Poor mortar adhesion leads to crumbling walls, falling tiles, and costly repairs. You need solutions that work fast, especially when projects are falling behind and clients are getting impatient.

To make mortar stick better, add hydroxypropyl methylcellulose (HPMC)1 as a bonding agent, ensure surfaces are clean and slightly damp, use the right water-to-mix ratio, and work in moderate temperatures. Proper substrate preparation and curing time2 are also essential for maximum adhesion.

Getting mortar to stick properly is one of the biggest challenges in construction. I've spoken with hundreds of contractors who face this issue daily. Let's look at why mortar fails to stick and what you can do to fix it.

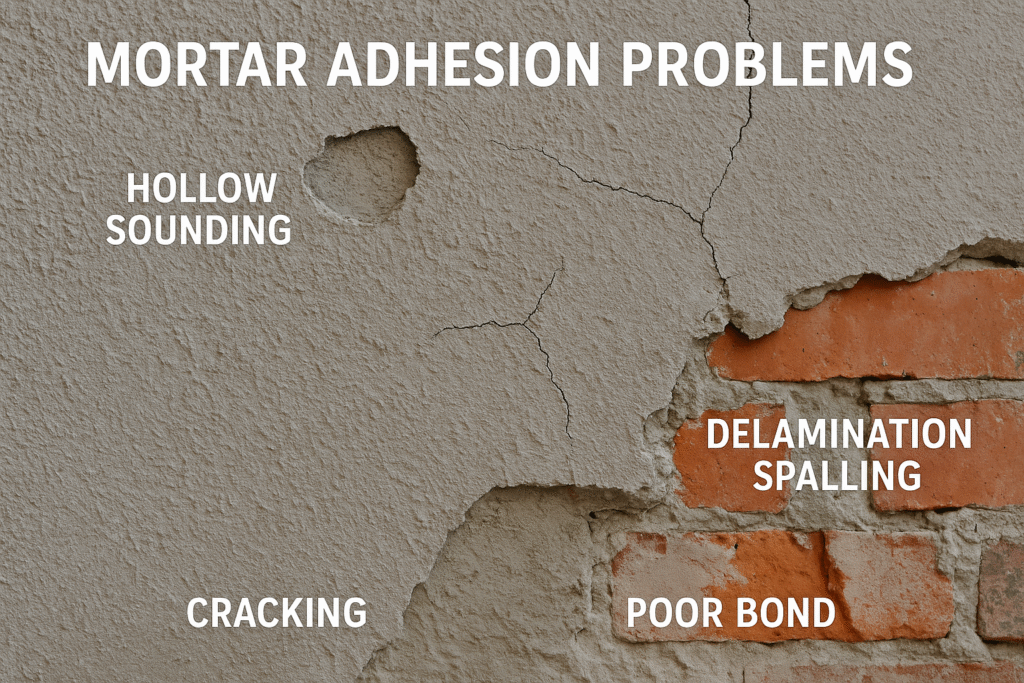

What Are Common Problems That Stop Mortar from Sticking?

Dealing with mortar that won't stick is frustrating and wastes time and money. I've seen entire walls that needed rebuilding because the mortar simply wouldn't bond properly.

Common problems preventing mortar adhesion include dirty or dusty surfaces, inappropriate substrate moisture levels (too wet or too dry), improper mixing ratios, extreme temperatures during application, and low-quality binding additives. Using the wrong mortar type for specific applications also causes adhesion failure.

I've visited countless construction sites where teams struggle with these exact issues. Let me break down these common problems further:

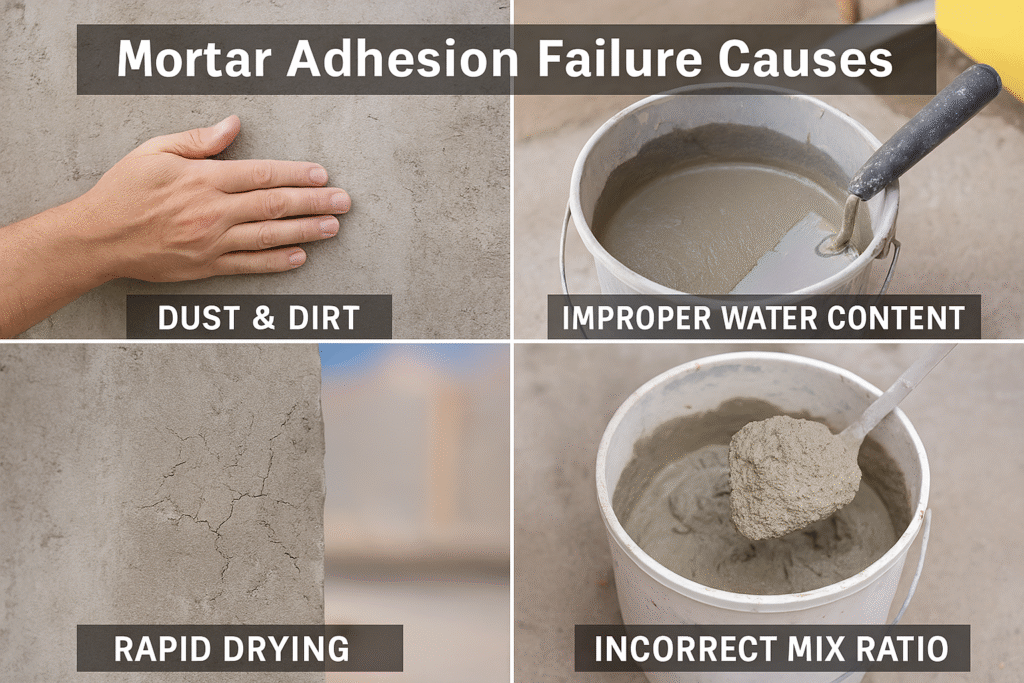

Surface Preparation Issues

Poor surface preparation is the number one reason mortar fails to stick. During a project in Dubai last year, I noticed workers applying mortar directly onto surfaces covered with dust. This is a recipe for disaster.

| Problem | Effect on Adhesion | Solution |

|---|---|---|

| Dust/Dirt | Prevents direct contact between mortar and substrate | Clean thoroughly with brush and water |

| Oil/Grease | Creates water-repellent barrier | Degrease with appropriate cleaner |

| Loose Material | Provides unstable foundation | Remove completely before application |

| Smooth Surfaces | Offers poor mechanical key | Roughen surface or apply bonding agent |

Moisture Problems

The substrate's moisture content is critical. Too dry, and it will suck water from the mortar too quickly. Too wet, and the mortar won't bond properly.

Temperature Extremes

Working in Saudi Arabia, I've seen firsthand how temperature affects mortar. When temperatures exceed 95°F (35°C), mortar dries too quickly, reducing adhesion strength.

How Can You Maintain Optimal Conditions for Mortar Adhesion?

When my mortar wasn't sticking on a project last month, I had to stop, reassess, and fix the conditions. Time was tight, and my client was getting worried about delays.

For optimal mortar adhesion, maintain temperature between 50-85°F (10-29°C), ensure relative humidity of 40-70%, shield work areas from direct sunlight and strong winds, and allow proper curing time (usually 24-48 hours minimum). Never apply mortar to frozen surfaces or during freezing conditions.

Controlling the environment is crucial for successful mortar application. In my experience, this attention to detail separates successful projects from problematic ones.

Temperature Control Methods

Temperature dramatically affects mortar performance. I've used various methods to manage temperature on job sites around the world, from Saudi Arabia to Singapore.

| Temperature Issue | Solution | Benefits |

|---|---|---|

| Too Hot (>85°F/29°C) | Shade work area, work during cooler hours, use cold water for mixing | Prevents premature drying |

| Too Cold (<50°F/10°C) | Tent and heat work area, use warm water for mixing, add approved accelerators | Ensures proper curing |

| Fluctuating | Create temperature-controlled enclosure | Maintains consistent curing conditions |

Humidity Management

Humidity works hand-in-hand with temperature. In very dry conditions like those I've experienced in Middle Eastern countries, mortar can dry too quickly, leading to poor adhesion and cracking.

Wind Protection

Strong winds can accelerate drying time too much. I always recommend setting up windbreaks when working in exposed areas. This simple step has saved countless projects from adhesion failures.

How to Make Mortar More Sticky?

Last year, I was consulting on a large tiling project in Pakistan where the mortar simply wouldn't hold. We needed a solution fast as deadlines were looming and costs mounting.

To make mortar stickier, add hydroxypropyl methylcellulose (0.2-0.5% by weight) to increase water retention and adhesion. For further improvements, incorporate redispersible polymer powder3 (3-5%), use acrylic bonding agents in mixing water, adjust water ratio properly, and ensure thorough mixing for at least 5 minutes.

Enhancing mortar stickiness is an area I've researched extensively. The right additives can transform an ordinary mortar mix into one with exceptional bonding properties.

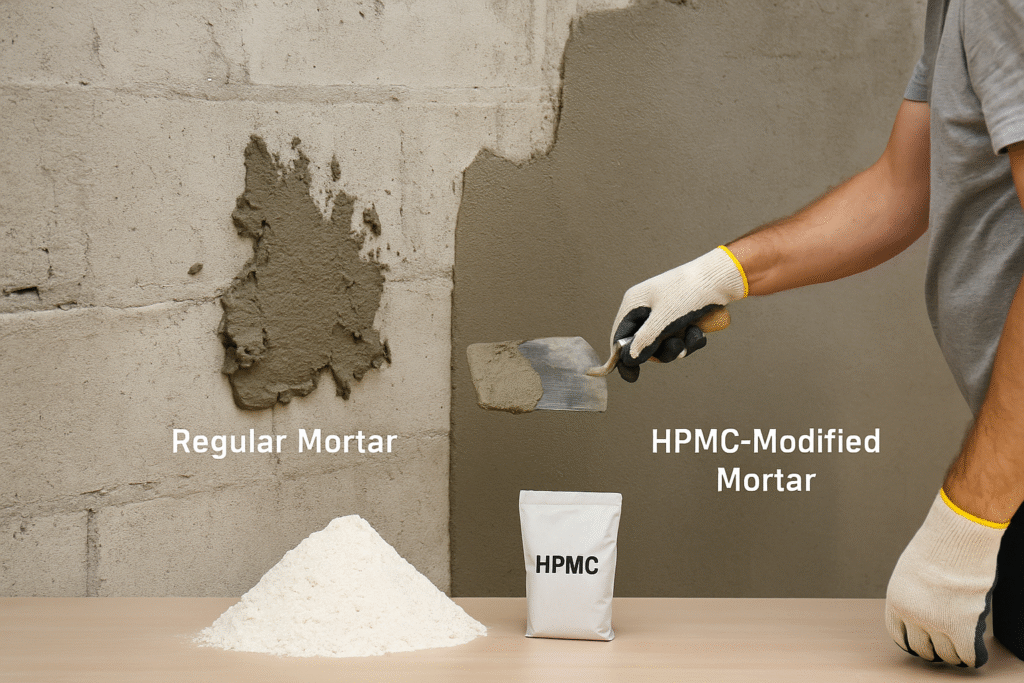

Cellulose Ethers: The Adhesion Champion

HPMC (hydroxypropyl methylcellulose) has revolutionized mortar performance. As a manufacturer, I've seen how this additive transforms mortar performance.

| HPMC Type | Viscosity | Best For | Adhesion Improvement |

|---|---|---|---|

| Low Viscosity (50,000-200,000) | Low | Basic mortars, grouts | 15-30% |

| Medium Viscosity (100,000-150,000) | Medium | General-purpose mortars | 30-50% |

| High Viscosity (200,000) | High | Tile adhesives, demanding applications | 50-100% |

When added to mortar, HPMC creates a gel-like structure that:

- Improves water retention, giving more working time

- Enhances adhesion to difficult substrates

- Prevents water from being drawn out too quickly

- Increases open time for better workability

Polymer Powders for Extra Strength

Redispersible polymer powders work alongside HPMC to create a powerful bonding system. I've tested various formulations and found that combining these two additives produces the best results for challenging applications.

Mixing Techniques Matter

How you mix mortar greatly affects its stickiness. I always recommend using mechanical mixers for at least 5 minutes to ensure homogeneous distribution of additives.

Why Is Mortar Not Sticking?

During a recent visit to a job site in Brazil, I noticed workers struggling with mortar that kept falling off the wall. The issue wasn't obvious at first, but after some investigation, we found several underlying problems.

Mortar fails to stick when surfaces are contaminated with dust, oil or release agents; when the mix is too wet or too dry; when insufficient pressure is applied during installation; or when using expired materials. Environmental factors like extreme temperatures and inappropriate substrate moisture content also cause adhesion failure.

After years of troubleshooting adhesion problems, I've identified several key issues that consistently cause problems. Understanding these can save you significant time and money.

Mix Proportion Problems

Incorrect water-to-mortar ratios are extremely common. I've analyzed hundreds of job site failures and found improper mixing at the heart of many issues.

| Mix Issue | Symptoms | Solution |

|---|---|---|

| Too Wet | Mortar slumps, takes too long to set, low strength | Reduce water, add more dry components |

| Too Dry | Poor workability, doesn't adhere well | Add water gradually, improve mixing |

| Inconsistent | Varying performance across the job | Use measuring tools, not "eyeball" estimates |

Material Quality Issues

Not all mortars are created equal. In my testing lab, I've compared various brands and found stunning differences in performance.

Application Technique

Even perfect mortar can fail if applied incorrectly. Proper troweling techniques create suction between the mortar and substrate, significantly improving adhesion.

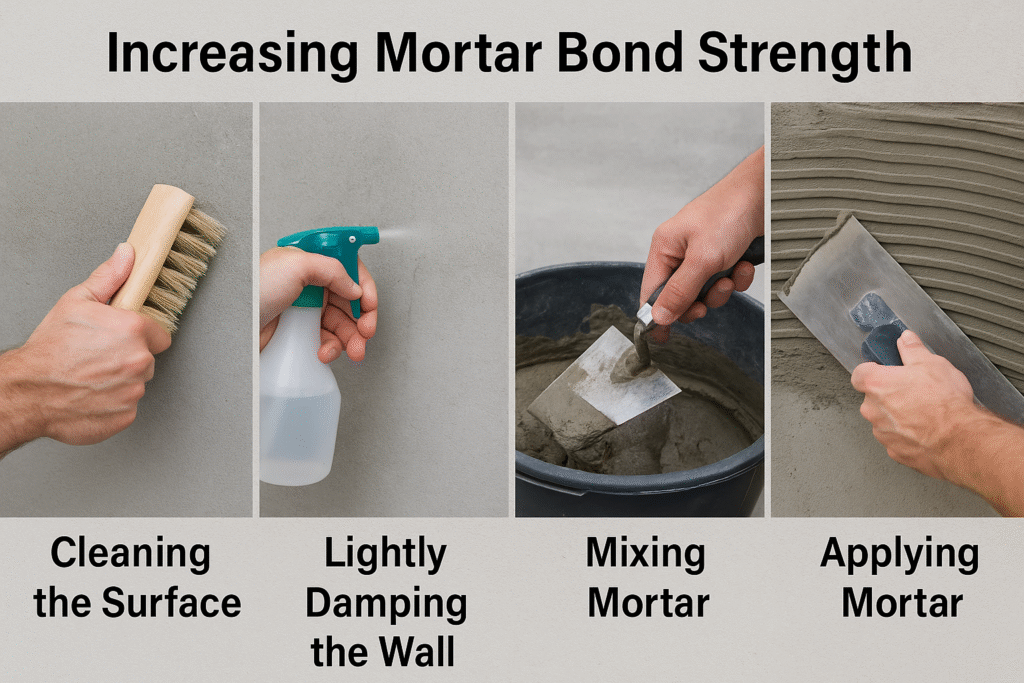

How Do You Increase the Bond Strength of Mortar?

When I was working on a hotel project in the UAE, the specification required exceptionally high bond strength for exterior cladding. We needed to develop a solution that would withstand extreme desert conditions.

To increase mortar bond strength, incorporate hydroxypropyl methylcellulose (HPMC)1 at 0.3-0.5% and redispersible polymer powder3 at 3-5% by weight. Prepare surfaces by cleaning thoroughly and creating a mechanical key through roughening. Apply a bonding slurry or primer coat before the main application.

Bond strength is particularly important for applications like tile adhesives, exterior rendering, and structural repairs. I've developed specific techniques to maximize bond strength in challenging applications.

Chemical Bonding Enhancers

The chemistry behind bond strength is fascinating. In our labs, we've tested various formulations to determine optimal additive combinations for different applications.

| Additive | Dosage | Bond Strength Increase | Best Applications |

|---|---|---|---|

| HPMC-P150 | 0.3-0.5% | 40-60% | General purpose |

| HPMC-P200 | 0.2-0.4% | 60-80% | Heavy tiles, vertical applications |

| Redispersible Powder | 3-5% | 100-150% | Exterior, wet areas |

| Combination Systems | Custom | Up to 200% | Critical applications |

Mechanical Bonding Techniques

Beyond chemical additives, mechanical techniques dramatically improve bond strength. I always recommend:

- Creating a roughened surface through scratching, grinding, or sandblasting

- Applying a thin scratch coat before the main application

- Using the right trowel pattern for the specific application

- Applying consistent pressure during installation

Testing Bond Strength

In professional applications, I recommend conducting pull-off tests to verify bond strength. This simple test provides concrete evidence of adhesion quality.

Conclusion

Adding hydroxypropyl methylcellulose, preparing surfaces properly, maintaining optimal temperature and humidity, and using the right mixing techniques4 will significantly improve mortar adhesion. With these techniques, you'll solve sticking problems and create longer-lasting, higher-quality work.

-

Explore how HPMC enhances mortar performance and why it's essential for construction projects. ↩ ↩

-

Find out why curing time is essential for achieving maximum adhesion in mortar applications. ↩

-

Understand how this additive can significantly improve the strength and durability of mortar. ↩ ↩

-

Discover effective mixing techniques that ensure uniform distribution of additives for better adhesion. ↩