Many construction professionals struggle with lumps and poor dispersion when mixing HPMC1. I've seen projects delayed and products wasted due to improper dissolution techniques2.

To dissolve HPMC properly, you need to understand its two main types: Instant (surface treated) and Hot Soluble (non-surface treated). Instant HPMC disperses directly in cold water, while Hot Soluble HPMC requires dispersion in hot water (80°C) before cooling to hydrate effectively.

I want to share my knowledge from years in the HPMC manufacturing industry. Our factory produces both types of HPMC, and I've helped countless customers improve their mixing processes. Let me show you how to get perfect results every time.

How Does Instant Type (Surface Treated) HPMC1 Dissolve?

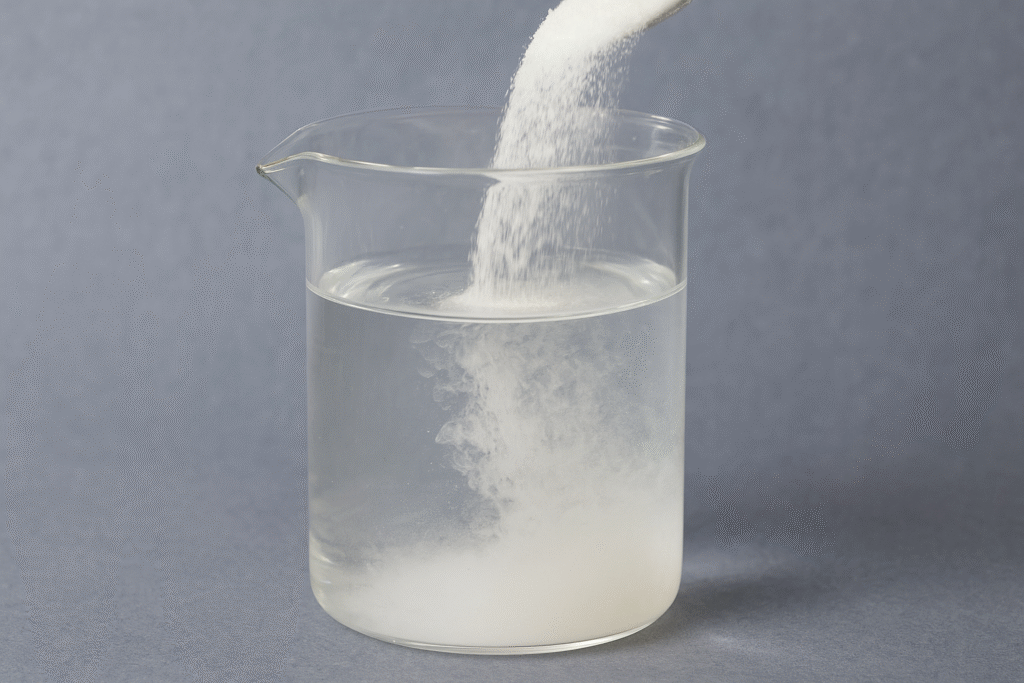

I often see customers struggling with clumping when they rush the dissolution process. Proper dispersion is critical for instant HPMC to function correctly in your formulations.

Instant HPMC dissolves directly in cold water because its particles are surface-treated with a small amount of glyoxal or other additives. This treatment prevents particles from immediately sticking together, allowing them to disperse individually before hydration begins.

Surface-treated HPMC has become increasingly popular in our market due to its convenience. The manufacturing process includes a unique step where we apply a hydrophobic coating to each HPMC particle. This coating temporarily prevents water from penetrating the particle, giving it time to disperse throughout the liquid before hydration begins.

When you add instant HPMC to cold water, each particle separates and disperses before the coating dissolves. This creates an even distribution throughout the solution. Once dispersed, the coating breaks down, allowing water to reach the HPMC and begin hydration.

To achieve optimal dissolution with instant HPMC:

- Use water at room temperature (15-25°C)

- Add HPMC powder slowly while stirring

- Maintain moderate agitation for 15-20 minutes

- Allow solution to rest for complete hydration

This process is particularly valuable for on-site mixing where hot water may not be available or when time is limited. Many of our customers in Saudi Arabia and the UAE prefer this type for their mortar and paint formulations due to the extreme heat in those regions making hot water processes impractical.

What Are the Main Applications for HPMC1?

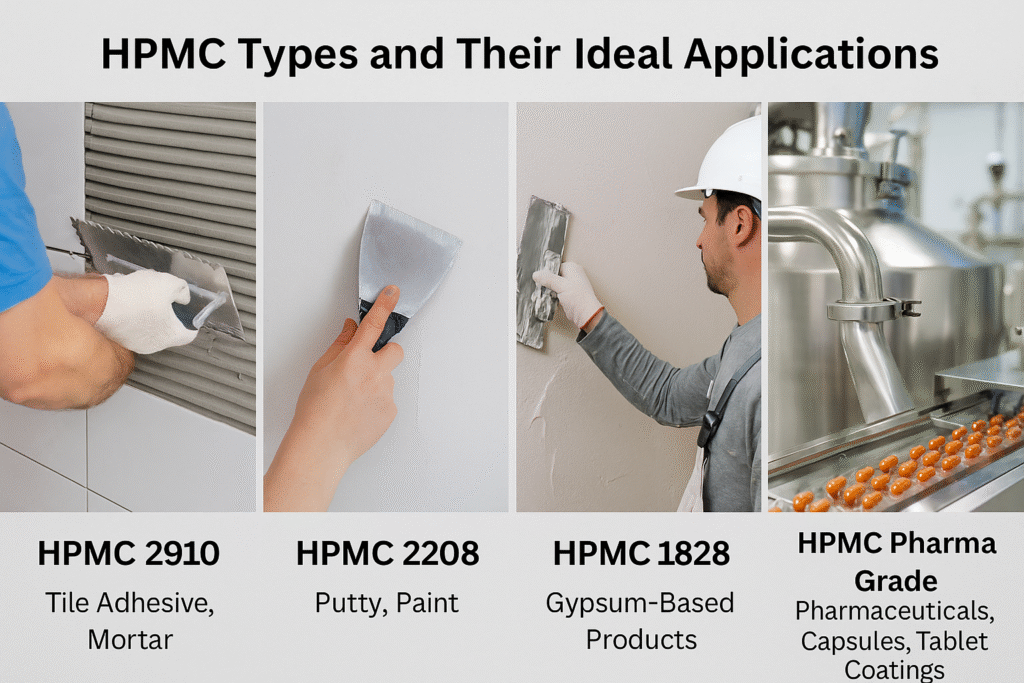

Working with customers across various industries, I've noticed confusion about which HPMC type suits specific applications. Using the wrong type can lead to serious formulation problems.

HPMC is widely used in construction (as a water retention agent in tile adhesives, renders, and plasters), pharmaceuticals (for tablet coatings and controlled release), personal care products (as a thickener), and food applications (as a stabilizer and thickener) with E464 food grade certification.

[^1] uses across industries HPMC applications in different industries](https://xhhpmc.com/wp-content/uploads/2025/09/ChatGPT-Image-2025%E5%B9%B49%E6%9C%885%E6%97%A5-17_53_15-1024x683.png)

In our experience serving customers across developing markets, the construction sector represents the largest application for HPMC. Each application has specific requirements that determine whether instant or hot-soluble HPMC is more appropriate.

Construction applications generally benefit from HPMC's water retention properties, which improve workability and extend open time. For ready-mixed dry mortars, instant HPMC is preferred for its ease of incorporation during production. However, for on-site mixing of large batches, hot-soluble HPMC might be more economical despite requiring more careful dissolution.

In pharmaceutical applications, the choice depends on the manufacturing process. Tablet coating operations often use hot-soluble types for their clarity in solution, while controlled-release formulations might prefer instant types for their more predictable hydration rates.

Personal care and food applications typically favor instant types for convenience and cold processing requirements. These industries often have equipment limitations that make hot dissolution processes impractical.

| Industry | Preferred HPMC Type | Key Properties Required |

|---|---|---|

| Construction | Both types (depends on specific application) | Water retention, adhesion, workability |

| Pharmaceuticals | Primarily hot-soluble | Purity, viscosity control, film-forming |

| Personal Care | Primarily instant | Thickening, stabilizing, smooth texture |

| Food | Instant (E464 grade) | Clean label, stabilizing, thickening |

What Makes Hot Soluble Type (Non-Surface Treated) HPMC Different?

I've had customers damage equipment by incorrectly dissolving hot-soluble HPMC, creating a gel block that seized their mixer. Understanding the proper technique is essential.

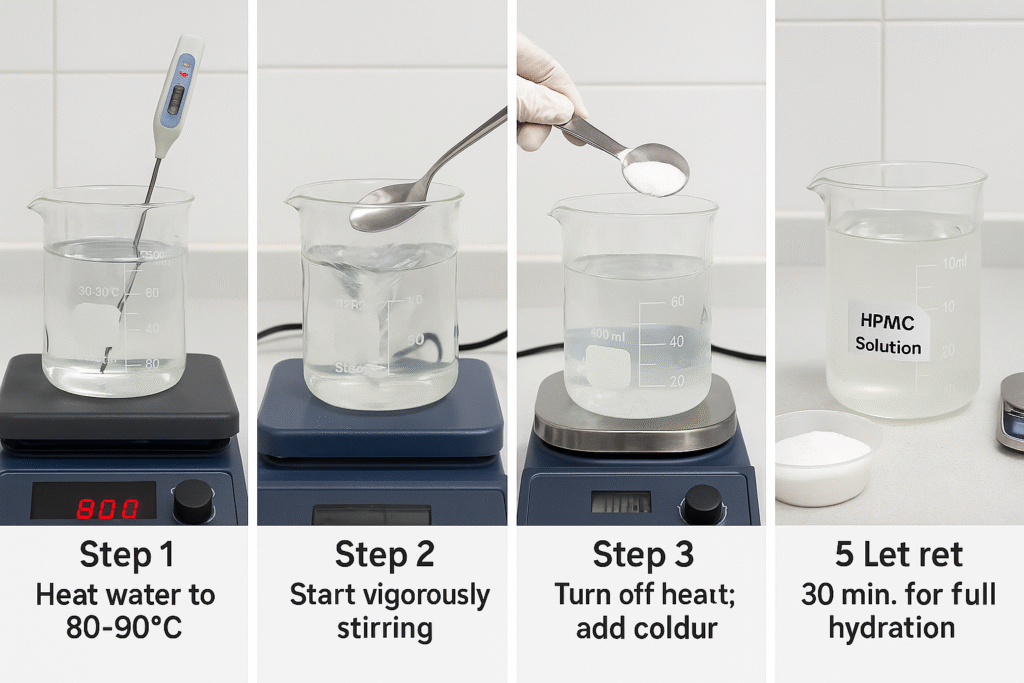

Hot soluble HPMC must first be dispersed in hot water (80-90°C) because heat prevents immediate hydration. After complete dispersion, the solution must cool below 40°C to allow proper hydration. This "hot-cold" method prevents lumping by separating the dispersion and hydration phases.

Hot soluble HPMC represents our traditional manufacturing method, without surface treatment. This type has particular dissolution requirements due to its natural tendency to form a gel layer when contacted with water below its gel temperature (typically 60-70°C depending on substitution degree).

The science behind this dissolution method relates to HPMC's thermal gelation properties. Above the gel temperature, HPMC becomes water-insoluble but can disperse as individual particles. As the temperature drops, these dispersed particles begin to hydrate uniformly, creating a homogeneous solution.

For best results with hot soluble HPMC:

- Heat water to 80-90°C

- Add HPMC powder gradually while stirring

- Maintain agitation until all particles are completely dispersed

- Allow the solution to cool naturally or with controlled cooling

- Continue stirring during cooling until full hydration (usually at 30-40°C)

This method, while more labor-intensive, often produces more consistent results and is preferred for applications requiring precise viscosity control3. Many of our customers in India and Pakistan who operate large mortar factories prefer this type because their established production processes are optimized for hot-soluble HPMC.

What Practical Considerations Should Guide Your HPMC Dissolution?

After visiting hundreds of customer sites, I've noticed that equipment limitations often cause dissolution problems. Proper planning can prevent most mixing issues before they occur.

When dissolving HPMC, consider your equipment capabilities (heating/cooling), batch size, time constraints, and final application requirements. For small batches without heating capability, instant HPMC is preferable. For precise viscosity control in large production, hot soluble HPMC may provide better results.

Throughout my years working with construction material manufacturers across developing markets, I've observed that practical constraints often dictate which dissolution method works best. For example, a customer in Vietnam struggled with inconsistent tile adhesive batches until we helped them optimize their mixing protocol based on their specific equipment limitations.

Equipment considerations should include:

- Mixer type and power (high-shear mixers can reduce dissolution time)

- Temperature control capabilities

- Batch size relative to mixer capacity

- Production schedule constraints

Time constraints are another critical factor. While instant HPMC provides faster dissolution, some applications benefit from the more controlled hydration of hot soluble types. For example, in gypsum-based products, the slightly slower hydration of hot soluble HPMC can prevent premature water consumption by the gypsum.

Water quality also impacts dissolution success. Hard water with high mineral content can interfere with proper hydration, particularly with instant types. In regions with poor water quality, additional water treatment or adjustment of dissolution parameters may be necessary.

| Consideration | Instant HPMC | Hot Soluble HPMC |

|---|---|---|

| Equipment Needs | Simple mixer | Mixer with heating capability |

| Time Required | 15-30 minutes | 30-60 minutes |

| Labor Intensity | Lower | Higher |

| Process Control | Simpler | More complex but precise |

| Water Quality Sensitivity | Higher | Moderate |

What Are the Recommended Uses for Each HPMC1 Type?

I've had customers waste money on expensive instant HPMC when their application didn't require it. Knowing which type to use can save significant costs without sacrificing performance.

Instant HPMC is ideal for ready-mixed dry mortars, on-site construction mixing, and applications without heating capabilities. Hot soluble HPMC is better for large-scale production facilities with proper equipment, applications requiring precise viscosity control3, and cost-sensitive projects.

Based on our experience supplying HPMC to customers across more than 20 countries, we've developed specific recommendations for different applications. These recommendations consider not only technical performance but also practical manufacturing constraints and economic factors.

For dry mix mortar manufacturers, the choice often depends on production scale and equipment. Large factories with sophisticated mixing equipment typically benefit from hot soluble HPMC's lower cost, while smaller operations or those with frequent product changeovers might prefer instant types for their operational simplicity.

In paint formulations, the choice is often influenced by the overall manufacturing process. Water-based paints produced in batches often use hot soluble HPMC, while continuous processes may prefer instant types to avoid production bottlenecks.

Self-leveling compounds present a special case where the choice depends on the other additives present. When used alongside fast-setting cements or accelerators, instant HPMC provides more consistent results because its rapid dissolution prevents interference with setting mechanisms.

For export products, we often recommend instant types when the end-user's mixing capabilities are unknown or limited. This ensures consistent performance regardless of the final mixing conditions.

| Application | Recommended Type | Reasoning |

|---|---|---|

| Ready-mixed dry mortars | Instant | Ensures reliable dissolution for end users |

| Large-scale tile adhesive production | Hot Soluble | Cost-effective with proper equipment |

| On-site cement mixing | Instant | No access to controlled heating |

| Interior paints | Both (depends on process) | Process dependent |

| Pharmaceutical tablet coating | Hot Soluble | Better clarity and film properties |

| Food thickeners | Instant | Cold process requirements |

How Do Hot Soluble and Instant HPMC Compare?

During factory tours, customers often ask me which HPMC type is "better." The truth is that each has distinct advantages depending on your specific needs.

When comparing HPMC types, hot soluble is typically 10-15% less expensive but requires more equipment and time. Instant HPMC4 offers easier handling and more reliable dissolution but at a higher cost. Performance characteristics (water retention, strength, adhesion) are similar once properly dissolved.

https://placehold.co/600x400)

My experience managing our six production lines has given me unique insight into the differences between these HPMC types. From a manufacturing perspective, hot soluble HPMC requires fewer processing steps, which translates to lower production costs. The surface treatment process for instant HPMC adds both material and energy costs, resulting in the price premium.

Performance testing in our laboratory shows that once properly dissolved, both types provide comparable technical properties in most applications. The differences emerge primarily in dissolution behavior and process requirements rather than end-product performance.

Economic considerations often drive the final decision for many of our customers. For large volume users like major mortar factories in Brazil and Mexico, the cost savings of hot soluble HPMC can be substantial over time, justifying investments in appropriate mixing equipment. Conversely, smaller operations or those with diverse product lines typically find the operational flexibility of instant HPMC outweighs its higher cost.

Storage stability also differs between types. Instant HPMC maintains its dissolution properties longer under adverse storage conditions (high humidity, temperature fluctuations) compared to hot soluble types, which can gradually lose their dissolution characteristics if improperly stored.

| Factor | Hot Soluble HPMC | Instant HPMC |

|---|---|---|

| Cost | Lower (baseline) | 10-15% higher |

| Equipment Needs | More complex | Simpler |

| Labor Requirements | Higher | Lower |

| Dissolution Time | Longer | Shorter |

| Storage Stability | Good | Better |

| End Performance | Equivalent | Equivalent |

| Batch-to-batch Consistency | Good | Better |

What Are the Best Methods for Hot Soluble HPMC Dissolution?

I once visited a customer who struggled with gel lumps in their product until we refined their hot dissolution process5. The right technique makes all the difference.

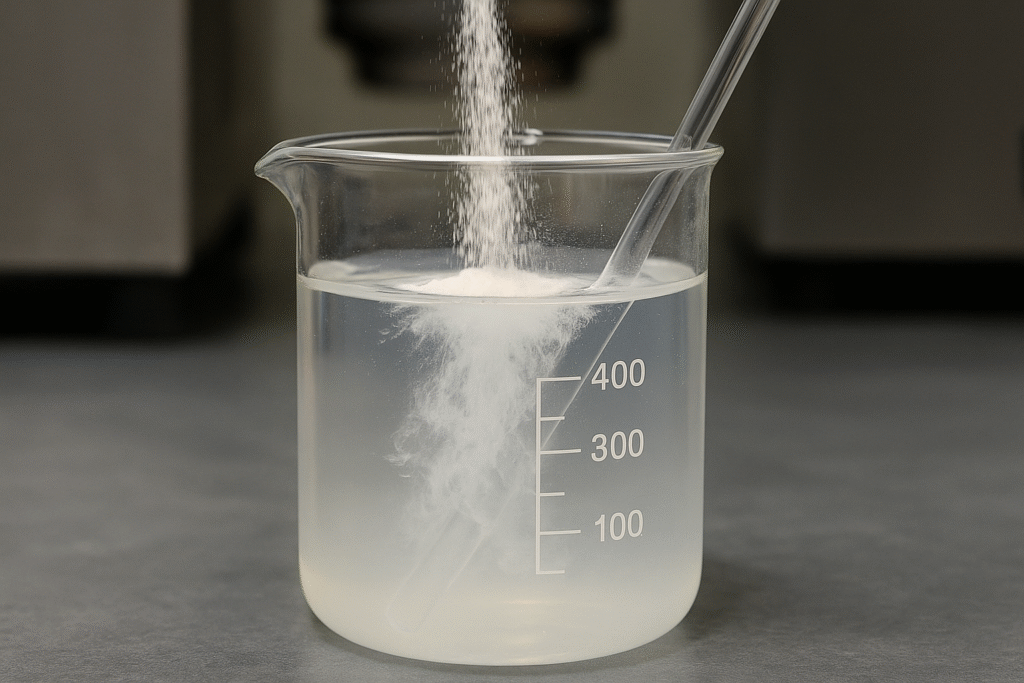

To dissolve hot soluble HPMC correctly, first heat water to 80-90°C, then add HPMC powder gradually while stirring vigorously. Maintain this temperature and agitation for 10-15 minutes until all particles are dispersed. Finally, cool the solution while continuing to stir until it hydrates fully below 40°C.

Having supervised countless batches in our factory's quality testing lab, I've identified the key factors that ensure successful hot soluble HPMC dissolution. Temperature control is absolutely critical - both during the initial dispersion phase and the cooling phase.

The initial water temperature must be sufficiently high (80-90°C) to prevent premature hydration. Many dissolution failures occur when the starting temperature is too low, or when adding too much HPMC causes a significant temperature drop. We recommend using water that's at least 10°C above the gel temperature of your specific HPMC grade.

The addition rate of HPMC powder is equally important. Adding too much too quickly will create agglomerates that are difficult to disperse even with vigorous mixing. For industrial processes, we recommend mechanical feeders calibrated to add powder at a controlled rate proportional to the mixer's capacity.

Agitation intensity during the entire process significantly impacts dissolution quality. Insufficient agitation during hot dispersion can leave undispersed particles, while inadequate mixing during cooling can result in uneven hydration. Different mixer types provide varying shear forces:

| Mixer Type | Advantages | Disadvantages | Recommended for |

|---|---|---|---|

| Propeller | Simple, cost-effective | Less effective with high viscosity | Small batches |

| High-shear | Excellent dispersion | Higher energy consumption | Medium batches |

| Planetary | Good for high viscosity | Higher cost | Large production |

The cooling phase must be controlled carefully. Rapid cooling can create viscosity gradients within the solution, while too-slow cooling can extend production time unnecessarily. We typically recommend cooling rates of 2-3°C per minute for optimal results.

For customers without temperature-controlled equipment, we've developed the "two-container method" where HPMC is dispersed in a smaller amount of hot water, then added to a larger volume of cold water while stirring, achieving the temperature drop needed for hydration.

How Should You Dissolve Instant HPMC for Best Results?

During a trade show demonstration, I showed a skeptical customer how properly dissolved instant HPMC outperformed his current solution. His surprise was worth every minute spent explaining the process.

To dissolve instant HPMC effectively, add the powder gradually to room temperature water (15-25°C) while stirring continuously. Maintain moderate agitation for 15-20 minutes to ensure complete dispersion. The solution will thicken as the HPMC hydrates, with complete dissolution typically taking 30-45 minutes.

Through years of providing technical support to our customers across developing markets, I've refined the instant HPMC dissolution process to account for real-world conditions. While the basic principle seems simple - add powder to cold water - several nuances make the difference between perfect dissolution and problematic results.

Water temperature plays a subtle but important role. While instant HPMC will eventually dissolve across a range of cold temperatures, the optimal range is 15-25°C. Below 15°C, dissolution slows significantly, while temperatures approaching 40°C can cause uneven hydration as the particles begin to approach their thermal gelation point.

The water quality in many developing regions varies considerably. In areas with hard water (high mineral content), we recommend a slight modification to the process - pre-dissolving a small amount of dispersing agent (like sodium hexametaphosphate) in the water before adding the HPMC. This prevents interference from calcium and magnesium ions that can otherwise hinder proper dissolution.

Mixing speed and duration require balancing. Excessive agitation can incorporate air, creating foam issues, while insufficient mixing leaves undispersed particles. This table outlines our recommended mixing parameters based on solution viscosity:

| Target Viscosity | Agitator Speed | Mixing Time | Rest Period |

|---|---|---|---|

| Low (<5,000 mPa·s) | Medium-High | 15-20 min | 10-15 min |

| Medium (5,000-15,000 mPa·s) | Medium | 20-30 min | 15-30 min |

| High (>15,000 mPa·s) | Low-Medium | 30-45 min | 30-60 min |

The ambient conditions during mixing also influence dissolution efficiency. In humid environments, HPMC powder can absorb moisture before reaching the water, leading to clumping. I recommend storing opened packages in sealed containers and adding powder in small increments under these conditions.

For large-scale production, we've helped customers implement automated systems that optimize the instant HPMC dissolution process. These typically include:

- Controlled powder dispensers to maintain consistent addition rates

- Variable-speed mixers that adjust based on solution viscosity

- Holding tanks that allow complete hydration before final use

One technique that's proven particularly effective for our customers in the paint industry is the "vortex method." By creating a strong vortex in the water before adding HPMC, then gradually adding powder at the edge of the vortex, particles disperse individually before they can agglomerate, significantly reducing dissolution time.

Conclusion

Whether you choose hot soluble or instant HPMC depends on your specific needs, equipment, and processes. Both types offer excellent performance once properly dissolved. Follow our guidelines to avoid common mixing problems and achieve perfect results every time.

-

Explore the versatile applications of HPMC in construction and other industries. ↩ ↩ ↩ ↩

-

Find effective methods to ensure proper dissolution of HPMC for optimal results. ↩

-

Learn how HPMC contributes to achieving precise viscosity in formulations. ↩ ↩

-

Learn about the unique properties of Instant HPMC and its advantages in formulations. ↩

-

Discover insights on the most effective dissolution processes for HPMC to enhance product quality. ↩