Working with PVA24881 without proper safety knowledge can lead to unnecessary risks and potentially harmful situations. Many users overlook critical handling procedures that could protect their health.

PVA24881 is safe when handled correctly, requiring basic precautions including proper PPE, adequate ventilation, correct storage between 5-35°C, and awareness of emergency procedures. Follow manufacturer guidelines and maintain a clean workspace to ensure maximum safety.

As a factory owner with six production lines, I've seen firsthand how proper safety protocols can prevent workplace incidents. Our team at Kehao has refined these practices over years of manufacturing hydroxypropyl methylcellulose and other chemical products. Let's explore the essential safety aspects of working with PVA2488.

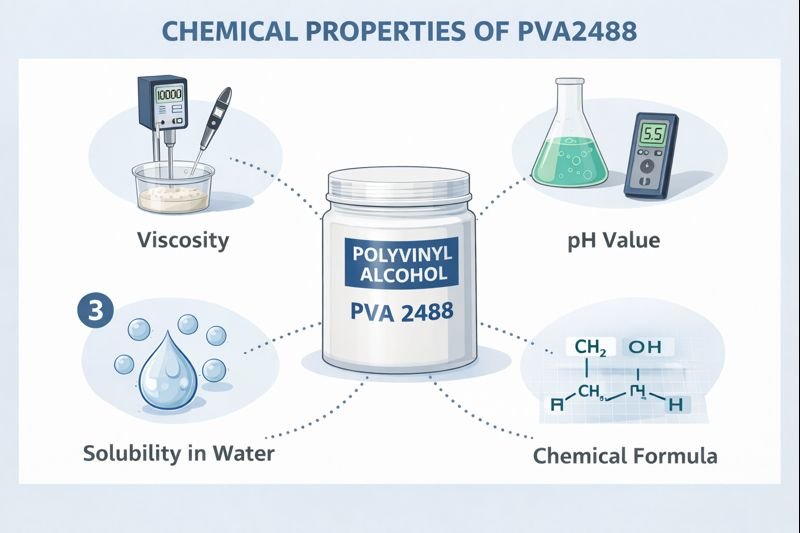

What Are the Key Properties of PVA 2488 That Impact Safety?

Many users experience handling difficulties because they don't fully understand the material's physical and chemical characteristics. This knowledge gap creates unnecessary exposure risks.

PVA24881 is a water-soluble synthetic polymer with low toxicity but potential for dust formation. Its properties include biodegradability, film-forming capability, and stability under normal conditions, though it can degrade at high temperatures above 200°C.

Understanding PVA2488's properties is critical for safe handling in industrial settings. PVA2488 is primarily valued for its excellent adhesive qualities and film-forming abilities, which make it ideal for various applications in building materials and coatings.

Key Physical Properties

| Property | Characteristic | Safety Implication |

|---|---|---|

| Physical Form | White to cream powder | Potential for dust generation |

| Solubility | Highly water-soluble | Spills can create slippery surfaces |

| Flammability | Low flammability | Relatively safe but not fireproof |

| Stability | Stable under normal conditions | Avoid extreme temperatures |

The molecular structure of PVA2488 contains hydroxyl groups that make it hydrophilic, explaining its excellent water solubility. This property is beneficial for its applications but means spills can create slippery work surfaces – a hazard I've witnessed in our own facility when a new worker improperly handled a container.

While PVA2488 has relatively low toxicity compared to many industrial chemicals, its fine particulate nature means inhalation remains a concern, especially during weighing and mixing operations. In our factory, we've implemented localized dust collection systems at transfer points to minimize this risk.

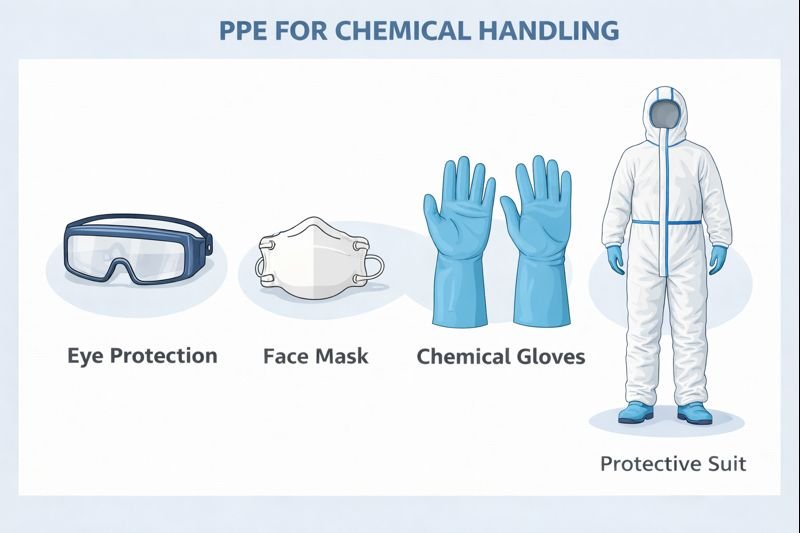

What Personal Protective Equipment (PPE) Is Essential When Handling PVA2488?

Workers often skip PPE requirements, thinking the mild nature of PVA doesn't warrant full protection. This misconception can lead to skin irritation, respiratory issues, and eye damage.

Essential PPE for PVA2488 handling includes dust masks or respirators with P2/N95 filtration, chemical-resistant gloves, safety goggles, and protective clothing to prevent skin contact and inhalation of airborne particles, especially during mixing and processing operations.

Personal protective equipment forms your first line of defense when working with PVA2488. I remember when we first started our production lines, we underestimated the importance of proper PPE - a mistake we quickly corrected after noticing minor respiratory complaints among staff.

Comprehensive PPE Strategy

Our experience has shown that different processing stages require specific PPE considerations:

| Processing Stage | PPE Requirements | Reasoning |

|---|---|---|

| Weighing & Measuring | Respirator, gloves, goggles | Highest risk of airborne particles |

| Mixing Operations | Full face shield, chemical-resistant suit, gloves | Splash protection during liquid phase |

| General Handling | Dust mask, gloves, safety glasses | Baseline protection |

| Maintenance | Complete PPE set + confined space gear if applicable | Potential for concentrated exposure |

We've found that nitrile gloves provide the best balance of dexterity and protection when handling PVA2488. Latex alternatives may degrade with prolonged chemical exposure. For respiratory protection, our teams use P2/N95 respirators during standard operations, upgrading to powered air-purifying respirators (PAPRs) for extended exposure periods or when dealing with large volumes.

During one facility inspection in our Saudi Arabian partner's factory, I noticed workers removing their eye protection during long shifts - we implemented a comprehensive training program emphasizing that even momentary PPE removal can lead to significant exposure risks.

How Should Work Spaces Be Set Up for Safe Handling of PVA2488?

Inadequate ventilation poses hidden dangers when working with PVA2488. Many workshops lack proper air extraction systems, creating pockets of dust that workers breathe throughout their shifts.

Safe workspace setup requires mechanical ventilation with 10-15 air changes per hour, dedicated mixing areas with local exhaust ventilation (LEV), anti-static flooring to prevent dust accumulation, and clearly marked emergency exits and eyewash stations within 10 seconds' reach of handling areas.

Creating a safe workspace for PVA2488 handling involves multiple engineering controls and procedural safeguards. After years of refining our production environment, I can confirm that proper ventilation might be the single most important factor in maintaining worker safety.

Our approach includes dividing the workspace into zones based on exposure risk. High-exposure areas like weighing stations and mixing points receive dedicated local exhaust ventilation with capture velocities of 0.5-1.0 m/s at the point of operation. This targeted approach has proven more effective than relying solely on general room ventilation.

Work surfaces should be smooth, non-porous, and easy to clean – we use stainless steel for most contact surfaces. Regular cleaning schedules are essential; we implement a "clean as you go" policy rather than end-of-shift cleaning to prevent dust accumulation.

Lighting plays an underappreciated role in chemical safety. In our facilities, we maintain illumination levels of at least 500 lux in processing areas to ensure operators can clearly observe material conditions and potential spills. Emergency lighting is independently powered to maintain visibility during power outages.

Temperature control also matters – we maintain ambient temperatures between 18-25°C with relative humidity between 40-60% to minimize dust formation while preventing excessive moisture that could prematurely activate the PVA2488.

What Are the Correct Storage Precautions for PVA2488?

Improper storage leads to product degradation and safety hazards. Many facilities store PVA2488 wherever space allows, exposing it to temperature fluctuations, moisture, and contamination risks.

Store PVA2488 in sealed containers in cool, dry areas (5-35°C) away from direct sunlight, moisture, and incompatible materials. Maintain inventory rotation (FIFO), keep containers closed when not in use, and follow height stacking limitations to prevent crushing or tipping hazards.

Proper storage of PVA2488 is crucial for both safety and maintaining product quality. In our facilities, we've developed comprehensive storage protocols based on years of experience and some valuable lessons learned along the way.

Temperature stability is essential – we maintain dedicated storage areas with temperature monitoring systems that alert managers if conditions drift outside the acceptable 5-35°C range. During a power outage at one of our facilities last year, we discovered the importance of backup temperature control systems to prevent product degradation.

Storage Hierarchy System

We implement a color-coded storage hierarchy:

| Zone Color | Purpose | Requirements |

|---|---|---|

| Green | Primary PVA2488 storage | Climate controlled, limited access |

| Yellow | Working inventory | 24-hour use supply, sealed containers |

| Red | Quarantine | For inspection or suspected contamination |

Humidity control is particularly important with PVA2488. Our storage areas maintain relative humidity below 60% using dehumidifiers where necessary. We learned this lesson when a batch stored near an external wall during monsoon season in our Vietnam facility absorbed moisture, leading to clumping and quality issues.

Container integrity cannot be overlooked. We use hermetically sealed containers with moisture barriers and inspect them regularly for damage. All containers are clearly labeled with product identification, batch numbers, and safety information including GHS pictograms.

For our distributors and end-users, we recommend secondary containment systems – especially in regions with extreme climate conditions like the Middle East where temperature fluctuations can be significant between day and night.

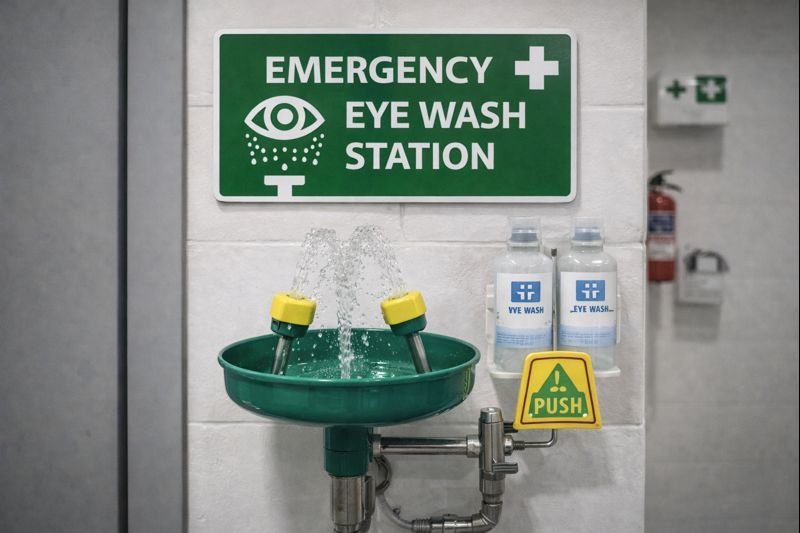

What Emergency Procedures Should Be in Place When Working with PVA2488?

Many facilities lack specific emergency protocols for PVA2488 incidents. This preparation gap can turn minor spills or exposures into major health and safety issues.

Essential emergency procedures include documented spill containment protocols, eyewash stations and safety showers within 10 seconds' reach, evacuation plans for dust release events, and training for first aid responders on specific treatments for eye/skin contact and inhalation incidents.

Being prepared for emergencies is part of responsible chemical handling. Throughout our years of manufacturing experience with materials like PVA2488, we've refined our emergency response procedures through regular drills and continuous improvement.

A comprehensive emergency plan for PVA2488 should address multiple scenarios including spills, dust releases, fires, and personal exposure incidents. We maintain emergency stations throughout our facilities with spill kits containing absorbent materials, neutralizing agents, personal protective equipment, and detailed response instructions.

For exposure incidents, the first moments are critical. Our emergency protocols specify:

| Exposure Type | Immediate Response | Secondary Actions |

|---|---|---|

| Eye Contact | Flush with water for 15 minutes | Seek medical attention |

| Skin Contact | Remove contaminated clothing, wash with soap and water | Monitor for irritation |

| Inhalation | Move to fresh air, administer oxygen if needed | Medical evaluation if symptoms persist |

| Ingestion | Rinse mouth, drink water, do not induce vomiting | Immediate medical attention |

Communication during emergencies must be clear and efficient. We use a combination of audible alarms and visual signals to indicate different types of emergencies, ensuring all workers understand the nature of the incident regardless of ambient noise levels.

After any incident, we conduct thorough investigations using a root cause analysis methodology. This has helped us identify procedural weaknesses – like when we discovered that language barriers among our international workforce were causing confusion during emergency drills, leading us to implement multi-language signage and instructions.

What Special Firing Safety Considerations Apply to PVA2488?

The fire behavior of PVA2488 is often misunderstood. Though not highly flammable, it can contribute to fire loads and produce toxic gases when burned, facts many users overlook.

While PVA2488 has low flammability, it requires standard fire safety measures including ABC fire extinguishers, heat source separation, dust management to prevent explosive concentrations, and evacuation plans accounting for potentially toxic combustion products like carbon monoxide.

Fire safety with PVA2488 requires understanding its specific combustion characteristics. Though less flammable than many industrial chemicals, proper precautions remain essential for facility and personnel safety.

In our production facilities, we implement comprehensive fire prevention strategies focused on elimination of ignition sources, regular electrical system inspections, and strict hot work permit systems. Our fire detection systems include both smoke and heat detectors, with particular attention paid to storage areas and processing locations where dust might accumulate.

The dust explosion pentagon – fuel, oxidizer, ignition, dispersion, and confinement – guides our fire prevention approach. We maintain dust collection systems that are properly grounded and equipped with explosion relief vents where appropriate. Regular cleaning schedules prevent dust accumulation on horizontal surfaces, which could become airborne during an emergency and create secondary explosion risks.

Our fire suppression strategy employs a layered approach:

| Fire Risk Level | Suppression Systems | Additional Measures |

|---|---|---|

| Low Risk Areas | ABC extinguishers | Training, clear signage |

| Medium Risk | Automatic sprinklers | Fire barriers, smoke control |

| High Risk | Specialized systems (e.g., clean agent) | Advanced detection, emergency response team |

During a facility expansion in our main plant, we consulted with fire protection engineers to ensure our systems accounted for the specific burn characteristics and potential combustion byproducts of PVA2488 and other materials we handle. This included modeling potential fire scenarios to optimize emergency response procedures.

What Environmental Considerations Matter When Working with PVA2488?

Environmental impacts of PVA2488 disposal often go unconsidered. Improper waste management pollutes water systems since the material, while biodegradable, can disrupt aquatic ecosystems when released in large quantities.

Environmental management2 for PVA2488 requires proper waste disposal through licensed contractors, zero discharge policies for production wastewater, dust filtration systems for air emissions, and spill containment infrastructure to prevent environmental contamination.

Environmental stewardship forms a core component of responsible PVA2488 handling. At Kehao, we've implemented comprehensive environmental management systems that go beyond basic compliance requirements.

The water-soluble nature of PVA2488 presents unique environmental challenges. While biodegradable, concentrated releases can temporarily increase biochemical oxygen demand in waterways, potentially affecting aquatic life. Our approach to wastewater management includes:

- Primary settling tanks to remove suspended solids

- Equalization basins to normalize flow and concentration

- Biological treatment optimized for polymer degradation

- Tertiary treatment including activated carbon filtration

- Regular effluent testing to verify treatment effectiveness

For solid waste containing PVA2488, we work exclusively with certified waste disposal contractors who understand the material's properties. Where possible, we implement waste minimization strategies like process optimization to reduce trim waste and rework requirements.

Air quality management focuses on particulate emissions through multi-stage filtration systems. Our dust collectors are equipped with high-efficiency filters capable of capturing particles down to PM2.5, with regular maintenance schedules to ensure optimal performance.

We also conduct periodic environmental risk assessments to identify potential improvement areas. During one such assessment, we discovered opportunities to optimize our water recycling processes, resulting in a 30% reduction in freshwater consumption at our main facility – a significant advantage in water-stressed regions where many of our customers operate.

Wanhong PVA2488: Industrial Super Cold-Resistant PVA Solution

Many manufacturers struggle with PVA products that underperform in cold environments. Traditional formulations become brittle and lose adhesion properties, causing costly failures and rework.

Wanhong PVA2488 offers superior cold temperature resistance down to -30°C while maintaining excellent adhesion and film-forming properties. This specialized formulation provides consistent performance in adverse conditions without sacrificing the safety and handling advantages of standard PVA.

Wanhong PVA2488 represents a significant advancement in polyvinyl alcohol technology3, specifically engineered to address the limitations of conventional PVA in cold environments. Through my visits to customer sites in regions like Georgia and northern China, I've witnessed the challenges posed by temperature fluctuations on construction materials.

The proprietary formulation of Wanhong PVA2488 incorporates specialized plasticizers and molecular weight distribution optimized for low-temperature flexibility. This results in films that maintain elasticity and adhesion even when exposed to temperatures as low as -30°C – critical for applications in cold regions or winter construction projects.

Performance Comparison

Our laboratory and field testing demonstrates significant advantages:

| Performance Parameter | Standard PVA | Wanhong PVA2488 |

|---|---|---|

| Cold Crack Resistance | Shows cracking at -5°C | Maintains integrity to -30°C |

| Tensile Strength Retention at 0°C | 65% of room temperature value | 91% of room temperature value |

| Adhesion at Low Temperatures | Significant reduction | Maintains >85% of optimal adhesion |

| Freeze-Thaw Stability (cycles) | 3-5 cycles | >20 cycles |

The enhanced cold resistance doesn't come at the expense of safety – Wanhong PVA2488 maintains the favorable handling characteristics of traditional PVA, including low toxicity and biodegradability. The safety guidelines outlined throughout this article apply equally to this specialized formulation.

One of our customers in Russia experienced repeated adhesion failures with traditional PVA during winter construction projects. After switching to Wanhong PVA2488, they reported zero temperature-related failures even during particularly harsh winter conditions, resulting in significant cost savings and project timeline improvements.

Conclusion

Handling PVA2488 safely requires proper PPE, ventilated workspaces, correct storage, clear emergency procedures, fire safety measures, and environmental considerations. By implementing these guidelines, you'll protect workers, facilities, and the environment while maximizing the benefits of this versatile polymer.

At Kehao, we're committed to not only providing quality products like our Wanhong PVA2488 cold-resistant solution, but also ensuring our customers understand how to handle them safely. I invite you to reach out with any specific safety questions related to your application needs.

-

Understanding safety guidelines for PVA2488 is crucial to prevent health risks and ensure safe handling in industrial settings. ↩ ↩ ↩

-

Learn about effective environmental management strategies to ensure compliance and sustainability in chemical handling. ↩

-

Stay updated on the latest advancements in polyvinyl alcohol technology for improved product performance. ↩