Rushing concrete curing can lead to weakened structures, excessive cracking, and project delays. Without proper additives like HPMC, your construction project risks serious quality issues.

HPMC (Hydroxypropyl Methylcellulose) significantly impacts concrete curing by controlling water retention, allowing cement to hydrate properly, and creating stronger bonds between particles. This results in more durable concrete with fewer cracks and better overall performance.

At our factory, we've spent years perfecting HPMC formulations for concrete applications. I've seen countless projects transformed by the proper use of this critical additive. Whether you're working on residential foundations or commercial high-rises, understanding how HPMC affects curing time will help you deliver stronger, longer-lasting concrete structures.

What Are the Critical Concrete Curing Stages?

Poor curing practices lead to weak concrete that cracks easily and deteriorates quickly. Without understanding each curing stage, your projects may fail prematurely.

Concrete curing occurs in three main stages: initial setting (first 1-4 hours when concrete transitions from plastic to rigid), strength development (days 1-14 when most strength is gained), and hardening completion (up to 28 days for full strength development). HPMC1 regulates moisture during each stage.

During the initial setting stage, HPMC forms a protective film that prevents rapid water evaporation from the concrete surface. This is crucial because premature water loss can lead to plastic shrinkage cracking. I've visited construction sites where concrete poured without HPMC developed surface cracks within hours due to rapid evaporation in hot weather.

In the strength development stage, HPMC continues to hold moisture within the concrete matrix. This ensures cement has access to water molecules needed for complete hydration.

The chemical reaction between cement and water produces calcium silicate hydrate (CSH) gel, which provides concrete's strength. Without adequate water retention during this phase, strength development stalls prematurely.

During the hardening completion stage, HPMC gradually releases its retained water, allowing for controlled curing even in challenging environmental conditions. This slow release mechanism is particularly valuable in dry climates or when concrete is exposed to wind or direct sunlight.

The molecular structure of HPMC1, with its hydroxypropyl and methyl substitution groups, enables it to form hydrogen bonds with water molecules. This water-binding capacity is what makes HPMC so effective at controlling the curing process throughout all stages.

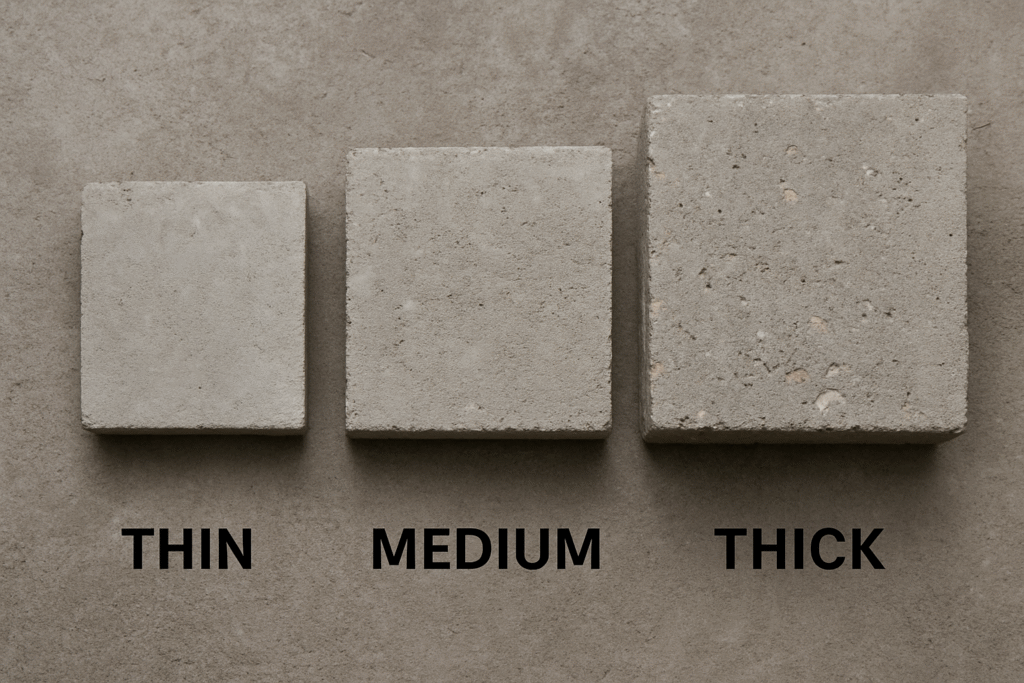

How Does Curing Time Vary for Different Thicknesses of Concrete?

I once consulted on a project where thin concrete overlays were cracking while thick foundation walls showed delayed strength gain. Both problems stemmed from failing to adjust curing protocols for different thicknesses.

Concrete thickness significantly affects required curing time: thin sections (under 10cm) need 7-10 days of moisture retention, medium sections (10-30cm) require 14-21 days, while thick sections (over 30cm) may need 28+ days. HPMC dosage must be adjusted accordingly.

Thin concrete sections have a high surface-to-volume ratio, meaning they lose moisture much faster than thicker elements. For these applications, I recommend HPMC with higher viscosity (15,000-30,000 mPa·s)2 at dosages of 0.3-0.5% by cement weight. This provides extended water retention to prevent rapid drying and subsequent cracking.

For medium-thickness concrete, the challenge lies in maintaining uniform moisture throughout the mass. HPMC helps prevent differential drying, where the surface dries faster than the interior. This prevents internal stress that could lead to cracking. Medium sections typically benefit from HPMC with viscosity ranges of 10,000-15,000 mPa·s at dosages of 0.25-0.4%.

Thick concrete sections face unique challenges. They generate more heat during cement hydration and take longer to release this heat. HPMC helps regulate internal moisture movement within these massive elements, ensuring continued hydration without excessive internal pressure from trapped water vapor. For these applications, HPMC with controlled water retention properties3 works best, typically at slightly lower dosages of 0.2-0.35%.

When working with varying concrete thicknesses on the same project, I've found it's worth investing in different HPMC formulations rather than trying to use a one-size-fits-all approach. The improved quality and reduced cracking far outweigh the additional material costs.

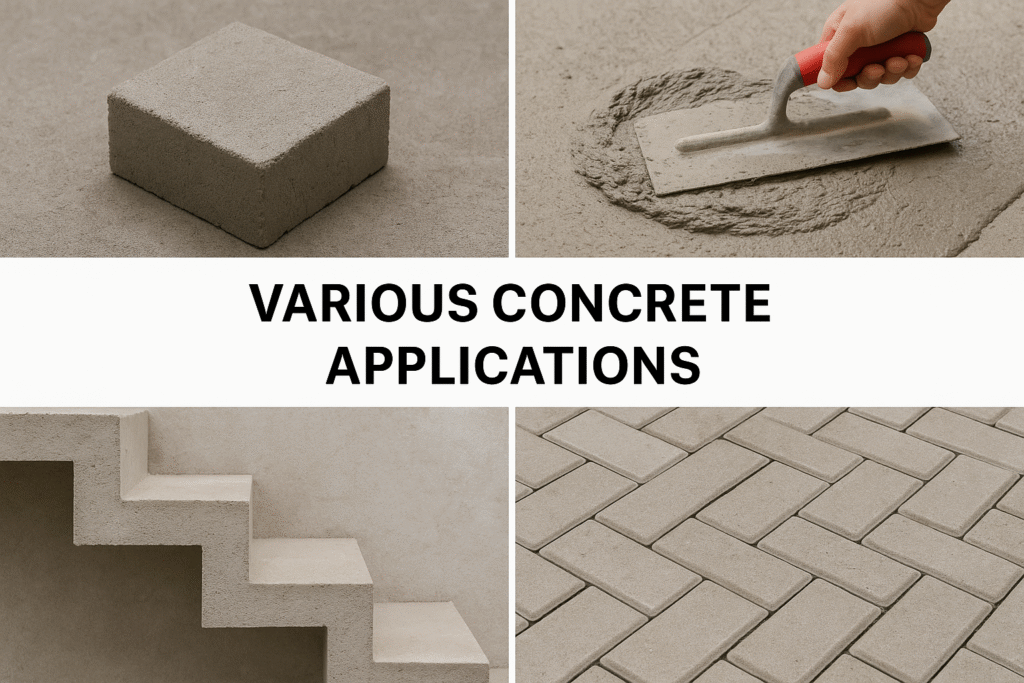

What Is the Concrete Curing Time for Different Applications?

During my visit to a large construction project in Saudi Arabia, I observed how different concrete applications - from foundation slabs to decorative elements - all required unique curing approaches to achieve optimal results.

Curing requirements vary by application: structural elements need 21-28 days, floor slabs require 7-14 days, decorative concrete demands 14-21 days, and repair mortars typically need 3-7 days. HPMC formulations should be specifically selected for each application.

For structural concrete elements like columns, beams, and load-bearing walls, complete curing is essential for achieving design strength. These elements typically use concrete with lower water-cement ratios, making HPMC's water retention properties particularly valuable.

Our clients report best results using HPMC4 grades with methoxyl content between 28-30% and hydroxypropyl content of 7-12%, which provides extended water retention without excessive set retardation.

Floor slabs present different challenges. They need to gain sufficient strength quickly to allow foot traffic and construction activities to resume, but also require proper curing to prevent curling and cracking. Medium-viscosity HPMC (10,000-15,000 mPa·s) balances these needs by providing adequate water retention while allowing timely strength development.

Decorative concrete demands special attention to curing. Insufficient curing often leads to color variations, surface dusting, and reduced durability - issues I've seen ruin otherwise beautiful installations.

For these applications, HPMC grades that minimize efflorescence (surface salt deposits) while maintaining workability prove most effective. Some of our clients combine HPMC with specific curing compounds designed for decorative concrete to achieve optimal aesthetic results.

Repair mortars need rapid strength development while maintaining good bond with existing concrete. HPMC with lower viscosity but good water retention properties helps achieve this balance. When formulating repair mortars at our lab, we typically use HPMC at 0.2-0.3% dosage combined with other additives to optimize both fresh and hardened properties.

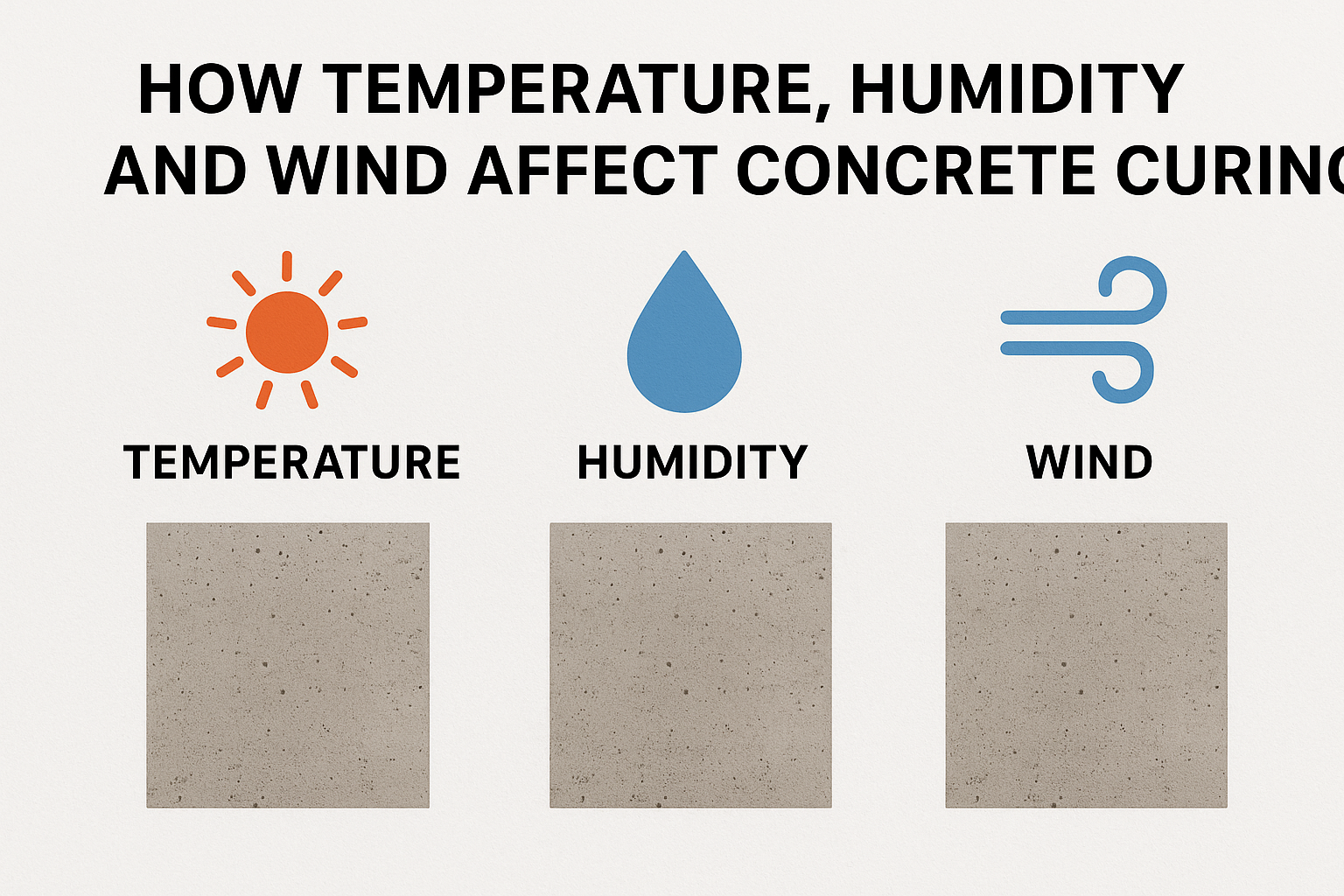

How Does the Environment Impact Concrete Curing Time?

I learned a hard lesson about environmental impacts on curing when visiting a project in Dubai where concrete was setting too quickly due to extreme heat, causing extensive cracking despite following standard mix designs.

Environmental factors dramatically affect curing: high temperatures (>32°C) accelerate hydration but increase cracking risk, cold temperatures (<10°C) slow curing significantly, low humidity increases water evaporation, and wind accelerates surface drying. HPMC4 helps counteract these challenges.

In hot weather conditions, cement hydration accelerates but water evaporation also increases dramatically. Without proper water retention, concrete can lose its mixing water before cement has fully hydrated. HPMC creates a protective barrier that significantly reduces evaporation rates. Our tests show that concrete with properly dosed HPMC can retain up to 80% more moisture in hot conditions compared to untreated mixes.

Cold weather presents opposite challenges. Hydration reactions slow significantly below 10°C and nearly stop below 5°C. HPMC helps by insulating the concrete internally and maintaining available moisture until temperatures rise enough for hydration to continue. For winter construction, we recommend combining HPMC with appropriate cold-weather admixtures and following proper temperature protection protocols.

Humidity levels interact directly with HPMC's effectiveness. In desert conditions with relative humidity below 40%, HPMC's water retention becomes critical. One of our clients in the Middle East reported that switching to our high-efficiency HPMC reduced surface cracking by over 70% in their precast elements during summer production.

Wind is often overlooked but critically important for concrete curing. Even moderate wind speeds of 15 km/h can increase surface evaporation rates by 300-400%. HPMC creates a protective moisture barrier that significantly reduces this evaporative effect. On particularly windy sites, we recommend increasing HPMC dosage by 0.05-0.1% to compensate for increased evaporation potential.

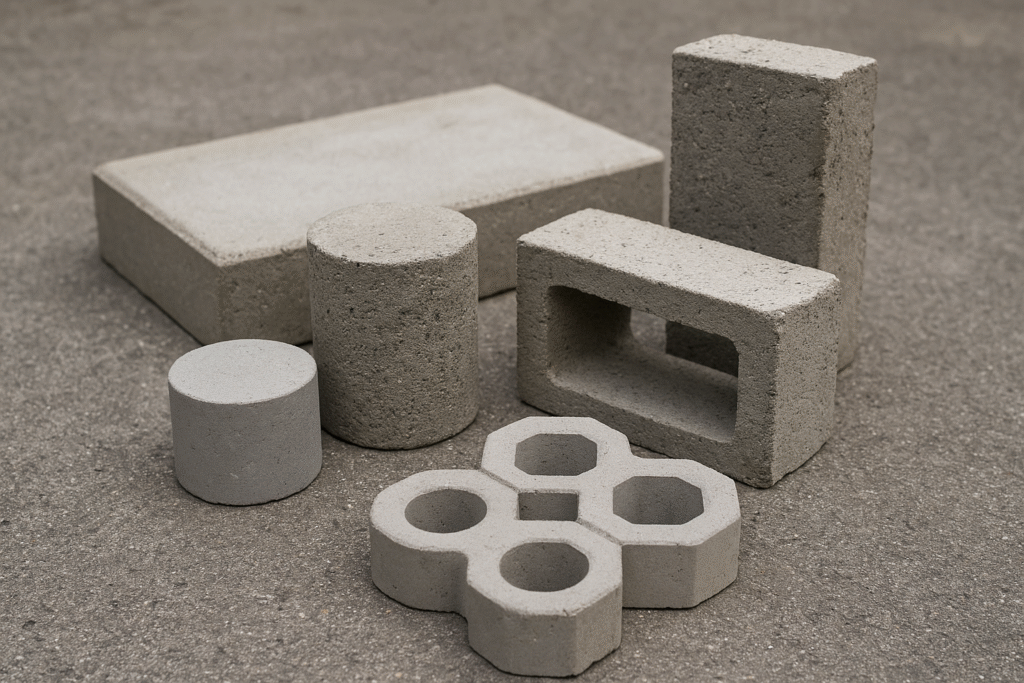

How Do Different Types of Concrete Products Affect Curing Time?

Through supplying HPMC to various concrete manufacturers, I've observed that different product types require specialized approaches to curing and water retention.

Different concrete products have unique curing requirements: standard concrete typically needs 28 days, high-strength concrete requires careful extended curing, lightweight concrete demands higher moisture retention, and self-consolidating concrete needs specialized curing regimens. HPMC must be tailored to each.

Standard concrete generally follows traditional curing protocols with 7-28 days of moisture maintenance. For these applications, middle-range HPMC5 products with balanced water retention and workability enhancement work well. Our WH-P150 grade provides good performance in most standard concrete applications at dosages of 0.2-0.4%.

High-strength concrete, with its lower water-cement ratios, faces increased risk of autogenous shrinkage (self-desiccation where cement consumes water faster than it can migrate through the dense concrete). HPMC helps maintain internal relative humidity, allowing continued hydration despite the limited water availability. For these applications, we recommend higher efficiency HPMC grades like our WH-P200M at slightly increased dosages.

Lightweight concrete containing porous aggregates presents unique moisture dynamics. The aggregates can either absorb mix water (if initially dry) or release water during curing (if pre-soaked). HPMC helps regulate this moisture exchange, creating more predictable curing conditions. Our laboratory testing shows that lightweight concrete benefits from HPMC with moderate viscosity and good water retention properties.

Self-consolidating concrete (SCC), with its high flowability requirements, needs careful balancing of rheological properties. HPMC contributes to stability while helping maintain sufficient water for complete hydration. When formulating SCC, we typically recommend combining HPMC with appropriate superplasticizers at carefully optimized dosages to achieve both flow characteristics and proper curing.

Fast-setting repair mortars present perhaps the greatest challenge for moisture retention. These products generate heat quickly and can dry out before hydration completes. Special grades of HPMC with rapid dissolution and immediate water retention effects help ensure these materials achieve their potential strength despite their accelerated reaction rates.

How to Maintain Concrete Curing?

Even with quality HPMC in your mix, proper curing maintenance remains essential. I've seen well-formulated concrete fail due to poor curing practices after placement.

Maintain proper concrete curing by keeping surfaces continuously moist, protecting from temperature extremes, using appropriate curing compounds or methods, and following a structured curing schedule. HPMC5 enhances these practices by providing internal moisture control.

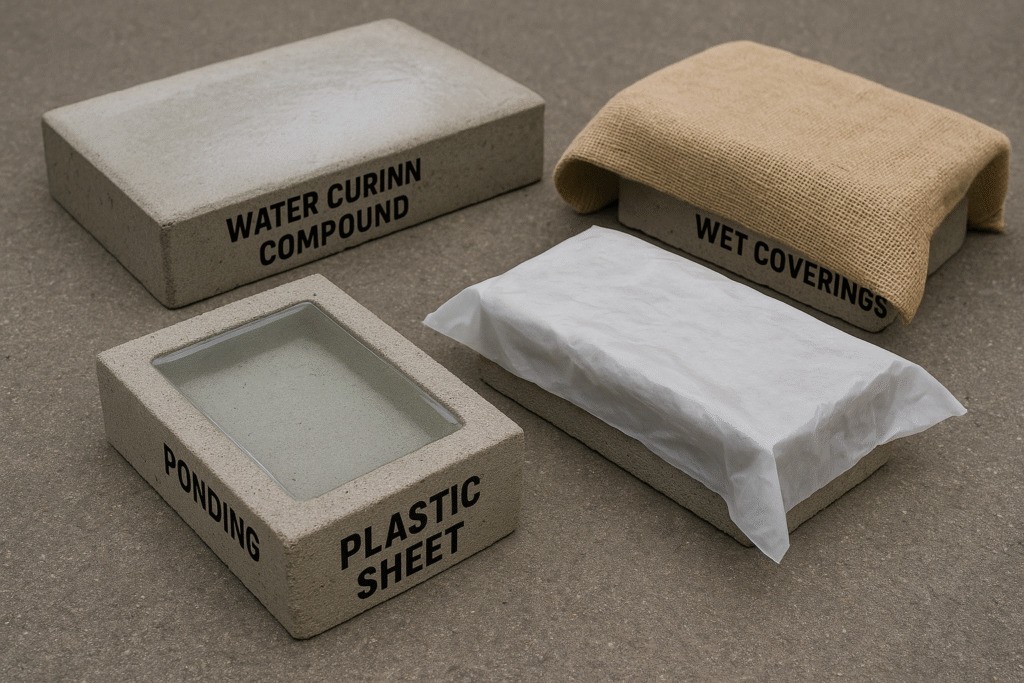

Water curing remains one of the most effective methods for maintaining adequate moisture. This can be accomplished through ponding, continuous sprinkling, or covering with water-saturated materials. HPMC6 works synergistically with these methods by controlling internal moisture movement and providing additional water retention beyond what external methods can achieve.

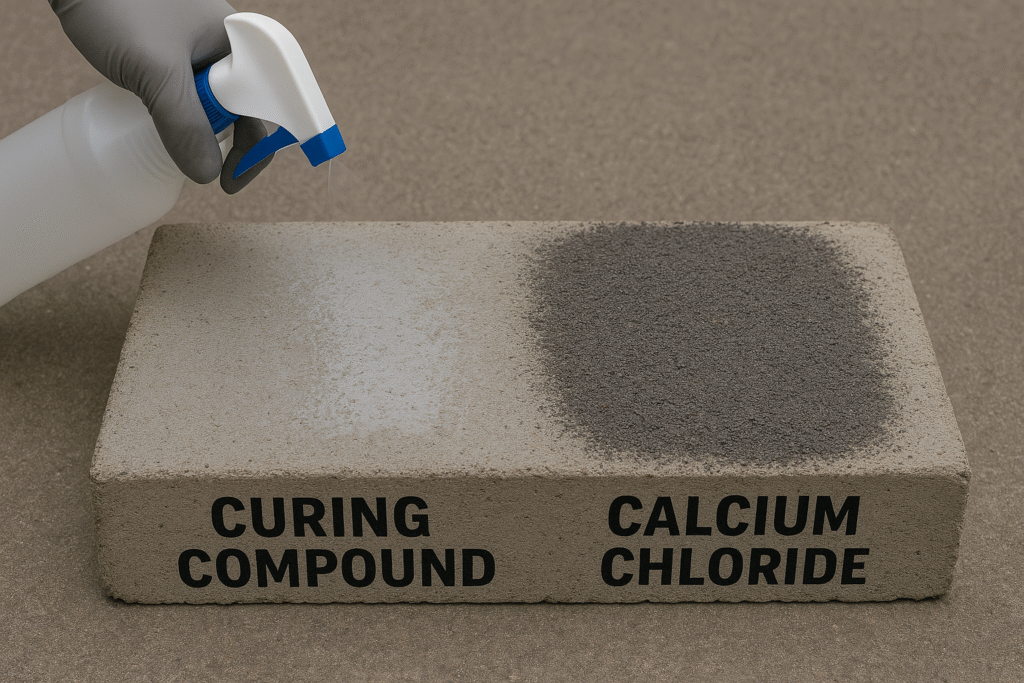

Curing compounds create a film that reduces water evaporation from the concrete surface. When used in conjunction with HPMC-modified concrete, they create a dual protection system: HPMC working from within while the curing compound protects from the surface.

We've found this combination particularly effective for horizontal surfaces exposed to direct sunlight or windy conditions.

Plastic sheeting provides a physical barrier against evaporation and can help maintain more consistent concrete temperature. For concrete containing HPMC, plastic sheeting can be applied slightly later than with conventional concrete, as the initial water retention is already enhanced by the HPMC. This helps reduce the risk of surface damage from early sheet application.

The timing of curing activities is critical. Initial curing should begin as soon as concrete has set sufficiently to prevent surface damage. HPMC provides flexibility in this timing by immediately beginning to regulate moisture loss after placement. For optimal results, external curing methods should be maintained for at least 7 days for most applications, though this varies with concrete type and environmental conditions.

One often overlooked aspect is the transition when removing curing measures. Sudden exposure to drying conditions can still damage concrete if curing is stopped abruptly. HPMC helps reduce this shock by continuing to release moisture gradually, but best practices still call for gradual curing termination, especially in dry environments.

How to Use Concrete Curing Additives?

After supplying HPMC to hundreds of concrete producers, I've found that proper additive use requires both technical knowledge and practical application skills.

Use concrete curing additives by selecting the appropriate HPMC grade for your application, following proper dosing guidelines (typically 0.2-0.5% of cement weight), ensuring thorough mixing, and considering compatibility with other admixtures. Quality HPMC significantly outperforms generic products.

Selecting the right HPMC7 grade involves considering multiple factors beyond basic water retention. The viscosity, substitution type, particle size, and dissolution rate all impact performance.

For general concrete applications, HPMC with viscosity between 10,000-20,000 mPa·s typically provides good water retention without excessive set retardation. The methoxyl content (typically 28-30%) and hydroxypropyl content (7-12%) should be balanced for optimal performance.

Proper mixing procedures are essential for HPMC effectiveness. For best results, HPMC should be pre-dispersed in cold water or thoroughly dry-blended with cement before adding to the mix. Inadequate dispersion leads to "fish-eyes" (undissolved HPMC clumps) that reduce effectiveness and create weak spots in the concrete. At our technical workshops, we demonstrate proper dissolution techniques to help customers maximize HPMC performance.

HPMC interacts with other concrete admixtures in complex ways. It generally works well with superplasticizers, but dosages may need adjustment. Some retarding admixtures can have compounded effects when used with HPMC. We recommend trial batches when combining HPMC with new admixture systems to ensure compatibility and optimize dosages.

Quality differences between HPMC products can significantly impact performance. Generic HPMC7 may save money initially but often leads to inconsistent results. Our specialized construction-grade HPMC undergoes rigorous quality testing to ensure consistent particle size, substitution level, and viscosity – factors critical to predictable concrete performance.

Cost-effectiveness calculations should consider HPMC's long-term benefits. While adding approximately $3-8 per cubic meter to initial concrete costs, the improvements in durability, reduced cracking, and enhanced strength development often extend service life significantly.

For critical infrastructure or high-performance applications, premium HPMC grades deliver value that far exceeds their cost difference.

Conclusion

HPMC transforms concrete curing by providing internal moisture control throughout all curing stages. By selecting the appropriate type, dosage, and implementation methods for your specific application, you'll achieve stronger, more durable concrete with fewer defects and longer service life.

-

Explore this link to understand how HPMC enhances concrete curing and prevents cracking, ensuring stronger structures. ↩ ↩

-

Explore this link to understand how HPMC enhances moisture retention and prevents cracking in thin concrete sections, ensuring durability. ↩

-

Discover how HPMC regulates moisture movement in thick concrete, ensuring proper hydration and reducing internal pressure, which is vital for structural integrity. ↩

-

Explore this link to understand HPMC's role in concrete curing and its benefits for structural integrity. ↩ ↩

-

Explore this link to understand how HPMC enhances concrete performance and moisture retention, crucial for various applications. ↩ ↩

-

Explore this link to understand how HPMC enhances moisture retention and improves concrete curing processes. ↩

-

Understanding HPMC's role in concrete can enhance your project's durability and strength. Explore this resource for in-depth insights. ↩ ↩