Are you struggling with your mortar sliding down walls or your self-leveling compounds1 refusing to flow? Choosing the wrong HPMC viscosity2 can waste your expensive materials and ruin entire projects, costing you thousands in repairs.

The right HPMC viscosity creates the perfect balance between workability and performance. For wall applications like putty powder and tile adhesives, higher viscosity (100,000-200,000 mPa·s) prevents sagging, while self-leveling mortars require lower viscosity (380-400 mPa·s) to flow properly and find their own level.

I've seen many customers make costly mistakes by thinking higher viscosity always means better quality. The truth is, viscosity is about application compatibility, not quality. Let me walk you through how to make the right choice for your specific needs.

What is HPMC and Why Does Viscosity Matter?

Pain point: Using the wrong HPMC grade in your formulation can lead to product failure, customer complaints, and wasted raw materials. I've seen this happen repeatedly.

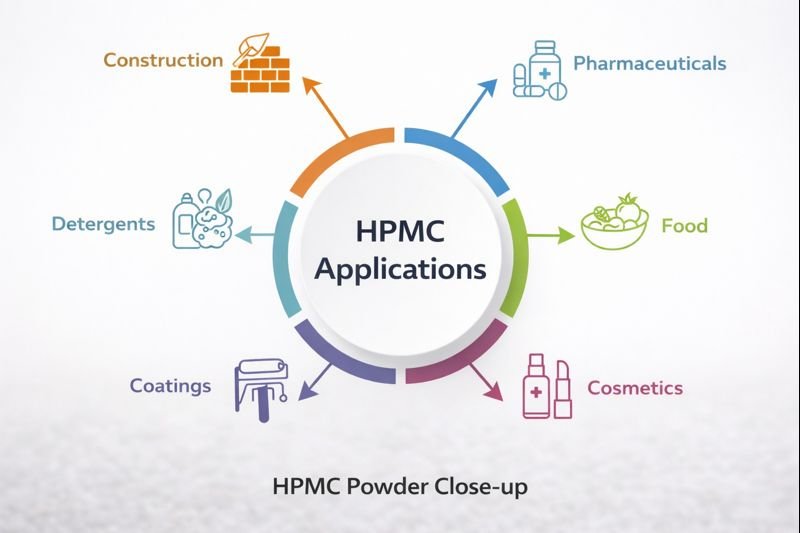

HPMC (Hydroxypropyl Methylcellulose3) is a cellulose ether that controls water retention, consistency, and workability in various mixtures. Its viscosity determines how thick or flowable your end product will be, directly affecting application performance and end-user satisfaction.

Understanding Viscosity in HPMC

Viscosity measures a fluid's resistance to flow - essentially how "thick" or "thin" a liquid is. When we talk about HPMC viscosity, we're referring to how much the cellulose powder can thicken water when dissolved.

HPMC viscosity2 is typically measured in millipascal-seconds (mPa·s) at a 2% concentration in water at 20°C. The measurement represents how much force is needed to make the solution flow. Common HPMC grades range from very low viscosity (400-3,000 mPa·s) to ultra-high viscosity (100,000-200,000 mPa·s).

The viscosity directly affects:

- Water retention

- Sag resistance

- Open time

- Workability

For example, when I visited a customer in Saudi Arabia last year, they were struggling with their tile adhesive sliding down vertical surfaces in their hot climate. By switching from a 15,000 mPa·s to a 100,000 mPa·s grade, their problem was immediately solved because the higher viscosity provided better anti-sag properties.

Factors Influencing HPMC Viscosity

Multiple factors affect how HPMC performs in your specific application:

- Molecular Weight: Higher molecular weight creates higher viscosity

- Degree of Substitution: Methoxyl and hydroxypropyl content adjustments change water solubility

- Temperature: Most HPMC exhibits thermal gelation at specific temperatures

- Concentration: Higher concentration increases viscosity exponentially

- pH Environment: Extreme pH values can degrade the cellulose chain

| Factor | Effect on Viscosity | Application Consideration |

|---|---|---|

| Temperature | Decreases with heat until gelation point | Consider environmental conditions |

| Concentration | Increases with higher concentration | Balance cost vs. performance |

| pH | Stable between pH 3-11 | Check compatibility with other ingredients |

| Shear Force | Temporary viscosity reduction | Important for spray applications |

| Particle Size | Finer powder dissolves faster | Affects dissolution time |

I remember visiting a construction site in Dubai where the contractor couldn't understand why the same mortar mix worked perfectly in the morning but failed in the afternoon. The answer was thermal gelation - as temperatures rose above 35°C, their HPMC was gelling prematurely. Switching to a grade with modified thermal gelation solved their problem.

Applications and Selection of the Right Viscosity

Pain point: One-size-fits-all approaches to HPMC selection lead to compromised performance and wasted resources. I see this mistake frequently among new customers.

The perfect HPMC viscosity depends entirely on your specific application requirements. Let's examine how to make the right choice for different industries.

Applications in Construction

In construction applications, viscosity selection fundamentally comes down to balancing between "anti-sag" properties and workability:

High Viscosity (100,000-200,000 mPa·s):

- Wall putty powder (100,000 mPa·s)

- Tile adhesives (150,000-200,000 mPa·s)

- Thermal insulation mortars (150,000-200,000 mPa·s)

These applications require excellent water retention and anti-sag properties to prevent material from sliding down vertical surfaces. The high viscosity creates a structure that holds water and keeps the mixture where it's applied.

Medium Viscosity (15,000-75,000 mPa·s):

- Rendering mortars

- Repair mortars

- Masonry mortars

Low Viscosity (400-10,000 mPa·s):

- Self-leveling compounds (380-400 mPa·s)

- Grouts

- Cement-based overlays

I once consulted for a large mortar manufacturer in Pakistan who couldn't understand why their self-leveling product wasn't spreading properly. They were using a 75,000 mPa·s HPMC because they thought "higher quality" meant higher viscosity. By switching to a 400 mPa·s grade, their product immediately began performing correctly, flowing smoothly to create a perfectly level surface.

Pharmaceutical Applications

Pharmaceutical applications require precise viscosity control:

High Viscosity:

- Extended-release tablet coatings

- Sustained-release formulations

Medium Viscosity:

- Film coating

- Binding agents

- Thickening agents for liquid medicines

Low Viscosity:

- Immediate release tablet coatings

- Capsule manufacturing

- Binding agents in direct compression

For pharmaceutical applications, regulatory compliance is as important as viscosity. You need pharmaceutical-grade HPMC that meets standards like USP, EP, or JP specifications.

Applications in the Food Industry

Food-grade HPMC requires specific viscosity ranges for different applications:

High Viscosity:

- Gluten-free baked goods

- Thickening agents for sauces and dressings

Medium Viscosity:

- Meat products

- Icings and frostings

Low Viscosity:

- Fruit glazes

- Emulsion stabilizers

Food applications must use food-grade HPMC that complies with regulations like FDA, JECFA, or EU specifications to ensure consumer safety.

Paints and Coatings

Paint applications use HPMC primarily as a thickener and water retention agent:

High Viscosity:

- Textured paints

- High-build coatings

Medium Viscosity:

- Interior wall paints

- Water-based architectural coatings

Low Viscosity:

- Primer paints

- Spray application coatings

I worked with a paint manufacturer in Vietnam who was experiencing problems with their paint sagging on vertical surfaces. By adjusting their HPMC from a 10,000 mPa·s to a 30,000 mPa·s grade, they achieved the perfect balance of application ease and sag resistance.

Tips for Choosing the Right HPMC Viscosity

Pain point: Selecting the wrong viscosity wastes money and compromises performance. I regularly help customers avoid this common pitfall.

Here are my practical tips for choosing the right HPMC viscosity:

-

Start with application requirements: Define what properties matter most (anti-sag, flow, open time)

-

Consider environmental conditions: Temperature and humidity at the application site significantly impact performance

-

Test before scaling up: Always conduct small-scale tests before full production

-

Consult viscosity tables:

| Application | Recommended Viscosity Range | Key Property |

|---|---|---|

| Wall putty powder | 80,000-100,000 mPa·s | Anti-sag |

| Tile adhesives | 150,000-200,000 mPa·s | Water retention |

| Self-leveling compounds | 380-400 mPa·s | Flowability |

| Renders | 15,000-50,000 mPa·s | Workability |

| Interior paints | 20,000-40,000 mPa·s | Thickness |

- Consider your mixing equipment: Higher viscosity requires more powerful mixing

One client in Mexico kept ordering our highest viscosity grade for their tile adhesive even though they only needed a medium grade. Not only were they paying a premium, but they were also struggling with mixing issues. After switching to the appropriate viscosity, they saved 15% on material costs and improved their production efficiency.

Common Mistakes to Avoid

I've witnessed these frequent errors in HPMC selection:

-

Assuming higher viscosity means better quality: Match viscosity to application requirements, not price point

-

Ignoring temperature effects: HPMC behaves differently at various temperatures

-

Using a single grade for multiple applications: Different products require different viscosities

-

Overlooking interaction with other ingredients: Some additives can alter HPMC performance

-

Insufficient testing: Laboratory conditions may not reflect real-world application environments

A large distributor in India once purchased a single high-viscosity HPMC grade for all their customers, assuming it would work universally. This led to numerous application failures and customer complaints. We helped them develop a proper selection guide based on application needs rather than a one-size-fits-all approach.

Conclusion

Selecting the right HPMC viscosity is about finding the perfect balance for your specific application. Remember: viscosity isn't about quality but compatibility. Match your choice to your application requirements, and you'll maximize performance while optimizing costs.

FAQs

Q: Can I mix different viscosity grades to get an intermediate viscosity?

A: Yes, but precise blending equipment is required for consistent results.

Q: Does HPMC viscosity change during storage?

A: Properly stored HPMC maintains stable viscosity for 2+ years when kept dry and at moderate temperatures.

Q: How quickly does HPMC dissolve?

A: Dissolution time depends on particle size, temperature, and mixing efficiency. Hot/cold mixing techniques can improve dissolution.

Q: Can environmental humidity affect HPMC performance?

A: Yes, high humidity can cause premature hydration, affecting dissolution and final viscosity.

Q: Is there a correlation between HPMC viscosity and water retention?

A: Generally, higher viscosity provides better water retention, but modified grades can offer enhanced water retention at lower viscosities.

-

Learn how self-leveling compounds function to achieve smooth surfaces in construction projects. ↩

-

Understanding HPMC viscosity is crucial for selecting the right grade for your application, ensuring optimal performance. ↩ ↩

-

Explore the diverse applications of HPMC in construction to enhance your project outcomes. ↩