Are you confused about whether hydroxypropyl methylcellulose1 (HPMC) is truly plant-based? Many contractors and manufacturers face this same problem when selecting eco-friendly materials for their projects.

HPMC is plant-based as it's derived from cellulose, which comes from plant cell walls. The manufacturing process modifies natural cellulose from wood or cotton through chemical treatments to create this semi-synthetic polymer that maintains many of its original plant-based properties.

When I first started supplying HPMC to construction companies across developing markets, I noticed widespread confusion about its origins. Let's clear up the misconceptions and dive deeper into what HPMC really is, where it comes from, and how it's made.

What is HPMC Made From?

Do you worry that the building materials you're using might contain harmful synthetic chemicals? This is a valid concern I hear from many of my customers in the UAE and Saudi Arabia.

HPMC is made from cellulose extracted from natural plant sources like wood pulp or cotton. This natural cellulose undergoes chemical modification with propylene oxide and methyl chloride to create hydroxypropyl methylcellulose, maintaining its plant-derived foundation.

The journey of HPMC begins in sustainable forestry operations or cotton fields. In our factory, we primarily source our cellulose from carefully managed wood pulp suppliers. The cellular structure of plants contains cellulose, which makes up about 40-50% of wood's composition.

When customers like Mark from Saudi Arabia visit our production facility, they're often surprised to see pallets of wood pulp as the starting material for our HPMC. The process transforms this natural material into a versatile building product used worldwide.

The modification process doesn't completely change the fundamental plant-based nature of the cellulose. Instead, it enhances certain properties to make it more useful in applications ranging from construction to pharmaceuticals and food products.

Key Sources of HPMC Raw Materials:

| Source | Cellulose Content | Advantages |

|---|---|---|

| Softwood | 40-45% | Widely available, sustainable |

| Hardwood | 38-49% | Higher purity possible |

| Cotton | 90-95% | Highest natural cellulose content |

Is HPMC a Natural Polymer?

Have you been told conflicting information about whether HPMC qualifies as a natural material? This confusion often leads to hesitation when selecting additives for environmentally conscious building projects.

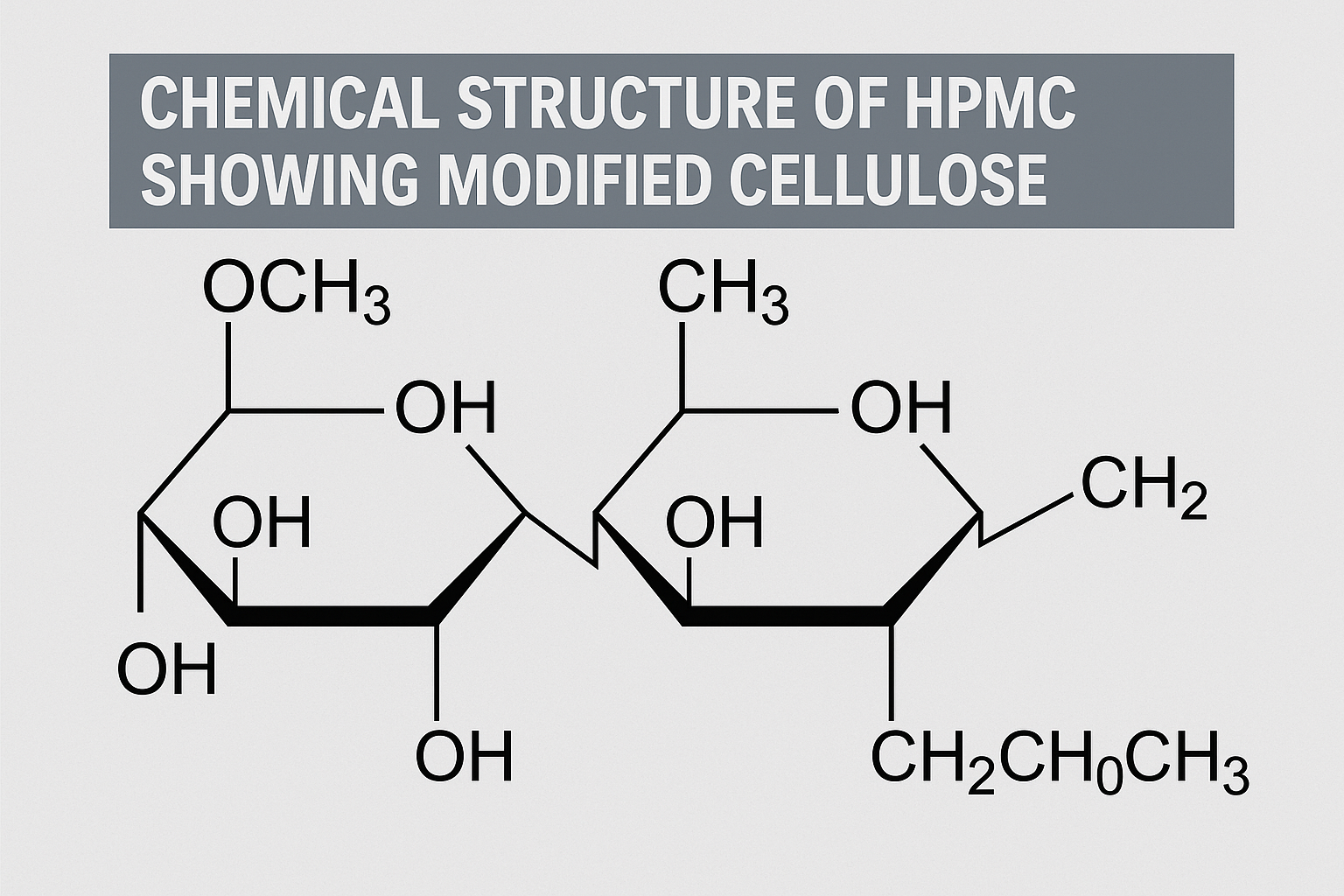

HPMC is a semi-synthetic polymer2, not a fully natural polymer. While its base material (cellulose) is completely natural and plant-derived, the chemical modifications make it a cellulose ether that combines natural origins with synthetic enhancements.

I remember explaining this concept to a large paint manufacturer from India who was specifically looking for natural additives. The distinction is important: HPMC starts as a natural polymer (cellulose) but undergoes chemical modification3 that changes its structure and properties.

The modification process involves substituting hydroxyl groups in the cellulose molecule with methoxy and hydroxypropyl groups. This transformation creates a compound that retains some of its natural characteristics while gaining new properties like improved water solubility and thermal gelation ability.

When compared to fully synthetic polymers made from petroleum derivatives, HPMC stands out with its renewable source material. This makes it a preferred choice for environmentally conscious projects4, even though it's not 100% natural in its final form.

HPMC Classification in the Polymer Spectrum:

| Polymer Type | Origin | Processing | Environmental Impact |

|---|---|---|---|

| Natural Polymers | Directly from nature | Minimal processing | Lowest impact |

| Semi-synthetic (HPMC) | Natural sources | Chemical modification | Moderate impact |

| Synthetic Polymers | Petroleum/chemical | Complete synthesis | Higher impact |

Is HPMC Organic?

Are you trying to determine if HPMC meets organic standards for your building materials or products? This question frequently comes up when regulatory compliance and marketing claims are at stake.

HPMC is not certified organic as it undergoes chemical processing that modifies its natural cellulose structure. While its source material is plant-based, the chemical modifications prevent it from qualifying as organic under most standard certification programs.

During a recent building materials exhibition in Dubai, I had several conversations with manufacturers looking to create "organic" product lines. The term "organic" has specific meanings in regulatory contexts, typically requiring materials to be produced without synthetic chemicals or modifications.

The chemical processing that transforms cellulose into HPMC1 involves reactions with propylene oxide and methyl chloride—both synthetic chemicals. These reactions permanently alter the molecular structure of the cellulose, creating ether linkages that weren't present in the original organic material.

However, HPMC can still be part of environmentally responsible building practices. Many of our customers in sustainable construction fields choose HPMC because, despite not being organic, it's still derived from renewable resources and offers performance advantages with less environmental impact than fully synthetic alternatives.

HPMC and Environmental Certifications:

| Certification | HPMC Qualification | Reason |

|---|---|---|

| Organic | No | Chemical modification process |

| Bio-based Material | Yes | Plant-derived source material |

| VOC-free | Yes (typically) | No volatile organic compounds |

| Renewable Material | Partially | Renewable source, synthetic processing |

How is HPMC Manufactured?

Have you wondered about the actual production process that transforms natural wood pulp into the white HPMC powder used in your construction materials? Many customers are curious about this transformation when they see our finished product.

HPMC5 is manufactured through a multi-step industrial process including alkalization of cellulose with sodium hydroxide, followed by etherification using methyl chloride and propylene oxide under controlled conditions. The resulting product is then purified, neutralized, dried, and milled into the final powder.

I've guided many visitors through our production facility in China, and they're always fascinated by the transformation process. Our six production lines operate continuously to meet global demand, following these main manufacturing steps:

First, raw cellulose fibers undergo an alkali treatment with sodium hydroxide6 (caustic soda), which activates the cellulose by breaking hydrogen bonds and making it more reactive. This activated cellulose, called alkali cellulose, then reacts with methyl chloride to introduce methoxy groups and propylene oxide to add hydroxypropyl groups to the cellulose backbone.

After the etherification reaction, the crude HPMC undergoes several purification steps including washing, neutralization, and filtration to remove byproducts and unreacted chemicals. The purified material is then dried in specialized dryers and milled to specific particle sizes based on customer requirements.

The entire manufacturing process is carefully controlled for quality and consistency. Variables like reaction temperature, concentration of reagents, and reaction time all affect the final properties of the HPMC, including viscosity, substitution degree, and gelation temperature.

HPMC Manufacturing Process Parameters:

| Process Stage | Critical Parameters | Quality Impact |

|---|---|---|

| Alkalization | NaOH concentration, temperature | Reactivity of cellulose |

| Etherification | Reagent ratios, reaction time | Substitution degree, solubility |

| Purification | Washing efficiency, pH control | Purity, stability |

| Drying & Milling | Temperature, particle size control | Flow properties, dissolution rate |

One key advantage of our manufacturing setup is the ability to customize HPMC properties7 for specific applications. For construction applications, we typically optimize for water retention and workability, while pharmaceutical grades require different specifications for viscosity and gelation temperature.

Conclusion

HPMC is a plant-based, semi-synthetic polymer derived from natural cellulose but modified through chemical processes. While not organic, it provides an environmentally friendlier alternative to fully synthetic additives in construction materials and other applications.

-

Explore this link to understand the origins and properties of HPMC, clarifying its plant-based nature and applications. ↩ ↩

-

Learn about semi-synthetic polymers, their characteristics, and their applications in sustainable materials. ↩

-

Learn about chemical modification processes in polymers to grasp how they enhance properties and applications in various industries. ↩

-

Discover how environmentally conscious projects are shaping the future of manufacturing and promoting sustainability in various sectors. ↩

-

Explore this link to understand HPMC's role in construction and its benefits for sustainable building practices. ↩

-

Learn about the crucial role of alkali treatment in enhancing cellulose reactivity and its impact on manufacturing processes. ↩

-

Discover the methods used to tailor HPMC properties for specific needs in construction and pharmaceuticals. ↩