveling. Lower molecular weight grades improve flow and leveling but may require higher dosages for equivalent thickening.

Can HPMC replace cellulosic thickeners like HEC in paint formulations?

Yes, HPMC can replace HEC in most paint formulations. HPMC typically offers better water retention and sag resistance, while HEC may provide faster drying in humid conditions. Some premium formulations use both for balanced performance.

What's the typical dosage range for HPMC in architectural paints?

For interior paints, typical dosage ranges from 0.3-0.6% of total formula weight. Exterior paints usually require 0.5-0.8%. Higher-PVC formulations and textured paints may require up to 1.0-1.5%.

How does HPMC affect paint drying time?

HPMC extends drying time by retaining water in the film. This benefit improves film formation but may be disadvantageous in high-humidity environments. Balance is key - our K15M grade offers optimal water retention without excessive drying delay.

Is HPMC viscosity affected by paint pH?

HPMC maintains relatively stable viscosity across typical paint pH ranges (7-9). However, extreme pH values (<6 or >10) can affect hydration and reduce thickening efficiency.

How can I test if my paint has the right HPMC viscosity?

Beyond standard Stormer viscosity testing, perform a sag resistance test (ASTM D4400), leveling test (ASTM D4062), and application testing on vertical surfaces at both room temperature and elevated temperatures (35°C) to thoroughly evaluate performance.

Does HPMC affect paint washability?

HPMC itself doesn't significantly impact final film washability. However, proper viscosity ensures adequate film build and uniform pigment distribution, which indirectly improves washability by creating a more coherent film structure.

Can I use the same HPMC grade for both interior and exterior paints?

While possible, it's not ideal. Exterior paints benefit from higher molecular weight grades (K30M-K50M) for better water retention and weather resistance. Interior paints perform better with medium grades (K15M-K25M) for superior flow and leveling.

How does methoxyl content in HPMC affect paint performance?

Higher methoxyl content (28-30%) creates stronger surface activity and better compatibility with latex emulsions, improving stability. Lower methoxyl content (19-24%) provides better water retention but may have compatibility issues with some surfactants.