Many construction project managers struggle with mortar that dries too quickly, creating weak bonds and poor workability. Poor water retention in your HPMC can cost you time, materials, and reputation.

To test HPMC water retention1, use the DIN 18555 method2. Place mortar on filter paper, apply 2kg pressure for 5 minutes, then calculate water retention by comparing the paper's weight before and after testing. Higher quality HPMC typically achieves 98%+ water retention.

I've been working with hydroxypropyl methylcellulose (HPMC) for over 15 years at our factory, and proper water retention testing is critical for quality control. Let me walk you through everything you need to know about HPMC water retention and testing methods used in the industry.

How to Test HPMC Properly?

Many customers receive HPMC without knowing how to verify its quality. This can lead to product failures, wasted materials, and project delays that damage your reputation.

Testing HPMC requires evaluating viscosity, fineness, moisture content, ash content, pH value, and water retention. Standard methods include rotational viscometer testing (ASTM D2196), moisture analysis (105°C oven method), and sieve analysis for particle size distribution.

When testing HPMC quality, we need to examine multiple properties beyond just water retention. Let me share our comprehensive testing approach at Kehao factory.

For viscosity testing, we use a rotational viscometer with precise temperature control at 20°C. We prepare a 2% HPMC solution and allow it to fully hydrate for 24 hours before testing. The viscosity measurement gives us critical information about the molecular weight and functionality of the HPMC.

Particle size distribution is another crucial factor. We use standardized sieve analysis with 80-mesh and 100-mesh screens to ensure proper fineness. Too fine particles may cause lumping issues, while overly coarse particles lead to slow dissolution.

Here's a breakdown of our standard HPMC testing protocol:

| Property | Test Method | Typical Value | Importance |

|---|---|---|---|

| Viscosity | Rotational viscometer | 100,000-200,000 mPa·s | Determines thickening ability |

| Moisture content | 105°C oven drying | ≤5% | Affects shelf stability |

| Ash content | 600°C furnace | ≤5% | Indicates purity level |

| pH value | 2% solution | 5.5-8.0 | Ensures compatibility |

| Fineness | Sieve analysis | >95% pass 100 mesh | Affects dissolution rate |

| Water retention | DIN 18555 | >98% | Critical for mortar workability |

How to Do Water Retention Test?

Water retention testing can seem complicated if you've never done it before. Improper testing leads to incorrect assessment of your HPMC quality, potentially causing issues in your final products.

To perform the water retention test, prepare a standard mortar mix with your HPMC sample. Place 15g of mortar on filter paper, apply 2kg pressure for exactly 5 minutes using a standardized apparatus, then weigh the filter paper before and after to calculate water retention percentage.

Water retention testing requires precision and consistency. At our Kehao factory, we follow the DIN 18555 method which is widely accepted in the industry. I'll take you through our exact process step by step.

First, we prepare a standard mortar formulation: 450g standard sand, 150g cement, 225g water, and the recommended dosage of HPMC (typically 0.2-0.3% of dry mix). We mix these ingredients in a standard mixer for 5 minutes to ensure uniform dispersion.

Next, we prepare the testing apparatus. This consists of a base plate with filter paper (Whatman No. 4 or equivalent), a perforated plate, a rubber ring to contain the mortar, and a 2kg weight. The filter paper is weighed precisely before testing (W1).

We then place exactly 15g of the prepared mortar onto the filter paper, spread it evenly within the rubber ring, place the perforated plate on top, and apply the 2kg weight for exactly 5 minutes.

After 5 minutes, we remove the weight and mortar sample, then immediately weigh the filter paper (W2). The water retention3 is calculated using this formula:

Water Retention (%) = [1 - (W2 - W1)/Water Content in Sample] × 100

For high-quality HPMC, we typically expect water retention values above 98%. This test method allows us to consistently assess and compare different HPMC batches and grades.

Does HPMC Swell?

New users of HPMC often struggle with clumping issues during mixing. This leads to uneven dispersion, wasted product, and inconsistent performance in mortar applications.

Yes, HPMC does swell when it contacts water. It undergoes a two-phase process: first surface hydration creating a gel layer, then swelling as water penetrates the particle core. This swelling property is vital for HPMC's water retention capability in construction materials.

https://placehold.co/600x400 "HPMC particle swelling in water")

https://placehold.co/600x400 "HPMC particle swelling in water")

The swelling behavior of HPMC is fascinating and directly relates to its effectiveness in mortar applications. At our factory, we've conducted numerous microscopic studies of this process to optimize our products.

When HPMC first contacts water, the outer portion of each particle immediately begins to hydrate. This forms a gel layer around the particle core. This gel layer actually slows down further water penetration, which is why HPMC doesn't dissolve instantly like sugar or salt.

As water continues to penetrate through this gel layer, the particle core gradually hydrates and swells. The complete hydration process can take anywhere from 15 minutes to several hours depending on water temperature, particle size, and the specific molecular structure of the HPMC.

The swelling ratio (the volume increase from dry to fully hydrated state) typically ranges from 4:1 to 7:1. This swelling property creates a three-dimensional network in mortar that traps water molecules, preventing them from evaporating too quickly or being absorbed by porous substrates.

We can manipulate the swelling properties through manufacturing processes. For example:

| HPMC Type | Swelling Rate | Hydration Time | Best Application |

|---|---|---|---|

| Hot-water soluble | Moderate | 20-30 minutes | Tile adhesives |

| Cold-water soluble | Rapid | 5-15 minutes | Self-leveling compounds |

| Surface-treated | Delayed | 30-60 minutes | Dry-mix mortars |

| Standard grade | Normal | 15-30 minutes | General construction |

Understanding this swelling mechanism helps explain why proper dispersion techniques are crucial when working with HPMC.

Is HPMC Hydrophobic or Hydrophilic?

Many formulators misunderstand HPMC's water interaction properties, leading to mixing problems and performance issues in their final products. This confusion costs time and money.

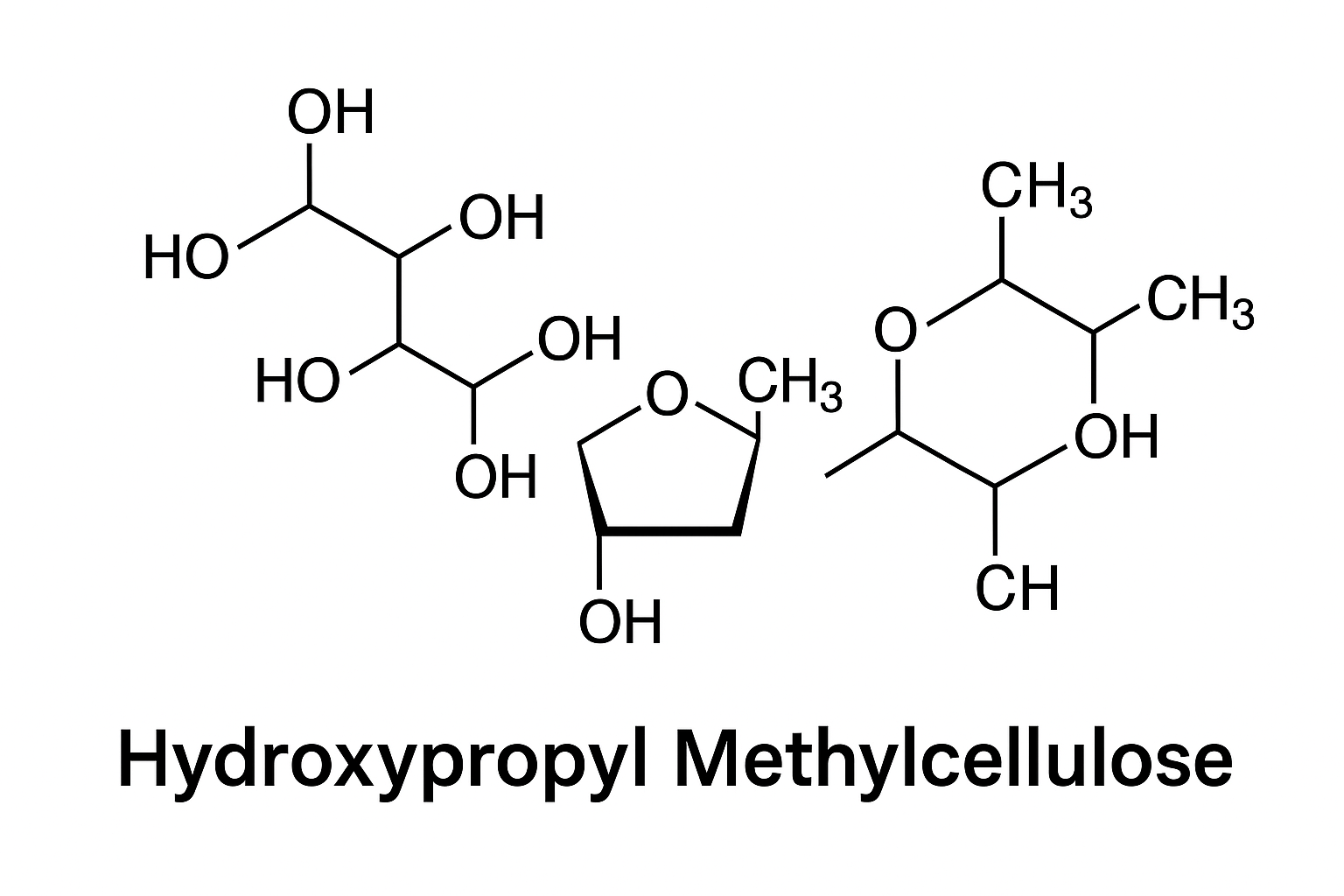

HPMC4 is fundamentally hydrophilic but can display initial hydrophobic properties. Its molecular structure contains both hydrophilic hydroxypropyl groups and slightly hydrophobic methoxy groups, making it amphiphilic. Once fully dissolved, HPMC functions primarily as a hydrophilic water-retaining agent.

The hydrophilic/hydrophobic balance of HPMC is one of its most interesting and useful characteristics. This dual nature contributes directly to its effectiveness in construction applications.

HPMC molecules have a cellulose backbone with two types of substituent groups: methoxy groups (–OCH₃) and hydroxypropyl groups (–OCH₂CH(OH)CH₃). The hydroxypropyl groups are strongly hydrophilic due to their hydroxyl (-OH) components that form hydrogen bonds with water molecules. The methoxy groups, while not strongly hydrophobic, are less water-loving than the hydroxypropyl groups.

This chemical structure creates what we call an "amphiphilic" molecule – one that has both water-loving and water-avoiding regions. The degree of substitution (DS) and molar substitution (MS) values indicate the relative proportions of these groups and directly affect how the HPMC interacts with water.

In practice, this means that HPMC can:

- Initially resist wetting when first added to water (appearing somewhat hydrophobic)

- Form a gel layer as partial hydration occurs

- Eventually dissolve completely to form a clear, viscous solution (demonstrating its ultimate hydrophilic nature)

At our factory, we modify these properties by adjusting the manufacturing process. For example:

| HPMC4 Type | Methoxy Content | Hydroxypropyl Content | Water Interaction |

|---|---|---|---|

| Low-substituted | 19-24% | 4-12% | More hydrophobic initially |

| Medium-substituted | 27-30% | 7-12% | Balanced properties |

| High-substituted | 28-30% | 19-24% | More rapidly hydrophilic |

For mortar applications, we typically recommend medium-substituted grades as they provide the optimal balance between workability, water retention, and open time.

Conclusion

Testing HPMC water retention is essential for quality construction materials. Use standardized methods, understand swelling behavior, and remember HPMC's amphiphilic nature to select the right grade for your specific application needs.

-

Understanding HPMC water retention is crucial for ensuring quality in construction materials. Explore this link for in-depth insights. ↩

-

The DIN 18555 method is a standard for testing water retention in HPMC. Discover its significance and application in quality control. ↩

-

Exploring this resource will deepen your understanding of how water retention affects the performance of construction materials, especially HPMC. ↩

-

Exploring this resource will deepen your understanding of HPMC's unique properties and its critical role in construction applications. ↩ ↩