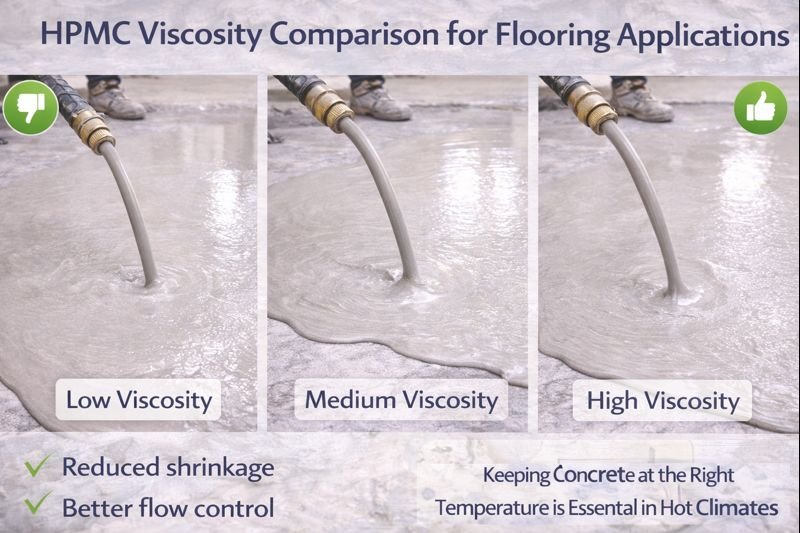

Selecting the wrong HPMC viscosity can ruin your entire flooring project. I've seen contractors waste thousands of dollars using high-quality materials incorrectly, resulting in floors that crack, shift, or never properly set.

The right HPMC viscosity1 depends entirely on your specific application. For self-leveling compounds2, use 400-2000 mPa·s to maintain flowability while preventing separation. For tile adhesives3, choose 100,000-200,000 mPa·s to prevent slippage. Matching viscosity to application is crucial for project success.

Think of HPMC viscosity as a "body adjuster" for your mortar. Are you making "light cream" or "butter"? The answer depends on what job you need it to do. It's not about "higher is better" but rather finding the "just right" balance for your specific application.

What is the viscosity range of HPMC?

Choosing the wrong HPMC viscosity range is like picking basketball shoes for swimming. I've watched customers struggle when they didn't understand that viscosity numbers tell you how the material will behave in real-world conditions.

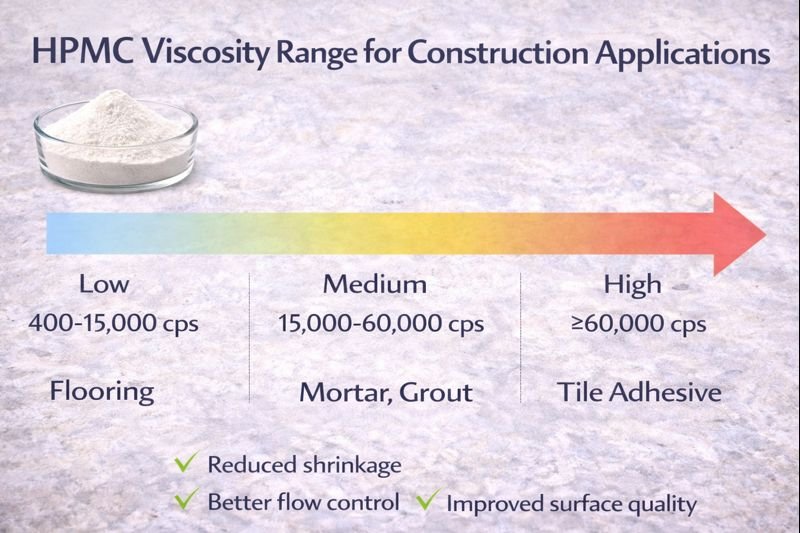

HPMC viscosity typically ranges from 400 to 200,000 mPa·s (millipascal-seconds). Low viscosity types (400-5,000 mPa·s) are ideal for self-leveling compounds. Medium viscosity (5,000-50,000 mPa·s) works for standard mortars. High viscosity types (50,000-200,000 mPa·s) are best for tile adhesives and wall applications.

Viscosity is really about how HPMC controls water in your mixture. I've tested hundreds of formulations in our lab, and the viscosity number directly impacts three key aspects of your flooring material: flowability, water retention, and sag resistance.

For self-leveling compounds2, you need enough viscosity to hold cement and sand particles in suspension (preventing separation) but low enough that the mixture can flow and level itself. This sweet spot is usually in the 400-2000 mPa·s range. When I tried using higher viscosity HPMC (like 100,000 mPa·s) in self-leveling applications, the mixture became like "dead dough" - completely defeating the "self-leveling" purpose.

Here's a simple breakdown of how different viscosities affect flooring applications:

| Viscosity Range (mPa·s) | Best For | Why It Works |

|---|---|---|

| 400- | Self-leveling compounds | Flows easily while preventing water separation |

| 5,000-50,000 | General purpose mortars | Balanced water retention and workability |

| 50,000-200,000 | Tile adhesives, wall applications | Strong sag resistance, holds tiles firmly |

I always tell customers that viscosity is just one property - you also need to consider substitution type (like methylcellulose vs. hydroxypropyl methylcellulose) and other additives in your complete formulation.

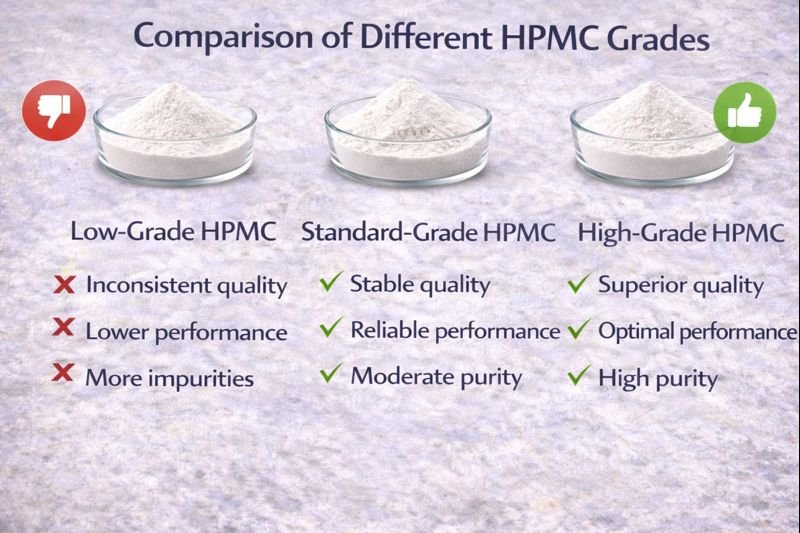

What is the difference between HPMC grades?

Many suppliers will try to sell you the most expensive grade, claiming it's always better. I've had customers spend thousands extra on premium grades when a standard grade would have worked perfectly for their application.

HPMC grades differ primarily in viscosity, methoxyl content, hydroxypropyl content, and particle size. The methoxyl content affects water solubility and gel temperature, while hydroxypropyl content influences surface activity and organic solvent solubility. Together, these determine the HPMC's performance characteristics.

When looking at different HPMC grades, you need to understand that manufacturers classify their products based on several chemical and physical properties that determine performance in different applications.

From my experience working with construction material manufacturers4 across Saudi Arabia and the UAE, I've found that understanding these grade differences is crucial for optimizing formulations. The main parameters that differentiate HPMC grades include:

-

Methoxyl content (%): This affects water solubility and gel temperature. Higher methoxyl content typically means faster dissolution in cold water but lower thermal gelation temperature.

-

Hydroxypropyl content (%): This influences surface activity and solubility in organic solvents. More hydroxypropyl groups generally mean better compatibility with other ingredients in your mortar.

-

Particle size: This affects dissolution rate. Finer particles dissolve faster but may cause lumping if not properly dispersed.

-

Molecular weight: This directly impacts viscosity. Higher molecular weight produces higher viscosity at the same concentration.

Here's a typical grade designation breakdown:

| HPMC Grade | Methoxyl (%) | Hydroxypropyl (%) | Typical Applications |

|---|---|---|---|

| E5 | 28-30 | 7-12 | Self-leveling compounds |

| E15 | 28-30 | 7-12 | General mortars |

| K100M | 19-24 | 7-12 | Tile adhesives |

When I formulate for different customers, I often remind them that the grade should match the application requirements. Using an unnecessarily high-grade HPMC doesn't improve performance - it just increases costs.

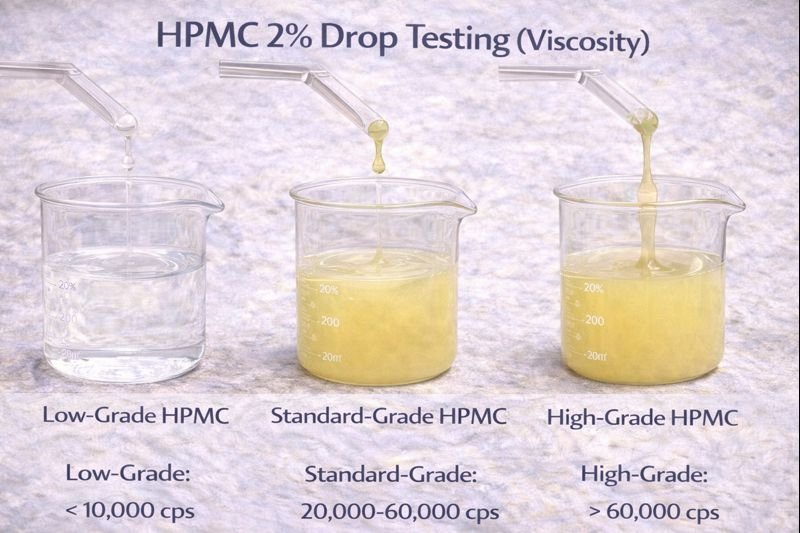

What is Hydroxypropyl Methylcellulose 2% drop?

I once had a customer call me in a panic because his supplier quoted a different viscosity than what was on the technical data sheet. He didn't understand that the "2% drop" is a standard measurement method that affects the actual number.

The "2% drop" refers to the measurement method where HPMC viscosity is tested in a 2% aqueous solution. This standardized testing method measures how thick the solution becomes when 2 grams of HPMC are dissolved in 100 grams of water. The resulting measurement in mPa·s becomes the product's viscosity specification.

The "2% drop" might sound technical, but it's actually quite straightforward once you understand the concept. When we test HPMC at our factory, we need a standardized way to measure viscosity so everyone speaks the same language.

Here's how we perform this test in our quality control lab: We take exactly 2 grams of HPMC powder and dissolve it in 98 grams of distilled water (making a 2% solution). After ensuring complete dissolution, we use a rotational viscometer to measure how much resistance there is when stirring this solution. This resistance, measured in millipascal-seconds (mPa·s), gives us the viscosity value.

Why is this important for your flooring projects? Because this standardized measurement lets you compare products from different suppliers. If supplier A offers HPMC 100,000 and supplier B offers HPMC 95,000 (both measured at 2% concentration), you can accurately compare their performance potential.

I've found that many construction material manufacturers don't realize that concentration dramatically affects viscosity. If you use HPMC at 0.3% in your actual formulation (common for self-leveling compounds), the viscosity contribution will be much lower than the labeled value. This is why formulation expertise is so important - the "2% drop5" is just a standardized reference point, not the actual viscosity you'll get in your specific application.

Conclusion

Choosing the right HPMC viscosity is about matching the material to your specific flooring application. Low viscosity (400-2000 mPa·s) for self-leveling, high viscosity (50,000-200,000 mPa·s) for tile adhesives. It's not about "better" - it's about "appropriate."

FAQ

Q: Can I use one type of HPMC for all my flooring applications?

A: Not recommended. Different applications require different viscosities for optimal performance.

Q: How does temperature affect HPMC viscosity?

A: HPMC solutions decrease in viscosity as temperature rises, until reaching the gel point where they suddenly thicken.

Q: Is higher viscosity HPMC always more expensive?

A: Generally yes, higher viscosity HPMC costs more due to longer polymer chains requiring more processing.

Q: How do I know if I'm using the wrong viscosity HPMC?

A: Self-leveling compounds won't flow if viscosity is too high. Tile adhesives won't hold if viscosity is too low.

Q: Can I mix different HPMC grades to achieve an intermediate viscosity?

A: Yes, blending different grades can be an effective way to customize viscosity for specific applications.

-

Understanding HPMC viscosity is crucial for selecting the right materials for your flooring project. ↩

-

Learn how self-leveling compounds can simplify your flooring installation process. ↩ ↩

-

Explore the best tile adhesives to ensure a strong and durable bond for your tiles. ↩

-

Learn key insights that can help manufacturers optimize their HPMC formulations. ↩

-

Understanding the 2% drop method can help you accurately compare HPMC products. ↩