I've seen many construction projects delayed because of inconsistent mortar quality. These problems cost time, money, and reputation. The solution? Switching to dry-mix mortar1 systems.

Dry-mix mortar offers significant advantages including consistent quality, reduced labor costs, minimized waste, extended shelf life, and improved worksite efficiency. By requiring only water addition on-site, it eliminates mixing errors while ensuring reliable performance across various construction applications.

"High-quality dry-mix mortar products")

"High-quality dry-mix mortar products")

Last month, a customer from Saudi Arabia called me about his ongoing project delays. After switching to our premium dry-mix mortar products with quality HPMC, his team completed the project ahead of schedule. Let me explain why dry-mix mortar creates such impressive results.

What Are the Benefits of Dry Mix?

Every construction manager I meet struggles with maintaining consistent quality across their projects. Traditional site-mixed mortar creates unpredictable results that compromise structural integrity and appearance.

Dry mix offers precise ingredient proportions that are factory-controlled, ensuring every batch performs identically. This eliminates the variability caused by on-site mixing and human error, resulting in stronger, more reliable structures with consistent appearance.

Key Benefits of Factory-Produced Dry Mix

When evaluating dry mix options, understanding the specific benefits helps you choose the right product for your project requirements. I've worked with customers across developing markets for years, and these advantages consistently deliver value:

-

Quality Control: Factory production means every bag contains precisely measured ingredients. Our manufacturing facility uses advanced equipment that ensures each component—cement, sand, and additives like our premium HPMC—is measured exactly. This creates batch-to-batch consistency impossible to achieve with site mixing.

-

Labor Efficiency: With pre-mixed products, your workers simply add water according to instructions. This reduces the skill level required and minimizes training needs. One customer in the UAE reported a 30% reduction in labor costs after switching to our dry mix products.

-

Reduced Material Waste: Traditional mixing often results in excess material that hardens before use. Dry mix allows for precise quantity preparation, reducing waste significantly. This not only saves material costs but also reduces environmental impact and cleanup expenses.

-

Extended Shelf Life: Our specially formulated dry mix products with quality cellulose ethers provide significantly longer storage capabilities compared to wet mixes that must be used immediately.

What Is the Use of Dry Mix Mortar?

Many distributors ask me about applications for dry mix. Traditional wet-mixed mortars create logistical challenges, especially on large projects where consistent quality is crucial for structural integrity.

Dry mix mortar serves multiple construction applications including bricklaying, plastering, tiling, floor screeding, and specialized repairs. Each formulation contains specific additives like our HPMC or redispersible powder to enhance properties such as water retention, adhesion, and workability.

Versatile Applications Across Construction Sectors

Working with construction material suppliers across Saudi Arabia, UAE, and other developing markets has shown me how versatile dry mix products are becoming. The technology continues to advance, offering specialized solutions for virtually every application:

-

Masonry Work: Our dry mix mortars for masonry contain precisely graded sand and specialized additives like our hydroxypropyl methylcellulose that enhance water retention2. This creates stronger bonds between bricks and blocks while providing optimal workability time for masons.

-

Plastering & Rendering: Interior and exterior plasters benefit from the consistency of factory-mixed formulations. Our customers report fewer callbacks for cracking and delamination issues after switching to quality dry mix products containing our cellulose ethers.

-

Tile Adhesives: Modern tile installation demands adhesives with specific performance characteristics. Dry mix adhesives containing our redispersible latex powder provide enhanced flexibility and bond strength that traditional site-mixed products cannot match.

-

Flooring Systems: Self-leveling compounds and floor screeds benefit tremendously from factory precision. The consistent flow characteristics and strength development are critical for successful floor installations, especially in large commercial projects.

-

Repair & Restoration: Specialized repair mortars3 for concrete structures contain complex additive packages that would be impossible to replicate consistently on-site.

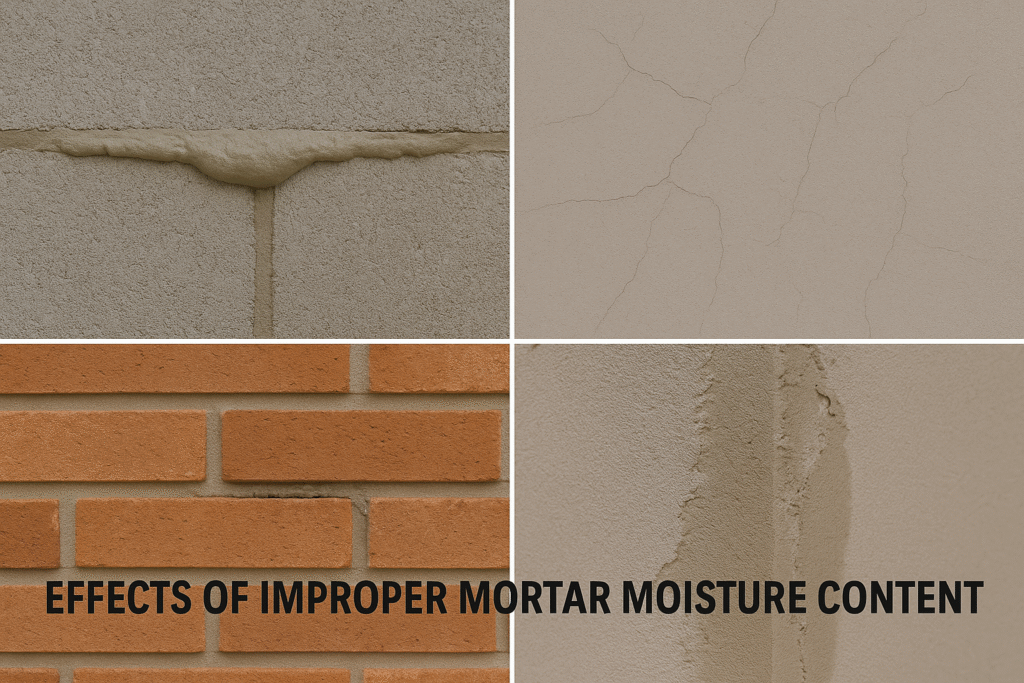

What Happens If Mortar Mix Is Too Dry?

I've visited countless construction sites where improper mortar consistency created serious problems. When mortar lacks proper moisture, it fails to create proper bonds and compromises structural integrity.

Excessively dry mortar mix causes poor adhesion, inadequate hydration of cement, reduced strength, and potential structural failure. Without proper moisture, the chemical reactions necessary for cement hardening cannot occur fully, resulting in a weakened final product prone to cracking and failure.

Critical Consequences of Improper Moisture Content

Working with mortar formulations has taught me that moisture balance4 is perhaps the most critical aspect of performance. When consulting with my customers' technical teams, I emphasize these key points about moisture content management:

-

Bond Strength Reduction: When mortar is too dry, it cannot properly wet the surface of bricks, blocks, or tiles. This creates a weak mechanical bond that may appear solid initially but will fail prematurely under stress. Our laboratory tests show that overly dry mixes can reduce bond strength by up to 60%.

-

Incomplete Cement Hydration: Cement requires a specific amount of water to complete its chemical reaction. Insufficient water prevents full hydration, leaving unreacted cement particles that never contribute to strength development. This is particularly critical in structural applications where load-bearing capacity is essential.

-

Workability Problems: Dry mixes are difficult to spread evenly, creating inconsistent bed depths and poor surface contact. This leads to voids and weak points throughout the structure. Our premium HPMC additives help maintain proper water retention even in challenging conditions, ensuring proper workability throughout the application process.

-

Shrinkage Cracking: Ironically, overly dry mortar often leads to excessive shrinkage cracking5. Without sufficient water, the mortar cannot undergo proper plastic shrinkage during initial setting, creating internal stresses that lead to cracks as the material hardens.

-

Durability Issues: Properly hydrated mortar creates a dense, impermeable matrix that resists water ingress and chemical attack. Dry mixes create a porous structure that allows moisture penetration, leading to accelerated deterioration, especially in harsh environments like those in many Middle Eastern and Asian markets.

What Are the Advantages of Dry Pack?

Project managers often ask about dry pack versus traditional methods. Traditional materials cause quality inconsistencies and logistical headaches that impact project timelines and budgets.

Dry pack mortars offer exceptional advantages including precise compaction, minimal shrinkage, enhanced durability, and superior load-bearing capacity. Their dense, stable structure makes them ideal for structural repairs, equipment bases, and applications requiring exceptional dimensional stability and strength.

Specialized Applications for Dry Pack Technology

Dry pack represents a specialized category of low-moisture, high-compaction mortar that serves unique construction needs. When consulting with engineering teams from large projects, I highlight these specific advantages:

-

Superior Load Distribution: The dense, well-compacted nature of dry pack creates an exceptional base for machinery, columns, and structural elements. The minimal water content prevents settlement and ensures forces are distributed evenly across the bearing surface. This is particularly important for industrial equipment installations where even minor settlement can cause alignment issues.

-

Minimal Shrinkage: With substantially less water than conventional mortars, dry pack experiences negligible shrinkage during curing. This makes it ideal for precision applications where dimensional stability is critical, such as bearing plates, column bases, and machinery foundations.

-

Enhanced Compressive Strength: The compaction process and low water-to-cement ratio create exceptionally high compressive strength values—often exceeding 50 MPa. This surpasses conventional mortars significantly, making dry pack suitable for high-stress applications in industrial and infrastructure settings.

-

Superior Durability: The dense, compact structure resists chemical penetration and environmental degradation. In applications exposed to oils, mild chemicals, or frequent washing, dry pack maintains integrity where conventional mortars would deteriorate. Our customers in industrial settings particularly value this characteristic.

-

Controlled Installation Process: While requiring skilled application, the dry pack method allows for precise control over the final installation. This is particularly valuable in retrofit and repair situations where exact dimensions must be maintained.

Conclusion

Dry-mix mortar delivers consistent quality, labor savings, and versatile applications that traditional mixing cannot match. By investing in quality products with premium additives like our HPMC and redispersible powders, you'll achieve superior results that enhance your reputation and profitability.

-

Explore the advantages of dry-mix mortar for consistent quality and efficiency in construction projects. ↩

-

Discover the significance of water retention in mortar for construction durability. ↩

-

Explore effective practices for using repair mortars to ensure structural integrity. ↩

-

Understanding moisture balance is crucial for achieving optimal mortar performance and preventing structural issues. ↩

-

Understanding shrinkage cracking is essential for maintaining the integrity of your construction projects. ↩