Are you struggling with runny water-based paints1 that won't stay where you apply them? Poor viscosity control wastes your material, time, and money while delivering subpar results that damage your reputation.

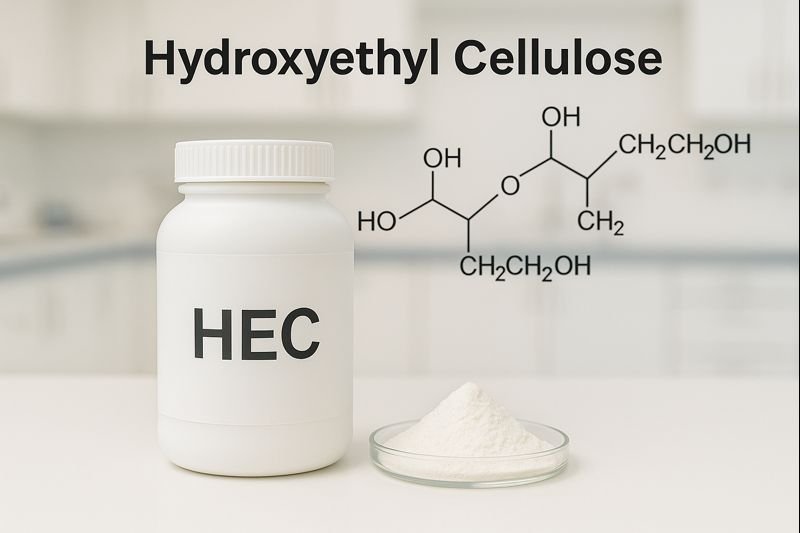

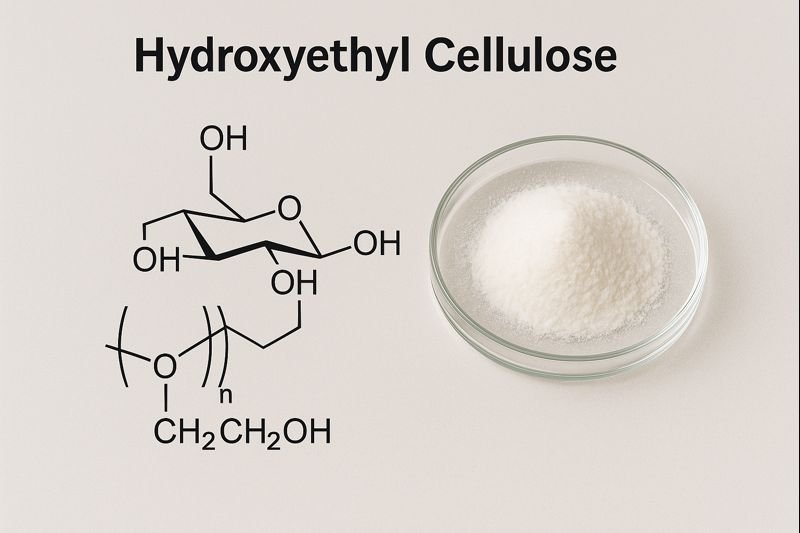

Hydroxyethyl cellulose (HEC)2 is a non-ionic water-soluble polymer that functions as an excellent thickener, stabilizer, and rheology modifier for water-based paints. When added at 0.5-2% concentration, it increases viscosity, prevents sagging, improves flow properties, and enhances paint stability without affecting the final finish.

I've been in the construction chemicals business for over 15 years, and I've seen firsthand how the right thickening agent transforms paint performance. Let me share what I know about HEC and how it can solve your water-based paint challenges.

How to Increase Viscosity of Water-based Paint?

Have you noticed your water-based paints dripping and running during application? This common problem often stems from improper viscosity adjustment and can ruin even the most carefully planned painting projects.

To increase water-based paint viscosity, add 0.5-2.0% hydroxyethyl cellulose (HEC) while mixing at medium speed. For best results, pre-disperse HEC in glycol or alcohol before adding to paint, or sprinkle slowly into the vortex while mixing. Adjust concentration based on desired thickness.

When I work with paint manufacturers, I always emphasize the importance of proper thickening technique. There are several methods for increasing paint viscosity, each with specific advantages depending on your formulation needs.

Different Methods for Adjusting Paint Viscosity

The method you choose for increasing paint viscosity depends on your specific requirements, equipment, and production scale. For large batch production, I recommend using a high-speed disperser with the following procedure:

- First mix your pigments, fillers, and additives in the paint base

- Create a pre-gel of HEC by dispersing it in glycol (typically propylene glycol) at a ratio of 1:5

- Add this pre-gel slowly to the paint mixture while stirring

- Continue mixing for 15-20 minutes until completely homogeneous

For smaller batches or lab testing, the direct powder addition method works well if you add the HEC very slowly to prevent clumping. The critical consideration is the shear force during mixing - too little and you'll get lumps, too much and you might reduce the effectiveness of the cellulose polymer chains.

| Viscosity Level | HEC Concentration | Application |

|---|---|---|

| Low (50-100 cP) | 0.3-0.5% | Spray applications |

| Medium (100-500 cP) | 0.5-1.0% | Roller applications |

| High (500-2000 cP) | 1.0-1.5% | Brush applications |

| Extra High (>2000 cP) | 1.5-2.0% | Textured finishes |

What is HEC Chemical for Paint?

Are you confused about the many thickeners available and wondering if HEC is the right choice for your paint formulation? Selecting the wrong thickener can lead to stability issues, poor application properties3, and customer complaints.

Hydroxyethyl cellulose (HEC)2 is a cellulose ether derived from natural cellulose. In paints, it functions primarily as a thickener and protective colloid that provides excellent water retention, stabilizes emulsions, prevents pigment settling, and creates pseudo-plastic flow behavior ideal for brush and roller application.

During my visits to paint factories across Asia and the Middle East, I've noticed increasing interest in HEC as a versatile coating additive. Unlike many synthetic thickeners, HEC is derived from renewable resources and offers unique advantages in water-based formulations.

HEC Characteristics for Paint Applications

Understanding the molecular structure and properties of HEC helps explain its effectiveness in paint formulations. HEC is produced by reacting alkali cellulose with ethylene oxide, creating hydroxyethyl substituents along the cellulose backbone. This modification makes the cellulose water-soluble while maintaining its ability to form hydrogen bonds.

The molecular weight of HEC directly affects its thickening efficiency and final paint properties. Our factory produces several grades:

| HEC Grade | Viscosity (2% solution) | Molecular Weight | Best For |

|---|---|---|---|

| Low MW | 10-100 mPa·s | 90,000-160,000 | Spray paints, primers |

| Medium MW | 100-400 mPa·s | 160,000-250,000 | Interior wall paints |

| High MW | 400-1000 mPa·s | 250,000-400,000 | Exterior paints, textured finishes |

| Ultra High MW | >1000 mPa·s | >400,000 | Heavy-duty coatings, putties |

One of the most valuable properties of HEC in paint formulations is its stability across a wide pH range (2-12), making it compatible with various paint systems from slightly acidic to highly alkaline. HEC also demonstrates excellent compatibility with surfactants, dispersants, and other additives commonly used in water-based paints.

How to Use Hydroxyethyl Cellulose?

Do you find that your cellulose thickeners form lumps or "fish eyes" when added to your paint formulations? This common problem can severely impact production efficiency and final product quality.

To use hydroxyethyl cellulose effectively, first disperse it in a non-solvent like glycol or alcohol before adding to water. Alternatively, use a high-shear mixer while slowly sprinkling the dry powder into the vortex. For optimal hydration, maintain pH between 6.5-8.5 and allow 15-30 minutes mixing time.

I remember visiting a paint factory in Saudi Arabia where they struggled with inconsistent batches due to poor HEC incorporation. After implementing the proper dispersion technique, their production efficiency improved by 30% and product consistency issues disappeared.

Step-by-Step Guide to Incorporating HEC

The successful incorporation of HEC into water-based paint depends on following the proper sequence and conditions. Based on my experience working with hundreds of paint manufacturers, I've developed this optimized process:

-

Preparation Phase:

- Check that your HEC powder is dry and free-flowing

- Ensure your mixing equipment is clean and in good working order

- Pre-heat water to 30-40°C to improve dissolution rate (optional)

-

Dispersion Methods (choose one):

- Slurry method: Mix HEC with glycol or alcohol (3-5 parts) to create a non-aqueous slurry

- Dry blend method: Mix HEC with other dry ingredients like calcium carbonate before adding to water

- Direct addition: Use high-shear mixer and add HEC very slowly to the vortex

-

Hydration Phase:

- Adjust pH to 7-8 using ammonia or sodium hydroxide

- Continue mixing for 15-30 minutes at medium speed

- Allow to stand for complete hydration (viscosity will increase over time)

The temperature during mixing significantly affects HEC hydration. Cold water slows dissolution but may be necessary for some heat-sensitive formulations. In most cases, room temperature or slightly warmed water (30°C) provides the best balance of dissolution speed and ease of handling.

| Process Parameter | Recommended Range | Effect if Too Low | Effect if Too High |

|---|---|---|---|

| Water Temperature | 20-35°C | Slow dissolution | Decreased final viscosity |

| pH | 6.5-8.5 | Poor hydration | Potential degradation |

| Mixing Speed | Medium-high | Incomplete dispersion | Air entrainment |

| Hydration Time | 15-60 min | Incomplete thickening | Extended production time |

How to Thicken a Water-Based Paint?

Is your paint too thin despite following standard formulations? This frustrating issue often occurs due to improper thickener selection or incorporation techniques, leading to inconsistent application and poor hiding power.

To thicken water-based paint, gradually add 0.5-2% hydroxyethyl cellulose while mixing thoroughly. For existing paints, prepare a 2-3% HEC solution separately and blend it into the paint. Allow 1-2 hours for complete hydration and viscosity development before assessing final thickness.

During my technical support visits to paint factories, I often help troubleshoot viscosity issues. One common mistake is adding too much thickener4 at once, which creates lumps and actually makes the mixing problem worse instead of better.

Practical Guidelines for Paint Thickening

Thickening water-based paint is both a science and an art that requires understanding the interaction between the thickener and other paint components. When working with HEC specifically, consider these important factors that impact final viscosity:

-

Water Quality:

Hard water containing calcium and magnesium ions can interfere with HEC hydration. For best results, use deionized or soft water when possible. If using hard water, you may need to increase HEC concentration slightly or add sequestering agents. -

Cosolvent Effects:

The presence of cosolvents like glycols and alcohols affects HEC performance. Generally, higher cosolvent levels decrease the efficiency of HEC, requiring higher dosages to achieve the same viscosity. -

Surfactant Interaction:

Most paint formulations contain surfactants for pigment wetting and stability. These can either enhance or reduce HEC thickening efficiency depending on their type and concentration. Nonionic surfactants typically have minimal negative impact, while certain anionic surfactants may reduce viscosity. -

Adjusting Existing Paints:

When modifying the viscosity of already-prepared paints:- Start with a small test batch to determine optimal addition level

- Add pre-dissolved HEC solution rather than dry powder

- Mix thoroughly using appropriate shear force

- Allow adequate time for equilibration before final viscosity measurement

| Common Issue | Cause | Solution |

|---|---|---|

| Lumps or "fish eyes" | Too rapid addition of HEC | Use slurry method or add more slowly |

| Insufficient thickening | Incomplete hydration | Extend mixing time or adjust pH |

| Viscosity loss during storage | Enzymatic degradation | Add biocide or use enzyme-resistant HEC grade |

| Spattering during application | Too high viscosity | Reduce HEC concentration or modify rheology profile |

Conclusion

Hydroxyethyl cellulose is the ideal thickener for water-based paints when properly selected and incorporated. By following the guidelines outlined above, you can achieve consistent viscosity, excellent application properties, and superior paint performance that will satisfy even your most demanding customers.

-

Learn about the advantages of water-based paints for eco-friendly and safe applications. ↩

-

Explore the unique properties of HEC and how it enhances paint formulations. ↩ ↩

-

Explore the essential application properties that affect paint performance. ↩

-

Find out which thickeners work best for achieving desired paint consistency. ↩