Are you struggling with poor adhesive properties in your construction projects? Unpredictable material performance can cost time and money. EVA emulsion might be the solution you've been looking for.

EVA emulsion1 is a water-based dispersion of ethylene vinyl acetate copolymer2 particles that provides excellent adhesion, flexibility, and water resistance properties. It's commonly used in construction adhesives, paints, coatings, and as a key additive in mortars and grouts.

As a factory owner with 6 production lines, I've seen firsthand how the right choice of additives can make or break a construction project. Let me walk you through everything you need to know about EVA emulsion1 and why it might be the perfect addition to your next project.

What is EVA Emulsion and Why Should You Care?

Pain point: Many construction projects fail due to poor adhesion3 between materials. Without proper bonding agents, even the best-designed structures can deteriorate quickly.

EVA emulsion is a milky white liquid dispersion of ethylene vinyl acetate copolymer particles in water. It acts as a binding agent that improves adhesion, flexibility, and water resistance in various construction materials like mortars, paints, and coatings.

EVA emulsion has become increasingly popular in the construction industry, especially in developing countries where building standards are rapidly advancing. I remember visiting a client in Saudi Arabia who switched to our EVA-modified mortars and saw a 40% increase in tile adhesion strength.

The popularity of EVA emulsion stems from its versatility and effectiveness. It can be added to various formulations to enhance performance without complicated processing. This makes it an ideal choice for manufacturers looking to improve their products without significant changes to their production lines.

Composition of EVA Emulsion: What's Inside This Powerful Additive?

Pain point: Understanding complex chemical compositions can be overwhelming. Without this knowledge, you might choose the wrong product for your specific needs.

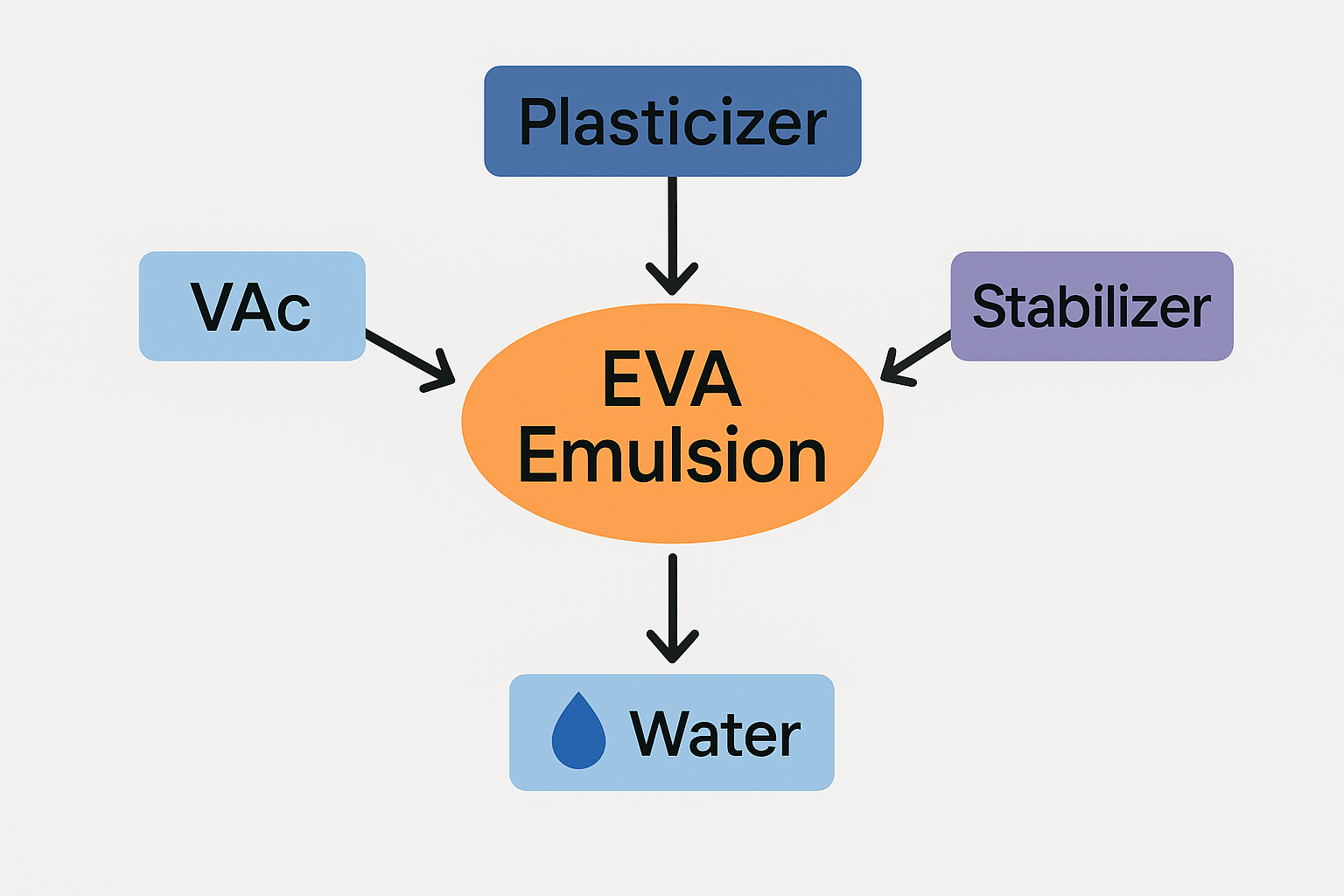

EVA emulsion consists of ethylene vinyl acetate copolymer particles dispersed in water, along with emulsifiers, protective colloids, and sometimes additional additives like plasticizers, defoamers, and preservatives to enhance stability and performance.

The effectiveness of EVA emulsion1 largely depends on its composition. The ratio of ethylene to vinyl acetate in the copolymer significantly affects the final properties of the emulsion. Let me share a deeper understanding of the key components:

Key Components and Their Functions

| Component | Function | Impact on Performance |

|---|---|---|

| Ethylene | Provides flexibility, water resistance | Higher ethylene content increases water resistance and flexibility |

| Vinyl Acetate | Enhances adhesion, film formation | Higher vinyl acetate improves adhesion but reduces water resistance |

| Emulsifiers | Stabilize polymer particles in water | Affect stability and compatibility with other materials |

| Protective Colloids | Prevent particle agglomeration | Improve freeze-thaw stability and shelf life |

| Additives | Address specific performance needs | Can include defoamers, biocides, plasticizers |

In our factory, we customize the ethylene-to-vinyl acetate ratio depending on the application. For example, for exterior applications in hot climates like those in the UAE, we increase the ethylene content to improve water resistance and prevent degradation under intense sun exposure. This customization has helped our clients achieve optimal performance in challenging environmental conditions without compromising on other essential properties.

Properties of EVA Emulsion: What Makes It Stand Out?

Pain point: Inconsistent material performance can lead to costly rework and damaged reputation. Construction project managers need reliable materials that perform as expected.

EVA emulsion provides excellent film formation, flexibility, water resistance, and adhesion to various substrates. It maintains performance across temperature ranges from -30°C to 70°C and offers UV resistance, making it ideal for both interior and exterior applications.

The remarkable properties of EVA emulsion stem from its unique molecular structure and can be tailored to meet specific application requirements. Let's examine these properties in greater detail:

Performance Properties of EVA Emulsion

| Property | Description | Practical Benefit |

|---|---|---|

| Film Formation | Forms continuous, clear films when dried | Creates seamless, attractive finishes on surfaces |

| Flexibility | Maintains elasticity even at low temperatures | Prevents cracking in mortar or coating during temperature fluctuations |

| Water Resistance | Creates hydrophobic barrier | Protects substrates from water damage and extends material lifespan |

| Adhesion | Bonds strongly to various materials | Ensures durable connections between different construction materials |

| Chemical Resistance | Withstands exposure to mild acids and bases | Maintains integrity in various environmental conditions |

| UV Stability | Resists degradation from sunlight | Prevents yellowing and breakdown in outdoor applications |

I recently visited a large construction project in Pakistan where they were using our EVA-modified mortars for external wall tiling. The project manager showed me installations from three years prior that still looked freshly applied, with no signs of the detachment or discoloration that was common with their previous materials. This real-world performance demonstrates why EVA emulsion has become an essential component in high-quality construction materials, especially in regions with extreme weather conditions.

Applications of EVA Emulsion: Where Can You Use This Versatile Material?

Pain point: Finding versatile additives that can improve multiple products is challenging. Using different additives for different applications increases inventory costs and complexity.

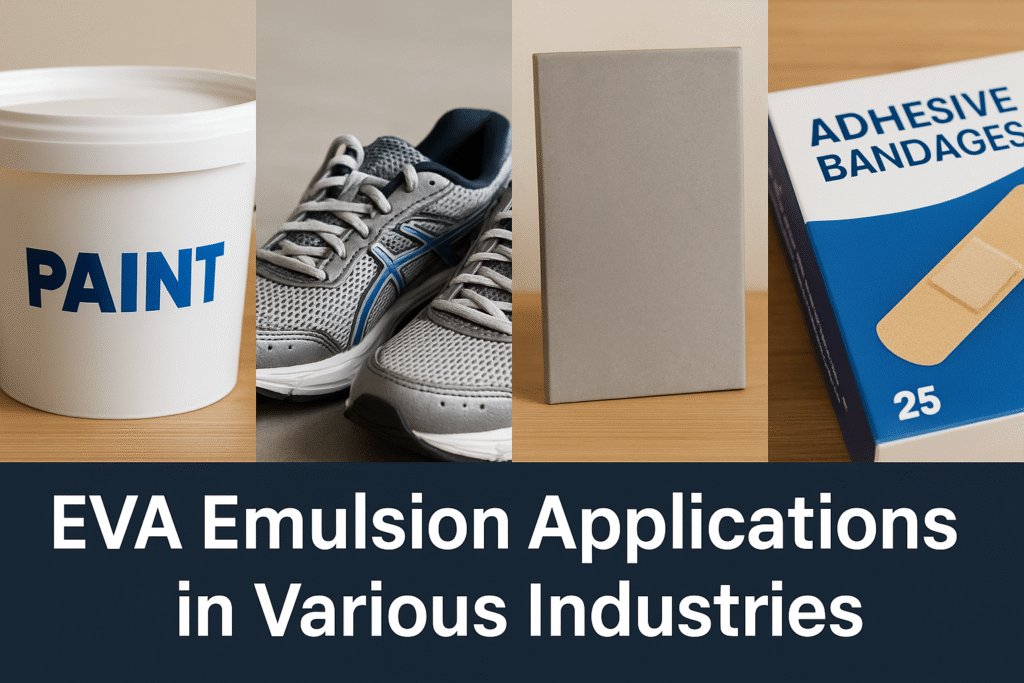

EVA emulsion is widely used in construction adhesives4, tile grouts, exterior insulation systems, waterproofing membranes, paints, coatings, and as a binder in paper and textile industries. It's particularly valuable in applications requiring water resistance and flexibility.

The versatility of EVA emulsion makes it a valuable component across numerous applications in the construction industry and beyond. Having worked with clients across various sectors, I've observed how this single additive can transform multiple products:

Key Applications and Performance Benefits

| Application | How EVA Emulsion Helps | Real-World Impact |

|---|---|---|

| Tile Adhesives | Improves bonding strength, flexibility, and water resistance | Reduces tile detachment issues, especially in wet areas |

| Exterior Insulation Systems | Enhances durability and weather resistance | Extends the lifespan of building façades in harsh climates |

| Waterproofing Membranes | Creates flexible, seamless water barriers | Prevents water infiltration in basements, bathrooms, and roofs |

| Decorative Coatings | Improves adhesion and crack resistance | Maintains aesthetic appearance longer with fewer maintenance needs |

| Repair Mortars | Increases bond strength to existing substrates | Ensures successful repairs without delamination |

| Joint Compounds | Improves workability and reduces cracking | Creates smoother finishes with fewer callbacks |

During a recent exhibition in Dubai, a distributor from Iran approached me with a specific problem: their clients needed grout that could withstand both extremely hot summers and occasional freezing temperatures in mountainous regions. We developed a custom EVA-modified grout formulation that maintained flexibility across this temperature range while providing exceptional water resistance. The solution has since become one of our most successful products in the region, demonstrating how EVA emulsion can be adapted to meet specific regional challenges.

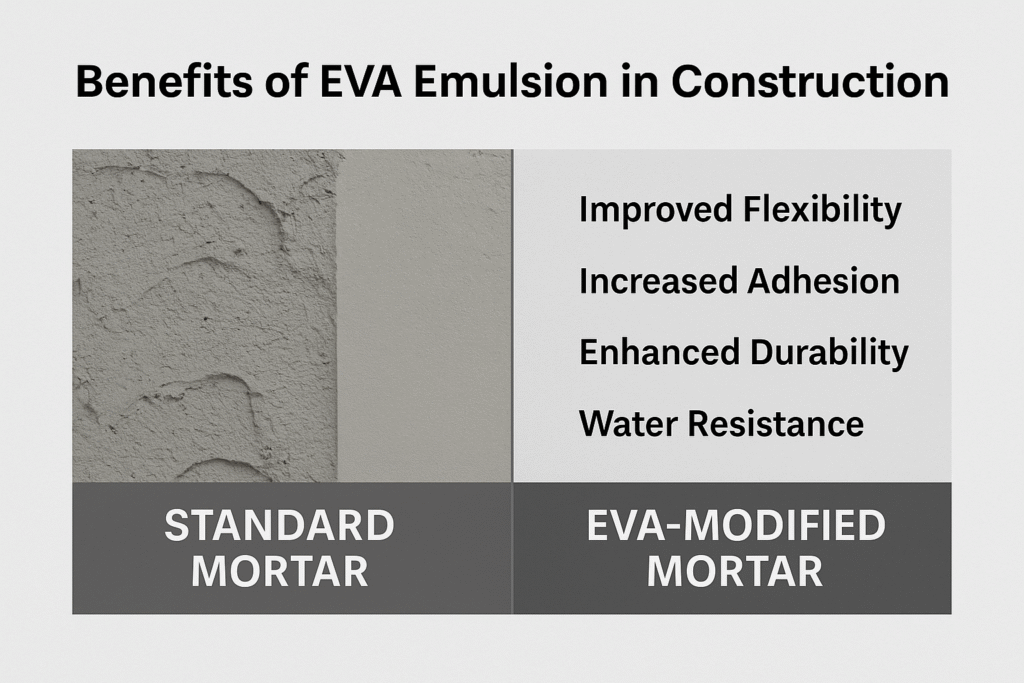

Benefits of Using EVA Emulsion: Why Make The Switch?

Pain point: Construction product manufacturers face intense competition and constantly need to improve their offerings without drastically increasing costs.

Using EVA emulsion improves product performance through enhanced adhesion, water resistance, and flexibility. It also simplifies production processes, extends product shelf life, and allows for customization to meet specific requirements, ultimately increasing customer satisfaction.

The decision to incorporate EVA emulsion into your products can transform your business outcomes. I've witnessed numerous clients achieve significant competitive advantages after making this change. Here's a deeper look at the benefits:

Economic and Performance Benefits

| Benefit | Description | Business Impact |

|---|---|---|

| Enhanced Product Performance | Improved adhesion, flexibility, and water resistance | Higher customer satisfaction, fewer complaints, stronger brand reputation |

| Production Efficiency | Easy incorporation into existing formulations | Reduced production costs and faster production cycles |

| Extended Shelf Life | Improved stability of finished products | Reduced waste, lower returns, better inventory management |

| Customization Potential | Ability to tailor properties for specific applications | Ability to serve niche markets and charge premium prices |

| Environmental Considerations | Water-based, low-VOC alternative to solvent-based systems | Compliance with stricter regulations and appeal to environmentally conscious customers |

One of our clients in Vietnam was struggling with frequent customer complaints about tile adhesive failure during the rainy season. After incorporating our EVA emulsion into their formulation, complaint rates dropped by 78% within six months, and they were able to position their product as a premium solution, increasing their profit margins by 15%. This transformation not only solved their immediate problem but also opened new market segments that were previously inaccessible to them.

For manufacturers looking to improve their existing products or develop new ones, EVA emulsion offers a relatively simple way to achieve significant performance enhancements without complete reformulation or major equipment investments.

Conclusion

EVA emulsion1 is a versatile, powerful additive that can transform construction materials through improved adhesion, water resistance, and flexibility. By choosing the right formulation for your specific needs, you can enhance product performance and stay ahead of competitors.

-

Explore how EVA emulsion can enhance adhesion and flexibility in construction materials. ↩ ↩ ↩ ↩

-

Discover the applications and benefits of ethylene vinyl acetate copolymer in construction. ↩

-

Understand the importance of adhesion in ensuring the durability of construction projects. ↩

-

Learn about top construction adhesives that ensure strong bonding in projects. ↩