You've just poured concrete for your project, but now the waiting game begins. The pressure to continue building is high, yet rushing could lead to cracking, weak foundations, and costly repairs.

Generally, concrete takes 28 days to fully cure1 to reach its maximum strength. However, it becomes usable at different stages: 24-48 hours for foot traffic, 7 days for vehicle traffic, and 28 days for full structural load-bearing. Environmental conditions and concrete thickness greatly impact these timeframes.

Understanding concrete curing is vital for any construction project. As someone who's supplied HPMC and other concrete additives to major construction companies for years, I've seen how proper curing directly impacts the durability and strength of finished structures.

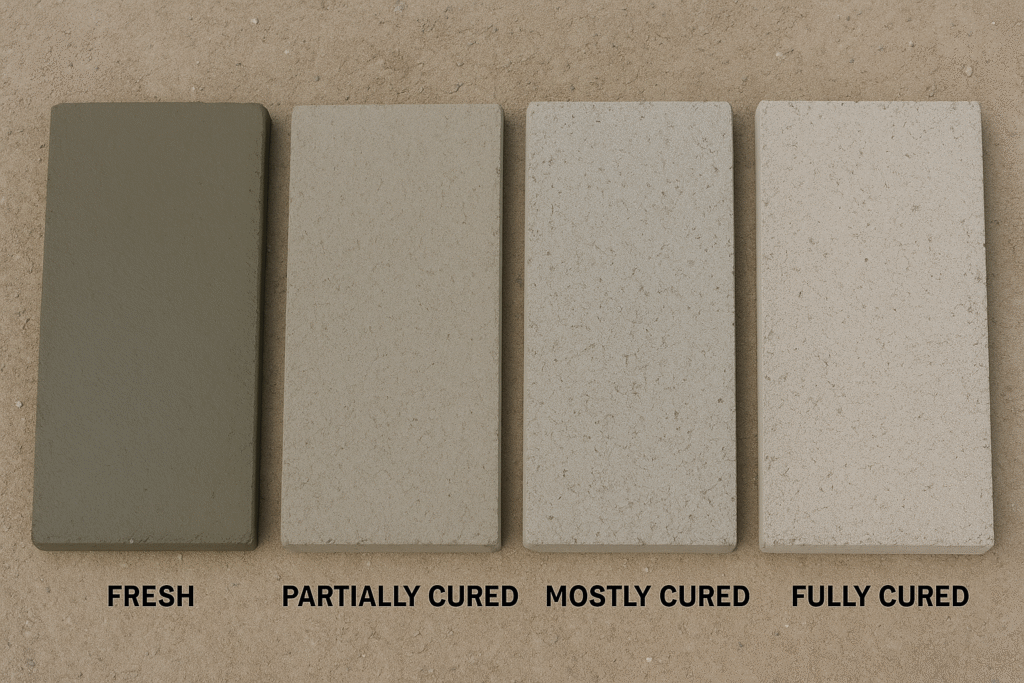

What Are The Different Concrete Curing Stages?

You've mixed and poured your concrete, but now what? The transformation from wet mixture to solid structure isn't instant, and rushing this process can ruin your entire project.

Concrete curing happens in stages: initial setting occurs in 2-4 hours when the mix becomes rigid; functional hardening takes 24-48 hours allowing light foot traffic; significant strength development occurs by day 7 (70% strength); and full curing reaches maximum design strength at 28 days.

Concrete curing is a chemical process, not simply "drying out" as many believe. When cement combines with water, it creates a reaction called hydration. This process forms calcium silicate hydrate crystals that interlock to create concrete's strength.

Initial Setting Stage (2-4 hours)

During this first stage, the concrete changes from a flowable material to a rigid mass. You can't finish or manipulate the surface anymore. Water begins reacting with cement particles, but the concrete has almost no structural strength at this point.

Early Strength Development (1-7 days)

This is the most critical period for proper curing techniques. By day 1, concrete typically reaches 16% of its final strength, allowing for form removal. By day 3, it reaches approximately 40% strength, and by day 7, about 65-70% of its final strength. During this period, maintaining moisture is crucial - if concrete dries out too quickly, the chemical reaction stops prematurely, permanently weakening the concrete.

Continued Hardening (7-28 days)

Strength continues to develop more slowly, with concrete reaching about 90% of its design strength by day 14 and its specified strength by day 28. This is why concrete strength is typically measured at 28 days in construction specifications.

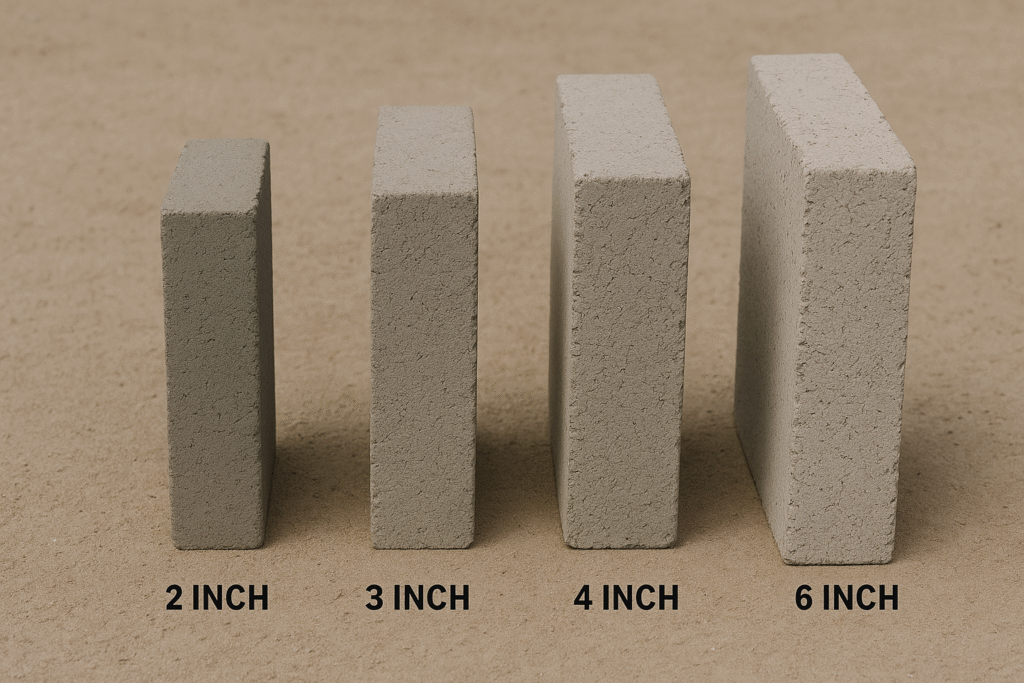

How Does Concrete Thickness Affect Curing Time?

The thicker your concrete, the longer your project timeline extends. Many builders make costly mistakes by applying the same curing expectations to slabs of different thicknesses.

Concrete thickness directly impacts curing time: thin overlays (1-2 inches) may be walkable in 24 hours but still need 3-5 days before finishing; standard slabs (4-6 inches) require 24-48 hours before foot traffic and 5-7 days for light vehicle traffic; thick foundations (8+ inches) need at least 3 days before any load and 10+ days before significant weight.

The relationship between concrete thickness2 and curing time is often misunderstood in construction projects. Thinner concrete sections cure faster on the surface but may not develop full internal strength as quickly as you might expect. Conversely, thicker sections may take longer to dry on the surface while curing more thoroughly internally due to the retained moisture.

For thin overlay applications (1-2 inches), the concrete typically dries quickly on the surface, sometimes giving the false impression it's fully cured. These applications might allow foot traffic within 24 hours but shouldn't receive final treatments or heavy loads for at least 3-5 days. The rapid moisture loss in thin applications actually makes proper curing techniques even more critical.

Standard residential slabs (4-6 inches) represent the most common thickness and follow the traditional curing timeline more closely. While surface drying allows foot traffic after 24-48 hours, these slabs need about 7 days before supporting vehicle traffic and the full 28 days to reach maximum strength.

Thick structural elements like foundations, piers, and heavy-duty industrial floors (8+ inches) maintain internal moisture longer, which helps the curing process but extends the time before the concrete can bear significant loads. These structures often require specialized curing compounds or techniques to ensure proper strength development throughout the entire mass. The core of very thick elements may continue curing for months or even years.

| Concrete Thickness | Walkable | Light Vehicle Traffic | Full Strength |

|---|---|---|---|

| 1-2 inches (overlay) | 24 hours | 3-5 days | 28 days |

| 4-6 inches (standard) | 24-48 hours | 5-7 days | 28 days |

| 8+ inches (structural) | 48-72 hours | 10-14 days | 28+ days |

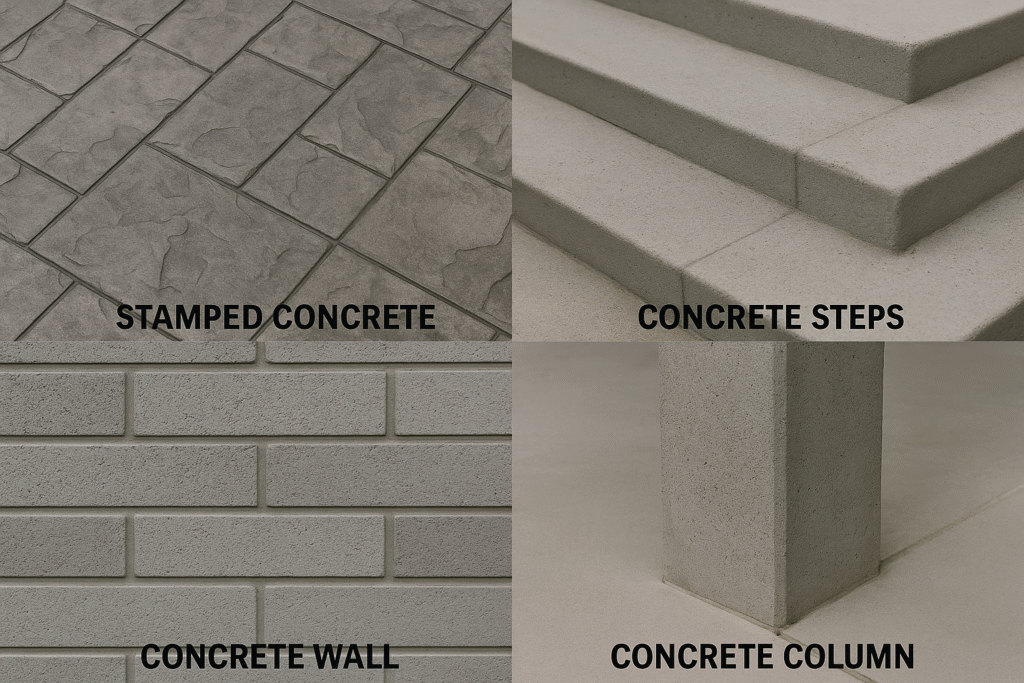

What Is The Concrete Curing Time For Different Applications?

You've selected concrete for your specific project, but each application has unique curing requirements that can make or break your timeline and results.

Different concrete applications require different curing times: decorative concrete needs 7-10 days before sealing; driveways require 7 days before vehicle use but 28 days before heavy trucks; concrete countertops need 7 days curing plus 14 days sealing; and structural elements must reach full 28-day strength before bearing design loads.

The purpose of your concrete installation significantly impacts how long you must wait before putting it into service. Each application faces different stresses and has unique performance requirements that directly relate to curing time. Through my experience supplying HPMC and other additives to construction projects worldwide, I've observed how application-specific curing times are often overlooked.

For residential driveways, premature use is one of the most common mistakes homeowners make. While you might be able to walk on your new driveway after 24-48 hours, vehicles should stay off for at least 7 days, and heavy trucks or machinery should wait the full 28 days. Early vehicle traffic can create permanent wheel depressions or cracking that no repair can fully fix.

Decorative concrete applications like stamped patios or colored walkways have additional considerations beyond structural strength. These surfaces may be physically strong enough for traffic after 3-5 days, but the curing process affects color development and sealant adhesion. Most decorative concrete contractors recommend waiting 7-10 days before applying sealants to ensure proper moisture levels and color stability.

Concrete countertops represent a specialized application with stricter requirements. These need not only the 7+ days of initial curing but often an additional 14-21 days after sealing before regular use. This extended timeline allows for complete curing of both the concrete and the often specialized sealers used in food preparation areas.

Critical structural elements like support columns, foundation walls, and bridge components typically follow the strictest adherence to the 28-day full cure requirement. Engineers design these components based on the strength concrete achieves at this benchmark, and premature loading can compromise not just aesthetics but structural integrity and public safety.

| Application | Minimum Curing Before Use | Full Curing | Special Requirements |

|---|---|---|---|

| Sidewalks/Patios | 3 days for foot traffic | 28 days | Protect from freezing first 48 hours |

| Driveways | 7 days for cars | 28 days | No heavy trucks until fully cured |

| Structural Elements | No load until engineer-specified | 28+ days | May require testing before use |

| Decorative Concrete | 7-10 days before sealing | 28 days | Maintain consistent moisture for color |

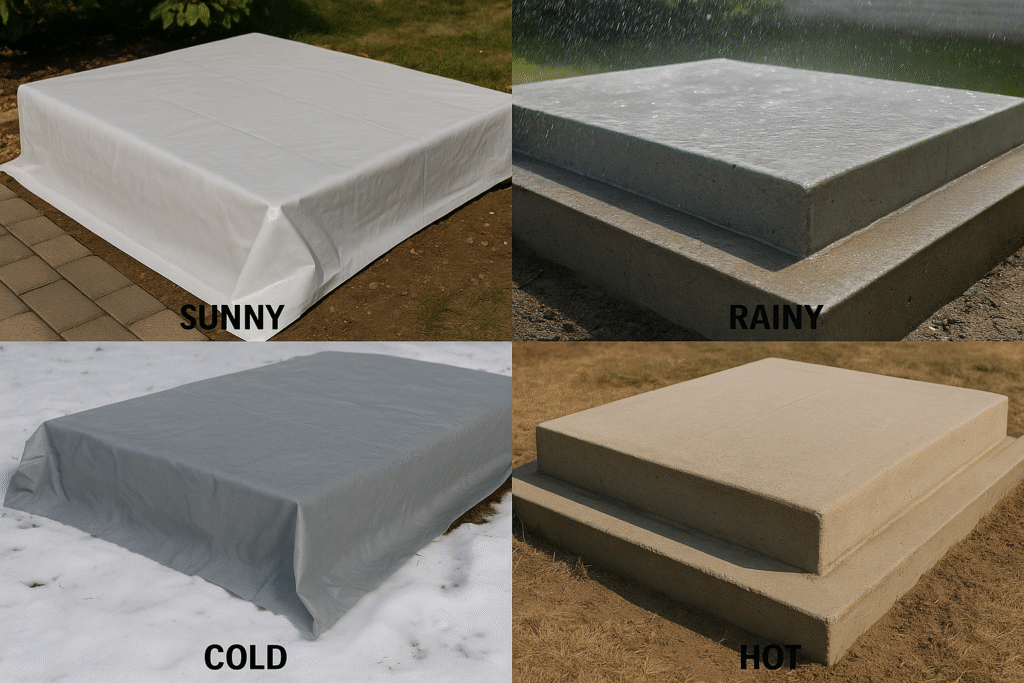

How Do Environmental Conditions Affect Concrete Curing Time?

Your perfect concrete mix can still fail if you ignore the weather forecast. Temperature and humidity dramatically alter curing times, often catching builders off guard.

Environmental conditions significantly impact concrete curing: ideal curing happens at 50-85°F with moderate humidity; hot weather (90°F+) speeds initial set but potentially weakens concrete; cold conditions below 50°F dramatically slow curing; and wind or low humidity causes rapid surface drying, leading to shrinkage cracks.

Environmental factors play a crucial role in determining concrete curing times, often creating more variation than any other aspect of concrete work. Having worked with construction clients across diverse climates from the Middle East to Northern Europe, I've witnessed firsthand how dramatically conditions affect outcomes.

Temperature is perhaps the most significant environmental factor. In hot weather (above 85°F/29°C), concrete sets more quickly but often with negative consequences. The rapid evaporation of water reduces the time available for finishing and increases the risk of plastic shrinkage cracking. Additionally, fast-tracked curing in hot conditions often leads to lower ultimate strength, as the cement doesn't have sufficient time to form strong crystalline structures. Projects in Saudi Arabia often require night pours and special cooling measures to manage these effects.

Cold weather presents the opposite challenge. When temperatures drop below 50°F (10°C), the chemical reactions that drive concrete curing slow dramatically. Below 40°F (4°C), hydration nearly stops. Concrete poured in cold conditions might take two to three times longer to reach comparable strength than the same mix in moderate temperatures. In extreme cases where concrete freezes before reaching approximately 500 psi strength (typically in the first 24 hours), the internal structure can be permanently damaged.

Humidity levels work alongside temperature to influence curing times. Low humidity accelerates surface drying, which can halt the curing process prematurely if moisture isn't maintained. High humidity slows evaporation, which generally benefits curing but may extend surface drying times. This particularly affects finishing operations and the application of sealers or coatings.

Wind speed creates another variable, as moving air dramatically increases the evaporation rate from concrete surfaces. Even moderate winds of 15 mph can double the rate of surface moisture loss compared to still air conditions, making wind breaks essential in many situations.

| Environmental Factor | Effect on Curing | Recommended Action |

|---|---|---|

| Hot Weather (85°F+) | Accelerates set time, risks strength loss | Use ice in mix water, erect sun shades, cure immediately |

| Cold Weather (<50°F) | Slows curing, risks freezing damage | Use heated water, insulating blankets, longer form time |

| Low Humidity (<40%) | Causes rapid surface drying | Apply curing compound quickly, use water fogging |

| High Wind | Accelerates moisture loss | Install windbreaks, apply curing methods immediately |

What Are The Curing Times For Different Types of Concrete Products?

You've probably noticed various concrete products claim different setting times, but understanding what these really mean for your project timeline can be confusing.

Different concrete products have varying curing times3: rapid-setting mixes reach 70% strength in 24-48 hours but still need protection; high-early-strength concrete achieves in 3 days what regular concrete reaches in 7; self-leveling overlays allow foot traffic in 2-4 hours but need 28 days for full cure; and specialized products like GFRC reach handling strength in just 24 hours.

The concrete industry has developed numerous specialized products to address specific project needs, each with unique curing characteristics. As a supplier of HPMC4 and other admixtures used in these formulations, I can share insights about how these products perform differently during the curing process.

Rapid-setting concrete products, often used for repairs and small projects, contain accelerating admixtures or specialized cement types that dramatically speed up the hydration process. While these products can achieve enough strength to bear weight in as little as 1-2 hours and reach approximately 70% of their ultimate strength within 24-48 hours, they still require proper curing techniques. In fact, because of their accelerated chemical reactions, these products often generate more heat and can be more susceptible to rapid drying issues if not properly protected.

High-early-strength concrete, commonly used in precast concrete manufacturing and fast-track construction projects, typically reaches in 3 days the strength that conventional concrete achieves in 7 days. This is accomplished through optimized cement content, lower water-cement ratios, and chemical admixtures. However, this acceleration comes at a cost—these mixes often have higher shrinkage potential and generate more heat during curing, requiring careful temperature control.

Self-leveling concrete overlays represent another specialty product with unique curing characteristics. These products typically allow foot traffic within 2-4 hours but require significantly longer before applying floor coverings or coatings. The ultra-flowable nature of these products means they often contain high amounts of polymer modifiers5 which affect the curing timeline differently than traditional concrete.

Glass Fiber Reinforced Concrete (GFRC)4 and other specialized architectural concrete products typically gain handling strength within 24 hours but continue developing strength for the standard 28 days. These products often rely heavily on polymer modification and specialized curing regimens to achieve their unique performance characteristics.

| Concrete Product Type | Initial Set | Walkable | Full Strength | Special Considerations |

|---|---|---|---|---|

| Rapid-Setting | 15-30 minutes | 1-2 hours | 7-28 days | Higher heat generation |

| High-Early-Strength | 1-2 hours | 12-24 hours | 7-28 days | Increased shrinkage potential |

| Self-Leveling Overlay | 2-4 hours | 4-6 hours | 28 days | Sensitive to excess moisture |

| GFRC | 1-2 hours | 24 hours | 28 days | Requires humidity control |

How Can Concrete Curing Additives Help With Curing Time?

Facing tight project deadlines or challenging weather conditions? Concrete additives might be the solution you're looking for, but knowing which ones to use and when makes all the difference.

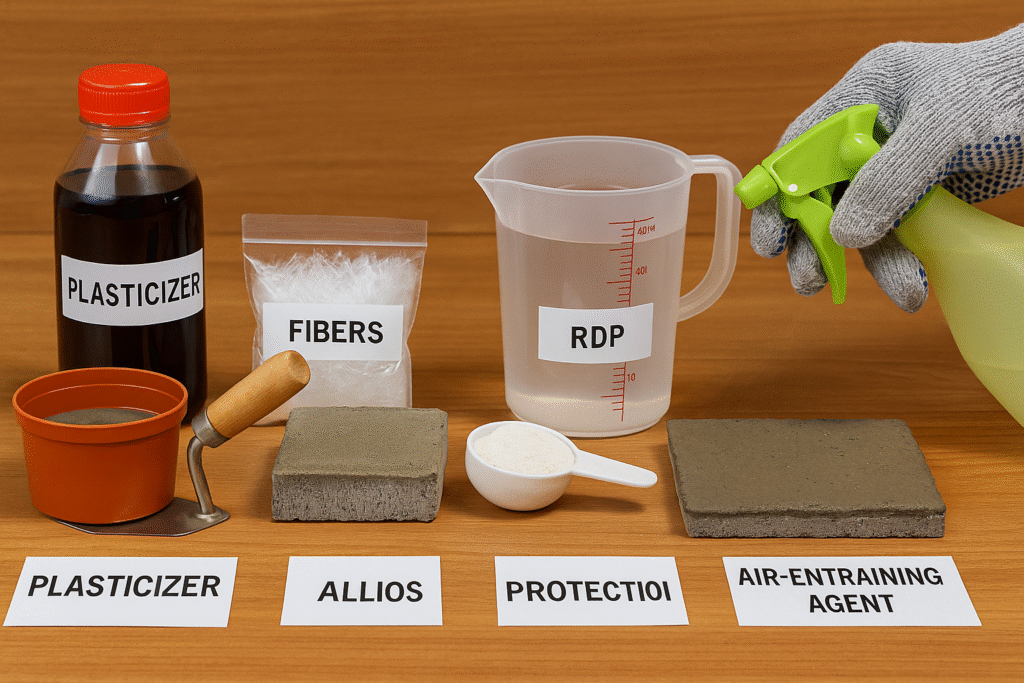

Concrete additives can significantly impact curing times: accelerators like calcium chloride can reduce set time by 1-3 hours and increase early strength by 30-40%; water-reducing admixtures allow lower water content while maintaining workability; HPMC4 improves water retention during curing; and specialized curing compounds form protective membranes to optimize strength development.

The strategic use of concrete additives can dramatically improve curing outcomes and adjust timing to meet project needs. At Kehao, we produce HPMC and other additives specifically designed to address curing challenges across different applications and environments.

Accelerating admixtures like calcium chloride, sodium nitrate, and calcium nitrite speed up the chemical reactions in concrete, reducing setting time and increasing early strength development. These additives are particularly valuable in cold weather conditions where natural curing would otherwise be significantly delayed. In dosages typically ranging from 1-2% by weight of cement, accelerators can reduce setting time by 1-3 hours and increase one-day strength by 30-40%. However, they may slightly reduce ultimate 28-day strength, making them better suited for non-structural applications or situations where early strength is more critical than maximum final strength.

Water-reducing admixtures allow concrete to maintain workability with less water, creating a lower water-to-cement ratio that directly correlates with faster strength development and higher ultimate strength. Mid-range and high-range water reducers (superplasticizers) can reduce water content by 5-30% while maintaining the same slump. This results in concrete that not only gains strength faster but also achieves greater durability and reduced permeability.

Hydroxypropyl methylcellulose (HPMC), one of our specialty products, serves as a water-retention agent in concrete mixtures. By holding moisture within the concrete during the critical early curing period, HPMC ensures more complete cement hydration, reducing the risk of surface crusting and shrinkage cracking. This is particularly valuable in thin applications and environments with low humidity or high wind conditions that would otherwise cause rapid surface drying.

Liquid membrane-forming curing compounds, while not admixtures per se, provide an effective way to ensure proper curing by forming a protective film that prevents premature water evaporation. These products, which include resin-based, wax-based, and water-based formulations, can be particularly helpful when traditional water curing methods are impractical. Some advanced formulations also contain white pigment to reflect sunlight, reducing heat buildup in the curing concrete.

| Additive Type | Primary Effect on Curing | Best Application | Considerations | |||

|---|---|---|---|---|---|---|

| Accelerators | Reduces set time by 1-3 hours | Cold weather, | Additive Type | Primary Effect on Curing | Best Application | Considerations |

| --------------- | -------------------------- | ----------------- | ---------------- | |||

| Accelerators | Reduces set time by 1-3 hours | Cold weather, tight schedules | May reduce final strength slightly | |||

| Water Reducers | Increases early and ultimate strength | Quality concrete, faster form removal | Requires proper finishing timing | |||

| HPMC | Improves water retention during curing | Hot/dry environments, thin applications | Optimal dosage is critical | |||

| Curing Compounds | Creates moisture-retaining membrane | Large horizontal surfaces | May affect bonding of subsequent layers |

Internal curing additives, such as specialized lightweight aggregates pre-saturated with water, provide a moisture reservoir within the concrete itself. These materials slowly release water during the curing process, enhancing hydration especially in the interior portions of thicker concrete elements. Research shows internal curing can increase strength development by up to 15% while reducing early-age cracking potential by over 80% in high-performance concretes.

HPMC and cellulose ethers offer multiple benefits beyond water retention. They improve the cohesiveness of fresh concrete, reducing segregation and bleeding, which leads to more uniform strength development throughout the concrete mass. At Kehao, we've formulated specific grades of HPMC that provide optimal water retention for different concrete applications and environmental conditions.

When selecting concrete additives, it's important to consider potential interactions between different admixtures. Some combinations can have counterproductive effects or require dosage adjustments. For example, air-entraining admixtures (which improve freeze-thaw durability) may need dosage modifications when used with certain water reducers. Professional guidance from admixture suppliers can help optimize these combinations for specific project requirements.

Conclusion

Concrete curing times3 vary based on thickness, application, environment, and mix design. While 28 days remains the standard for full strength, understanding these variables and using appropriate additives can help optimize your construction timeline while ensuring quality results.

-

Explore the science behind the 28-day curing period to appreciate its importance in achieving maximum strength. ↩

-

Explore the relationship between thickness and curing to avoid costly mistakes in your projects. ↩

-

Understanding curing times is crucial for project planning and ensuring optimal results. ↩ ↩

-

HPMC is a key additive for water retention; learn how it can optimize your concrete curing process. ↩ ↩ ↩

-

Polymer modifiers can enhance performance; discover their impact on curing and strength. ↩