Working with mortar in scorching summer conditions often leads to rapid setting and poor workability. Many contractors struggle to maintain quality when temperatures soar, causing wasted materials and project delays.

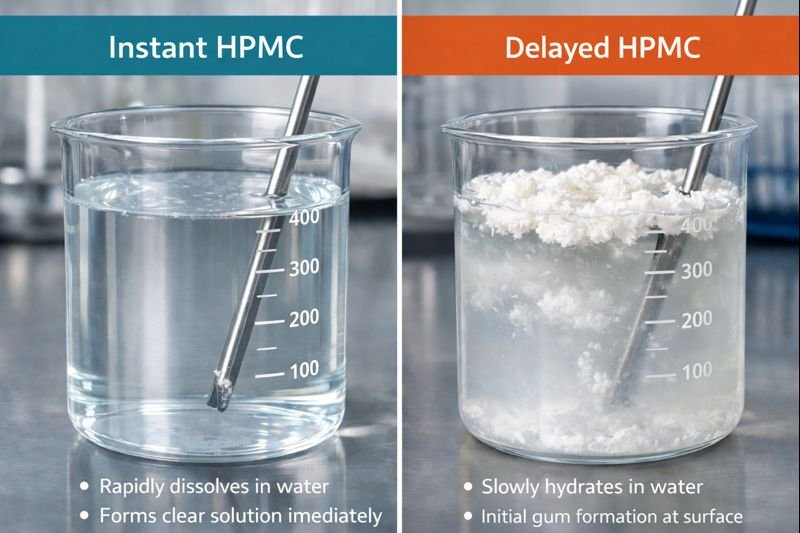

For high-temperature mortar applications, delayed-type (thermal soluble) HPMC1 significantly outperforms instant-type HPMC2. The delayed dissolution mechanism provides longer open time, better workability, and prevents premature setting despite high ambient temperatures.

This finding might seem counterintuitive at first. After all, wouldn't something labeled "instant" work better when you need fast results? Let me walk you through why the opposite is true in high-temperature conditions and how choosing the right HPMC type can save your summer construction projects.

At what temperature does HPMC decompose?

The summer heat makes mortar set too quickly, leaving workers struggling to apply it before hardening. This leads to poor adhesion, surface cracks, and wasted material that cuts into your profits.

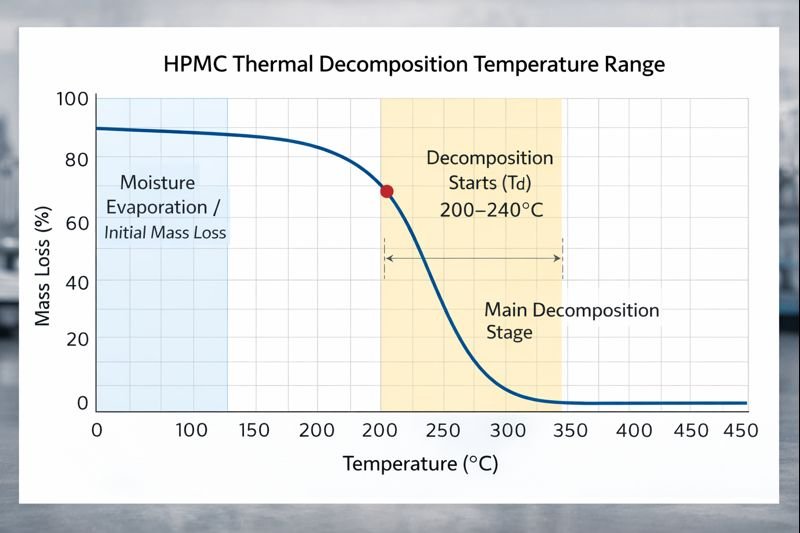

HPMC typically begins to decompose at temperatures between 190-200°C (374-392°F), with complete thermal decomposition occurring around 280-300°C (536-572°F). However, its functional properties start to change at much lower temperatures, around 60-70°C.

Understanding HPMC decomposition temperatures is crucial for formulators and contractors working in extreme conditions. When ambient temperatures rise, chemical reactions speed up - including cement hydration. This accelerated reaction can significantly reduce workability time.

The decomposition process of HPMC occurs in stages. First, there's moisture loss, then the methoxyl and hydroxypropyl groups begin to separate, and finally, the cellulose backbone breaks down. But long before reaching decomposition temperatures, HPMC undergoes another critical phase change: gelation.

In mortar applications, we're more concerned with HPMC's behavior at working temperatures (20-60°C) rather than decomposition temperatures. This is where the difference between instant and delayed HPMC becomes most apparent. At these temperatures, delayed HPMC maintains its water retention capabilities longer, while instant HPMC may release water too quickly, causing premature stiffening.

| HPMC Type | Initial Property Change | Functional Limitation | Complete Decomposition |

|---|---|---|---|

| Instant | 50-60°C | 70-80°C | 280-290°C |

| Delayed | 60-70°C | 80-90°C | 290-300°C |

Which HPMC is best?

Customers often come to me frustrated after using "premium" instant HPMC that somehow performed worse in summer conditions. Their mortar dried too quickly, leading to poor workability and surface defects they couldn't explain.

The best HPMC for high-temperature mortar applications is delayed-type (thermal soluble) HPMC1 with viscosity between 60,000-100,000 mPa·s and methoxyl content of 28-30%. This type provides optimal open time, water retention, and workability when ambient temperatures exceed 30°C.

Selecting the ideal HPMC involves more than just choosing between instant and delayed types. You must consider several critical factors that impact performance in different applications and climate conditions.

Viscosity plays a crucial role in determining workability and water retention. Higher viscosity grades (75,000-100,000 mPa·s) provide superior water retention but may require more mixing energy. Medium viscosity grades (40,000-60,000 mPa·s) offer a good balance for general-purpose mortars. Low viscosity grades (15,000-30,000 mPa·s) improve flowability but provide less water retention.

The methoxyl content significantly influences solubility, surface activity, and gelation temperature. HPMC with higher methoxyl content (28-30%) provides better water retention and adhesion, making it ideal for tile adhesives and EIFS mortars. Lower methoxyl content types offer faster dissolution but may struggle in high-temperature applications.

Substitution degree affects dissolution characteristics and thermal gelation behavior. A higher hydroxypropyl substitution produces HPMC with better compatibility with other additives like redispersible polymer powders3 and superplasticizers.

For high-temperature environments specifically:

- Choose delayed-type HPMC with thermal solubility characteristics

- Select higher viscosity grades (60,000+ mPa·s) for extended open time

- Opt for higher methoxyl content (28-30%) for superior water retention

- Consider slightly increasing dosage (0.1-0.2%) to compensate for accelerated cement hydration

What is the water retention mechanism of HPMC in cement mortar?

Many contractors don't realize their summer mortar problems stem from poor water retention. When water evaporates too quickly in hot weather, mortar becomes unpredictable and difficult to work with, leading to costly rework.

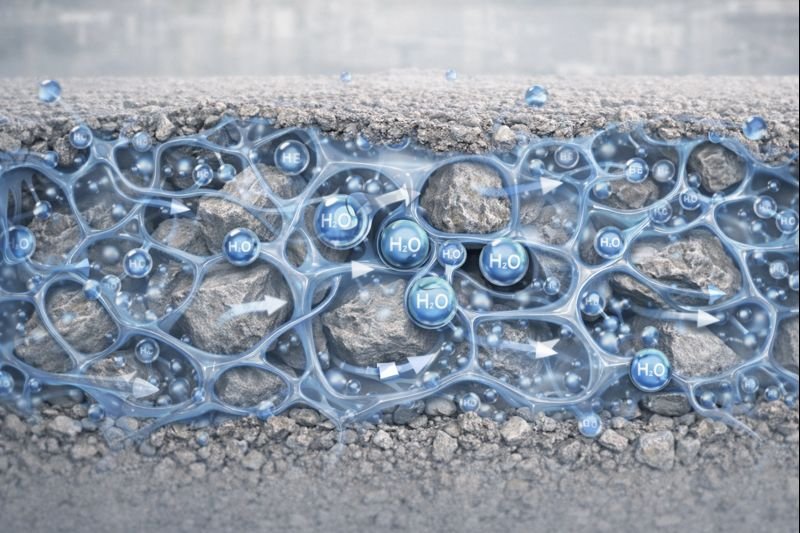

HPMC retains water in cement mortar through three primary mechanisms: physical adsorption of water molecules to its hydroxyl groups, formation of a reversible gel network that traps water, and creation of a temporary diffusion barrier that slows water movement to the surface and into porous substrates.

The water retention capability of HPMC in cement mortar systems is fascinating and multifaceted. When HPMC dissolves in water, its hydrophilic hydroxyl groups form hydrogen bonds with water molecules, creating a three-dimensional network that physically traps water. This network significantly increases the solution's viscosity, physically slowing water movement throughout the mortar matrix.

Additionally, HPMC molecules adsorb onto cement and aggregate surfaces, forming a thin polymer film. This film creates a physical barrier that reduces the rate of water loss both to the atmosphere and to porous substrates. The film's effectiveness depends greatly on the HPMC's molecular weight (viscosity) and substitution pattern.

What makes delayed HPMC superior in high temperatures is how it gradually forms this protective network. Unlike instant HPMC that immediately creates its gel structure upon water contact, delayed HPMC dissolves more gradually. This controlled dissolution means water is released more evenly throughout the cement hydration process.

The difference becomes even more pronounced when we examine what happens at the mortar-substrate interface:

| Mechanism | Instant HPMC | Delayed HPMC |

|---|---|---|

| Initial water binding | Rapid, potentially uneven | Gradual, more uniform |

| Gel network formation | Immediate, can trap dry powder | Progressive, allowing complete mixing |

| Water migration control | Good initially, but diminishes quickly | Maintains effectiveness longer |

| Cement hydration impact | May accelerate too quickly in heat | Moderates hydration rate |

| Open time in 30°C+ conditions | 15-20 minutes | 30-45 minutes |

What is the gelation temperature of HPMC?

When summer temperatures rise, conventional mortars often fail because manufacturers don't account for how heat affects HPMC gelation. This oversight can turn promising projects into costly nightmares.

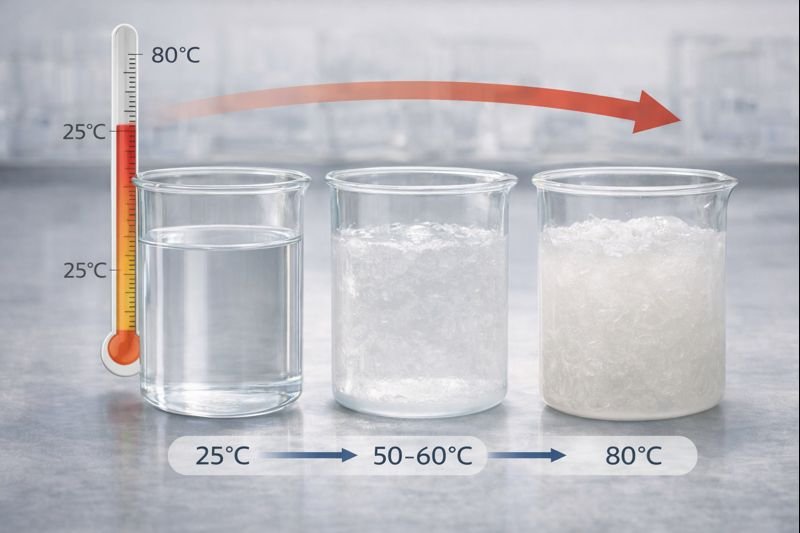

The gelation temperature of HPMC typically ranges from 60°C to 90°C (140°F to 194°F), varying based on molecular weight, methoxyl content, and hydroxypropyl substitution. Instant-type HPMC generally exhibits lower gelation temperatures (60-70°C) compared to delayed-type HPMC (70-90°C).

Gelation temperature represents a critical point in HPMC behavior that directly impacts mortar performance in high-temperature conditions. When HPMC solution reaches its gelation temperature, it undergoes a phase change from a soluble state to an insoluble gel network. This property is both beneficial and challenging, depending on application conditions.

The science behind this transformation involves the balance between hydrophilic and hydrophobic interactions. At lower temperatures, hydrogen bonding between HPMC and water molecules dominates. As temperature rises, these hydrogen bonds weaken while hydrophobic interactions between methoxyl groups strengthen, causing polymer chains to associate and form a gel network.

Different HPMC formulations show varied gelation behaviors based on their chemical structure:

- Higher methoxyl content typically lowers gelation temperature because methoxyl groups are more hydrophobic than hydroxypropyl groups

- Higher molecular weight (viscosity) HPMC generally shows stronger gelation at slightly lower temperatures

- Higher hydroxypropyl substitution tends to increase gelation temperature and weaken gel strength

In high-temperature mortar applications, a delayed-type HPMC with higher gelation temperature provides a crucial advantage. It remains fully functional at temperatures where instant-type HPMC might already be forming gel structures that impair workability.

This temperature tolerance creates a buffer zone that allows proper mortar application even when ambient temperatures approach 40°C (104°F). For contractors working in hot climates or summer conditions, this difference can mean the difference between successful application and material failure.

Conclusion

In high-temperature mortar applications, delayed-type HPMC clearly outperforms instant varieties. Its gradual dissolution mechanism provides extended workability, better water retention, and superior finish quality when temperatures soar.

FAQ

Can I mix instant and delayed HPMC to get the benefits of both?

Yes, but it requires precise formulation. I typically recommend a 30:70 ratio of instant to delayed HPMC for moderate temperatures, adjusting to 10:90 for very hot conditions.

How do I know if my HPMC is instant or delayed type?

Place a small amount in cold water. Instant HPMC will immediately form lumps and begin dissolving. Delayed HPMC will sink and remain mostly undissolved until heated.

Does delayed HPMC cost more than instant types?

Typically, delayed HPMC costs 5-10% more than instant varieties, but the superior performance in high temperatures and reduced material waste quickly offset this difference.

Can I use temperature-resistant additives instead of changing my HPMC type?

While retarders can help, they don't address the fundamental water retention issues. Delayed HPMC remains the most effective solution for high-temperature applications.

How should I adjust my mixing procedure when using delayed HPMC in hot weather?

Use cooler water (10-15°C) and mix for 30-60 seconds longer than usual to ensure complete HPMC activation while avoiding excessive air entrainment.