Quality control is critical when using HPMC1 in construction materials. Without proper viscosity testing, your entire production could waste resources and damage your reputation with customers.

To test HPMC1 viscosity before large-scale production, first verify specifications using a Brookfield viscometer to measure water solution viscosity, then conduct practical application tests by making small batch samples to evaluate workability, slip resistance, and water retention in your specific application.

When I receive a new batch of hydroxypropyl methylcellulose (HPMC), I never rush it straight to production. This two-step testing approach has saved me countless times from costly mistakes. Let me show you why both instrument testing and hands-on evaluation are non-negotiable steps in your quality control process.

Why Is Viscosity Verification So Critical for HPMC1 Performance?

Many mortar manufacturers face product inconsistency issues despite using the same HPMC grade. Their mistake? Skipping proper viscosity verification upon delivery.

HPMC1 viscosity directly affects workability, water retention, and adhesion strength in mortars and other construction materials. Even small variations can significantly impact final product performance, potentially causing product failure, customer complaints, and damage to your brand reputation.

Dive deeper Paragraph:

From my experience managing multiple production lines, viscosity variations can originate from multiple sources. Sometimes it's batch-to-batch inconsistency from suppliers, other times it's improper storage conditions affecting the polymer chains2. Most concerning are cases where suppliers provide products that don't match the specifications on their Certificate of Analysis (COA)3.

Common Causes of HPMC Viscosity Variations

| Cause | Impact | Prevention |

|---|---|---|

| Manufacturing inconsistency | Unpredictable performance | Regular supplier audits |

| Improper storage | Degradation of polymer | Climate-controlled warehousing |

| Transport conditions | Moisture absorption | Moisture-resistant packaging |

| Mislabeling | Wrong grade in production | Independent verification testing |

When I discovered one of my suppliers consistently provided HPMC with 10-15% lower viscosity than specified, we immediately implemented mandatory testing for all incoming materials. This single quality control measure improved our product consistency dramatically.

How Can You Perform Accurate Instrument-Based Viscosity Testing?

Many factory owners rely solely on supplier certificates, risking production failures and customer complaints. This approach is dangerously insufficient.

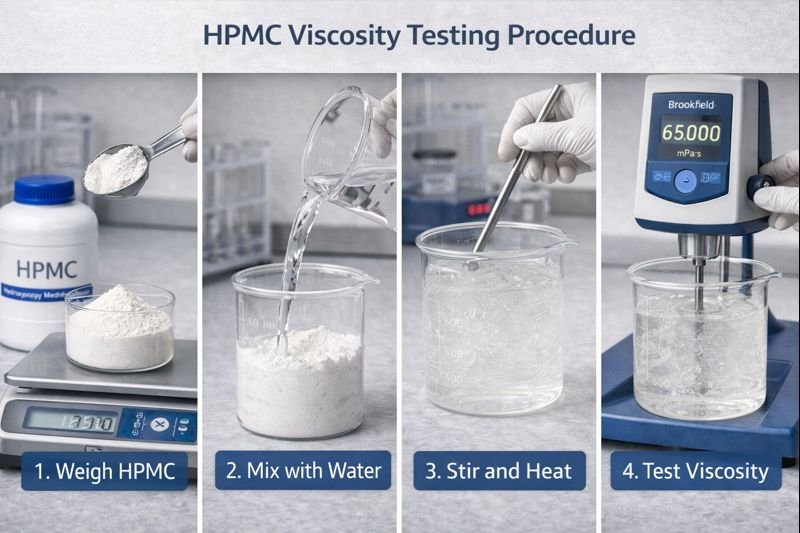

To accurately test HPMC viscosity, use a calibrated Brookfield viscometer with the appropriate spindle and speed settings (typically 20 rpm). Prepare a 2% solution by dispersing HPMC in hot water (80°C), then cooling to 20°C while stirring until fully dissolved, and measure viscosity after 24 hours of rest.

Dive deeper Paragraph:

The precision of your viscosity measurement depends heavily on your sample preparation technique. I've found that proper dispersion is critical - inadequate dispersion leads to fish-eyes (undissolved particles) that skew results. The temperature control during measurement is equally important; a 1°C difference can change viscosity readings by 2-3%.

Critical Parameters for Accurate Viscosity Testing

| Parameter | Recommendation | Common Mistakes |

|---|---|---|

| Water quality | Use distilled water | Using tap water with minerals |

| Dispersion method | High-shear mixing in hot water | Adding HPMC to cold water |

| Temperature control | Maintain exact 20°C (±0.5°C) | Ignoring temperature fluctuations |

| Rest time | Full 24 hours for stabilization | Rushing measurements |

| Spindle selection | Based on expected viscosity range | Using incorrect spindle size |

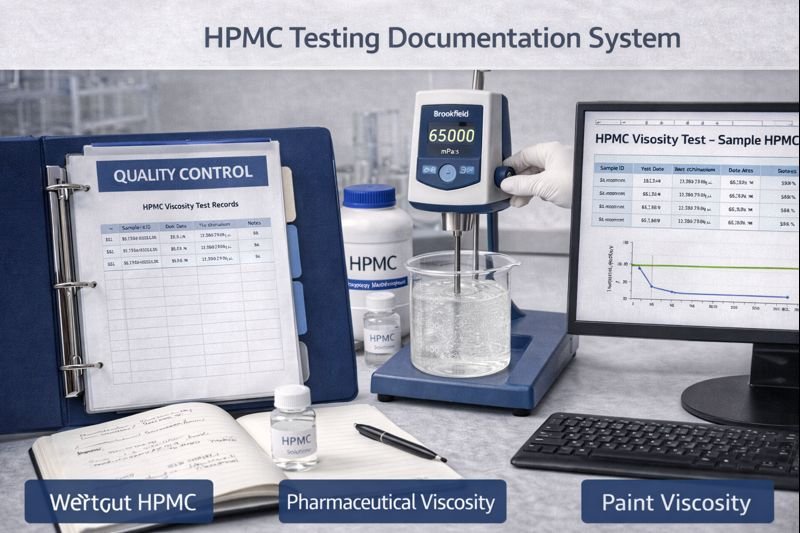

In our laboratory, we maintain detailed records of all viscosity measurements with batch numbers, testing conditions, and operator signatures. This traceability has been invaluable when troubleshooting production issues or supplier disputes.

Why Is Practical Application Testing Essential After Instrument Verification?

Instrument readings alone don't guarantee performance in your final product. I've seen materials with identical viscometer readings behave differently in actual applications.

Practical application testing involves creating small-batch samples of your final product (mortars, adhesives, etc.) using the new HPMC batch. Test for workability, sag resistance, water retention, and application feel. For tile adhesives, conduct vertical slip tests by applying tiles to a wall and monitoring displacement over time.

Dive deeper Paragraph:

My approach to practical testing evolved after a costly lesson when a batch of HPMC with acceptable viscometer readings produced tile adhesive that failed in the field. The adhesive lacked sufficient water retention despite meeting numerical specifications. Now, I insist on comprehensive application testing that simulates real-world conditions.

Essential Practical Tests for Different HPMC Applications

| Application | Key Test | Evaluation Method |

|---|---|---|

| Tile adhesives | Anti-slip resistance | Vertical tile placement with weighted tiles |

| Rendering mortars | Workability | Trowel application on vertical surfaces |

| Joint compounds | Smoothness | Hand-feel during application and sanding |

| Wall putty | Water retention | Open time measurement in various conditions |

| Paints | Sag resistance | Vertical application thickness test |

I recommend creating a standardized testing protocol for each product type. For example, our tile adhesive testing includes applying 30×30cm ceramic tiles to a vertical surface with standardized adhesive thickness, then measuring downward displacement after 20 minutes. We reject any HPMC batch allowing more than 0.5mm slip, regardless of what the viscometer readings show.

What Specific Tests Should Be Conducted for Different HPMC Applications?

Many production managers apply generic testing across all HPMC applications. This oversight leads to product failures that only become apparent after customer complaints.

Different HPMC applications require specialized testing. For tile adhesives, conduct anti-slip and open time tests. For renders, check workability and sag resistance. For paints, evaluate leveling and spatter resistance. Always test water retention across all applications using appropriate methods for your specific product type.

Dive deeper Paragraph:

I've found that tailoring tests to specific end-uses leads to much more reliable quality control. For example, when evaluating HPMC for cement-based tile adhesives, we perform a modified water retention test where we measure weight loss in controlled conditions (23°C, 50% humidity) over 30 minutes. This correlates strongly with field performance. For renders, we apply material to both absorbent and non-absorbent substrates to evaluate workability differences – a test that has revealed performance issues that standard viscosity measurements missed entirely.

Application-Specific Testing Parameters for HPMC

| Application | Critical Property | Testing Method | Acceptance Criteria |

|---|---|---|---|

| Tile adhesives | Open time | Tile pull-off strength after set time | >0.5 N/mm² after 20 min |

| Exterior renders | Workability | Application effort measurement | <15% increase in force |

| Self-leveling compounds | Flow properties | Flow ring diameter | 140-160mm diameter |

| Drywall joint compounds | Cracking resistance | Shrinkage observation | No visible cracking |

| Construction adhesives | Bond strength | Tensile adhesion test | >1.0 N/mm² after curing |

When we switched suppliers last year, we discovered that despite identical viscosity readings, the new HPMC required different dosages in our exterior render to achieve the same workability. Only through application-specific testing were we able to adjust our formulation and maintain product consistency.

How Should You Document HPMC Testing Results for Quality Assurance?

Poor documentation leads to repeated mistakes and inability to trace issues to their source. This oversight costs manufacturers significant time and money troubleshooting recurring problems.

Create a comprehensive documentation system that records both instrumental and practical test results. Include batch numbers, testing conditions, measurements, observations, and final acceptance decision. Maintain these records for at least the shelf life of your final products to enable traceability if field issues arise.

Dive deeper Paragraph:

Documentation isn't just bureaucratic paperwork – it's a powerful quality control tool. In our facility, we implement a three-tiered documentation approach. First, we have raw data collection sheets where technicians record all measurements and observations. Second, we maintain a digital database where this information is organized by supplier, batch number, and date. Third, we create quarterly analysis reports to identify trends or shifts in material performance. This system has allowed us to identify subtle quality drift from suppliers before it reached problematic levels.

Essential Elements of HPMC Testing Documentation

| Documentation Element | Purpose | Implementation |

|---|---|---|

| Batch tracking | Material traceability | QR code scanning system |

| Test conditions | Reproducibility | Automated environmental monitoring |

| Pass/fail criteria | Clear decision-making | Predefined acceptance ranges |

| Operator identification | Accountability | Personal digital signatures |

| Comparison to historical data | Trend identification | Statistical process control charts |

When a customer reported unusual behavior in one of our products last year, our documentation system allowed us to trace the issue to a specific HPMC batch that had passed instrumental testing but showed borderline results in practical application tests. This enabled us to quickly isolate affected products and implement corrective actions.

Conclusion

Thorough HPMC1 viscosity testing requires both instrumental verification and practical application assessment. Never rely on supplier certificates alone. Only when both technical specifications and real-world performance meet your standards should you approve materials for large-scale production.