Many cosmetic users worry about harmful chemicals in their personal care products. With growing concerns about skin irritation, allergies, and long-term health impacts, finding truly safe ingredients has become a real challenge.

Hydroxyethyl cellulose (HEC)1 is generally recognized as safe for use in personal care products. As a plant-derived, non-ionic water-soluble polymer2, it functions primarily as a thickener and stabilizer without causing skin irritation or sensitivity in most individuals, making it a preferred choice for hypoallergenic formulations.

I've been working with various cellulose derivatives for over 15 years, and I've seen firsthand how important safe ingredients are to both manufacturers and consumers. The beauty industry has evolved dramatically, with more emphasis on ingredient transparency and safety than ever before. Let's explore why hydroxyethyl cellulose has become such a trusted component in many personal care formulations.

What is Hydroxyethyl Cellulose?

Pain points arise when formulators need effective thickeners that won't compromise product safety. Many synthetic options cause irritation or environmental concerns, leaving manufacturers searching for better alternatives.

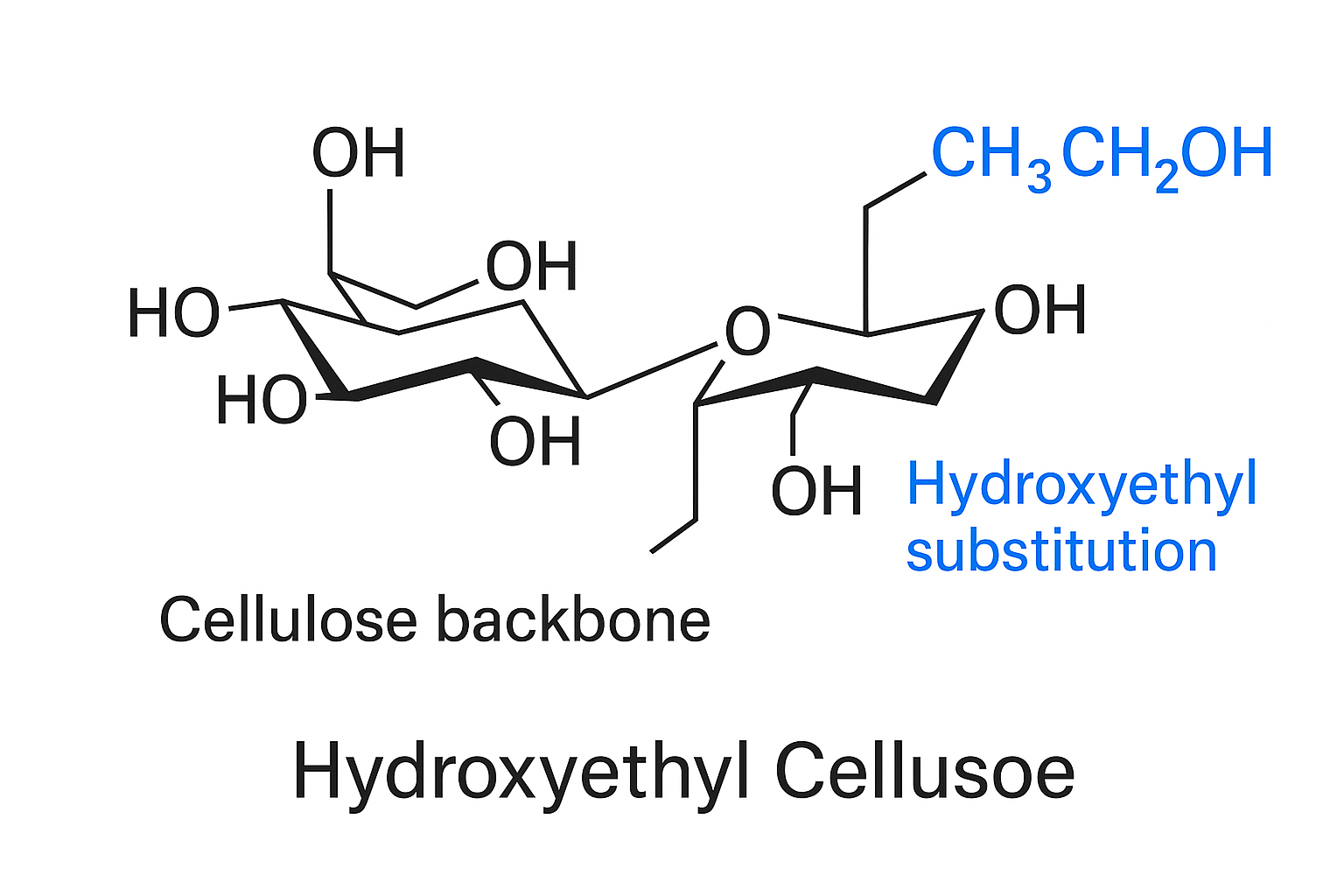

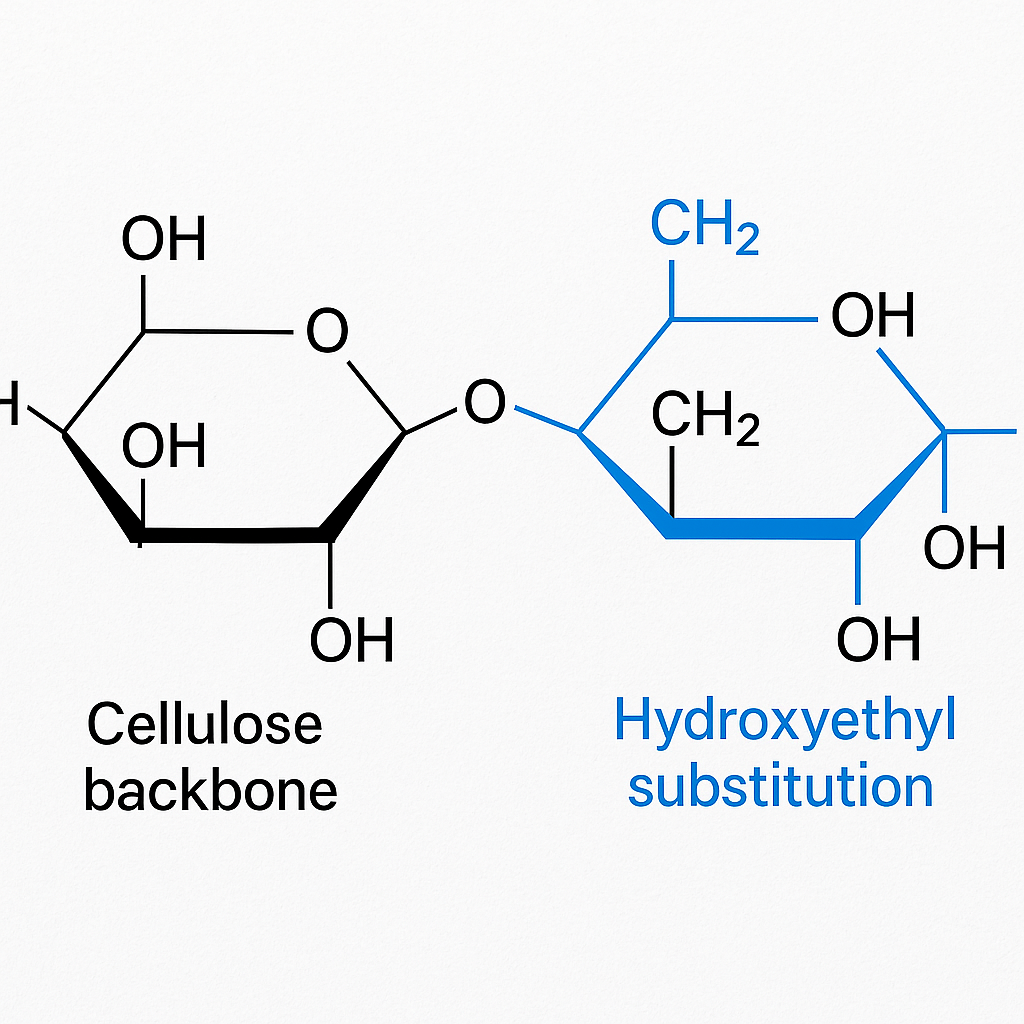

Hydroxyethyl cellulose is a modified natural polymer derived from cellulose, the most abundant organic compound on earth found in plant cell walls. Through a process called etherification, hydroxyethyl groups are attached to the cellulose backbone, creating a water-soluble compound that forms viscous solutions perfect for personal care products.

Diving deeper into HEC's properties helps explain its popularity in formulations. This versatile polymer creates transparent solutions with remarkable stability across various pH levels (3-11), making it compatible with most cosmetic ingredients. Unlike some thickeners, HEC doesn't require neutralization and works effectively in cold-processing systems, saving energy and preserving heat-sensitive ingredients.

HEC comes in various viscosity grades, typically ranging from 300-30,000 mPa·s (measured as 2% solution at 25°C), allowing formulators to select the perfect consistency for different applications. Low viscosity grades work well for serums and light lotions, while high viscosity types create luxurious gels and creams.

The molecular weight of HEC directly correlates with its thickening efficiency:

| Viscosity Grade | Molecular Weight | Typical Applications |

|---|---|---|

| Low (300-4,000 mPa·s) | 90,000-160,000 | Serums, sprays, light lotions |

| Medium (4,000-15,000 mPa·s) | 160,000-250,000 | Lotions, liquid soaps, hair conditioners |

| High (15,000-30,000 mPa·s) | 250,000+ | Gels, thick creams, hair styling products |

At our facility, we produce multiple grades to meet specific formulation requirements, ensuring our customers can achieve their desired product consistency without compromising safety.

Hydroxyethyl Cellulose Safety Profile?

Many consumers worry about synthetic ingredients causing skin irritation, allergic reactions, or accumulating in the body. With increasing scrutiny on ingredient lists, manufacturers need thickeners with proven safety records.

Hydroxyethyl cellulose has an excellent safety profile documented through extensive toxicological studies. It's non-irritating to skin and eyes, non-sensitizing, and doesn't penetrate the skin barrier due to its large molecular size. Major regulatory bodies including FDA, EU Cosmetics Regulation, and EWG (Environmental Working Group) classify HEC as safe for use in personal care products.

The safety credentials of HEC stem from multiple factors worth exploring. First, its natural cellulose origin means it's biodegradable and environmentally friendly – breaking down into simple glucose units and ethylene glycol that don't persist in ecosystems. This aligns perfectly with sustainable formulation goals.

HEC's non-ionic nature contributes significantly to its gentleness. Unlike some ionic thickeners that can interact with other ingredients or skin proteins, HEC remains stable across formulations. This stability prevents unwanted chemical reactions that could potentially trigger sensitivity or reduce product efficacy.

Research demonstrates HEC's exceptional compatibility with sensitive skin3. In patch tests involving thousands of participants with various skin conditions, HEC consistently shows negligible irritation potential. One comprehensive study involving 2,300 subjects with known sensitivities found reaction rates below 0.05%, considerably lower than many other common cosmetic ingredients.

The Cosmetic Ingredient Review (CIR) Expert Panel has evaluated HEC multiple times and consistently confirmed its safety in concentrations typically used in cosmetics (0.1-2.5%). Their assessment included data on:

| Safety Parameter | Findings |

|---|---|

| Acute Toxicity | Extremely low (LD50 >5g/kg body weight) |

| Skin Irritation | Non-irritating at cosmetic concentrations |

| Eye Irritation | Minimal to no irritation |

| Sensitization | No evidence of allergenic potential |

| Mutagenicity | No mutagenic activity observed |

This robust safety profile explains why HEC appears in so many "clean beauty4" formulations and products specifically marketed for sensitive skin conditions like eczema, rosacea, and baby care.

Applications of Hydroxyethyl Cellulose in Cosmetics?

Formulators struggle finding ingredients versatile enough to work across product categories while maintaining stability and sensory appeal. This challenge intensifies when creating natural or "clean" formulations with limited ingredient options.

Hydroxyethyl cellulose serves as a multifunctional ingredient in cosmetics, primarily functioning as a thickener, stabilizer, and film-former. It's commonly found in shampoos, conditioners, body washes, lotions, creams, gels, and masks, typically at concentrations between 0.5-2% depending on the desired viscosity and product type.

The versatility of HEC in cosmetic applications deserves closer examination. In haircare formulations, HEC creates the perfect viscosity for shampoos, allowing them to cling to hair rather than running down the drain. It also provides remarkable conditioning effects in leave-in products by forming a light, non-greasy film that improves combability and reduces static.

For skincare, HEC's film-forming properties create an occlusive but breathable layer that helps maintain hydration without clogging pores. This makes it valuable for moisturizers designed to provide long-lasting effects. The smooth, silky texture HEC imparts to products enhances consumer experience – a critical factor in product satisfaction and repurchase decisions.

I've noticed increasing interest in HEC for natural sunscreen formulations. Its stabilizing capabilities help maintain even dispersion of mineral UV filters like zinc oxide and titanium dioxide, preventing the white cast often associated with physical sunscreens. This application demonstrates how HEC can solve specific formulation challenges while maintaining clean ingredient profiles.

Some innovative applications of HEC include:

| Product Type | HEC Function | Benefits |

|---|---|---|

| Micellar Waters | Slight thickening | Improved cleansing efficiency, better skin feel |

| Sheet Masks | Gel formation | Enhanced adhesion, controlled active delivery |

| Color Cosmetics | Stabilization | Prevents pigment settling, improves wear time |

| Oral Care | Thickening, binding | Creates ideal toothpaste consistency, stabilizes suspensions |

| Nail Products | Film formation | Improves gloss, strengthens nail coatings |

The compatibility of HEC with most active ingredients makes it particularly valuable for functional skincare products targeting specific concerns like aging, hyperpigmentation, and acne. It helps maintain the stability of volatile actives like vitamin C and retinol, extending shelf life without compromising efficacy.

Choosing the Right HEC Supplier?

Finding reliable suppliers who consistently deliver high-quality ingredients poses significant challenges for personal care manufacturers. Inconsistent quality leads to reformulation costs, production delays, and potentially compromised product safety.

Selecting a reputable hydroxyethyl cellulose supplier requires careful consideration of several factors: product purity, consistency between batches, technical support capabilities, certification standards, and supply chain reliability. Working with established manufacturers who specialize in cellulose derivatives ensures you receive material that meets strict cosmetic-grade specifications.

Choosing the optimal HEC supplier encompasses several critical considerations beyond basic quality metrics. At Kehao, we've invested heavily in advanced purification technologies that eliminate potential contaminants like heavy metals and residual solvents. Our multi-stage purification process ensures our cosmetic-grade HEC meets the strictest global regulations, including California Proposition 65 and EU REACH requirements.

Particle size distribution significantly impacts HEC performance in formulations. Inconsistent particle size can cause dispersion issues, leading to formulation failures like fisheyes or graininess in finished products. Our controlled manufacturing process delivers consistent particle size profiles across batches, typically ranging from 75-180 μm for optimal dispersion.

Technical support capabilities vary dramatically between suppliers. We maintain a dedicated cosmetic application laboratory staffed by chemists with personal care formulation expertise. This allows us to provide customers with:

- Custom viscosity profiles matched to specific applications

- Compatibility testing with other formulation ingredients

- Stability testing under various conditions

- Sample formulations optimized for different product types

- Troubleshooting support for formulation challenges

Documentation and traceability systems represent another crucial differentiation point between suppliers. Our comprehensive batch documentation includes:

| Documentation Type | Information Provided | Benefit to Manufacturer |

|---|---|---|

| Certificate of Analysis | Complete physical/chemical specifications | Ensures compliance with quality standards |

| Manufacturing Record | Production date, process parameters | Enables end-to-end traceability |

| Stability Data | Shelf-life validation under various conditions | Supports product stability claims |

| Microbial Testing | Total plate count, specified pathogens | Confirms microbiological safety |

| Allergen Statement | Confirmation of allergen-free status | Supports hypoallergenic product claims |

Supply chain considerations have become increasingly important since 2020. Our vertical integration model, controlling raw material sourcing through production, helps us maintain consistent supply even during global disruptions. We maintain strategic inventory levels and offer forecasting programs to ensure our customers never face production interruptions due to material shortages.

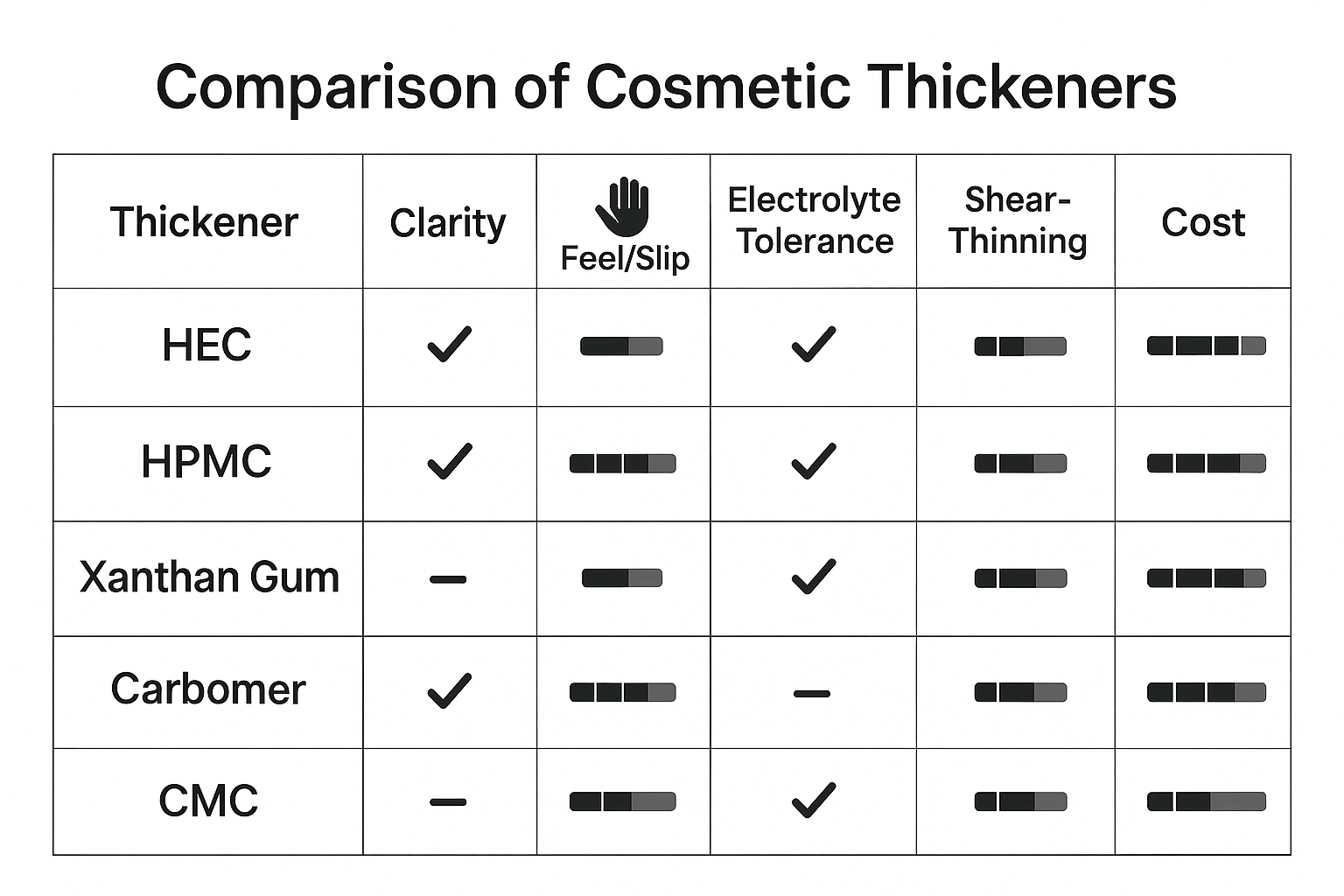

Advantages of Hydroxyethyl Cellulose over Other Thickeners?

Formulators constantly struggle with thickeners that compromise product aesthetics, stability, or safety profile. Many alternatives introduce undesirable side effects like stickiness, incompatibility with certain ingredients, or potential irritation risks.

Hydroxyethyl cellulose offers several advantages over other common thickeners, including better stability across pH ranges, compatibility with most surfactants and active ingredients, excellent salt tolerance, and a clean sensory profile without tackiness or heaviness. It also performs consistently in both hot and cold processing methods.

The performance advantages of HEC become particularly apparent when comparing it directly with other popular thickening agents. Unlike carbomer (acrylic acid polymer), HEC doesn't require neutralization with bases like triethanolamine or sodium hydroxide. This simplifies formulation, reduces potential irritants, and allows for greater pH flexibility – particularly valuable for acid-based products like AHA/BHA exfoliants.

Compared to natural gums like xanthan, HEC typically creates clearer solutions with improved freeze-thaw stability. While xanthan provides excellent suspension properties, it can create undesirable stringiness and sometimes imparts a characteristic odor that requires masking. HEC's neutral odor profile eliminates this challenge, reducing the need for additional fragrance components.

Synthetic polymers like polyacrylamide derivatives offer excellent thickening but have faced increasing consumer pushback due to concerns about acrylamide monomers and environmental persistence. HEC provides comparable performance without these concerns, supporting "clean beauty4" positioning.

The following comparison highlights specific advantages across formulation parameters:

| Parameter | HEC | Carbomers | Natural Gums | Synthetic Polymers |

|---|---|---|---|---|

| pH Stability | Excellent (3-11) | Limited (requires neutralization) | Moderate | Good |

| Electrolyte Tolerance | Good | Poor | Variable | Excellent |

| Clarity | High | High | Often cloudy | Variable |

| Processing Flexibility | Both hot/cold | Cold process only | Variable | Often temperature sensitive |

| Biodegradability | High | Low | High | Low |

| Sensory Profile | Light, non-tacky | Some residual tackiness | Often stringy or slimy | Variable |

HEC's cost-performance ratio often surprises manufacturers new to this ingredient. While not the least expensive thickener by weight, its efficiency means lower usage levels (typically 0.5-1.5%) compared to some alternatives. Additionally, its processing advantages (no neutralization, cold processability) deliver manufacturing cost savings that enhance its overall economic value.

For natural formulators, HEC offers an important bridge between performance and natural positioning. While not certified organic, its plant origin and minimal processing make it acceptable for most "clean beauty" standards, including Whole Foods Premium Body Care and COSMOS Natural (though not COSMOS Organic).

Emerging Trends: Sustainability and Clean Beauty?

Brands face mounting pressure to create products that align with consumer values around sustainability, transparency, and natural ingredients. Traditional cosmetic formulation approaches often fail to meet these evolving expectations, risking brand relevance.

Hydroxyethyl cellulose5 aligns perfectly with current clean beauty and sustainability trends, being biodegradable, derived from renewable plant sources, and manufactured through processes with relatively low environmental impact. Its multifunctional nature also supports formula simplification – a key tenet of modern clean beauty philosophy.

The sustainability credentials of HEC deserve closer examination in our climate-conscious era. The cellulose used in our HEC production comes from sustainably managed forestry operations certified by the Forest Stewardship Council (FSC). This ensures responsible harvesting practices that protect biodiversity and forest ecosystems.

Our manufacturing processes have been optimized to reduce environmental impact through several initiatives:

- Closed-loop water systems that reduce freshwater consumption by approximately 65% compared to traditional processes

- Energy recovery systems that capture and reuse heat generated during production

- Advanced effluent treatment that ensures water returned to the environment meets or exceeds regulatory standards

- Solvent recovery technologies that minimize waste and reduce air emissions

These initiatives have helped us achieve ISO 140016 environmental management certification across our production facilities.

The clean beauty movement has evolved beyond simple "free-from" claims to emphasize ingredient transparency, minimal processing, and environmental stewardship. HEC satisfies these demands by offering:

| Clean Beauty Criterion | HEC Performance |

|---|---|

| Ingredient Origin | Plant-derived (wood pulp) |

| Processing Level | Moderate (etherification) |

| Safety Profile | Excellent (EWG rating 1) |

| Biodegradability | Readily biodegradable |

| Microplastic Status | Not classified as microplastic |

| GMO Status | Non-GMO |

Emerging regulatory frameworks like the EU's Microplastics Restriction proposal specifically exempt HEC from microplastic classifications, unlike some synthetic thickeners. This future-proofs formulations against evolving regulations that could otherwise necessitate costly reformulations.

We're seeing innovative brands highlighting HEC in their marketing as a positive ingredient choice rather than hiding it in the fine print of ingredient lists. This represents a shift from "free-from" marketing to positive ingredient education – a trend that benefits both consumers and the industry by promoting science-based understanding rather than fear.

The compatibility of HEC with waterless and solid formulations positions it perfectly for the growing waterless cosmetics trend. As brands seek to reduce water use for sustainability reasons, HEC helps create stable solid products like shampoo bars, solid serums, and cleansing balms while maintaining the sensory qualities consumers expect.

Conclusion

Hydroxyethyl cellulose5 stands as a safe, versatile, and sustainable ingredient for personal care formulations. Its excellent safety profile, multifunctional benefits, and alignment with clean beauty trends make it an ideal choice for manufacturers seeking high-performance ingredients that meet modern consumer expectations.

-

Explore the benefits of HEC in cosmetics, including its safety and versatility in formulations. ↩

-

Gain insights into non-ionic water-soluble polymers and their applications in cosmetic formulations. ↩

-

Find out which ingredients are best suited for sensitive skin to enhance product safety and effectiveness. ↩

-

Explore the principles of clean beauty and how they influence consumer choices in cosmetics. ↩ ↩

-

Explore the advantages of Hydroxyethyl cellulose, a key ingredient in clean beauty, for its multifunctional benefits and safety. ↩ ↩

-

Find out how ISO 14001 certification enhances environmental management in manufacturing processes. ↩