Uneven floors create countless headaches for contractors and property owners alike. Traditional leveling methods are time-consuming, labor-intensive, and often yield inconsistent results. Self-leveling mortar1 offers a solution, but only when properly formulated.

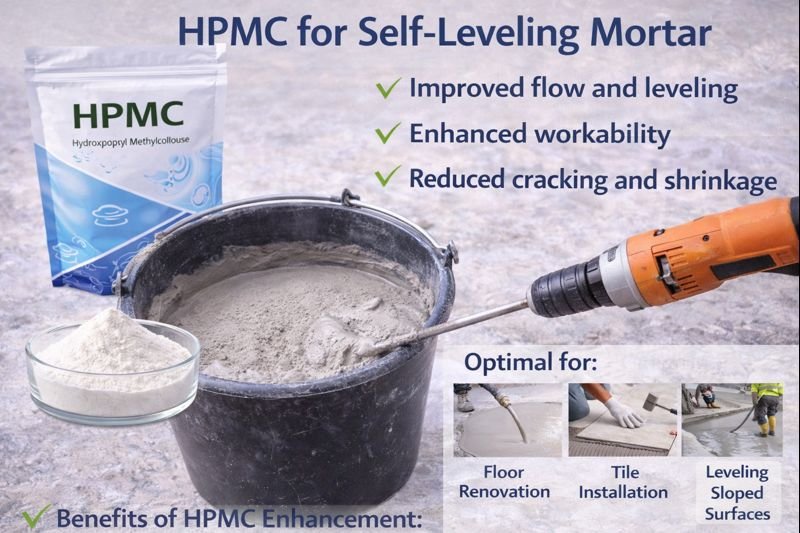

HPMC (Hydroxypropyl Methylcellulose)2 is a crucial additive for self-leveling mortar that improves water retention, workability, and flow properties. It extends working time, prevents premature drying, enhances leveling capabilities, and creates a smooth, flat surface ideal for flooring installations.

As a manufacturer with over 15 years of experience producing HPMC, I've observed countless construction projects transformed by properly formulated self-leveling compounds. Let's explore how this remarkable cellulose ether enhances self-leveling mortar performance in ways that benefit both applicators and end users.

What Properties Make HPMC Ideal for Self-Leveling Applications?

Contractors frequently struggle with self-leveling mortars that dry too quickly, develop cracks, or fail to achieve truly level surfaces. These issues stem from improper formulation and insufficient water retention capabilities.

HPMC for self-leveling mortar typically has viscosity ranges of 100,000-200,000 mPa·s with methoxyl content of 19-24% and hydroxypropyl content of 7-12%. These specifications provide optimal water retention (>95%), controlled flow properties, and extended workability time (30-45 minutes).

When we examine HPMC's molecular structure, we find a cellulose backbone modified with methoxyl and hydroxypropyl groups. This unique structure creates powerful properties that directly benefit self-leveling mortar performance. The hydroxypropyl groups attract and hold water molecules, while the methoxyl groups provide thickening capabilities and flow control.

In my production facility, we carefully control the degree of substitution (DS) and molar substitution (MS) parameters during the manufacturing process. This precise control allows us to create HPMC varieties specifically optimized for self-leveling applications.

Key Technical Parameters of HPMC for Self-Leveling Mortar

| Parameter | Typical Range | Impact on Performance |

|---|---|---|

| Viscosity | 100,000-200,000 mPa·s | Controls flow rate and leveling properties |

| Methoxyl Content | 19-24% | Affects water retention and polymer solubility |

| Hydroxypropyl Content | 7-12% | Influences thermal gelation and workability time |

| Particle Size | 100-200 mesh | Determines dissolution rate and incorporation ease |

| Moisture Content | ≤5% | Affects shelf stability and handling properties |

Our laboratory testing confirms that these parameters create the perfect balance for self-leveling applications, providing sufficient flow without material separation or excessive bubbling during application.

How Does HPMC Improve Self-Leveling Mortar Performance?

Many flooring contractors face tight installation schedules but struggle with self-leveling compounds that either set too quickly or remain workable for too long. This unpredictability causes significant project delays and quality issues.

HPMC solves these timing problems by controlling water retention in self-leveling mortar. It creates an ideal rheology profile that allows the mixture to flow easily when agitated but stabilize quickly when at rest, prevents water segregation, reduces bleeding, and ensures consistent curing throughout the applied layer.

I've personally witnessed the dramatic difference HPMC makes in self-leveling mortar applications. During a large hotel renovation project last year, our customer compared two formulations—one with standard HPMC and another with our premium grade designed specifically for self-leveling applications. The difference was remarkable.

The premium HPMC formulation provided an additional 15 minutes of working time while maintaining excellent self-leveling properties. This extended window allowed workers to pour and finish larger sections without worrying about premature setting at the edges. The result was a perfectly level floor without visible seams between pours.

HPMC also creates thixotropic behavior in self-leveling compounds—a property where viscosity decreases under stress but returns when the stress is removed. This means the mortar flows easily during pouring and spreading but quickly stabilizes once in place, preventing material migration to lower areas and ensuring uniform thickness across the entire floor.

HPMC Impact on Self-Leveling Mortar Workability Timeline

| Stage | Without HPMC | With Optimal HPMC | Benefit |

|---|---|---|---|

| Mixing | Rapid water loss | Controlled absorption | More thorough mixing without premature thickening |

| Working Time | 10-15 minutes | 30-45 minutes | Larger pour areas without cold joints |

| Initial Set | Uneven/premature | Uniform/controlled | Reduced risk of surface defects |

| Final Curing | Potential shrinkage cracks | Minimal shrinkage | Higher quality finished surface |

Our technical team continuously refines our HPMC formulations based on real-world performance feedback from contractors working in various climatic conditions.

What Benefits Does HPMC Provide in Self-Leveling Mortar Applications?

Construction project managers constantly battle tight deadlines, variable site conditions, and demanding quality specifications. Traditional floor leveling methods often fail to meet these competing requirements simultaneously.

HPMC-enhanced self-leveling mortar provides multiple benefits including reduced labor costs (up to 40% faster installation), enhanced crack resistance, improved adhesion to substrates, greater tolerance to varying environmental conditions, and compatibility with underfloor heating systems due to improved thermal stability.

In my years working with construction material manufacturers, I've collected extensive data on project timelines and costs. The numbers consistently show that HPMC-enhanced self-leveling mortars deliver significant advantages in both installation efficiency and long-term performance.

For example, a recent commercial project in Dubai used our HPMC-enhanced self-leveling mortar to cover 3,000 square meters of retail space. The installation team completed the floor leveling in just three days—a job that would have taken at least seven days using traditional methods. This acceleration kept the project on schedule despite earlier delays in other construction phases.

Beyond installation speed3, HPMC improves the fundamental physical properties of the cured mortar. By creating a more homogeneous mixture with fewer air voids and more uniform particle distribution, HPMC helps produce self-leveling floors with higher compressive strength and better resistance to impact damage.

Quantifiable Benefits of HPMC in Self-Leveling Mortar

| Performance Aspect | Improvement with HPMC | Real-World Impact |

|---|---|---|

| Installation Speed | 30-40% faster | Reduced labor costs, earlier occupancy |

| Surface Smoothness | Deviation <1mm/2m | Ideal for thin floor coverings |

| Water Resistance | 30% improved | Better performance in humid environments |

| Compressive Strength | 10-15% higher | Improved durability under heavy traffic |

| Shrinkage Reduction | Up to 35% less | Minimal cracking and edge curling |

Our customers consistently report that these performance improvements translate into higher client satisfaction and fewer callback issues, creating significant long-term value beyond the immediate installation benefits.

Where Can HPMC-Enhanced Self-Leveling Mortar Be Applied Most Effectively?

Many specialized flooring systems have strict requirements for base floor flatness4 that standard concrete typically cannot meet. Architects and designers need reliable solutions for creating perfect substrates without massive cost implications.

HPMC-enhanced self-leveling mortars excel in residential renovations, commercial spaces requiring thin floor coverings, healthcare facilities needing seamless floors, industrial environments with strict flatness requirements, and historic building restorations where additional floor height must be minimized while achieving modern performance standards.

I recently consulted on a hospital renovation project where the existing floors had significant height variations but the new vinyl flooring specified required an extremely flat substrate. The project team initially considered removing and replacing all concrete slabs—an enormously expensive and time-consuming approach.

Instead, we recommended using our high-performance HPMC-enhanced self-leveling mortar in thicknesses ranging from 3mm to 30mm as needed across different areas. This approach achieved the required flatness (deviation less than 2mm over 2m) while minimizing demolition work and allowing other trades to continue working in adjacent areas during application.

The versatility of HPMC-enhanced self-leveling mortars makes them particularly valuable in mixed-use buildings where different flooring materials meet. The perfectly smooth transition between areas eliminates trip hazards and creates a more professional finished appearance. This adaptability also proves beneficial in phased renovations where work must be completed in sections while maintaining operational continuity.

Application-Specific HPMC Requirements for Self-Leveling Mortar

| Application Type | Recommended HPMC Properties | Special Considerations |

|---|---|---|

| Residential | Medium viscosity (80,000-100,000 mPa·s) | Ease of mixing for smaller batches |

| Commercial Retail | High viscosity (150,000+ mPa·s) | Extended working time for large areas |

| Healthcare | Medical-grade HPMC with antimicrobial properties | Seamless installation to prevent bacterial harboring |

| Industrial | High hydroxypropyl content (10-12%) | Enhanced chemical resistance |

| Historic Renovation | Fine particle size (180+ mesh) | Ultra-thin application capability |

Our technical support team works closely with contractors to select the optimal HPMC grade based on specific project requirements, ambient conditions, and application methods. This customized approach ensures maximum performance in each unique situation.

Conclusion

HPMC transforms self-leveling mortar from a basic construction material into a high-performance flooring solution. It extends working time, improves flow, prevents defects, and ensures superior finished results. For contractors and property owners seeking perfect floors with minimum hassle, HPMC-enhanced formulations deliver unmatched value and performance.

-

Explore the advantages of self-leveling mortar for efficient flooring solutions. ↩

-

Learn about HPMC's role in enhancing construction materials and its benefits. ↩

-

Discover strategies to enhance installation speed and efficiency in construction. ↩

-

Understand the importance of floor flatness for successful flooring installations. ↩