Working with HPMC in hot climates often leads to unexpected viscosity drops, ruining carefully formulated mixtures. This problem costs time, materials, and customer satisfaction when products fail to perform.

To adjust HPMC viscosity for high temperatures, use heat-resistant grades1 like HEMC or HMHPMC, blend with 2-5% PVA or bentonite as co-thickeners, and select HPMC with higher methoxyl content (≥28%) but lower initial viscosity. Always test samples in actual site conditions rather than relying solely on laboratory data.

I've seen countless projects fail because formulators didn't account for how temperature affects HPMC performance. Let me share what I've learned from helping clients in Saudi Arabia and UAE where temperatures regularly exceed 40°C, and how you can avoid these costly mistakes.

How does temperature affect the viscosity of a lubricant?

Pain point: Many formulators are shocked when their perfectly mixed HPMC solutions turn watery in hot weather, causing application failures and customer complaints.

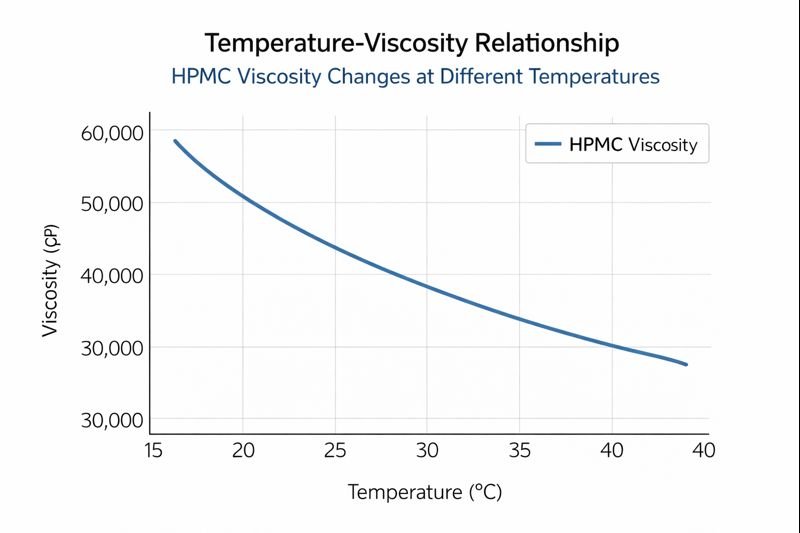

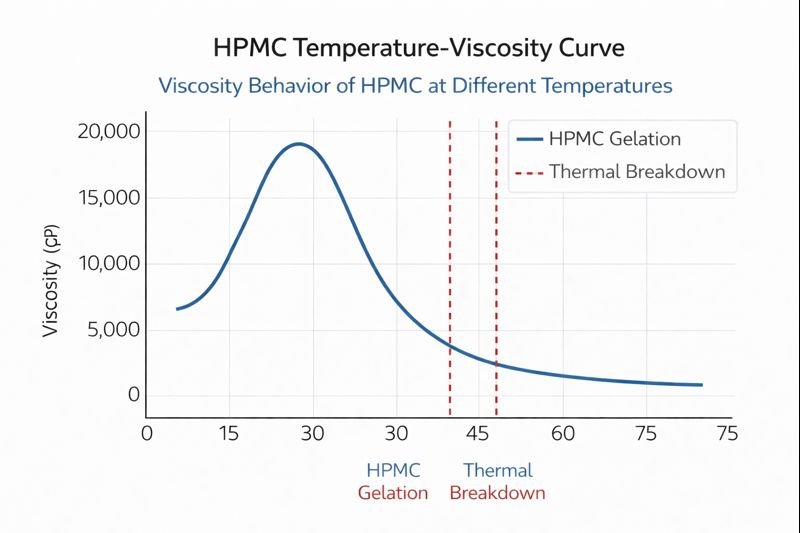

Temperature significantly affects lubricant viscosity by increasing molecular movement. As temperature rises, molecules move faster with more energy, reducing intermolecular forces and causing viscosity to decrease. For HPMC specifically, a 10°C temperature increase can reduce viscosity by 15-30%, making your mixture too thin for proper application.

I've analyzed this relationship extensively through our laboratory tests. The temperature-viscosity relationship follows a negative correlation that's especially pronounced with standard HPMC grades. This relationship is critical for formulators to understand because it directly impacts product performance in the field.

When working with HPMC in construction materials, the viscosity response to temperature follows the Arrhenius equation, showing exponential decreases as temperatures rise. Our data shows that standard HPMC grades can lose up to 40% of their initial viscosity when temperatures climb above 40°C, which is common in Middle Eastern construction sites. This viscosity reduction affects sag resistance, water retention, and workability of mortars and renders.

To counter this effect, we can examine the molecular structure of different cellulose ethers. Standard HPMC has hydroxypropyl and methoxyl groups that form hydrogen bonds with water molecules, creating the thickening effect. However, these bonds weaken significantly at elevated temperatures. This is why alternative grades like HEMC (Hydroxyethyl Methylcellulose) or HMHPMC (Hydrophobically Modified HPMC) perform better in hot conditions - their modified chemical structure maintains stronger intermolecular interactions even when heat increases.

At what temperature does HPMC degrade?

Problem: Using HPMC above its stable temperature range causes permanent viscosity loss and product failure, yet many users don't know the critical thresholds.

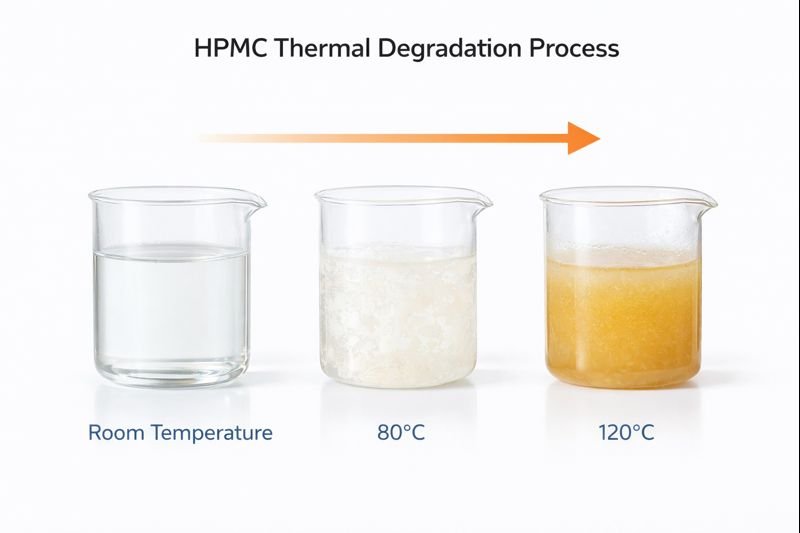

HPMC begins to chemically degrade at temperatures exceeding 190-200°C, but its functional properties deteriorate at much lower temperatures. In solution, HPMC undergoes gel phase separation around 60-85°C (depending on grade), causing temporary thickening followed by significant viscosity reduction upon cooling if maintained at high temperatures.

Though chemical degradation requires high temperatures, functional issues start much sooner. This is crucial knowledge I've gained from extensive field testing. HPMC solutions display a complex thermal behavior that directly impacts application performance.

The thermal behavior of HPMC can be divided into three distinct phases, each with different implications for formulators. Below 50°C, most HPMC grades maintain reasonable viscosity stability with gradual, reversible decreases as temperature rises. Between 50-65°C, many HPMC grades reach their cloud point temperature (CPT), where they undergo phase separation and temporarily form a gel before becoming a two-phase system. Above 65°C for prolonged periods, hydrogen bonds that maintain the polymer chain structure begin to break down, causing irreversible viscosity loss.

For practical applications, this means that short exposures to temperatures up to 80°C generally don't cause permanent damage to the HPMC polymer structure, but they do cause temporary viscosity reductions that can affect application properties. However, sustained exposure above 60°C for more than 14 days (common in hot climate construction scenarios) can lead to significant performance degradation.

In our laboratory tests with various HPMC grades, we've documented that methoxyl substitution levels play a key role in thermal stability. HPMC grades with methoxyl content above 28% retain approximately 15-20% more of their original viscosity after high-temperature aging tests compared to standard grades.

What is the viscosity range of HPMC2?

Issue: Selecting the wrong viscosity grade wastes money and compromises performance, but the wide range of available options confuses many buyers.

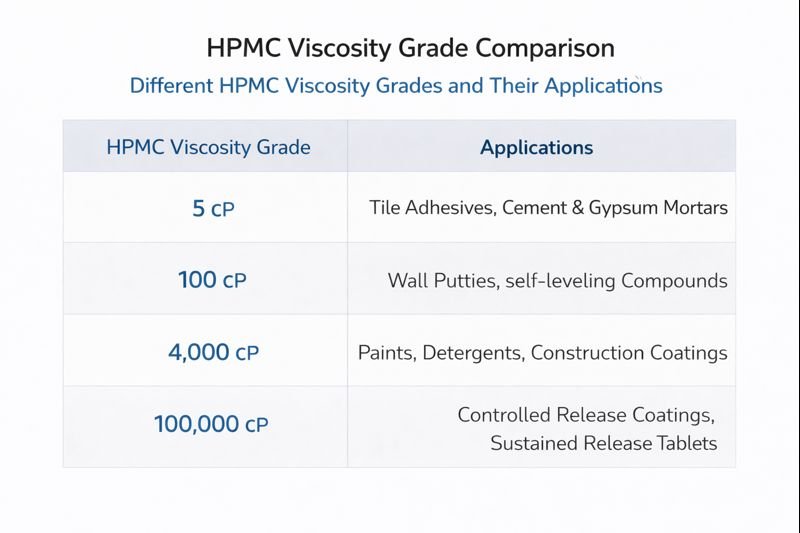

HPMC viscosity typically ranges from 5 to 100,000 mPa·s (centipoise), measured as a 2% aqueous solution at 20°C. Low-viscosity grades (5-400 mPa·s) suit sprayable formulations, medium grades (4,000-15,000 mPa·s) work well for general construction, while high-viscosity grades (15,000-100,000 mPa·s) provide maximum water retention.

I recommend carefully matching viscosity to application requirements. In our factory, we've developed specialized testing to help customers identify the optimal viscosity for their specific conditions.

Understanding HPMC viscosity ranges requires considering both the numerical values and practical implications for different applications. The viscosity range directly correlates with molecular weight – higher molecular weight HPMC produces higher viscosity solutions at equal concentrations. This relationship follows a power law where viscosity increases exponentially with molecular weight.

For hot climate applications, the viscosity selection becomes even more critical. Our testing shows that higher initial viscosity grades experience larger percentage drops when exposed to heat. For example, a 100,000 mPa·s HPMC grade might lose 40% of its viscosity at 40°C, while a 5,000 mPa·s grade might only lose 25% under identical conditions.

This table summarizes typical HPMC viscosity ranges and their recommended applications:

| Viscosity Range (mPa·s) | Primary Applications | Temperature Sensitivity | Dosage Range |

|---|---|---|---|

| 5-400 (Low) | Sprayable coatings, Ceramic tile adhesives | Low to Moderate | 0.2-0.4% |

| 400-4,000 (Medium-Low) | Self-leveling compounds, Cement-based tile adhesives | Moderate | 0.3-0.5% |

| 4,000-15,000 (Medium) | Renders, Plasters, General mortars | High | 0.4-0.6% |

| 15,000-100,000 (High) | Masonry mortars, Heavy renders, EIFS systems | Very High | 0.5-0.8% |

For high-temperature environments, we typically recommend selecting a viscosity grade 20-30% higher than would be used in moderate climates to compensate for temperature-related viscosity reduction.

How to thicken HPMC?

Problem: When HPMC solutions become too thin in hot weather, projects face delays and quality problems, but many formulators don't know how to effectively thicken them.

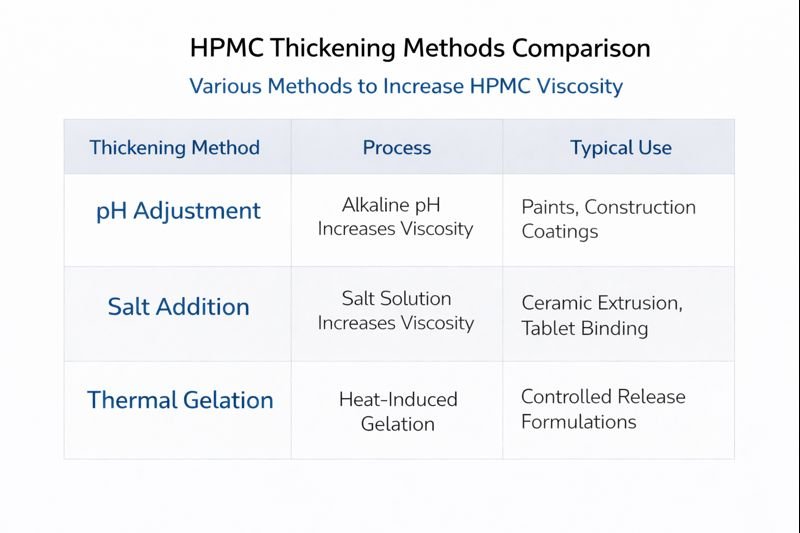

To thicken HPMC solutions, increase the concentration by 0.1-0.2%, switch to a higher-viscosity grade, or add complementary thickeners like bentonite (2-3%) or PVA (1-2%). For heat resistance, HMHPMC grades maintain up to 30% more viscosity at elevated temperatures compared to standard HPMC.

From my experience solving thickening problems for clients in hot regions, blending different viscosity modifiers often works better than simply using more HPMC.

The challenge of thickening HPMC solutions becomes particularly important in high-temperature environments where viscosity naturally decreases. Through extensive testing at our laboratory, we've identified several effective approaches to enhance viscosity stability across temperature ranges.

Synergistic thickening systems provide the most reliable results in challenging environments. When we combine HPMC with other rheology modifiers, we create systems that maintain performance across wider temperature ranges. For example, adding 2-3% bentonite clay to an HPMC solution creates a dual thickening mechanism – the HPMC provides solution viscosity while the bentonite forms a weak gel structure that's less temperature-sensitive.

Another effective approach involves modifying the chemical structure of the HPMC itself. Hydrophobically modified HPMC (HMHPMC) contains additional hydrophobic groups that create stronger associations between polymer chains at elevated temperatures. Our tests show these modified grades can maintain up to 30% higher viscosity at 40°C compared to standard HPMC of equivalent initial viscosity.

The methoxyl/hydroxypropyl substitution ratio3 also plays a crucial role in thermal stability. HPMC grades with higher methoxyl content (typically above 28-30%) and lower hydroxypropyl content show improved heat resistance. This is because methoxyl groups create stronger, more heat-stable interactions than hydroxypropyl groups. When reviewing technical data sheets for different HPMC grades, this substitution pattern should be carefully evaluated for hot climate applications.

For practical implementation, we recommend a testing protocol that includes viscosity measurements at both application temperature and after heat aging (60°C for 14 days) to properly predict field performance.

Does high temperature increase viscosity?

Problem: Confusion about how temperature affects HPMC viscosity leads to formulation errors and application failures in seasonal temperature changes.

No, high temperature typically decreases HPMC viscosity. While some polymers exhibit inverse behavior, standard HPMC loses viscosity as temperature rises because increased thermal energy weakens hydrogen bonding between polymer chains and water molecules. At very specific temperature points (around 65-85°C), HPMC briefly gels before separating into phases.

I've helped numerous customers understand this counter-intuitive behavior. While most liquids like water become less viscous with heat, the relationship for HPMC solutions is more complex due to its polymer structure.

The temperature-viscosity relationship of HPMC solutions1 is governed by complex polymer physics that differs from simple Newtonian fluids like water or oil. HPMC solutions are non-Newtonian, meaning their viscosity changes not only with temperature but also with shear rate (how fast they're stirred or applied).

At the molecular level, HPMC polymers in solution form a three-dimensional network through hydrogen bonding and polymer chain entanglements. As temperature increases from room temperature (around 20°C) up to about 50-60°C, thermal energy gradually overcomes these interactions, reducing viscosity in a predictable manner. Field tests we've conducted show that this viscosity reduction follows approximately a 5-8% decrease per 5°C temperature increase in this range.

However, HPMC solutions display unique behavior at their cloud point temperature (typically 65-85°C depending on the specific grade). At this point, the polymer undergoes phase separation where hydrophobic interactions suddenly dominate over hydrogen bonding, causing the formation of a temporary gel network. This creates a brief increase in viscosity before the system separates into polymer-rich and polymer-poor phases.

This complex behavior has practical implications for construction applications. During midday heat on construction sites in places like Saudi Arabia or UAE where I've consulted extensively, surface temperatures can reach 50-60°C. At these temperatures, HPMC-modified mortars can lose up to 40% of their room-temperature viscosity, significantly affecting sag resistance and workability.

To counter this effect, we've developed testing protocols that examine viscosity across the entire application temperature range rather than just at standard laboratory conditions.

What are the four factors that affect viscosity?

Problem: Without understanding what affects HPMC viscosity, formulators struggle to maintain consistent product performance across varying conditions.

Four key factors affecting HPMC viscosity are: temperature (higher temperatures reduce viscosity), concentration (higher concentrations increase viscosity), molecular weight (higher molecular weight increases viscosity), and substitution degree (higher methoxyl content improves heat stability). pH also matters, with optimal viscosity at pH 6-8.

I've worked with these factors daily in our laboratory to develop customized HPMC solutions for challenging environments. Understanding their interrelationships is essential for successful formulations.

The influence of these factors on HPMC viscosity is not merely academic – it has direct practical implications for formulation stability and performance. Based on our extensive research and field experience, I can share specific insights about how these factors interrelate.

Temperature effects on HPMC viscosity follow a predictable pattern up to the cloud point, with approximately 6-8% viscosity reduction per 5°C increase. This temperature sensitivity varies with molecular weight – higher molecular weight grades (above 50,000 mPa·s) show more pronounced viscosity reductions with temperature increases than lower molecular weight grades.

Concentration effects follow a power law relationship, where viscosity increases exponentially with concentration. This relationship can be expressed as: η ∝ cᵃ, where η is viscosity, c is concentration, and the exponent a typically ranges from 3.0 to 4.5 for most HPMC grades. This means doubling the concentration can increase viscosity by 8-22 times, making concentration adjustments a powerful but sensitive tool.

Molecular weight directly correlates with viscosity, but this relationship also affects temperature stability. Our testing shows that while higher molecular weight provides greater initial viscosity, it also leads to more dramatic viscosity reductions at elevated temperatures. For hot climate applications, medium molecular weight grades often provide better overall performance despite lower initial viscosity.

Substitution degree influences both viscosity and thermal stability. HPMC with higher methoxyl substitution (28-30%) and lower hydroxypropyl substitution demonstrates superior heat stability. The methoxyl/hydroxypropyl ratio affects the gelation temperature and the extent of viscosity loss at elevated temperatures.

For practical application, we've developed a matrix approach to formulation that considers these four factors simultaneously rather than in isolation. This allows us to optimize HPMC performance for specific temperature conditions while maintaining other critical properties like water retention and adhesion strength.

Conclusion

Mastering HPMC viscosity in hot environments requires selecting heat-resistant grades, blending with co-thickeners, and understanding how temperature, concentration, molecular weight and substitution degree interact. Always test in actual site conditions for reliable results.