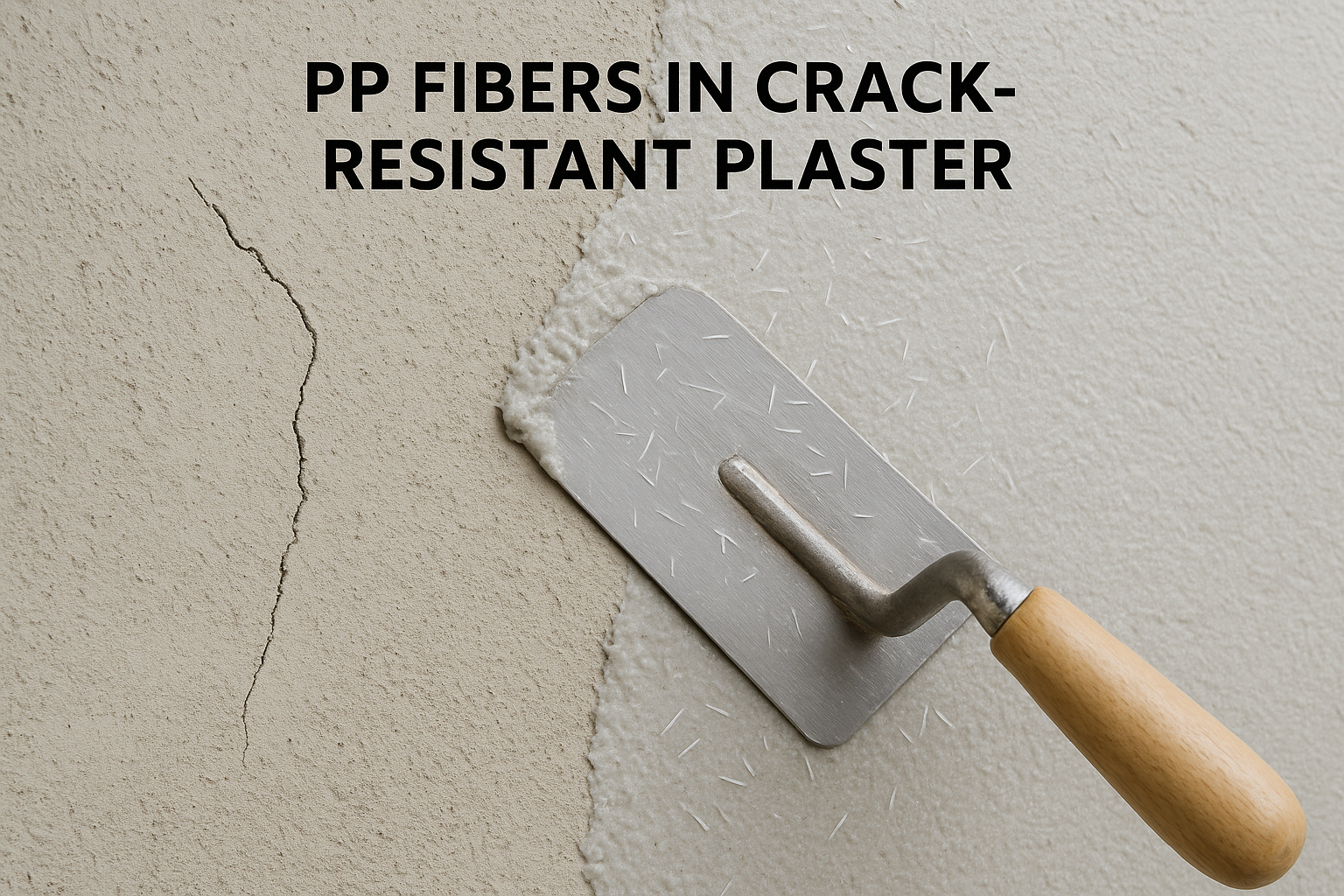

Cracked plaster surfaces lead to costly repairs, unhappy clients, and damaged reputation. Adding polypropylene fibers to your plaster mix could be the simple preventative solution you've been overlooking.

Polypropylene fibers1 act as microscopic reinforcement in plaster, creating an internal structure that prevents early shrinkage cracks by distributing tension forces throughout the entire mixture while maintaining workability and strength.

As professional contractors, we're always looking for cost-effective ways to improve our work quality and reduce callbacks. I've been using PP fibers for years in my projects, and the difference in durability is remarkable. Let me share what I've learned about this game-changing additive.

What are the different types of polypropylene fibers?

Choosing the wrong fiber type can waste money and compromise your plaster's integrity. Understanding the differences helps ensure optimal performance for your specific application.

Polypropylene fibers1 come in three main types: monofilament (single strand), multifilament (bundled strands), and fibrillated (net-like). Each type offers different benefits for crack resistance, with lengths typically ranging from 3mm to 19mm and varying diameters.

Diving deeper into polypropylene fiber types reveals important distinctions that affect performance in plaster applications. Monofilament fibers are individual strands that distribute evenly throughout the mix, providing consistent three-dimensional reinforcement. They excel at preventing plastic shrinkage cracks that form during the critical first 24 hours of curing. Multifilament fibers consist of multiple strands bundled together, offering increased tensile strength and better performance for reducing settlement cracks. Fibrillated fibers feature a unique mesh-like structure that creates superior bonding with the plaster matrix.

The fiber length also significantly impacts performance. Shorter fibers (3-6mm) distribute more uniformly and work best in thin plaster applications, while longer fibers (12-19mm) provide enhanced structural reinforcement for thicker applications. Most contractors find that 6-12mm fibers offer the ideal balance for standard plastering work. The diameter of fibers (measured in deniers or microns) affects both workability and reinforcement capability—thinner fibers provide more individual strands per weight but may be more difficult to disperse properly.

| Fiber Type | Ideal Length | Best Applications | Key Benefits |

|---|---|---|---|

| Monofilament | 6-12mm | Thin plaster coats | Even distribution, early crack prevention |

| Multifilament | 12-19mm | Thicker applications | Higher tensile strength |

| Fibrillated | 12-19mm | Load-bearing plaster | Superior bonding, structural reinforcement |

What fiber is used in plaster?

When plaster starts cracking, contractors often face angry customers and expensive fixes. Choosing the right fiber type for your specific plaster application is critical.

While various fibers can be used in plaster including glass, cellulose, and synthetic options, polypropylene fibers are most commonly preferred due to their excellent alkali resistance, cost-effectiveness, and superior ability to prevent shrinkage cracks without affecting workability.

The plaster environment presents unique challenges for reinforcing fibers. The highly alkaline nature of cement-based plasters (with pH levels often exceeding 12) quickly degrades many fiber types, but polypropylene remains chemically inert in these conditions, maintaining its reinforcing properties throughout the plaster's lifetime. This is crucial because fiber deterioration can actually create weak points rather than reinforcement.

While glass fibers offer excellent initial strength enhancement, they tend to become brittle over time in alkaline environments unless specially alkali-resistant formulations are used (which significantly increases cost). Natural fibers like cellulose provide good workability but decompose over time, potentially creating voids. Steel fibers, while extremely strong, are generally too heavy and rigid for plaster applications, potentially causing application difficulties and surface rust problems.

The specific plaster application also determines optimal fiber choice. For interior decorative plaster, finer polypropylene fibers (3-6mm) prevent unsightly surface cracks without affecting the finish quality. For external renders exposed to temperature fluctuations, longer polypropylene fibers (12-19mm) provide the necessary dimensional stability. Base coat plasters benefit from fibrillated polypropylene fibers that create stronger mechanical bonding with subsequent layers.

| Fiber Type | Alkali Resistance | Surface Finish Impact | Cost Efficiency | Shrinkage Control |

|---|---|---|---|---|

| Polypropylene | Excellent | Minimal | High | Excellent |

| Glass | Poor (unless AR-grade) | Low | Medium | Good |

| Cellulose | Poor | Medium | Medium | Fair |

| Steel | Good | High | Low | Good |

Does fiber keep concrete from cracking?

Contractors often hesitate to add fibers, questioning whether the extra step and cost truly deliver results. Will fibers actually prevent those frustrating client callbacks for crack repairs?

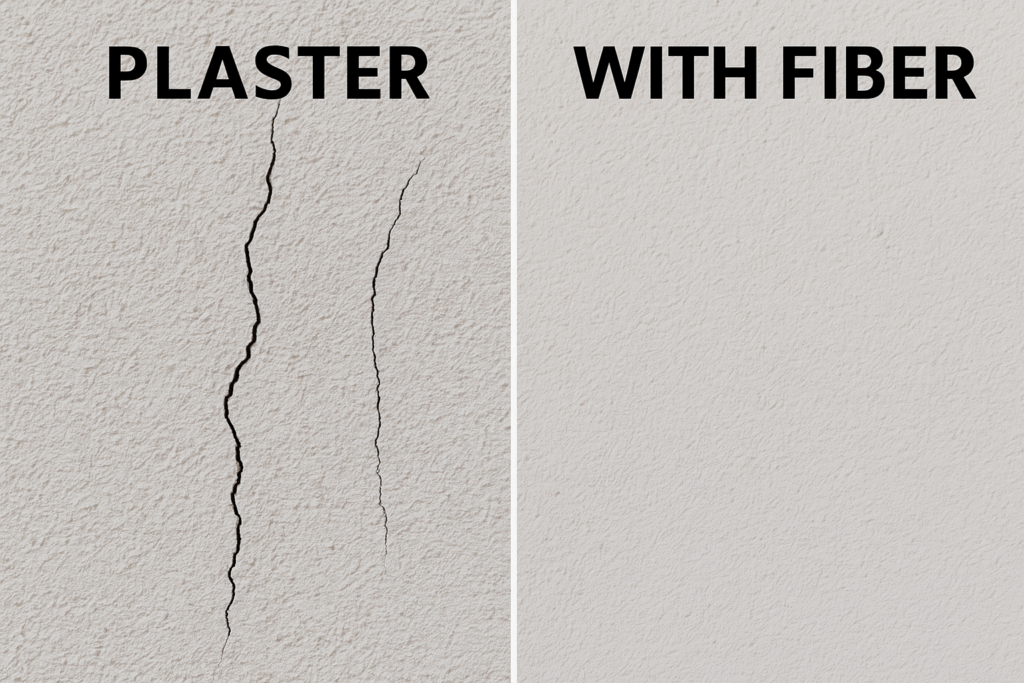

Yes, fibers significantly reduce cracking in concrete and plaster by absorbing tensile stresses that occur during drying and curing, with studies showing up to 80% reduction in early-age shrinkage cracking when properly incorporated at recommended dosages of 0.5-1.5 kg/m³.

Understanding the science behind crack formation helps explain why polypropylene fibers are so effective. As plaster dries, water evaporates creating internal tension forces that pull the material apart. Without reinforcement, these forces concentrate at weak points, resulting in visible cracks. Polypropylene fibers1 create millions of tiny bridges across these potential crack points, distributing tension forces throughout the entire matrix rather than allowing them to concentrate.

The effectiveness of PP fibers depends critically on proper mixing and dosage. In my experience, the most common mistake contractors make is improper dispersion. To maximize crack prevention, I always follow the "dry mix first" technique—combining fibers with dry components for 2-3 minutes before adding water ensures even distribution. When fibers clump together (often visible as "hairy" spots in the mix), they create weak points rather than reinforcement.

Dosage precision matters tremendously. Too little fiber (below 0.5 kg/m³) provides insufficient crack protection, while excessive amounts (above 1.5 kg/m³) can reduce workability and actually decrease strength. I've found that 0.9 kg/m³ offers optimal balance for most plastering work. Temperature and humidity conditions also impact effectiveness—in hot, dry environments where evaporation happens quickly, increasing the dosage by 25% significantly improves results.

| Crack Type | PP Fiber Effectiveness | Optimal Fiber Length | Additional Measures |

|---|---|---|---|

| Plastic Shrinkage | Very High (80%+ reduction) | 6-12mm | Proper curing |

| Settlement Cracks | High (60-70% reduction) | 12-19mm | Proper substrate preparation |

| Thermal Cracks | Moderate (30-40% reduction) | 12-19mm | Control joints still needed |

| Structural Cracks | Limited | N/A | Requires structural solutions |

What is the price of polypropylene fiber per kg?

Adding cost to a project always raises questions from clients. How can you justify this extra expense when bidding on competitive projects?

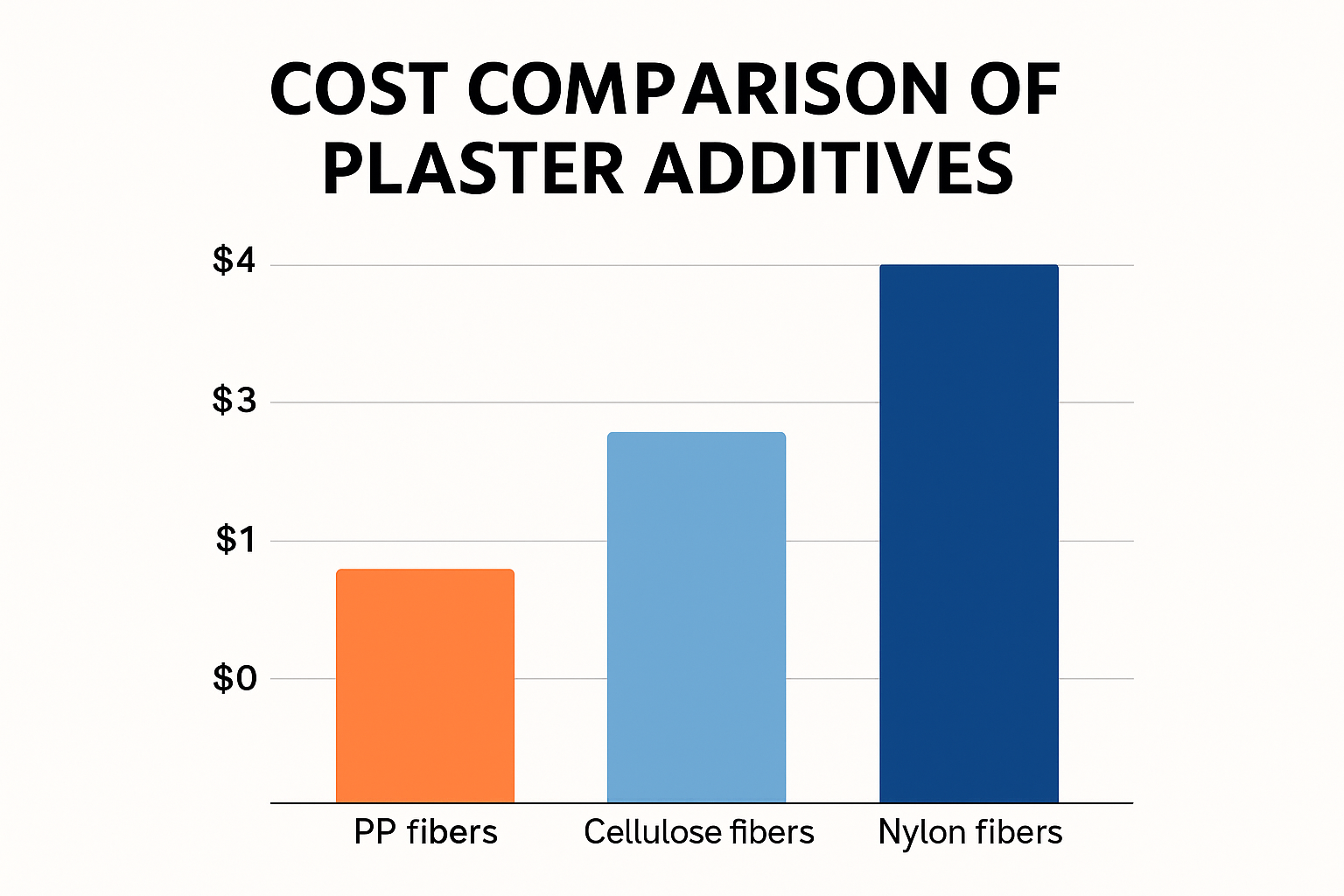

Polypropylene fiber typically costs between $2.50-$5.00 per kilogram depending on quality, type, and purchase volume, translating to approximately $0.03-$0.07 of additional cost per square meter of plaster—a minimal investment compared to crack repair expenses.

The economics of using polypropylene fibers becomes compelling when viewed through the lens of risk management rather than simply material costs. Let's break down the real numbers: At a typical dosage of 0.9 kg/m³ and a 10mm plaster thickness, each square meter requires approximately 0.009 kg of fiber. Even using high-quality fibers at $5/kg, this adds only $0.045 per square meter to your material costs—essentially "insurance" against future problems.

The true cost comparison becomes clear when considering the alternatives. A single callback to repair cracks typically costs a minimum of $150-200 when accounting for labor, materials, and transportation—equivalent to the fiber cost for over 4,000 square meters of plaster. More significantly, the reputational damage from visible cracks can impact future business opportunities far beyond the monetary repair costs.

Quality differences between fiber products significantly impact performance. Lower-cost fibers (around $2.50/kg) often exhibit poorer dispersion characteristics, inconsistent dimensions, and lower tensile strength. I've found that mid-range products ($3.50-4.00/kg) typically offer the best value, providing reliable performance without unnecessary premium costs. Purchasing in larger quantities (25kg bags rather than 1kg packages) can reduce costs by 15-20%.

When presenting costs to clients, I frame PP fibers as a value-adding feature rather than an expense. Positioning the addition as "advanced crack-prevention technology" that demonstrates your commitment to quality workmanship allows you to potentially increase overall project pricing rather than simply absorbing the minimal cost.

| Purchase Volume | Average Price/kg | Quality Level | Value Ratio |

|---|---|---|---|

| 1kg packages | $4.50-5.00 | Standard | Low |

| 5kg packages | $3.50-4.50 | Standard | Medium |

| 25kg bulk | $2.80-3.50 | Professional | High |

| 500kg+ bulk | $2.50-3.00 | Industrial | Very High |

Conclusion

Adding PP fibers to plaster is an inexpensive insurance policy against costly cracks. With proper mixing techniques and the right dosage, you'll deliver superior results that enhance your professional reputation and justify premium pricing.