I often see buyers struggling to choose between HPMC1 and MC for their projects. This confusion costs them money through trial and error when the wrong cellulose ether is selected for specific applications.

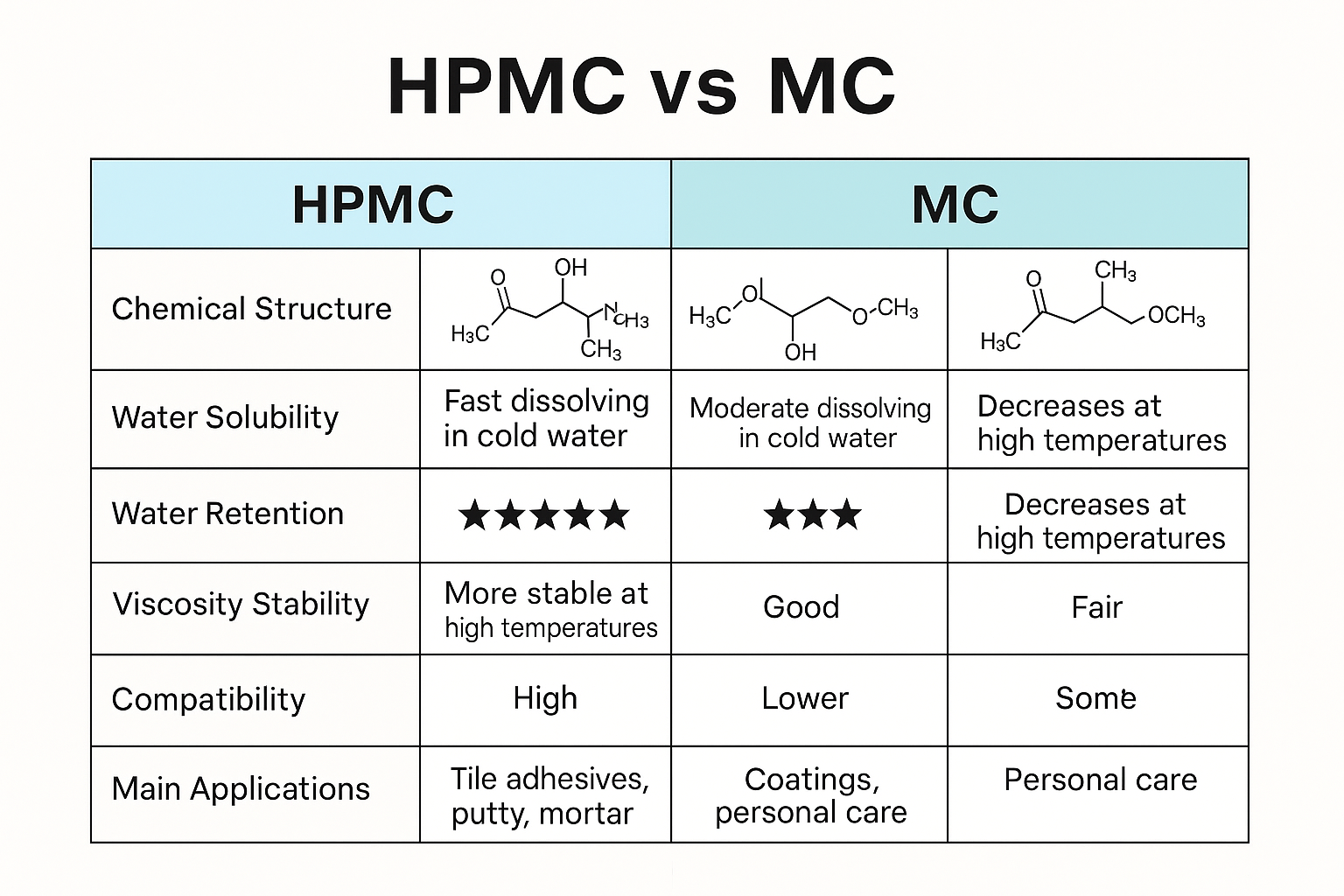

HPMC1 and MC are both cellulose ethers2, but HPMC has hydroxypropyl groups that give it better water retention, wider solubility range, and enhanced stability in alkaline environments. MC offers higher gel strength but lower temperature resistance compared to HPMC.

After 15 years of manufacturing both HPMC and MC at our Kehao production facilities, I've helped hundreds of customers find the right cellulose ether for their needs. In this article, I'll break down the key differences that matter most to your applications.

Chemical Structure and Solubility: How Do They Differ?

Many of my customers get confused about why HPMC and MC behave differently in their formulations. The answer lies in their molecular structure, which affects everything from dissolution to final performance.

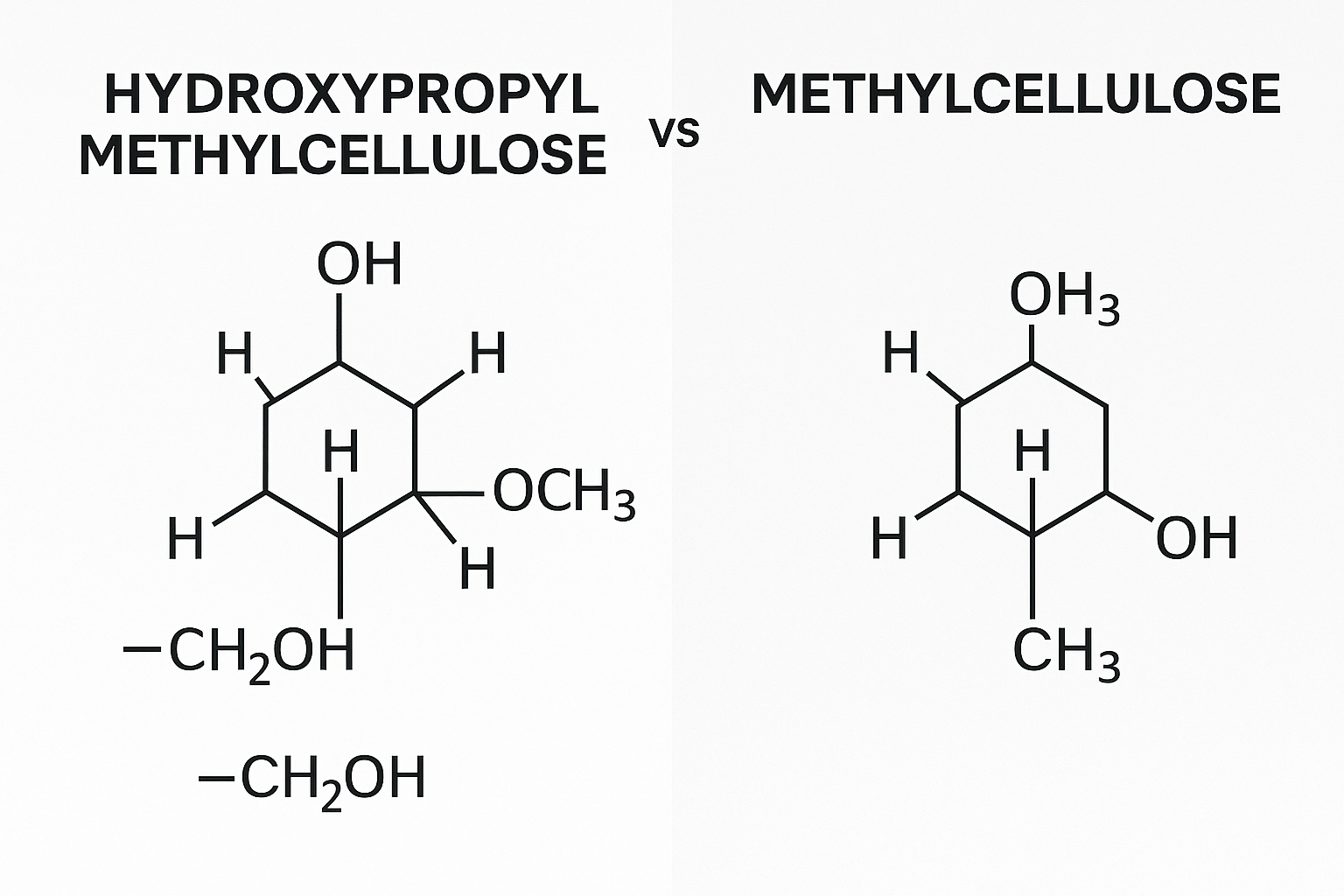

HPMC contains hydroxypropyl groups3 attached to the cellulose backbone in addition to methyl groups, while MC only has methyl groups. This gives HPMC broader solubility in both hot and cold water, while MC dissolves best in cold water but forms a gel in hot water.

When we look deeper at these structural differences, we can understand their practical implications. The hydroxypropyl groups in HPMC make it more hydrophilic, which explains its improved water solubility across a wider temperature range. This is particularly important in construction applications4 where mixing conditions may vary.

Solubility Comparison Table

| Property | HPMC | MC |

|---|---|---|

| Cold Water Solubility | Good | Excellent |

| Hot Water Solubility | Good | Poor (forms gel) |

| Organic Solvent Solubility | Better | Limited |

| Gel Temperature | 65-90°C (varies by grade) | 50-55°C |

During my visits to construction sites in Saudi Arabia and UAE, I've observed that HPMC's versatile solubility makes it more forgiving in varying climate conditions, especially when mixing mortars in hot weather. The hydroxypropyl substitution also gives HPMC improved compatibility with other ingredients in complex formulations.

Viscosity and Temperature Stability: Which Performs Better?

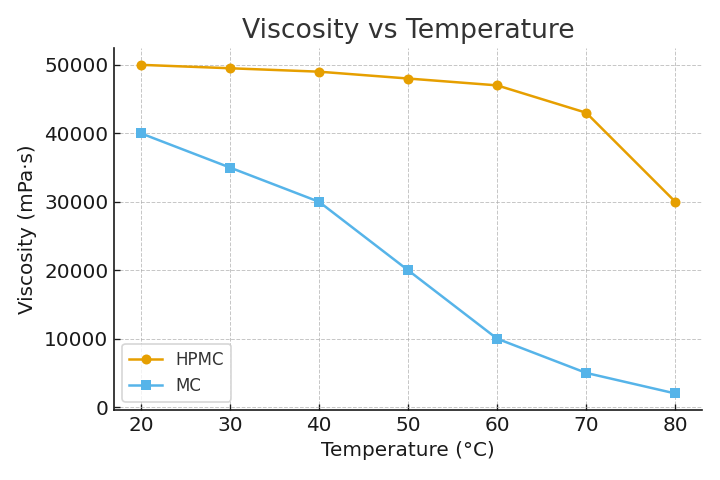

I've had customers complain about inconsistent performance in their products when temperatures fluctuate. This is often because they didn't understand the temperature stability differences between HPMC and MC.

HPMC maintains more stable viscosity across temperature ranges (5-40°C), while MC shows dramatic viscosity changes with temperature. HPMC's thermal gelation point (65-90°C) is typically higher than MC's (50-55°C), making HPMC1 more suitable for hot climate applications.

Temperature stability is critical for ensuring consistent performance in real-world applications. From our extensive testing at Kehao's laboratories, we've documented how these materials behave differently under various conditions.

Thermal Behavior Analysis

HPMC1 demonstrates superior temperature stability due to its hydroxypropyl substitution, which interrupts hydrogen bonding between cellulose chains. This structural feature allows HPMC to maintain workability in mortars and renders even when ambient temperatures change throughout the day.

When working with customers in regions like the Middle East, I always recommend HPMC for exterior applications where materials will experience significant temperature fluctuations. The data from our field tests shows that HPMC-based mortars maintain workable consistency for 30-45 minutes longer than MC-based alternatives in hot weather conditions.

For interior applications in controlled environments, MC may be sufficient and can offer cost advantages. However, for most construction applications, HPMC's temperature stability translates to fewer job site problems and more consistent results.

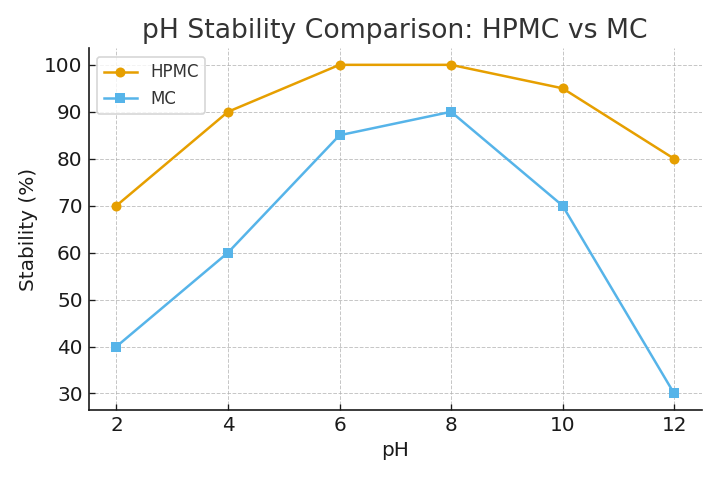

pH Stability and Salt Tolerance: Which Is More Versatile?

Construction site delays often happen when materials break down or lose effectiveness in highly alkaline environments. Choosing between HPMC and MC can help avoid these costly problems.

HPMC shows superior stability in alkaline environments (pH 2-12) and higher salt tolerance compared to MC, which performs best in neutral to slightly alkaline conditions (pH 3-11). For cement-based applications where pH levels can exceed 12, HPMC is generally the safer choice.

Diving deeper into pH stability5 reveals why this property matters so much in construction applications. Cement-based materials typically create highly alkaline environments during hydration, with pH values often reaching 12-13 in fresh mixes.

Stability in Different Environments

| Environment | HPMC Stability | MC Stability |

|---|---|---|

| Acidic (pH 2-6) | Good | Moderate |

| Neutral (pH 6-8) | Excellent | Excellent |

| Alkaline (pH 8-12) | Excellent | Good to Moderate |

| High Alkaline (pH >12) | Good | Poor |

| High Salt Concentration | Good | Poor to Moderate |

From my experience with customers in India and Pakistan, where cement quality can vary significantly, HPMC provides a valuable safety margin against unexpected pH variations in the mix. The hydroxypropyl substitution shields the cellulose backbone from alkaline degradation, preserving the polymer's functionality throughout the curing process.

Salt tolerance becomes particularly important when using hard water for mixing or in coastal construction projects. HPMC's superior salt tolerance means it maintains its water retention and viscosity properties even in these challenging conditions.

Water Retention Capability: Why Does It Matter?

Water retention problems lead to cracking, poor adhesion, and reduced strength in finished projects. I've seen this firsthand while visiting customer sites throughout the Middle East.

HPMC typically provides 10-15% higher water retention than MC at equal concentrations, which results in better cement hydration, reduced cracking, and improved strength development in mortars and renders. This difference is critical in hot or windy application conditions.

Water retention is perhaps the most important functional property for many construction applications. When we analyze this capability more closely, we see why HPMC has become the preferred choice for modern construction materials.

The hydroxypropyl groups in HPMC create additional hydrogen bonding sites that interact with water molecules, effectively "trapping" them within the matrix for longer periods. Our laboratory testing shows that HPMC-modified mortars retain workability for approximately 30-45 minutes longer than identical formulations using MC.

In practical terms, this means:

- Extended open time for tile adhesives6

- Reduced risk of "burning" in renders and plasters

- More complete cement hydration, resulting in higher final strength

- Fewer application issues like shrinkage cracking

- Better performance in challenging weather conditions

When I work with customers in hot climates like Saudi Arabia or UAE, I typically recommend our higher viscosity HPMC grades specifically engineered for enhanced water retention. The modest additional cost is easily justified by the reduced material waste and callbacks.

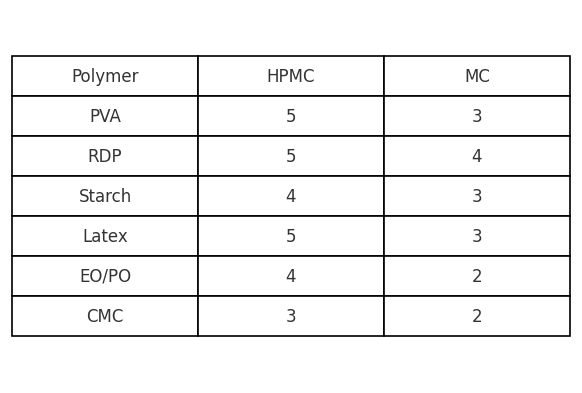

Compatibility with Other Polymers: Which Blends Better?

Formulation incompatibilities cost manufacturers time and money through failed products. Understanding polymer compatibility differences between HPMC and MC helps avoid these expensive mistakes.

HPMC shows better compatibility with redispersible polymer powders7, latex, and other additives compared to MC. This makes HPMC the preferred choice for complex formulations like tile adhesives and EIFS8 (External Insulation Finishing Systems).

The molecular structure of HPMC, particularly its hydroxypropyl groups, creates better interaction points with other polymers commonly used in construction formulations. This improved compatibility manifests in several practical advantages.

Compatibility Analysis

When formulating high-performance construction products, we often need to combine cellulose ethers with other polymers like:

- Redispersible polymer powders (VAE, VeoVa, acrylics)

- Latex emulsions

- Polyethylene glycols

- Other rheology modifiers

Our testing at Kehao shows that HPMC forms more stable blends with these materials, resulting in fewer phase separation issues during storage and improved performance consistency. This is particularly evident in demanding applications like tile adhesives, where the cellulose ether must work in harmony with redispersible powders to provide both open time and adhesion.

For customers developing premium construction products, this compatibility advantage often makes HPMC the only viable option, despite its higher cost compared to MC. I've helped several customers in Brazil and Mexico reformulate problematic products by switching from MC to HPMC, solving stability issues that had been plaguing their production.

Adhesion and Enzyme Resistance: Which Lasts Longer?

Product failures and callbacks are expensive problems that my customers want to avoid. The differences in adhesion and long-term stability between HPMC and MC directly impact these concerns.

HPMC typically provides superior adhesion strength to various substrates and offers better resistance to enzymatic degradation compared to MC. This results in more durable bonds and longer shelf life for products formulated with HPMC.

The improved adhesion properties of HPMC stem from several factors related to its molecular structure. The hydroxypropyl groups create additional hydrogen bonding opportunities with substrates, especially porous materials like concrete and masonry. This enhanced interaction at the molecular level translates to stronger bonds in the finished application.

Durability Factors

Long-term performance differences between HPMC and MC become particularly evident when we examine:

| Property | HPMC | MC | Impact |

|---|---|---|---|

| Wet Adhesion | Superior | Good | Better tile adhesive performance |

| Dry Adhesion | Very Good | Good | Stronger render attachment |

| Enzymatic Degradation Resistance | Better | Good | Improved shelf stability |

| UV Resistance | Better | Good | Better exterior durability |

From my experience working with customers in humid tropical environments like Philippines and Vietnam, the improved enzymatic degradation resistance of HPMC can extend shelf life by 3-6 months compared to MC-based formulations. This is a significant advantage for distribution channels where inventory might sit in warehouses under less-than-ideal conditions.

For applications requiring strong adhesion to challenging substrates, like tile adhesives for non-porous tiles or renders for XPS insulation boards, HPMC consistently outperforms MC in our laboratory tests and real-world applications.

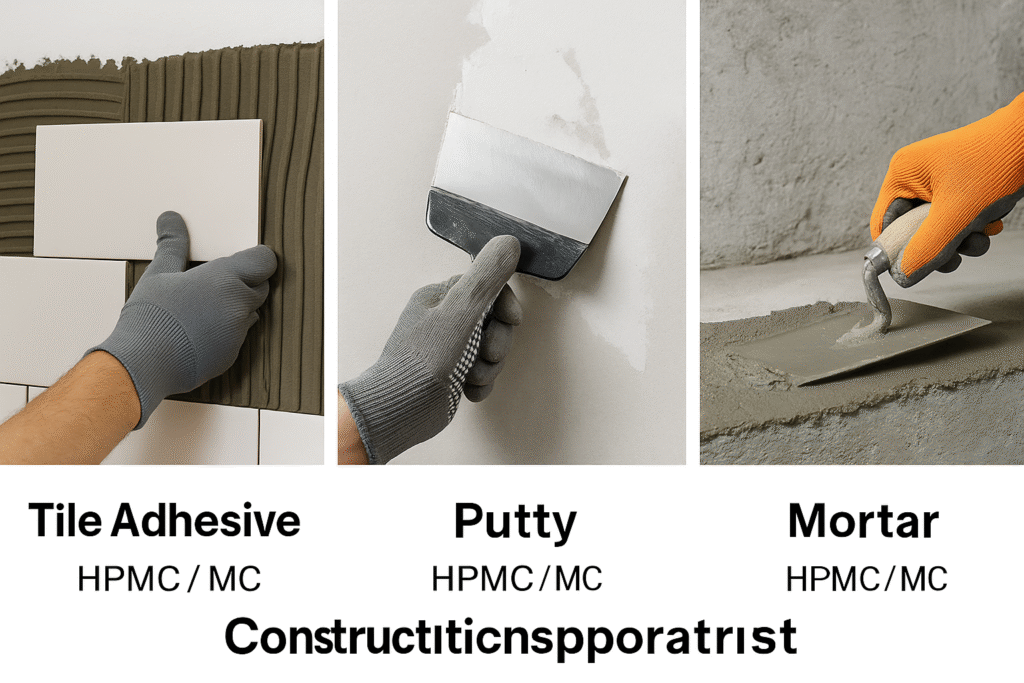

Industrial Applications: HPMC vs MC in Construction

I frequently get asked which specific construction applications benefit most from HPMC versus MC. The choice impacts final product performance and can mean the difference between success and failure.

HPMC is preferred for demanding applications like tile adhesives, EIFS mortars, and exterior renders due to its superior water retention and alkaline stability. MC is sometimes used in interior applications like jointing compounds and decorative plasters where cost is a primary concern.

When selecting between these materials for specific construction applications, several factors come into play. Based on our extensive experience supporting customers across different markets, I've compiled typical application recommendations:

Application Suitability Table

| Application | Preferred Material | Key Benefit |

|---|---|---|

| Tile Adhesives | HPMC | Superior open time and adhesion |

| Renders & Plasters | HPMC | Better water retention and workability |

| Self-leveling Compounds | HPMC | Improved flow and alkaline resistance |

| Joint Fillers | Either | Cost vs performance balance |

| Gypsum-based Products | Either | Depends on performance requirements |

| Cement Paints | HPMC | Better adhesion and weathering resistance |

| Wallpaper Adhesives | MC | Good initial tack, cost-effective |

During my technical support visits to customers in Saudi Arabia and UAE, I've observed that those who switched from MC to HPMC in their exterior renders experienced a significant reduction in application problems, especially during hot summer months. The additional cost of HPMC was easily justified by fewer callbacks and improved reputation for quality.

For interior applications in controlled environments, MC often provides adequate performance at a lower cost. However, as construction schedules become more demanding and application conditions less controlled, many of our customers have moved toward HPMC even for these less demanding applications.

FAQ – Frequently Asked Questions

The questions I get most often from new customers center around practical considerations for choosing between HPMC and MC. Here are answers to help in your selection process.

When choosing between HPMC and MC, consider your application environment, required water retention level, compatibility with other ingredients, and budget constraints. For most modern construction applications, especially those exposed to weather or varying temperatures, HPMC offers performance advantages that justify its higher cost.

Key Questions to Consider

When customers approach me about cellulose ethers, I find these questions help clarify their needs:

-

Application conditions: Will your product be used in extreme temperatures or humidity? HPMC performs better in challenging environments.

-

Required open time: Do installers need extended working time? HPMC provides superior water retention.

-

Substrate compatibility: Are you applying to difficult substrates? HPMC typically offers better adhesion.

-

Formulation complexity: Does your formula contain multiple polymers? HPMC shows better compatibility.

-

Budget sensitivity: Is cost your primary concern? MC may be suitable for less demanding applications.

Based on my experience serving customers across multiple markets, I've found that most professional formulators eventually migrate toward HPMC for its performance reliability. While the initial cost per kilogram is higher, the overall formulation cost difference is often minimal (typically less than 5% of total formula cost), making HPMC the more cost-effective choice when considering the full lifecycle costs.

Conclusion

HPMC outperforms MC in water retention, temperature stability, alkaline resistance, and polymer compatibility, making it the superior choice for most modern construction applications despite its higher cost. For best results, choose the cellulose ether that matches your specific application requirements.

-

Explore the advantages of HPMC for construction, including its superior water retention and stability. ↩ ↩ ↩ ↩

-

Discover the role of cellulose ethers in construction and their impact on material performance. ↩

-

Explore the role of hydroxypropyl groups in enhancing the properties of cellulose ethers. ↩

-

Find out which cellulose ethers are best suited for various construction applications. ↩

-

Find out how pH stability can prevent material breakdown in construction environments. ↩

-

Understand the key properties that contribute to effective tile adhesive formulations. ↩

-

Explore the role of redispersible polymer powders in enhancing construction material performance. ↩

-

Learn about External Insulation Finishing Systems and their advantages in building projects. ↩