I get this question every week from my clients. They stand in front of two bags - wall putty and white cement. They don't know which one to pick. This confusion costs them money and time.

Wall putty and white cement1 serve different purposes in construction. Wall putty creates smooth interior walls ready for painting. White cement works as a strong binding agent for exterior applications. Choose wall putty2 for interior finishing and white cement for structural work.

Last month, Mark from Saudi Arabia called me. He mixed up his order. He bought white cement for interior walls. His workers couldn't get a smooth finish. I helped him understand the difference. Now he orders the right product every time.

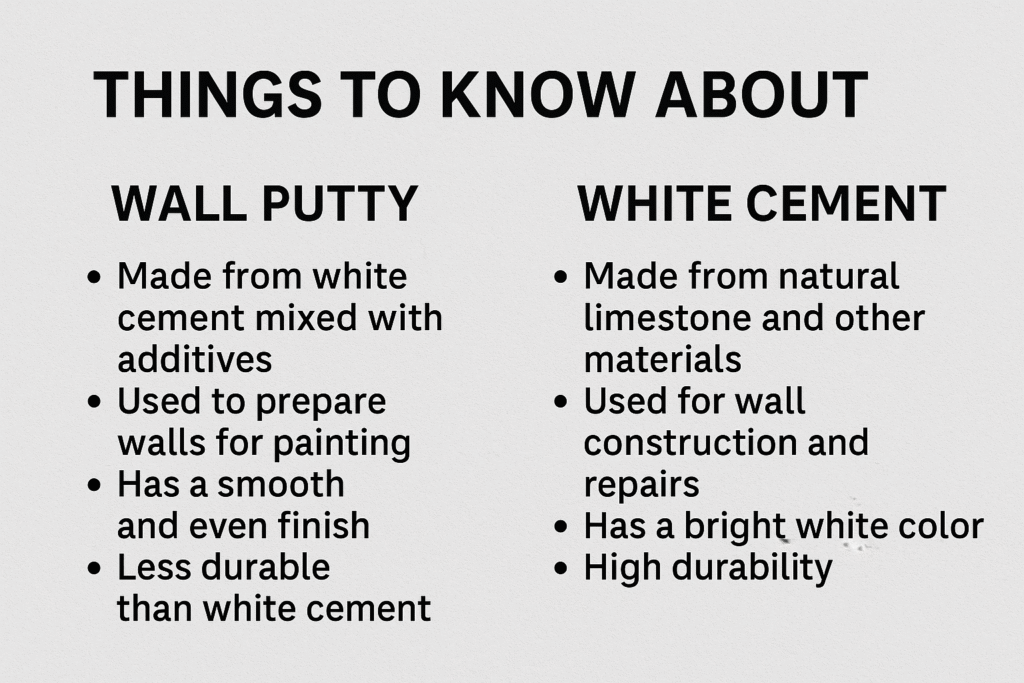

Things You Should Know

Many buyers think wall putty and white cement are the same. They see white powder in both bags. This mistake leads to project failures.

You need to know five key facts. Wall putty contains polymers3 for smoothness. White cement has high lime content for strength. Wall putty needs two coats. White cement requires mixing with sand. Wall putty costs more per bag but covers more area.

I learned these differences the hard way. In 2015, I visited a construction site in Dubai. The contractor used white cement instead of wall putty on interior walls. The paint started peeling after three months. The whole building needed rework. That experience taught me why product knowledge matters. Now I share this knowledge with every customer.

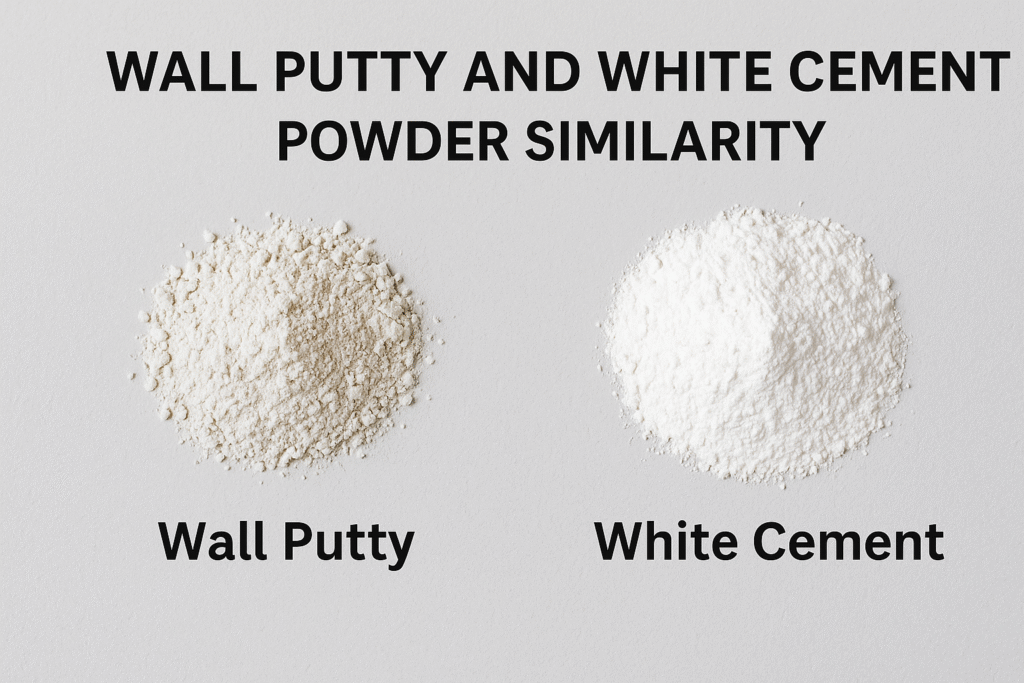

Wall Putty vs White Cement – Similarities

People confuse these products because they look alike. Both come as white powder. Both need water for mixing.

Wall putty and white cement share three similarities. Both products come in powder form. Both require water for application. Both create white surfaces after drying. These similarities cause confusion among first-time buyers.

Common Features Table

| Feature | Wall Putty | White Cement |

|---|---|---|

| Color | White | White |

| Form | Powder | Powder |

| Mixing | With water | With water |

| Packaging | 20-40 kg bags | 25-50 kg bags |

I remember a customer from Brazil who ordered 100 tons of white cement. He thought it was wall putty. We caught the mistake before shipping. These similarities fool even experienced buyers. That's why I always confirm the intended use before processing orders.

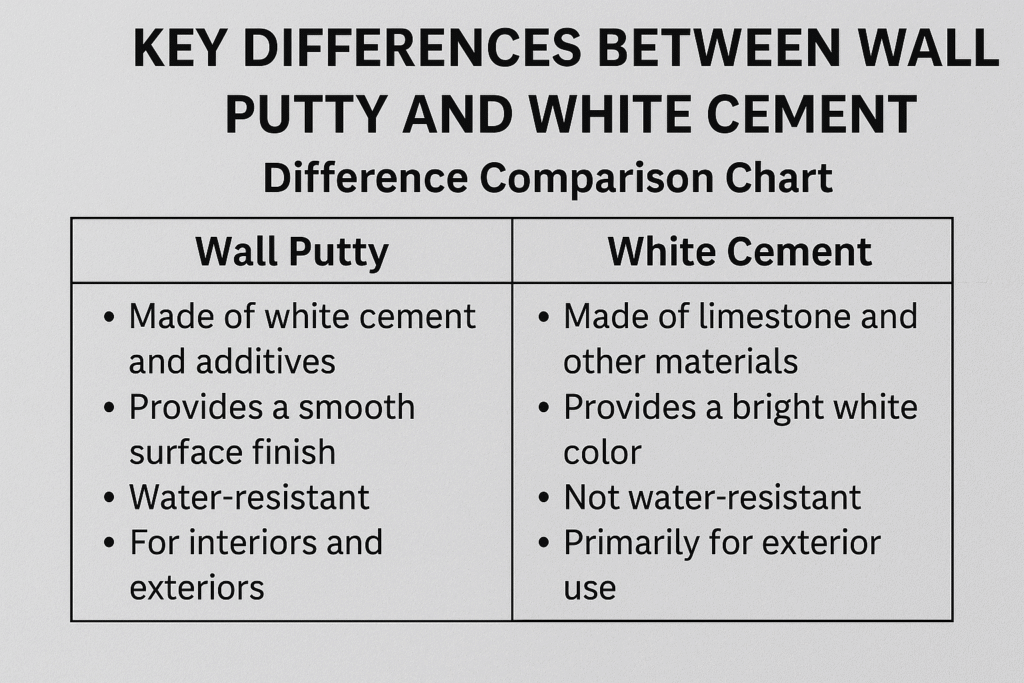

Wall Putty vs White Cement – Differences

The differences matter more than similarities. Each product has its own purpose. Using the wrong one ruins your project.

Wall putty and white cement differ in five ways. Composition varies - putty has polymers, cement has limestone. Application differs - putty for finishing, cement for binding. Durability changes - cement lasts longer outdoors. Cost varies - putty costs more initially. Coverage differs - putty covers more area per bag.

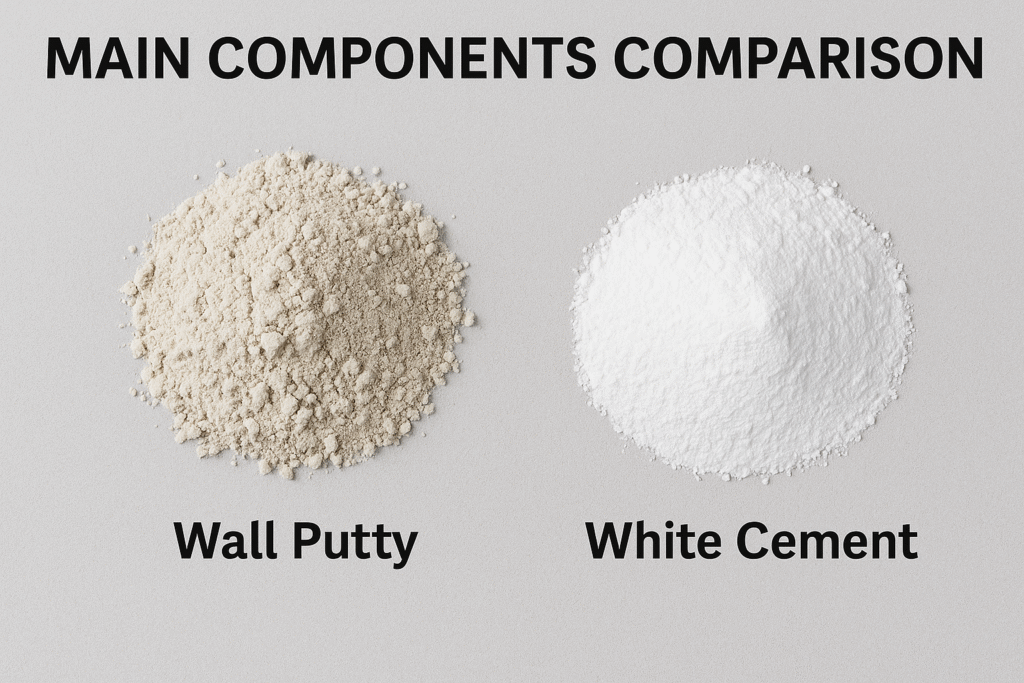

Differences in main components

The ingredients make all the difference. I show this to customers in our factory lab. They see the chemical composition clearly.

Wall putty contains white cement, polymers4, and minerals. White cement contains limestone, clay, and gypsum. Polymers in wall putty create smoothness. Limestone in white cement provides strength. These components determine their specific uses.

Component Comparison

| Product | Main Components | Function |

|---|---|---|

| Wall Putty | White cement (40%), Polymer (20%), Minerals (40%) | Smooth finish |

| White Cement | Limestone (75%), Clay (20%), Gypsum (5%) | Strong binding |

Last year, a paint factory owner from India visited us. He wanted to understand why his putty formula failed. I showed him our component testing. He missed the polymer ratio. One ingredient change fixed his entire production line. Understanding components prevents such costly mistakes. Our HPMC additives enhance both products differently. That's why component knowledge helps you choose correctly.

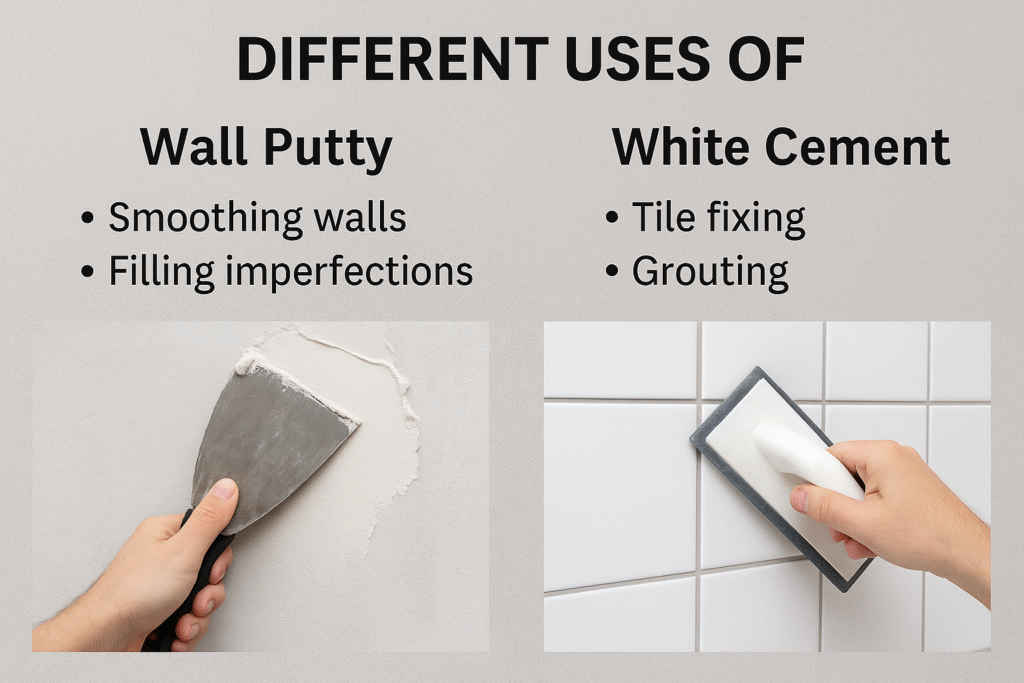

Difference in use

Each product serves specific purposes. I see contractors waste money using products wrongly. Let me explain the right applications.

Wall putty works on interior walls before painting. White cement works for tile fixing, gap filling, and decorative elements. Use wall putty5 for smooth finishes indoors. Use white cement3 for strong bonds and outdoor applications. Never interchange these uses.

Application Guide

| Application | Wall Putty | White Cement |

|---|---|---|

| Interior walls | ✓ | ✗ |

| Exterior walls | ✗ | ✓ |

| Tile fixing | ✗ | ✓ |

| Crack filling | ✓ (small) | ✓ (large) |

| Pre-paint base | ✓ | ✗ |

I helped a Sri Lankan distributor last month. His customers complained about poor paint adhesion. They used white cement as a paint base. I sent them wall putty samples. The paint now lasts five years instead of one. Proper use saves money and reputation. My experience shows that 70% of failures come from wrong product selection.

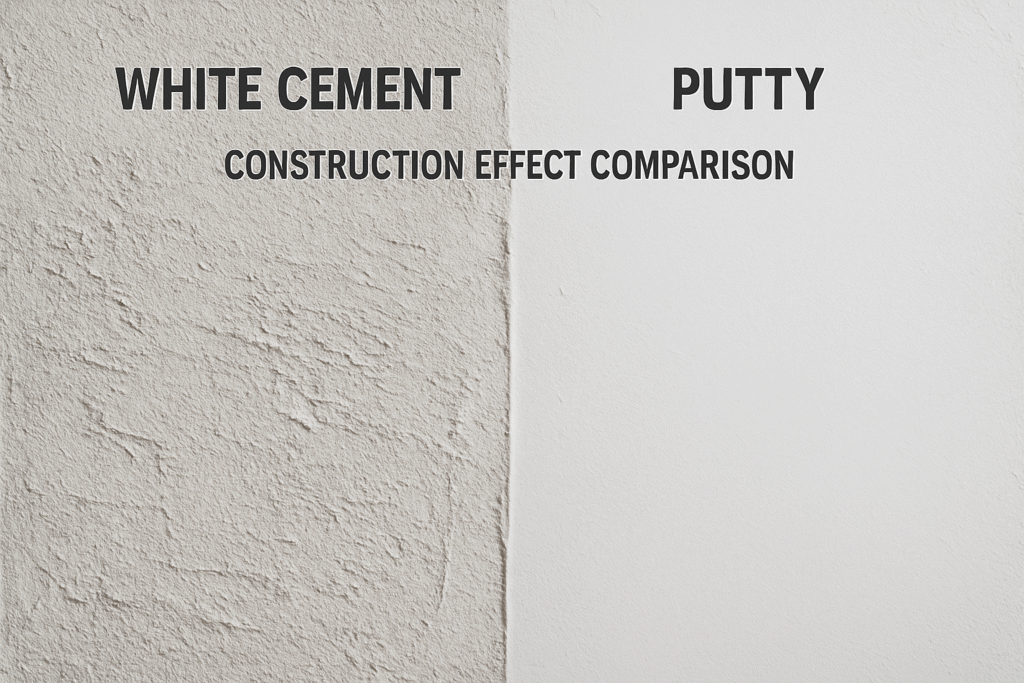

Differences in construction effect6

The final result shows the biggest difference. I take photos at customer sites. The visual difference convinces skeptics immediately.

Wall putty creates ultra-smooth surfaces perfect for painting. White cement leaves a rough texture needing additional finishing. Putty reduces paint consumption by 20%. White cement increases paint usage due to absorption. Choose based on your desired finish quality.

Two months ago, a Mexican contractor sent me photos. One wall used putty, another used white cement. The putty wall looked like glass. The cement wall showed every imperfection. He now specifies wall putty for all premium projects. The construction effect directly impacts customer satisfaction. Smooth walls command higher prices in the real estate market. This difference alone justifies the product choice. Our customers report 30% fewer callbacks when using the right product.

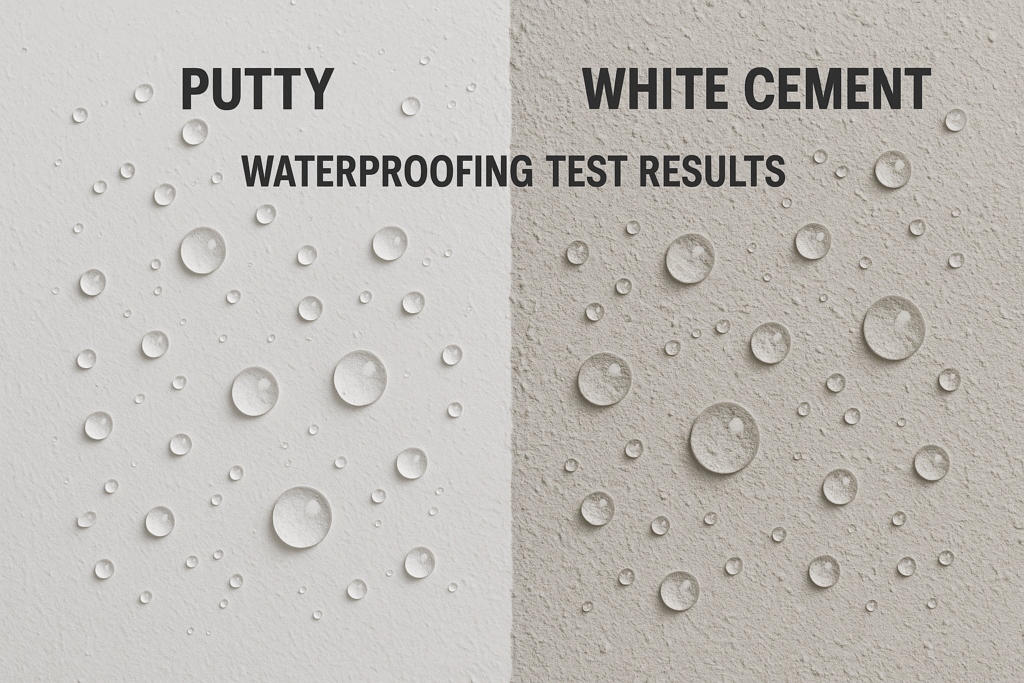

Difference in waterproofing

Water resistance matters in construction. I test both products in our lab rain chamber. The results surprise many buyers.

White cement offers better water resistance than wall putty. Wall putty absorbs moisture in wet conditions. White cement forms a water-resistant barrier when mixed properly. Use waterproof wall putty for bathrooms. Use white cement for exterior applications exposed to rain.

Water Resistance Data

| Test Condition | Wall Putty | White Cement |

|---|---|---|

| Light moisture | Good | Excellent |

| Heavy rain | Poor | Good |

| Underwater | Fails | Moderate |

| Bathroom use | Special grade | Standard OK |

A Pakistani customer learned this lesson expensively. He used regular wall putty in bathrooms. The walls developed fungus within months. Now he buys our waterproof wall putty grade. It contains special additives for moisture resistance. Understanding waterproofing properties prevents costly repairs. Each climate needs different protection levels.

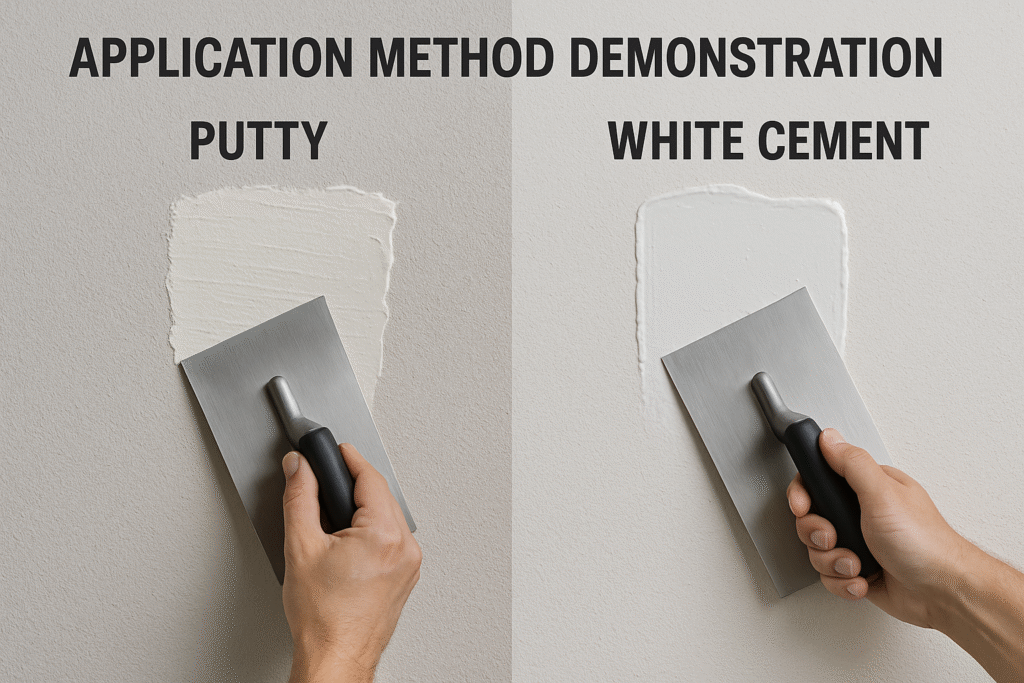

Wall Putty vs White Cement – Method of Application

Application methods differ completely. I train customer teams regularly. Proper technique ensures perfect results.

Wall putty needs two thin coats with 4-hour gaps. White cement requires thick single application with sand mixture. Putty uses a flat trowel for spreading. White cement needs a rough trowel for adhesion. Different tools and techniques produce different results.

Application Steps Comparison

| Step | Wall Putty | White Cement |

|---|---|---|

| Mixing ratio | 2:1 (powder:water) | 3:1 (cement:sand) |

| Application layers | 2 thin coats | 1 thick coat |

| Drying time | 4-6 hours | 24-48 hours |

| Tools needed | Flat trowel, sandpaper | Rough trowel, float |

| Surface prep | Clean, dry | Damp, rough |

Last week, I conducted training for a Vietnamese team. They applied wall putty like cement - too thick, one coat. The surface cracked everywhere. I showed them the two-coat method. Now their walls look professional. Application technique makes or breaks the project. Even the best product fails with wrong application. Our technical team provides video guides for both products.

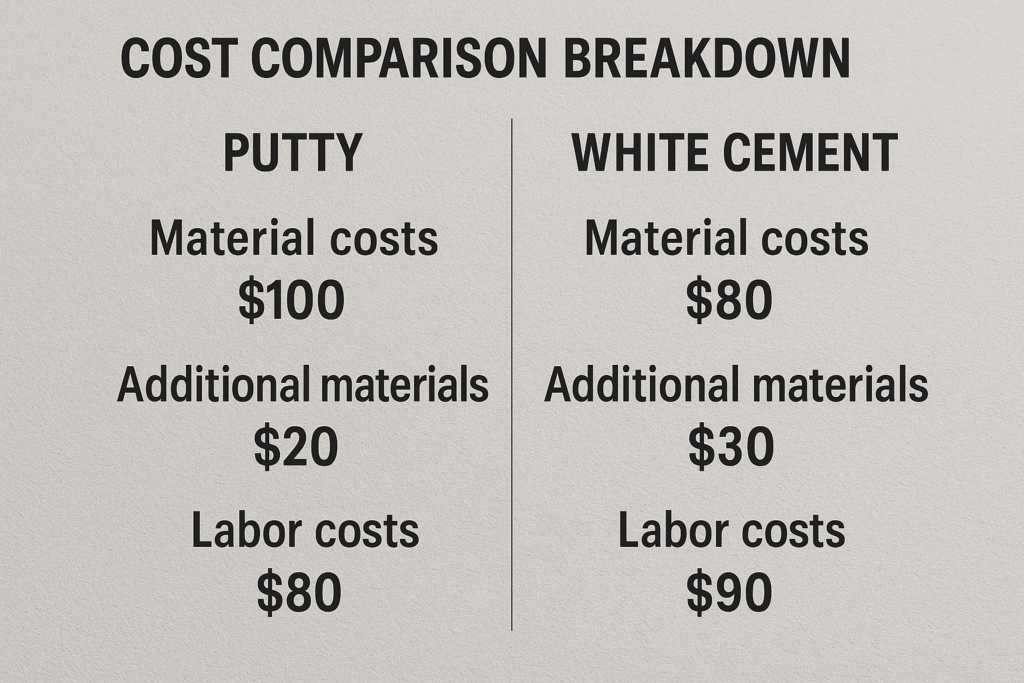

Wall Putty vs White Cement – Cost

Price comparisons confuse buyers. I explain the real cost calculation. Initial price doesn't tell the full story.

Wall putty costs 30% more per bag than white cement. But putty covers 40% more area per kg. Labor costs less with putty due to easier application. Total project cost favors wall putty for interior finishing. White cement remains cheaper for structural work.

A Georgian distributor questioned our putty prices last year. I calculated his total project cost. Wall putty saved him 20% overall. He now promotes putty for all interior projects. Smart buyers calculate coverage, not just bag price. Our business grows because customers understand value. The right product reduces long-term maintenance costs significantly.

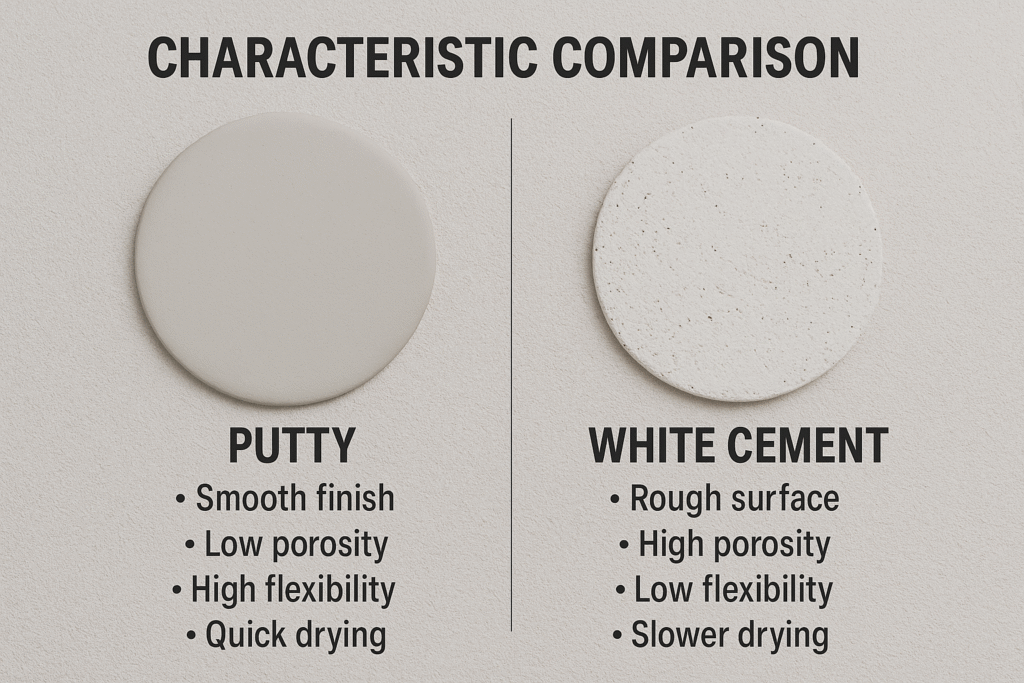

Wall Putty vs White Cement – Characteristic

Each product has unique characteristics. I keep samples in our showroom. Customers touch and feel the difference.

Wall putty feels smooth and light, perfect for interior aesthetics. White cement feels rough and heavy, ideal for strength. Putty resists minor cracks through flexibility. Cement prevents major structural failures through rigidity. Choose based on your primary need - beauty or strength.

Characteristic Comparison Table

| Characteristic | Wall Putty | White Cement |

|---|---|---|

| Texture | Very smooth | Rough |

| Weight | Light | Heavy |

| Flexibility | High | Low |

| Bonding | Moderate | Very high |

| Workability | Easy | Moderate |

| Shelf life | 6 months | 3 months |

A UAE contractor switched to our products after feeling the difference. His previous supplier's putty felt grainy. Our putty felt like silk. Quality shows in characteristics. These differences impact worker satisfaction too. Smooth products reduce application fatigue. Our quality control ensures consistent characteristics in every batch.

Summary

Wall putty and white cement serve different purposes. Choose wall putty for smooth interior walls7. Choose white cement for strong exterior bonds. Understanding these differences saves money and ensures project success.

-

Discover the various applications of white cement, especially in structural work, to make informed choices for your projects. ↩

-

Explore this link to understand the benefits and applications of wall putty in creating smooth, paint-ready walls. ↩

-

Understanding the function of polymers in wall putty can help you select the best product for your projects. ↩ ↩

-

Explore this resource to understand wall putty's unique properties and applications for better project outcomes. ↩

-

Learn about white cement's benefits and applications to ensure you choose the right product for your needs. ↩

-

Understand the impact of wall putty on the final appearance of your projects for better results. ↩

-

Discover effective techniques for applying wall putty on interior walls to achieve a professional finish. ↩