Uneven floors can ruin your perfect home renovation. Self-leveling underlayments promise to solve this problem, but choosing between cement and gypsum options leaves many contractors and DIYers confused and frustrated.

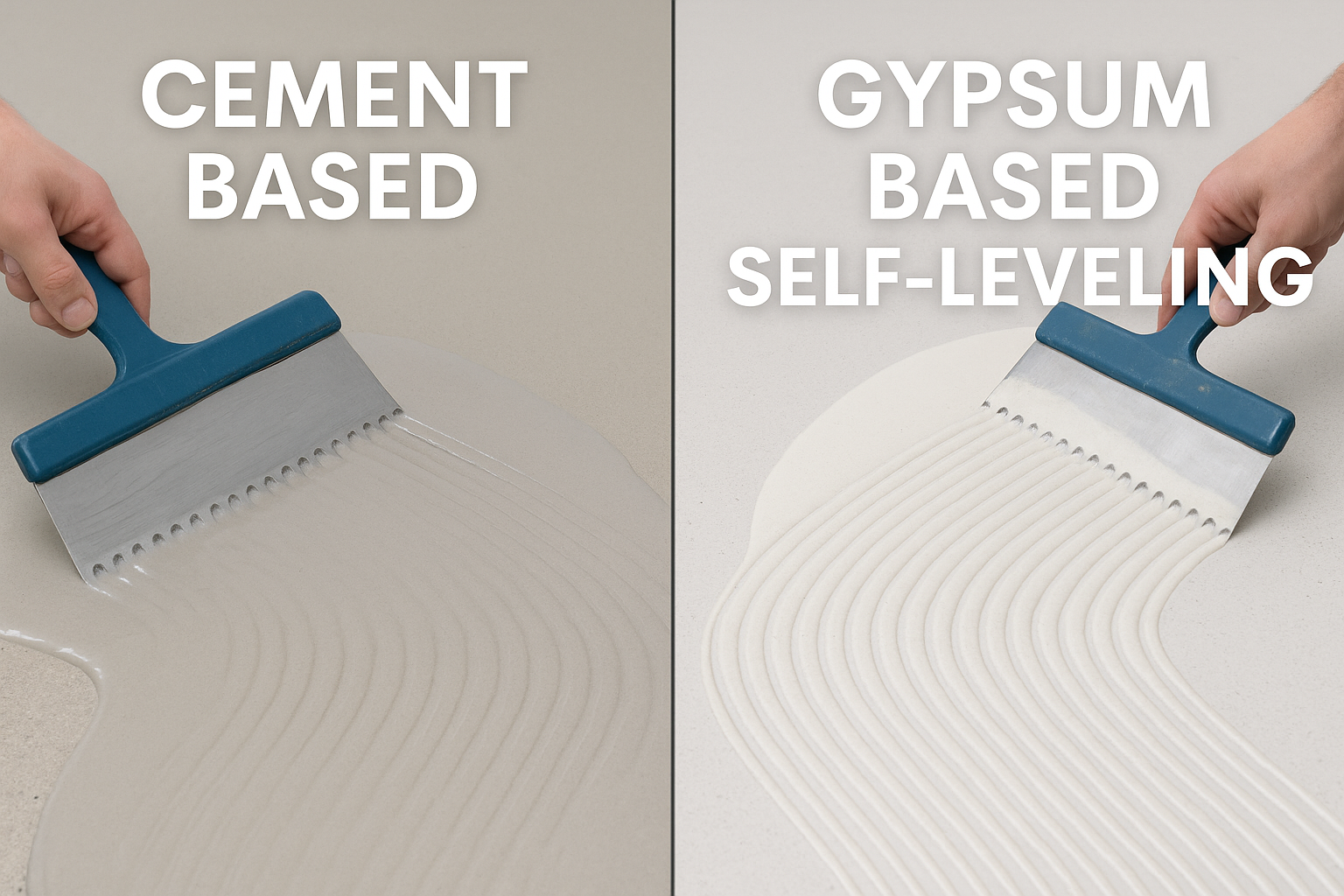

The key factor in choosing between cement-based and gypsum-based self-leveling underlayment is moisture exposure. Cement-based products are water-resistant and ideal for wet areas like bathrooms and kitchens, while gypsum-based options1 offer superior flatness for dry spaces like bedrooms and living rooms.

Making the wrong choice could lead to costly repairs down the road. I've seen beautiful floors ruined because someone used the wrong underlayment in the wrong environment. Let's break down exactly when to use each type so you can make the right decision the first time.

When Should You Not Use Self-leveling Concrete?

You've probably heard that self-leveling concrete is a miracle solution for uneven floors. But there are situations where using it could lead to wasted money, failed installations, and frustrated clients.

Self-leveling concrete should not be used on unstable subfloors, outdoor areas with freeze-thaw cycles, surfaces with active water leaks, or when proper substrate preparation isn't possible. It's also unsuitable for slopes exceeding manufacturer specifications or when sufficient curing time isn't available.

Self-leveling concrete isn't the answer to every flooring challenge. I learned this the hard way when I used it in a basement with moisture issues. Despite looking perfect initially, the installation failed within months.

Understanding Self-leveling Concrete Limitations

Self-leveling concrete products are designed for specific scenarios, and recognizing their boundaries is crucial for successful installations. The most critical limitation is moisture handling. While cement-based products2 can tolerate some moisture, they aren't designed for active water exposure or standing water conditions.

Substrate quality also matters significantly. Self-leveling compounds require stable, clean surfaces free of contaminants. I've seen projects fail because contractors skipped proper floor preparation, assuming the self-leveling product would "fix everything." Additionally, temperature restrictions are crucial - most products need environments between 50-90°F (10-32°C) during installation and curing.

Here's a breakdown of common scenarios where self-leveling concrete should be avoided:

| Scenario | Why It's Problematic | Better Alternative |

|---|---|---|

| Active water leaks | Prevents proper curing, ruins bond | Fix water issue first, then use waterproofing membrane |

| Structurally unsound subfloor | Product can't compensate for structural movement | Repair structural issues before leveling |

| Outdoor applications | Not designed for freeze/thaw cycles | Use exterior-rated concrete products |

| Sloped drainage areas | Self-leveling means flat, not sloped | Use traditional mortar bed techniques |

| Extremely hot/cold conditions | Affects flow properties and curing | Wait for appropriate temperature range |

Is Gypsum Cement Underlayment the Same as Gypcrete?

When researching flooring options, I kept seeing both "gypsum cement underlayment" and "Gypcrete" mentioned, which left me wondering if they were different products or just different names for the same thing.

Gypcrete is actually a brand name that has become a generic term for gypsum-based underlayments, similar to how Kleenex refers to tissues. While all Gypcrete is gypsum cement underlayment, not all gypsum underlayments are Gypcrete - they may be different formulations from other manufacturers.

The distinction between these terms matters because it affects what you're actually getting and how it will perform. I once specified "Gypcrete" on a project, assuming any gypsum underlayment would work, only to discover significant differences in performance between brands.

Understanding Gypsum-Based Products

Gypsum-based underlayments represent a specialized category of floor leveling products with distinct properties that set them apart from traditional cement-based options. The core ingredient is calcium sulfate hemihydrate3 (gypsum), which creates a remarkably smooth, crack-resistant surface when properly installed. These products typically incorporate lightweight aggregates and flow enhancers to achieve their characteristic self-leveling properties.

What makes these products unique is their installation process and performance characteristics. When mixed with water, gypsum underlayments can be poured to create exceptionally flat surfaces with minimal shrinkage - a significant advantage when preparing floors for sensitive finishes like vinyl, laminate, or engineered wood. However, their moisture sensitivity means they require specific site conditions both during and after installation.

The terminology confusion stems from market evolution:

| Term | What It Refers To | Important Considerations |

|---|---|---|

| Gypcrete | Brand name from Maxxon Corporation | Original formulation, specific performance metrics |

| Gypsum cement | Generic descriptor for similar products | Varies by manufacturer in strength and additives |

| Gypsum concrete | Another generic term | May indicate higher compressive strength formulations |

| Gypsum underlayment | Generic category name | Focuses on underlayment application rather than composition |

Most professionals in the industry use these terms somewhat interchangeably, though technically they can represent different specific products with varying performance characteristics. When specifying materials, it's always best to reference exact product names rather than generic categories.

Why Gypsum Underlayment?

With cement-based options widely available, you might wonder why anyone would choose a gypsum product that seems more finicky about moisture conditions. What benefits could possibly outweigh this apparent disadvantage?

Gypsum underlayment offers exceptional flatness with minimal cracking or shrinkage, creates lighter loads on structures, provides superior sound insulation between floors, and offers excellent thermal conductivity for radiant heating systems. These advantages make it ideal for dry interior spaces like bedrooms and living areas.

I was initially skeptical about gypsum underlayment until I used it in a large apartment renovation. The flawlessly flat surface it created made the floating wood floor installation incredibly easy, with no hollow spots or creaking afterward.

The Technical Advantages of Gypsum Systems

Gypsum underlayment systems offer several technical advantages that explain their growing popularity despite moisture limitations. When properly installed in appropriate environments, these systems deliver performance benefits that cement-based alternatives struggle to match.

The molecular structure of gypsum crystals creates a unique combination of strength and flexibility that results in exceptional dimensional stability. Unlike cement-based systems that can experience significant shrinkage during curing (potentially creating tension and cracks), gypsum formulations exhibit minimal shrinkage. This property allows installation in larger continuous areas without the control joints often required with cement products.

Thermal performance is another significant advantage, especially with radiant heating systems. Gypsum conducts heat more efficiently than cement-based materials, improving energy efficiency and creating more comfortable, evenly heated environments. In multi-story buildings, the acoustic benefits become particularly valuable:

| Performance Aspect | Gypsum Advantage | Practical Benefit |

|---|---|---|

| Weight | 75% lighter than traditional concrete | Reduces structural load requirements |

| Sound Transmission | Superior STC/IIC ratings | Better sound isolation between floors |

| Installation Speed | Faster drying time | Earlier floor finish installation |

| Thermal Conductivity | Higher than cement products | More efficient radiant heating |

| Crack Resistance | Superior to cement under normal conditions | Smoother finished floor appearance |

| Environmental Impact | Lower carbon footprint | Reduced environmental impact |

For projects prioritizing interior comfort, acoustic performance, and perfect finishes on large floor areas, these advantages often outweigh the moisture limitations - particularly when proper waterproofing measures are implemented in potentially wet areas.

Conclusion

Water exposure is the decisive factor in choosing between cement and gypsum underlayments. Use cement-based products2 for bathrooms, kitchens and other moisture-prone areas. Choose gypsum for dry spaces where flatness and crack resistance matter most.

-

Discover the advantages of gypsum-based flooring options and how they can enhance your home renovation. ↩

-

Learn about the benefits of cement-based products, especially in moisture-prone areas like bathrooms and kitchens. ↩ ↩

-

Learn about the key ingredient in gypsum underlayment and its benefits for flooring applications. ↩