Poor adhesion causes tiles to crack, detach, and fail prematurely. Frustrating, costly, and damages your reputation. You need a reliable solution that won't let you down.

C1 tile adhesives1 are standard-setting mortars designed for interior tiling on stable surfaces with light traffic. They provide adequate bonding strength (≥0.5 MPa) for non-porous tiles up to 30x30cm and work best in dry environments with minimal temperature fluctuations.

As a manufacturer with over 15 years in the industry, I've seen countless projects compromised by substandard adhesives. Quality matters more than many realize. Let me share what makes our KEHAO C1 tile adhesive solutions stand out and why they're the smart choice for your tiling projects.

Reliable Tiling with C1 Tile Adhesives: What Makes Them Essential?

Pain: Weak adhesives lead to callbacks, wasted materials, and damaged reputation. Your business deserves better than constantly fixing failed installations.

C1 tile adhesives are standard cementitious adhesives that provide normal tensile adhesion strength (≥0.5 MPa). They're ideal for interior applications on stable substrates with ceramic tiles up to 30x30cm, offering reliable performance when properly applied in controlled environments.

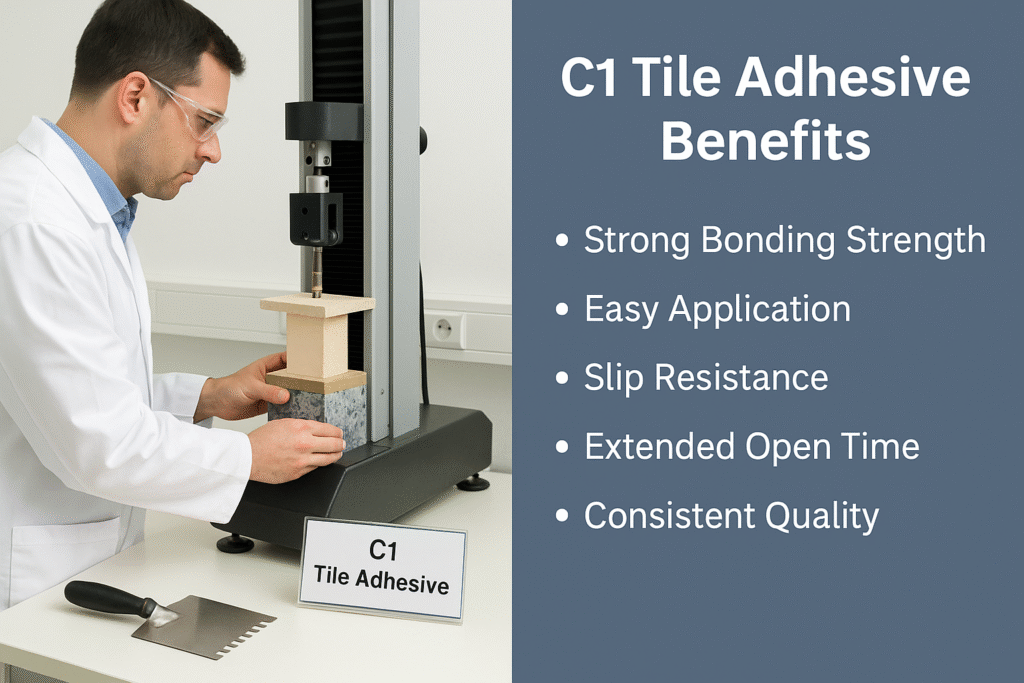

C1 tile adhesives serve as the foundation for many tiling projects, especially in residential and light commercial settings. At our factory, we've perfected these formulations through rigorous testing and customer feedback. The reliability of C1 adhesives comes from their balanced composition and performance characteristics.

Performance Characteristics of Quality C1 Adhesives

| Property | Standard Requirement | KEHAO C1 Adhesive |

|---|---|---|

| Tensile Adhesion Strength | ≥0.5 MPa | 0.6-0.8 MPa |

| Open Time | ≥20 minutes | 25-30 minutes |

| Slip Resistance | ≤0.5mm | 0.3mm |

| Pot Life | N/A | 3-4 hours |

Our C1 adhesives provide the perfect balance between performance and cost-effectiveness2. They maintain excellent workability during application, with the right consistency for vertical and horizontal surfaces. Through careful selection of raw materials, including premium quality cement, graded silica sands, and our specialized cellulose ethers3, we ensure consistent performance batch after batch.

From my experience working with major contractors in Saudi Arabia and the UAE, I've found that contractors particularly value the predictable working time and clean application of our C1 adhesives. This reliability translates directly to faster project completion and fewer callbacks, which significantly impacts their bottom line.

Choosing the Right Adhesive: Tile Adhesive Classification Explained?

Pain: With so many adhesive types available, making the wrong choice wastes money and compromises installation quality. The classification system seems needlessly complex.

Tile adhesives are classified using letters and numbers according to EN 120044. C1 means standard cementitious adhesive (C) with normal adhesion strength5 (1). Other types include C2 (improved), D (dispersion), and R (reaction resin) with additional properties like F (fast-setting), T (slip-resistant), and E (extended open time6).

Navigating the world of tile adhesive classification doesn't need to be overwhelming. Having supplied products to major projects across developing markets, I've helped countless clients find the perfect adhesive for their specific needs. Understanding the classification system is the key to making informed decisions.

Understanding EN 120044 Classification System

| Class | Type | Minimum Adhesion Strength | Best Applications |

|---|---|---|---|

| C1 | Standard cementitious | ≥0.5 MPa | Interior walls and floors with stable substrates |

| C2 | Improved cementitious | ≥1.0 MPa | Exterior surfaces, larger tiles, areas with temperature fluctuations |

| D1 | Standard dispersion | ≥1.0 MPa | Interior wall tiling with minimal water exposure |

| D2 | Improved dispersion | ≥1.0 MPa with additional requirements | Bathroom walls, kitchen backsplashes |

| R1 | Standard reaction resin | ≥2.0 MPa | Chemical-resistant applications, swimming pools |

| R2 | Improved reaction resin | ≥2.0 MPa with additional requirements | Industrial floors, food processing areas |

Additional property designations enhance adhesive functionality for specific applications. For example, a C1TE classification indicates a standard cementitious adhesive with reduced slip (T) and extended open time (E). These properties make the adhesive ideal for larger wall tiles where preventing slippage during installation is crucial.

Based on our extensive testing and customer feedback from projects across the Middle East and Asia, we've found that most residential applications don't require the higher cost of C2 adhesives. Our premium C1 formulations often provide more than adequate performance at a better price point. When clients ask me about which adhesive to choose, I always emphasize matching the adhesive class to the specific project requirements rather than automatically selecting the most expensive option.

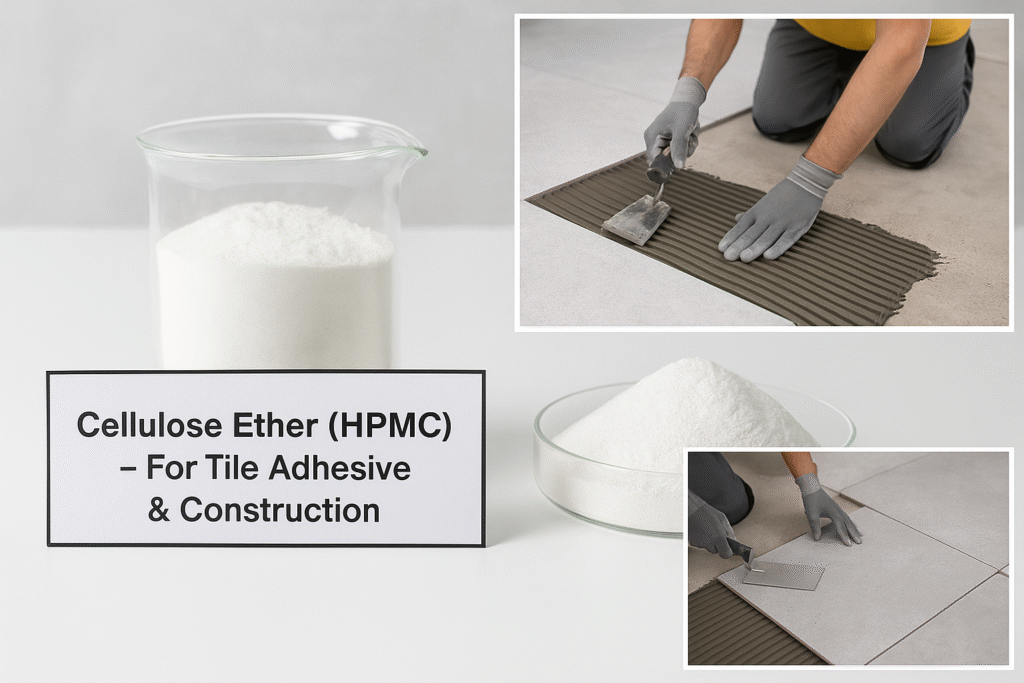

Cellulose Ethers Available for C1 Tile Adhesive: How Do They Enhance Performance?

Pain: Poor water retention7 causes premature drying, weak bonding, and tile failure. Standard adhesives often lack the workability needed for efficient installation.

Hydroxypropyl methylcellulose (HPMC8) is the ideal cellulose ether for C1 tile adhesives1. It provides crucial water retention, improves workability, extends open time, and prevents premature drying. The optimal viscosity range for tile adhesives is typically 15,000-75,000 mPa·s with methoxyl content around 28-30%.

At our KEHAO production facility, we manufacture specialized HPMC grades specifically designed for tile adhesive applications. Our experience shows that the right cellulose ether makes a dramatic difference in adhesive performance and workability. Let me explain why this component is so crucial.

Critical Parameters of HPMC8 for Tile Adhesives

| Parameter | Standard Range | Premium Range | Impact on Performance |

|---|---|---|---|

| Viscosity | 15,000-30,000 mPa·s | 40,000-75,000 mPa·s | Higher viscosity improves sag resistance and water retention |

| Methoxyl Content | 19-24% | 28-30% | Higher methoxyl content improves workability and open time |

| Hydroxypropyl Content | 7-12% | 7-10% | Optimized for balanced water retention and cement compatibility |

| Particle Size | Standard | Fine | Finer particles dissolve faster, reducing lumping |

| Gel Temperature | 65-80°C | 70-85°C | Higher temperature improves stability in hot climate applications |

Our most popular HPMC grade for C1 tile adhesives is our HPMC KH150M, which provides excellent water retention while maintaining optimal workability. I've personally visited installation sites in Saudi Arabia where contractors switched to our cellulose ethers and immediately noticed improved consistency and longer working time, especially crucial during hot weather applications.

One customer in Dubai reported that after switching to our HPMC product, they were able to extend their open time by nearly 15 minutes, significantly increasing their installation efficiency. The technical properties of our cellulose ethers are carefully controlled to ensure consistent performance batch after batch, with special attention to particle size distribution for quick, lump-free dispersion.

Our laboratory testing confirms that the right HPMC dosage (typically 0.2-0.3% of the dry mix) maximizes performance while maintaining cost-effectiveness. We provide detailed technical support9 to help customers optimize their formulations based on local climate conditions and specific application requirements.

RDP Powder Available for C1 Tile Adhesive: Why Is It a Game-Changer?

Pain: Standard C1 adhesives lack flexibility and can fail when substrates move or expand. Low adhesion to difficult surfaces limits their application range.

Redispersible Polymer Powder10 (RDP) enhances C1 tile adhesives by improving flexibility, adhesion strength, and water resistance. Even at low dosages (1-2%), RDP significantly improves adhesion to difficult substrates and provides crucial deformability for applications where minor substrate movement occurs.

In my 15 years working with construction chemicals, I've seen remarkable improvements in C1 adhesive performance through the addition of our specialized RDP. Our KEHAO RDP powders transform basic cement-based adhesives into versatile products that approach C2 performance at a fraction of the cost.

Performance Enhancement with RDP Addition

| Property | C1 Without RDP | C1 With 2% RDP | Improvement |

|---|---|---|---|

| Adhesion Strength (standard conditions) | 0.5-0.6 MPa | 0.8-1.0 MPa | ~60% increase |

| Adhesion After Water Immersion | 0.3-0.4 MPa | 0.5-0.7 MPa | ~80% increase |

| Adhesion to Difficult Substrates | Poor | Good | Significant |

| Flexibility/Deformability | Minimal | Moderate | Substantial |

| Resistance to Freeze/Thaw Cycles | Limited | Good | Significant |

Our most popular RDP grade for C1 tile adhesives1 is our KH-5044P, which is a VAE (vinyl acetate-ethylene) copolymer powder specifically engineered for tile adhesive applications. This grade provides an excellent balance of improved adhesion, flexibility, and workability while maintaining cost-effectiveness.

During technical workshops with customers in Pakistan and Iran, I've demonstrated how even small additions of our RDP can transform standard C1 adhesives into premium products. One customer in Mexico reported that adding just 1.5% of our RDP to their standard formulation allowed them to compete effectively against imported premium adhesives at a more competitive price point.

The hydrophobic properties of our RDP also improve the water resistance of C1 adhesives, making them suitable for application in mildly wet areas like kitchens or bathrooms. This versatility allows manufacturers to broaden their product offerings with minimal formulation changes. Our technical team provides comprehensive support to help customers optimize their formulations based on local raw materials and specific performance requirements.

Your Solution for Superior Tile Adhesive Applications: How Can We Help?

Pain: Finding reliable, consistent raw material suppliers is challenging. Product variability leads to formulation headaches, quality concerns, and customer complaints.

KEHAO provides premium HPMC and RDP specifically engineered for tile adhesive applications, with consistent quality, technical support, and customized solutions. Our products enhance adhesive performance through improved water retention, workability, adhesion strength, and flexibility while maintaining cost-effectiveness.

As a manufacturer with six production lines and extensive experience serving customers across Saudi Arabia, UAE, Iran, India, and many other markets, we understand the challenges faced by mortar and adhesive producers. Our solutions are built on both technical expertise and practical knowledge gained from real-world applications.

KEHAO Advantages for Tile Adhesive Manufacturers

| Benefit | How We Deliver |

|---|---|

| Consistent Quality | Six dedicated production lines with strict quality control protocols |

| Technical Support | Formulation assistance, troubleshooting, and application development |

| Customized Solutions | Products tailored to specific climate conditions and local raw materials |

| Supply Reliability | Large production capacity ensures timely delivery even for large orders |

| Comprehensive Testing | Full laboratory facilities for product validation and quality assurance |

| Cost Optimization | Technical advice to achieve maximum performance at optimal cost |

Our approach combines high-quality products with comprehensive technical support. When you work with us, you're not just buying chemicals; you're gaining a partner committed to your success. I personally work with many of our customers to understand their specific challenges and develop tailored solutions.

One key advantage we offer is consistency. Our advanced production technology and strict quality control ensure that every batch performs identically, eliminating the formulation adjustments often needed with variable raw materials. A customer in Brazil once told me that before switching to our products, they had to adjust their production parameters weekly to compensate for raw material variations. With our products, they maintain the same parameters month after month.

We also understand the importance of timely delivery, especially for large projects with tight schedules. Our large production capacity and efficient logistics ensure that you receive your materials when needed, preventing costly production delays. Whether you need standard products or customized solutions, our team is ready to help you enhance your tile adhesive performance and grow your business.

Conclusion

Quality raw materials make the difference between failing tiles and lasting installations. With KEHAO's specialized HPMC8 and RDP, your C1 adhesives will deliver reliable performance, satisfied customers, and growing profits.

-

Explore the advantages of C1 tile adhesives for reliable and efficient tiling solutions. ↩ ↩ ↩

-

Learn how to achieve cost-effectiveness without compromising on adhesive quality. ↩

-

Discover how cellulose ethers improve tile adhesive performance and workability. ↩

-

Explore the EN 12004 classification to make informed decisions about tile adhesive selection. ↩ ↩

-

Understanding adhesion strength measurement helps ensure the right adhesive choice for your projects. ↩

-

Understanding open time can help you choose the right adhesive for your installation needs. ↩

-

Explore the importance of water retention in tile adhesives for better bonding and durability. ↩

-

Discover the benefits of HPMC in tile adhesives for improved performance and workability. ↩ ↩ ↩

-

Explore the technical support options that can help improve your tile adhesive formulations. ↩

-

Learn how RDP enhances adhesive performance and flexibility for various applications. ↩