Builders globally face a common challenge: creating mortar1s with superior adhesion, flexibility, and durability. Traditional cement-based materials simply can't meet modern construction demands without proper modification.

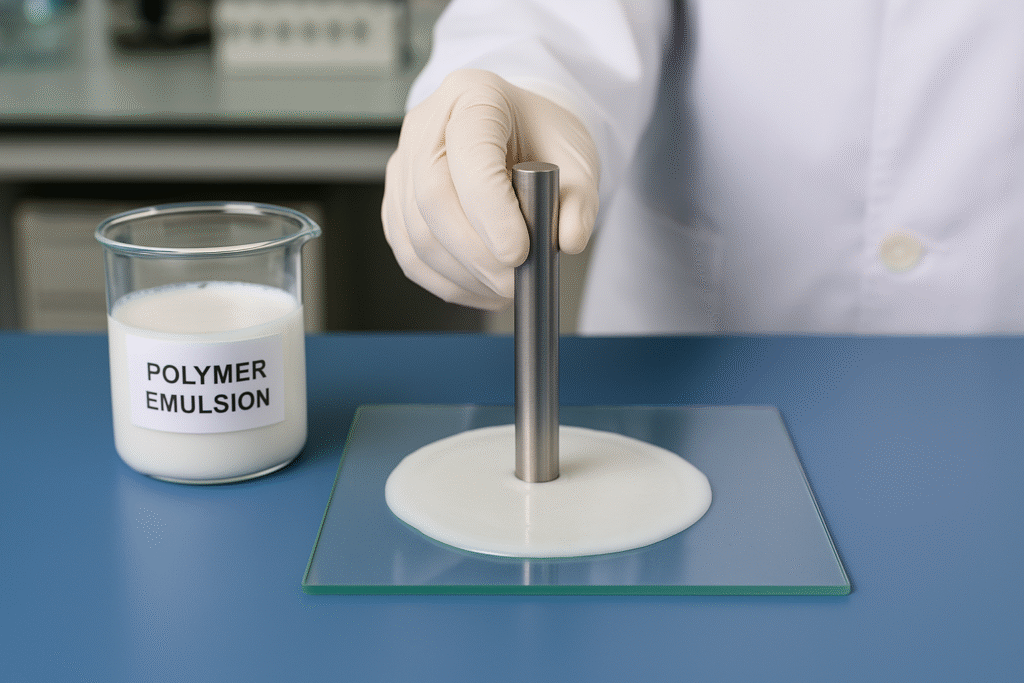

Redispersible polymer powder2 (RDP) is a spray-dried polymer emulsion that disperses back into liquid form when mixed with water, enhancing cementitious mixtures with improved adhesion, flexibility, water resistance, and workability while maintaining breathability and compatibility with cement components.

As a leading manufacturer with six production lines, I've seen firsthand how the right RDP transforms ordinary building materials into high-performance solutions. Let me walk you through the different emulsion types and how they can benefit your construction projects.

Introduction: What makes redispersible polymer powder so essential in modern construction?

Construction professionals often struggle with material failure, especially in demanding environments. Cracks, delamination, and poor water resistance can ruin projects and damage reputations.

Redispersible polymer powder2 acts as a critical modifier in dry-mix mortars3 by creating a polymer film that bridges micro-cracks while maintaining breathability. This results in dramatically improved adhesion, flexibility, workability, and water resistance in cement-based applications.

In my 15+ years producing RDP for clients across Saudi Arabia, UAE, India, and other developing markets, I've witnessed a revolution in construction practices. Traditional mortars simply cannot compete with RDP-modified systems in performance or longevity. The technology behind these powders involves complex polymer chemistry, but understanding the basic emulsion types will help you make informed decisions for your specific applications.

Emulsion Types: What forms the foundation of RDP performance?

Selecting the wrong polymer base can lead to system failure, wasted materials, and costly repairs. The underlying polymer emulsion determines how your modified mortar will perform under stress.

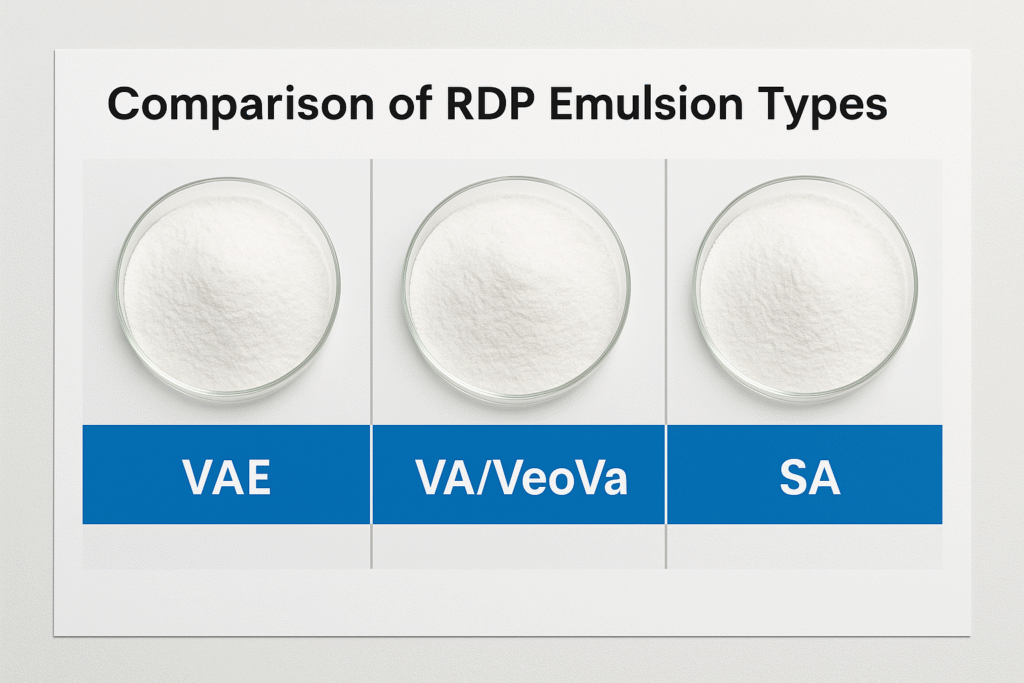

The primary emulsion types used in RDP production include polyvinyl acetate (PVAc)4, vinyl acetate-ethylene (VAE)5, acrylics, styrene-acrylics, and specialty copolymers. Each polymer base provides specific performance benefits and limitations based on its chemical structure and properties.

The emulsion type selection critically impacts your end product performance. During my factory tours with clients, I often demonstrate how different polymer bases behave in various applications. For example, when I tested samples for a client from Pakistan last year, we saw dramatic differences in water resistance between VAE and acrylic-based products. The chemistry matters tremendously, especially when your mortars must withstand extreme desert conditions or high humidity environments.

PVAc Emulsion-Based RDP: How does this traditional option perform today?

Many contractors choose the cheapest option available, only to face material failure months later. Poor bonding and water sensitivity can destroy otherwise solid workmanship.

PVAc (polyvinyl acetate) emulsion-based RDP represents the most basic and economical option, offering good adhesion in dry conditions but limited water resistance and flexibility. These limitations make pure PVAc suitable only for interior applications with minimal thermal or mechanical stress.

PVAc was among the first polymers used in RDP production due to its simplicity and low cost. Its molecular structure contains acetate groups that provide good initial adhesion to various substrates. However, these same groups are susceptible to hydrolysis (breaking down in water), especially under alkaline conditions present in cement.

In practice, when I work with clients looking to reduce costs, I often recommend limited use of PVAc-based products. For example:

| Application | PVAc Suitability | Recommendation |

|---|---|---|

| Interior wall putty | Acceptable | Use in dry areas only |

| Bathroom tile adhesive | Poor | Avoid completely |

| Self-leveling underlayment | Moderate | Limited use in dry areas |

The glass transition temperature (Tg) of PVAc is around 30°C, which means it becomes brittle in cold conditions and too soft in hot environments. This temperature sensitivity further limits its application range. While we still produce PVAc-based RDP for certain markets, I typically guide customers toward more versatile options for most applications.

VAE Emulsion-Based RDP: Why is this the most versatile solution?

Construction timelines are tight, and builders need materials that perform reliably across various conditions. Unpredictable weather and site conditions demand adaptable solutions.

VAE (Vinyl Acetate-Ethylene) copolymer RDP offers the best balance of performance and cost, featuring improved water resistance, flexibility, and temperature stability compared to PVAc. The ethylene content in VAE (typically 10-20%) dramatically enhances durability while maintaining excellent workability.

VAE has become our bestselling RDP category, representing over 65% of our production capacity. The reason is simple: versatility. When I consult with customers like Mark from Saudi Arabia, I often recommend VAE-based products for their balanced performance profile.

The ethylene component in VAE provides critical benefits:

- Improved water resistance - The hydrophobic ethylene units protect the polymer from water damage

- Lower Tg - Typically between -10°C and +15°C, allowing flexibility across temperature ranges

- Enhanced durability - Better resistance to UV degradation and weathering

- Excellent cement compatibility - Forms strong bonds with cementitious materials

Our factory produces VAE-based RDPs with ethylene content ranging from 12% to 18%, allowing us to fine-tune properties for specific applications:

| Ethylene % | Flexibility | Water Resistance | Recommended Applications |

|---|---|---|---|

| 12% | Moderate | Good | General-purpose tile adhesives |

| 15% | Good | Very good | Exterior renders, repair mortar1s |

| 18% | Excellent | Excellent | Waterproofing membranes, EIFS adhesives |

VAE-based RDPs work exceptionally well in both dry and wet environments, making them ideal for developing markets where construction conditions vary widely and material versatility is essential.

Acrylic-Based and Styrene-Acrylic RDPs: When do these premium options make sense?

Extreme weather conditions and demanding applications can quickly break down standard polymer systems. Premium projects require premium materials.

Acrylic and styrene-acrylic RDPs offer superior water resistance, UV stability, and alkaline resistance compared to vinyl acetate-based products. These premium options are ideal for exterior applications facing severe weather conditions, with styrene-acrylic providing enhanced hardness and acrylic offering maximum flexibility.

Working with high-end construction projects across the Middle East has taught me that sometimes only acrylic-based systems can provide the performance needed. Last year, I consulted on a luxury resort project in the UAE where the exterior rendering would face extreme heat, sandstorms, and occasional heavy rain. The styrene-acrylic RDP we supplied has performed flawlessly despite these challenges.

The chemical structure of acrylic polymers makes them inherently more resistant to hydrolysis and UV degradation. This stability comes at a higher price point, but the long-term performance justification is clear:

| Property | Acrylic RDP | Styrene-Acrylic RDP | Best Applications |

|---|---|---|---|

| Water Resistance | Excellent | Very Good | Waterproofing, exterior facades |

| UV Stability | Excellent | Good | Sun-exposed surfaces |

| Flexibility | High | Moderate | Crack-bridging, waterproofing |

| Hardness | Moderate | High | Heavy-traffic areas, flooring |

| Cost | Highest | High | Premium construction |

The production process for acrylic-based RDPs is more complex and requires tighter quality control. Our factory uses advanced spray-drying technology with precisely controlled temperature profiles to ensure consistent particle size distribution and redispersibility of these sophisticated polymers.

Advanced Tripolymer RDPs6: How do VAc/VeoVa/Acrylic combinations offer superior performance?

Construction in extreme environments—whether scorching desert heat or tropical humidity—demands extraordinary material performance. Standard polymers often fail under these conditions.

Tripolymer RDPs6 combining vinyl acetate, VeoVa (vinyl esters of versatic acid), and acrylic monomers create high-performance powders with exceptional water resistance, UV stability, and alkaline resistance. This advanced formulation approach delivers premium performance for the most demanding applications.

The inclusion of VeoVa in these advanced formulations provides remarkable benefits. VeoVa's highly branched structure creates steric hindrance (a spatial crowding effect) that protects the polymer backbone from chemical attack. When we developed our premium RDP line for clients in coastal regions, this tripolymer approach proved revolutionary.

Our laboratory testing demonstrates the performance advantages:

| Test Condition | Standard VAE | VAc/VeoVa/Acrylic Tripolymer |

|---|---|---|

| Water immersion (28 days) | 25% strength retention | 65% strength retention |

| UV exposure (1000 hours) | Visible yellowing | No visible change |

| Alkaline resistance pH 12 (14 days) | Moderate degradation | Minimal effect |

| Freeze-thaw cycling (50 cycles) | Performance loss | Stable performance |

The molecular architecture of these tripolymers provides a unique balance of properties that cannot be achieved with simpler systems. The VeoVa component contributes exceptional water repellency and chemical resistance, while the acrylic portion enhances UV stability and durability. The VAc base maintains good compatibility with cementitious materials and cost-effectiveness.

For clients with truly demanding applications, such as a recent project supplying a factory in Singapore producing exterior insulation finishing systems (EIFS), we recommend these advanced tripolymer formulations despite their premium price point.

Other Emulsion Types: How do VC, PU, and Epoxy RDPs serve specialized needs?

Standard construction solutions sometimes fall short for specialized applications like chemical plants, healthcare facilities, or infrastructure projects requiring extreme durability.

Specialized RDPs based on vinyl chloride (VC), polyurethane (PU), and epoxy resins address highly specific performance requirements beyond what conventional types can deliver. These niche products offer exceptional chemical resistance, abrasion resistance, and structural enhancement for specialized applications.

These specialized RDPs represent a smaller portion of our production but are critical for certain high-value applications. I recently worked with a client developing industrial flooring for chemical manufacturing facilities in India. Their requirements for chemical resistance far exceeded what standard VAE or acrylic systems could provide.

The unique properties of these specialized polymers derive from their distinctive chemical structures:

| Polymer Type | Key Advantage | Main Limitation | Primary Applications |

|---|---|---|---|

| Vinyl Chloride (VC) | Chemical resistance | Environmental concerns | Chemical-resistant mortars |

| Polyurethane (PU) | Abrasion resistance | Cost | Industrial flooring |

| Epoxy | Strength enhancement | Brittleness | Structural repair compounds |

Production of these specialized RDPs requires additional safety measures and specialized equipment. For example, our PU-based RDP production line includes nitrogen blanketing and moisture control systems to prevent unwanted reactions during processing.

While these specialized RDPs command premium prices, their performance in targeted applications justifies the investment. A recent project using our epoxy-modified RDP for bridge repair in Vietnam demonstrated strength values nearly double those of conventional repair mortars.

Conclusion

Choosing the right redispersible polymer powder dramatically impacts construction quality, durability, and project success. From basic PVAc for simple interior applications to advanced tripolymers for extreme environments, the chemistry behind these powders enables modern construction technologies.

Frequently Asked Questions (FAQ)

What is the shelf life of redispersible polymer powder?

Properly stored RDP typically maintains its properties for 12-24 months when kept in original sealed packaging in a cool, dry place away from direct sunlight.

Can different RDP types be mixed together?

Yes, blending different RDPs can create customized property profiles, but this should be done with technical guidance to ensure compatibility and performance.

How does RDP affect setting time in cement-based applications?

Most RDPs slightly delay setting time due to their film-forming properties. Special grades with setting accelerators are available for specific applications.

Is RDP environmentally friendly?

Modern RDPs are formulated to be low-VOC and environmentally compliant. Many grades are solvent-free and designed for green building applications.

What percentage of RDP is typically used in dry mortar formulations?

Usage levels typically range from 1-5% for basic applications like renders and masonry mortars, up to 10-15% for demanding applications like waterproofing membranes and flexible adhesives.

I'll continue the blog post from where we left off, focusing on the remaining secondary headings.

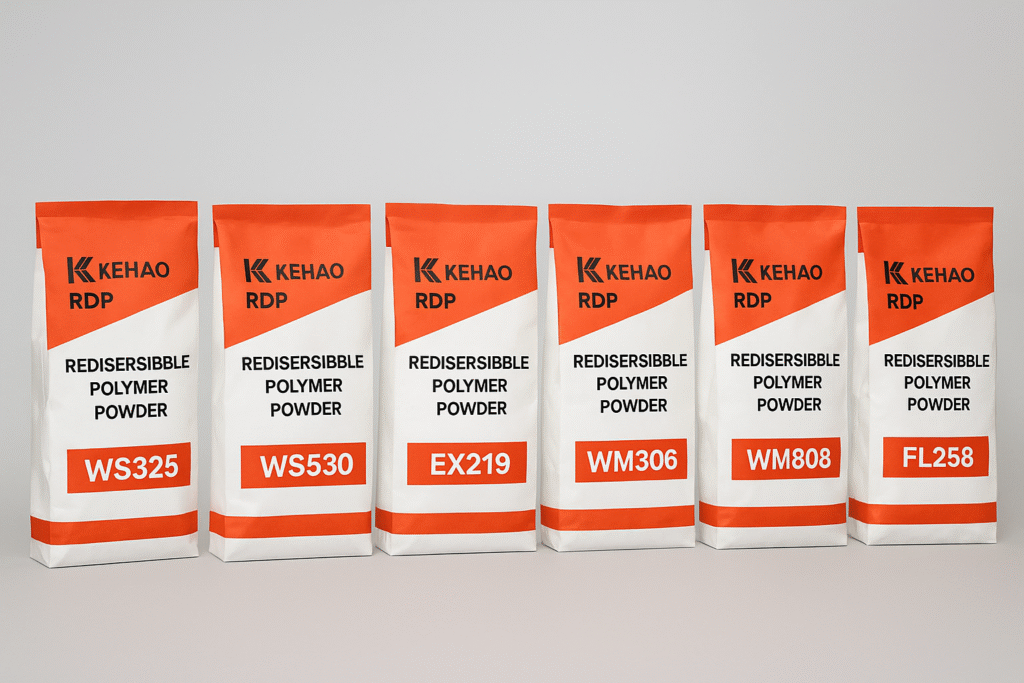

KEHAO's Redispersible Powder Product Range: Which options meet your specific needs?

Choosing from countless RDP products7 without expert guidance often leads to costly mistakes. Material incompatibility causes project delays and expensive rework.

Our Kehao brand offers specialized RDP grades tailored for specific applications, from general-purpose VAE powders8 to advanced tripolymer formulations. Each product undergoes rigorous quality testing at our six-line production facility before shipping to customers across Middle East, Asia, and beyond.

I've personally overseen the development of our comprehensive product range over the past decade. When Mark from Saudi Arabia first visited our facility, he was particularly impressed by our ability to customize formulations for his specific regional challenges. The extreme temperature variations and occasional sandstorms in his region required specially modified VAE-based RDPs.

Our current product lineup includes:

| Product Code | Type | Key Features | Primary Applications |

|---|---|---|---|

| WH-5010 | PVAc | Economical, good adhesion | Interior wall putties, basic joint fillers |

| WH-CF | VAE (12%) | Balanced properties, good workability | General tile adhesives, repair mortars |

| WH-1009 | VAE (15%) | Enhanced water resistance | Exterior renders, EIFS base coats |

| WH-1006 | VAE (18%) | High flexibility, waterproofing | Waterproofing membranes, flexible adhesives |

| WH-6220 | Acrylic | Premium water resistance | Waterproofing, exterior applications |

| WH-6320 | Styrene-Acrylic | High hardness, durability | Self-leveling compounds, repair mortars |

| WH-7000 | VAc/VeoVa/Acrylic | Maximum performance | Premium exterior systems, coastal applications |

Each product in our range undergoes comprehensive testing before release. I remember one instance where our quality control detected a slight variation in one batch of KH-5410. Despite the pressure to ship quickly to a waiting customer in Pakistan, we held the batch for additional testing and optimization. This commitment to quality has built our reputation in developing markets where consistent performance is critical.

Our technical team provides customized recommendations based on specific project requirements. For instance, when working with a major mortar producer in Iran facing extremely dry application conditions, we developed a special grade with extended open time and improved water retention.

Technical Considerations for RDP Selection: How do you choose the perfect powder for your project?

Many construction projects fail because materials were selected based on price alone, ignoring crucial technical parameters. Poor material selection leads to premature failure and expensive repairs.

Proper RDP selection requires consideration of multiple factors: Tg (glass transition temperature), MFT (minimum film formation temperature), particle size distribution, protective colloid type, and anti-blocking agent content. These parameters determine final performance in specific applications and climatic conditions.

During my technical consultations with clients, I emphasize the importance of matching RDP properties to application requirements. The science behind these materials is complex, but understanding a few key parameters makes selection much more straightforward.

The glass transition temperature (Tg) particularly impacts performance across temperature ranges. During a visit to our lab with a client from Georgia last winter, we demonstrated how different Tg values affect flexibility at low temperatures:

| Tg Value | Low Temperature Performance | High Temperature Performance | Recommended Climate |

|---|---|---|---|

| -15°C | Excellent flexibility in cold | May soften in extreme heat | Cold to moderate regions |

| 0°C | Good general flexibility | Good stability in heat | Temperate regions |

| +15°C | May become brittle in cold | Excellent stability in heat | Hot regions |

Beyond Tg, the minimum film formation temperature9 (MFT) determines whether the polymer can form a continuous film at the application temperature. This is critical for exterior applications in colder regions. Our technical data sheets provide both values to help customers select appropriate products for their climate conditions.

Particle size distribution also dramatically impacts performance. Finer particles generally provide:

- Better cement distribution and interaction

- More uniform film formation

- Enhanced mechanical properties

- Improved workability

However, extremely fine particles can cause handling issues and require special anti-blocking agents. Our advanced spray drying technology maintains optimal particle size distribution for each product grade.

The protective colloid system (typically polyvinyl alcohol or modified cellulose derivatives) determines redispersion behavior and stability. For clients in humid environments like Vietnam and the Philippines, we recommend formulations with specialized protective colloid systems that resist premature activation during storage.

When consulting with large mortar manufacturers, I always recommend comprehensive performance testing rather than focusing exclusively on technical parameters. Real-world performance often depends on the complex interaction of multiple factors beyond individual specifications.

RDP Testing and Performance Standards: How do you verify quality and performance?

Inconsistent quality and unreliable performance claims create significant risks for construction projects. Without standardized testing, it's impossible to compare products or predict their behavior.

Industry-standard RDP testing methods include redispersibility measurement, mechanical property evaluation in cement mortars, and durability testing under various conditions. Key standards include EN 934, ASTM C1438, and ISO 16529 test methods for polymer-modified cementitious mixtures.

Our quality control laboratory runs continuous testing to ensure every batch meets specifications. I've implemented a rigorous quality management system that exceeds industry requirements because I've seen firsthand what happens when substandard materials reach construction sites.

The most important performance tests we conduct include:

| Test Method | What It Measures | Why It Matters |

|---|---|---|

| Redispersibility | How well the powder returns to emulsion form | Ensures proper mixing and performance |

| Tensile adhesion (EN 1348) | Bond strength to various substrates | Predicts real-world adhesion performance |

| Flexibility (EN ISO 527-1) | Elongation at break and elastic modulus | Indicates crack-bridging ability |

| Water absorption (EN 12808-5) | Water uptake after curing | Predicts water resistance in application |

| Wet scrub resistance | Surface durability when wet | Important for facade coatings |

| Freeze-thaw stability | Performance after temperature cycling | Critical for cold climate applications |

During a recent technical seminar I hosted for clients from Saudi Arabia and UAE, we demonstrated these testing methods and explained how they correlate to field performance. The comparison between properly tested premium RDP and untested budget alternatives was eye-opening for many participants.

Beyond standard tests, we also conduct application-specific testing to simulate real-world conditions. For example, for a client producing tile adhesives for exterior applications in hot climates, we conducted extended open time testing at elevated temperatures to ensure reliable performance.

When evaluating competing products, I encourage customers to request comprehensive test reports rather than relying solely on technical data sheets. The difference between claimed and actual performance can be significant, especially with suppliers who don't maintain strict quality control.

Our factory maintains certifications to ISO 900110, ISO 14001, and other relevant standards, with regular third-party audits ensuring compliance. When Mark visited our facilities, he was particularly impressed with our documented quality procedures and traceability systems that allow us to track every batch from raw material to finished product.

Ultimately, consistent quality is what builds long-term relationships. A customer from India once told me, "I can find cheaper RDP, but I can't find more reliable RDP." This philosophy guides our approach to quality control and testing.

Conclusion

Selecting the right redispersible polymer powder is crucial for achieving optimal performance in construction applications. From understanding basic emulsion types to considering technical parameters and verifying performance through standardized testing, each step impacts your project's success. With six production lines and extensive experience serving developing markets, our Kehao brand offers the quality, consistency, and technical support11 needed for your specific applications.

Frequently Asked Questions (FAQ)

How do I know which RDP type is best for my specific application?

Contact our technical team with details about your application, environmental conditions, and performance requirements. We can recommend the optimal product based on extensive experience.

What certifications do Kehao RDP products have?

Our products comply with various international standards including ISO, ASTM, and EN specifications. We provide full documentation with each shipment.

How should RDP be stored to maintain its properties?

Store in cool, dry conditions in original sealed packaging. Avoid exposure to moisture, high temperatures, and direct sunlight. Typical shelf life is 12-24 months under proper storage conditions.

Can Kehao provide custom formulations for specific requirements?

Yes, our R&D team can develop tailored formulations to meet specific performance requirements or regional conditions. Minimum order quantities apply for custom products.

How does RDP content affect the cost of my final product?

While RDP is typically one of the more expensive components in dry mortar formulations, it represents only 1-5% of the total mix for most applications. The performance benefits and reduced failure rates typically outweigh the marginal cost increase.

What are the environmental benefits of using RDP in construction materials?

RDP-modified mortars often contribute to sustainable building practices by improving durability and extending service life. Many of our formulations are low-VOC and solvent-free, meeting green building requirements while reducing maintenance and replacement frequency.

How quickly can you ship RDP products internationally?

We maintain significant inventory of standard products, allowing shipment within 1-2 weeks after order confirmation. Our logistics department specializes in exports to the Middle East, South Asia, and Southeast Asia, with established shipping routes to major ports.

What packaging options are available?

Standard packaging includes 25kg multi-layer paper bags with PE inner liner for moisture protection. We also offer 500kg and 1000kg big bags for larger operations. All packaging is designed to protect the powder during transportation and storage in various climates.

Do you provide technical support for using your RDP products?

Yes, our technical team provides comprehensive support including formulation recommendations, troubleshooting, and on-site training. We regularly conduct workshops and seminars for clients in key markets to share best practices and application techniques.

Can mixing different types of RDP cause compatibility issues?

While some combinations work well together, others may cause unexpected results. It's always best to consult our technical department before mixing different RDP types. We can recommend proven combinations for specific performance enhancements.

How does water quality affect RDP performance?

Water quality can significantly impact redispersion and film formation. High mineral content (hard water) may interfere with redispersion and affect workability. In areas with poor water quality, we recommend testing with local water and potentially adjusting formulations accordingly.

What safety considerations apply when working with RDP?

RDP is generally considered non-hazardous, but standard dust precautions should be observed during handling. We provide Safety Data Sheets (SDS) with detailed information and recommend dust masks when handling large quantities in confined spaces.

How do temperature extremes affect RDP performance in finished applications?

Temperature effects depend on the specific RDP type. Products with lower Tg values maintain flexibility in cold conditions but may soften in extreme heat. Conversely, higher Tg formulations provide better heat resistance but may become brittle in cold. Our technical team can recommend optimal products based on expected temperature ranges in your application environment.

Can RDP help achieve rapid-setting formulations?

Most standard RDPs slightly delay setting time. For rapid-setting applications, we offer specialized grades that are compatible with accelerators commonly used in fast-setting mortars. These formulations maintain the benefits of polymer modification while allowing quick return to service.

What is the difference between redispersible latex powder and liquid latex additives?

Redispersible powder offers significant advantages in storage stability, shipping costs, and formulation simplicity. While liquid latex provides immediate availability of the polymer, it requires special packaging, is heavier to transport, can freeze in cold weather, and has shorter shelf life. RDP allows the creation of one-component systems that only require water addition at the job site.

-

Understand the importance of mortar in building stability and integrity. ↩ ↩

-

Explore how RDP enhances construction materials, improving adhesion and durability. ↩ ↩

-

Learn about the benefits of using dry-mix mortars in various applications. ↩

-

Learn about PVAc's benefits and limitations in construction applications. ↩

-

Discover the advantages of VAE in various construction conditions. ↩

-

Explore how tripolymer formulations enhance performance in extreme conditions. ↩ ↩

-

Explore this link to discover a range of RDP products tailored for various construction needs. ↩

-

Learn about VAE powders and how they can enhance your construction projects. ↩

-

Learn about minimum film formation temperature and its impact on application success. ↩

-

Explore the significance of ISO 9001 certification in ensuring quality in construction. ↩

-

Find out how technical support can enhance your experience with RDP products. ↩