Temperature extremes can wreak havoc on tile installation projects, causing adhesive failure, cracking, and costly repairs. Many contractors and manufacturers struggle with inconsistent adhesive performance across different climate conditions.

The ideal temperature range for cement-based tile adhesives1 is 15-25°C (59-77°F). Below 5°C, curing slows dramatically or stops, while above 35°C, rapid evaporation can weaken bonds. These temperature effects directly impact adhesive strength, working time, and long-term performance.

When I first started supplying HPMC2 for tile adhesives, I was puzzled by complaints about varying performance in different regions. Then I realized how significantly temperature impacts cement-based formulations. Let me share what I've learned about this critical relationship that affects everyone from manufacturers to installers.

Introduction: Why Temperature Matters in Tile Adhesive Applications?

Pain point: Tile failures due to temperature-related adhesive issues cost the construction industry millions annually. Many manufacturers formulate products without understanding climate impacts, resulting in callbacks, warranty claims, and damage to reputation.

Temperature affects cement-based tile adhesives1 by controlling hydration rate, water retention, open time, and ultimate bond strength. Too cold slows chemical reactions and can lead to freeze damage, while too hot accelerates setting but risks incomplete hydration and reduced strength.

Temperature variations affect every aspect of adhesive performance, from mixing to final curing. Our research at Kehao shows that temperature is often the hidden culprit behind mysterious adhesive failures. From Saudi Arabia's extreme heat to cooler European climates, we've studied how temperature alters adhesive behavior across markets.

Chemical Reactions and Curing Time

Most people don't realize that cement-based adhesives cure through hydration, not drying. This chemical reaction between water and cement forms crystal structures that create the bond. Temperature directly controls how fast this happens.

In cold conditions below 10°C, the reaction slows dramatically. I've seen projects in winter where adhesives took 3-4 times longer to cure than expected. This extends project timelines and leaves tiles vulnerable to movement and damage.

Conversely, in hot conditions above 30°C, rapid water evaporation can actually halt the curing process before it completes. This causes weakened bonds and powdery adhesive layers that fail prematurely.

The table below shows typical curing times based on our laboratory testing:

| Temperature Range | Initial Set Time | Full Cure Time | Special Considerations |

|---|---|---|---|

| 5-10°C (41-50°F) | 12-24 hours | 14-21 days | Risk of freeze damage if temps drop further |

| 15-25°C (59-77°F) | 4-8 hours | 7-14 days | Optimal conditions |

| 30-35°C (86-95°F) | 1-3 hours | 5-7 days | Requires water misting to prevent rapid drying |

| Above 35°C (95°F) | 30-90 minutes | 3-5 days | High risk of improper curing, reduced strength |

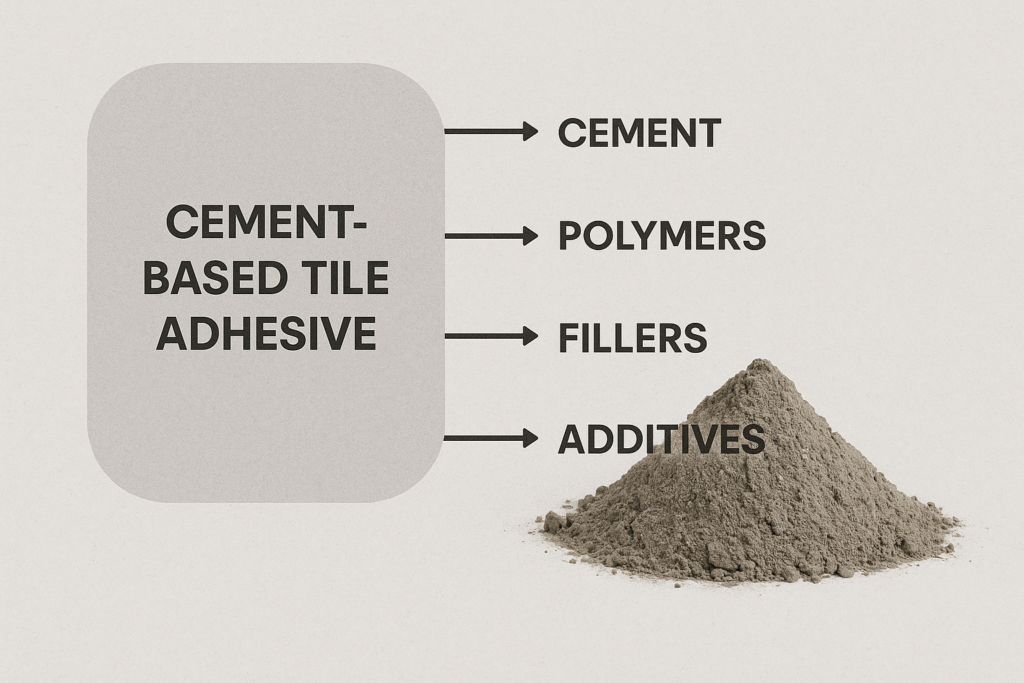

Composition of Cement-Based Tile Adhesives?

Pain point: Many contractors and even manufacturers don't understand how adhesive components interact differently at various temperatures, leading to incorrect product selection and application methods that doom installations from the start.

Cement-based tile adhesives typically contain Portland cement (40-60%), aggregates (30-40%), and additives like cellulose ethers3 (HPMC2/HEMC at 0.2-0.5%) and redispersible polymer powders4 (1-5%). These components respond differently to temperature, with cellulose ethers being particularly sensitive.

The composition of cement-based tile adhesives directly impacts their temperature sensitivity. Having manufactured cellulose ethers for over 15 years, I've observed how these critical components behave differently across temperature ranges, often in ways that surprise even experienced manufacturers.

The Role of Hydroxypropyl Methylcellulose (HPMC)

HPMC is the unsung hero of temperature-resistant tile adhesives. As a water-retention agent and thickener, it's particularly sensitive to temperature fluctuations. At Kehao, we've developed specialized HPMC grades that perform differently based on expected application temperatures.

In hot climates, like our customers experience in Saudi Arabia and UAE, higher viscosity HPMC (100,000-150,000 mPa·s) with enhanced water retention properties is crucial. These grades slow water loss through evaporation, extending open time even in 35°C+ temperatures.

For colder regions, lower viscosity HPMC (30,000-80,000 mPa·s) with faster dissolution rates works better, as it doesn't overly delay the already slowed hydration process. This balance helps maintain workable setting times even in cooler conditions.

Our testing shows that the right HPMC formulation can extend open time by up to 300% in hot conditions compared to standard grades, and can improve low-temperature flexibility by up to 40%. This is why we offer customized HPMC solutions based on regional climate conditions rather than one-size-fits-all products.

Temperature's Effect on Adhesive Performance?

Pain point: Without understanding the specific ways temperature affects adhesive properties, installers often make critical application errors, like continuing to work with adhesive that's already started setting in hot weather or expecting normal curing times in cold conditions.

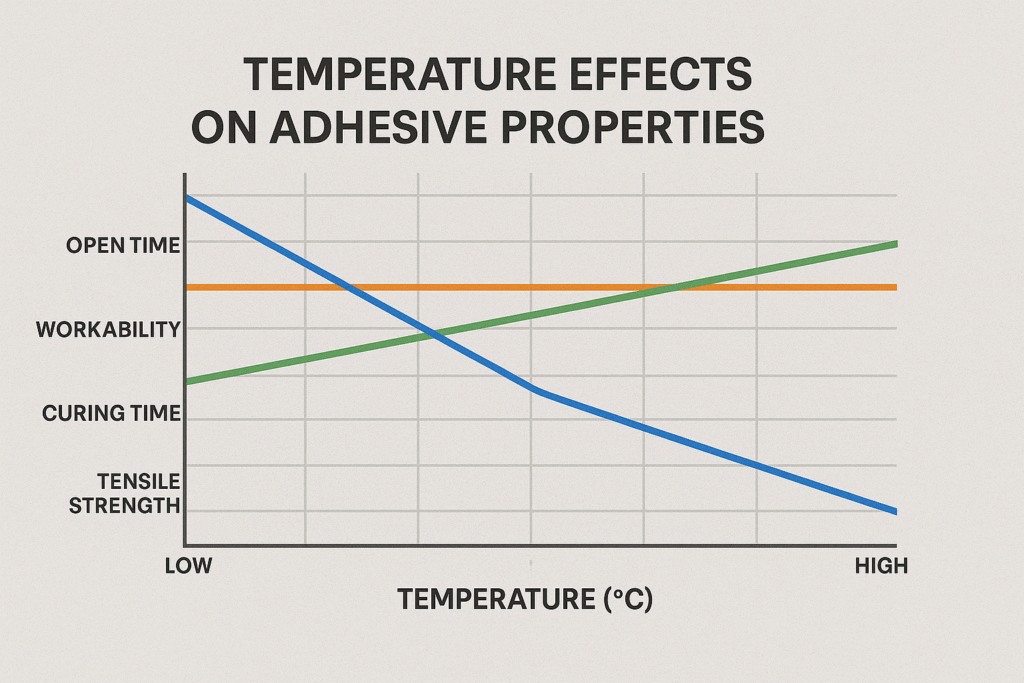

Temperature primarily affects four critical properties: open time (decreasing by 50% for every 10°C increase above 25°C), sag resistance (diminishing in heat), bond strength (potentially reduced by 30-40% at temperature extremes), and workability (becoming either too stiff in cold or too runny in heat).

Through years of product testing and field feedback, I've identified specific patterns in how temperature alters adhesive behavior. These insights help explain why the same adhesive can perform brilliantly or fail completely depending on the temperature during installation and curing.

Critical Impact on Open Time and Workability

Open time—the period when adhesive remains receptive to tile placement—is perhaps the most temperature-sensitive property. Our laboratory testing shows remarkable differences: the same C2-class adhesive with 20 minutes open time at 23°C may have only 7-8 minutes at 35°C, while extending to 30+ minutes at 10°C.

This creates significant practical challenges. In hot conditions, installers must work in smaller sections and may need to adjust techniques. I remember visiting a project in Dubai where installers were forced to apply adhesive in sections just 30cm wide to combat the rapid skinning caused by 40°C temperatures and low humidity.

Temperature also transforms workability characteristics:

- Cold conditions (5-10°C): Adhesive remains stiff, requires more mixing effort

- Optimal range (15-25°C): Smooth, creamy consistency with ideal workability

- Hot conditions (30°C+): Too fluid initially, then rapidly stiffens as water evaporates

These changes require adjustments to water content and mixing procedures that many installers don't realize are necessary when transitioning between seasons or climate zones.

Experimental Results: Performance Across Temperatures?

Pain point: Many manufacturers make broad claims about temperature performance without actual testing data, leaving contractors with products that fail under real-world conditions and no scientific explanation for why.

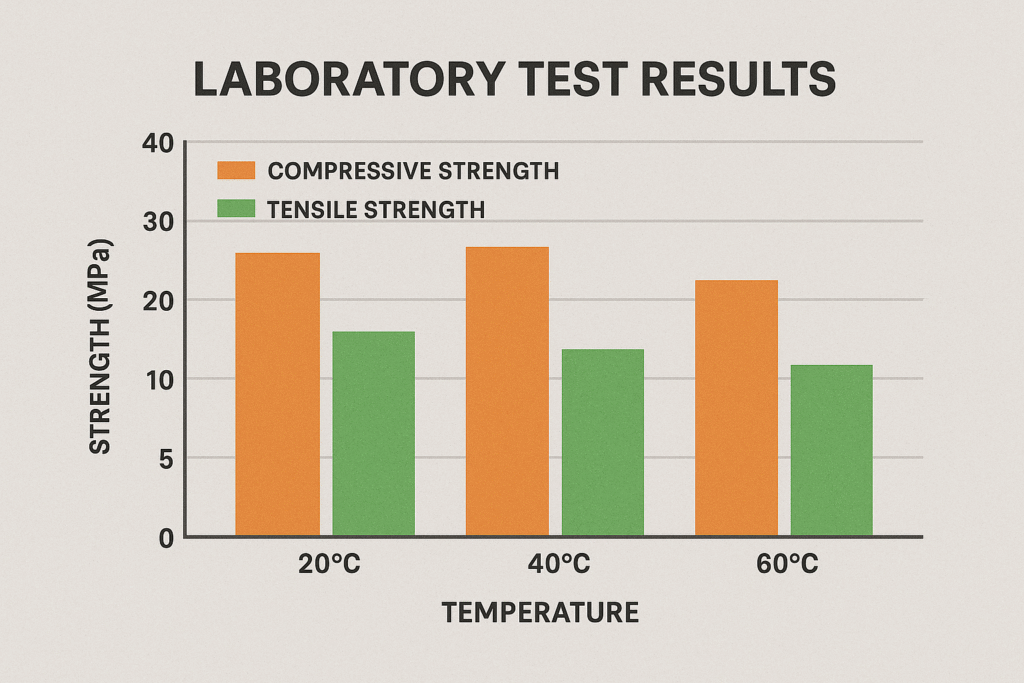

Testing shows cement-based adhesives achieve maximum tensile adhesion strength (typically 1.5-2.0 MPa) when cured at 20-25°C. Strength decreases by approximately 15% at 10°C and by 20-30% at 35°C. Water retention capabilities show similar patterns, dropping significantly above 30°C.

In our Kehao technical center, we regularly test our cellulose ethers3 in actual adhesive formulations across temperature ranges from 5°C to 40°C. These controlled experiments reveal clear patterns that help our customers optimize their formulations.

Tensile Adhesion Strength Variations

The most critical performance metric for tile adhesives—tensile adhesion strength—shows marked temperature dependence. Our testing protocol involves curing identical adhesive samples at different temperatures, then measuring pull-off strength at 7 and 28 days.

The results are eye-opening:

| Curing Temperature | 7-Day Strength | 28-Day Strength | Failure Mode |

|---|---|---|---|

| 5°C | 0.3-0.5 MPa | 0.8-1.0 MPa | Often cohesive failure within adhesive |

| 15°C | 0.7-0.9 MPa | 1.3-1.5 MPa | Mixed adhesive/cohesive failure |

| 23°C | 1.0-1.2 MPa | 1.6-1.8 MPa | Primarily substrate failure (optimal) |

| 35°C | 0.6-0.8 MPa | 1.2-1.4 MPa | Adhesive failure at tile interface |

| 40°C | 0.4-0.6 MPa | 1.0-1.2 MPa | Adhesive failure, often with cracking |

These findings have significant implications for warranty periods and durability expectations. Adhesives installed during temperature extremes simply don't achieve the same structural integrity as those installed under optimal conditions.

One particularly interesting observation from our research: adhesives with higher quality HPMC (like our Kehao KH100000S grade) show much less performance variation across temperature ranges than those with basic cellulose ethers or inadequate water retention additives.

Best Practices for Extreme Temperatures?

Pain point: Installers often don't know how to adjust their techniques for temperature extremes, resulting in failed installations and finger-pointing between material suppliers and contractors over who's responsible.

For cold temperatures (below 10°C): use warm mixing water, store materials indoors overnight, consider adding accelerants, and protect installations from freezing for 48+ hours. For hot conditions (above 30°C): use cool water, store materials in shade, work during cooler hours, and mist curing tiles.

Through partnerships with major mortar manufacturers across diverse climate zones, I've compiled practical techniques that dramatically improve adhesive performance at temperature extremes. These approaches have been validated through both laboratory testing and successful field applications.

Formulation Adjustments for Climate Resilience

For adhesive manufacturers, temperature resilience begins with proper formulation. This is where our specialized cellulose ethers make a critical difference.

For hot-climate formulations, we recommend:

- HPMC with higher methoxyl content and viscosity (100,000+ mPa·s)

- Increasing HPMC content by 0.05-0.1% compared to standard formulations

- Adding 0.5-1.0% additional redispersible polymer powder to improve flexibility

- Including retarding admixtures to extend workability time

For cold-climate formulations:

- Lower viscosity HPMC (30,000-80,000 mPa·s) with faster dissolution properties

- Slightly lower HPMC dosage to prevent excessive setting delays

- Addition of accelerating admixtures (calcium formats or calcium nitrates)

- Higher cement content to generate more hydration heat

One customer in Mexico implemented these recommendations and reported a 70% reduction in hot-weather related callbacks. The minor cost increase (approximately 3-5%) was trivial compared to the performance benefits and reduced warranty claims.

Why Choose Kehao for Temperature-Resilient Adhesives?

Pain point: Generic cellulose ethers and additives don't provide the temperature stability needed for reliable adhesive performance, but many suppliers don't offer specialized solutions or technical guidance for different climate challenges.

Kehao produces specialized HPMC grades specifically engineered for different temperature ranges, backed by technical support from experts with practical construction experience. Our KH-Therm series offers superior water retention at high temperatures, while KH-ColdSet provides enhanced performance in cool conditions.

At Kehao, we don't just sell HPMC—we engineer climate solutions. With six production lines and decades of experience serving hot-climate markets like Saudi Arabia, UAE, and India, we've developed specialized expertise in temperature-resilient formulations that generic suppliers simply can't match.

Scientific Approach to Climate-Specific Solutions

What sets Kehao apart is our scientific approach to solving temperature-related challenges. Our R&D center specifically tests all products across temperature gradients before they reach customers.

Our climate-specialized product lineup includes:

-

WH-P200: High-temperature specialized HPMC with modified particle size distribution for faster dissolution even in cold water while maintaining exceptional water retention in heat. This product maintains at least 85% of its water retention capability even at 40°C.

-

KH-P160S: Cold-weather optimized HPMC that dissolves efficiently even in cold water and doesn't excessively delay setting times in low temperatures.

-

WH-RDP-CF: Temperature-stable redispersible polymer powder that maintains consistent flexibility across temperature ranges from 5-40°C.

The difference is measurable. In controlled testing, adhesives formulated with our specialized HPMC maintained an open time of 15+ minutes at 35°C, while generic formulations skinned over in less than 7 minutes under identical conditions.

Conclusion

Temperature dramatically influences cement-based tile adhesives at every stage from mixing to final curing. By understanding these effects and choosing temperature-appropriate materials like Kehao's specialized HPMC products, manufacturers and contractors can ensure consistent performance across all climate conditions.

FAQ: Temperature and Tile Adhesive Performance

Q: Can I install tiles when temperatures might drop below freezing overnight?

A: No. Fresh adhesive must be protected from freezing for at least 48 hours, as ice formation disrupts the cement hydration process and permanently damages bond strength.

Q: Does humidity affect adhesive performance alongside temperature?

A: Absolutely. Low humidity accelerates water evaporation, especially in hot conditions. High humidity slows curing in cold conditions. Both extremes require formulation adjustments.

Q: Can I accelerate curing in cold conditions?

A: Yes, by using warm mixing water (30-35°C), storing materials indoors beforehand, and potentially adding chemical accelerants. However, never use direct heat sources on freshly installed tiles.

Q: Why does my adhesive perform differently in summer versus winter?

A: Temperature affects setting time, water demand, workability, and final strength. The same product may need different mixing ratios and application techniques across seasons.

Q: How can I test if temperature is affecting my adhesive performance?

A: Compare open times by creating a test area. Apply adhesive, then press tiles at 5-minute intervals until they no longer bond properly. This simple test reveals your actual working time under current conditions.

Q: Are there visual indicators of temperature-related adhesive problems?

A: Yes. Premature skinning (surface drying while underneath remains wet) indicates excessive heat/evaporation. Watery consistency without thickening suggests temperatures too cold for proper reaction.

Q: How does temperature affect mixing water requirements?

A: Higher temperatures typically require 5-15% more mixing water to maintain workability, while colder temperatures generally require slightly less water than manufacturer specifications.

Q: Do temperature considerations change for different tile types?

A: Yes. Large format and non-porous tiles are more sensitive to temperature effects because they rely more heavily on perfect open time and curing conditions than smaller, porous tiles.

Q: Can additives solve temperature-related problems?

A: Partially. While certain additives help (accelerators for cold, retarders for heat), they can't replace high-quality temperature-stable cellulose ethers like HPMC as the foundation of climate-resilient formulations.

Q: How long should curing times be extended in cold conditions?

A: A good rule of thumb is to add 24 hours of curing time for every 5°C below the ideal temperature range (15-25°C). At 10°C, allow at least an extra 1-2 days before grouting or traffic.

Q: Why do adhesives sometimes fail months after installation despite initially appearing successful?

A: Temperature extremes during curing can create microscopic weaknesses that aren't immediately apparent. These weaknesses manifest later under stress from building movement, heavy loads, or thermal expansion.

-

Explore the advantages of cement-based tile adhesives for durable and reliable installations. ↩ ↩

-

Learn about HPMC's critical role in improving adhesive performance. ↩ ↩

-

Discover how cellulose ethers enhance the performance of tile adhesives. ↩ ↩

-

Learn about the benefits of redispersible polymer powders for flexibility. ↩