Water retention problems can cost mortar manufacturers thousands in failed projects and customer complaints. Poor water retention leads to cracking, poor bonding, and reduced workability in mortars and renders.

HPMC (Hydroxypropyl Methylcellulose)1 water retention is affected by four key factors: molecular weight, substitution degree, viscosity, and dosage. Higher molecular weight and viscosity generally result in better water retention, while proper substitution degree and optimal dosage ensure balanced performance.

I've worked with countless construction material manufacturers who struggled with inconsistent mortar performance. Understanding these four factors has helped my clients develop products that perform reliably in even the most challenging environments.

How Does Molecular Weight Impact HPMC Water Retention?

Many mortar manufacturers struggle with premature drying and poor workability. Higher molecular weight HPMC could be the solution you're missing.

The molecular weight of HPMC directly influences its water retention capability. Higher molecular weight creates longer polymer chains that form stronger networks in the mortar, trapping water molecules more effectively and preventing rapid evaporation.

In my experience working with major mortar producers across Saudi Arabia and the UAE, molecular weight is often the most misunderstood yet critical factor in HPMC selection. The molecular weight of HPMC typically ranges from 10,000 to 200,000 Daltons, and this variation significantly impacts performance.

Higher molecular weight HPMC creates a more robust polymer network within the mortar matrix, which physically restricts water movement.

This restriction works in two important ways: first, it prevents water from evaporating too quickly from the mortar surface, which is especially important in hot, dry climates; second, it minimizes water migration to porous substrates.

I've observed that increasing molecular weight from 86,000 to 125,000 Daltons can improve water retention by approximately 15-20% in standard cement mortars.

However, there's an important trade-off to consider. While higher molecular weight improves water retention, it may reduce workability if not properly balanced with other additives. For optimal results, I recommend:

| Molecular Weight Range | Best Applications | Expected Water Retention |

|---|---|---|

| 20,000-50,000 | Thin-set mortars | 85-88% |

| 50,000-100,000 | General purpose mortars | 88-92% |

| 100,000-150,000+ | High-performance renders | 92-98% |

What Role Does Substitution Degree Play in Water Retention?

Your mortar's performance varies widely in different conditions? The substitution degree of your HPMC might be causing these inconsistencies in water retention.

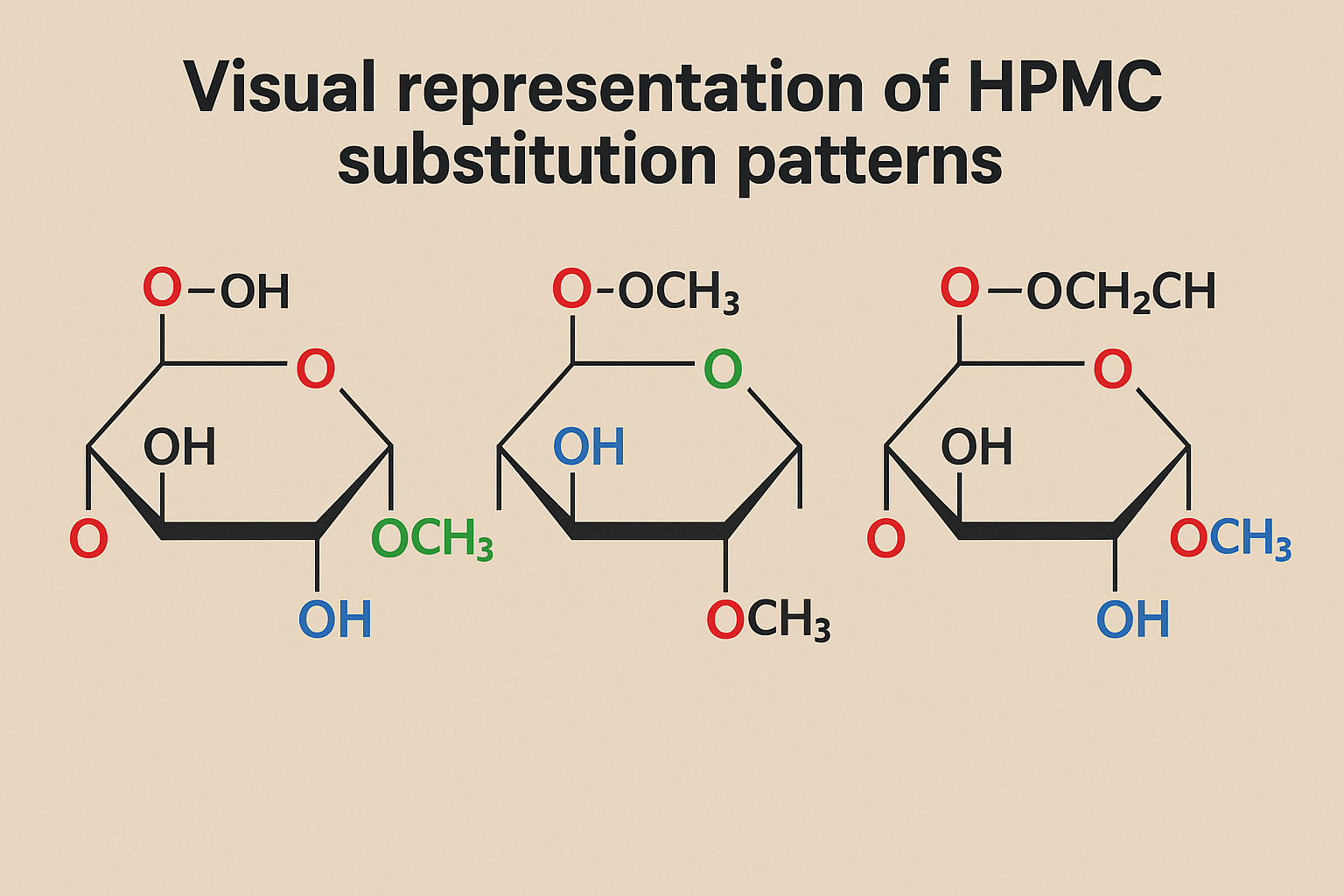

The substitution degree2 of HPMC refers to the ratio of methoxy and hydroxypropyl groups attached to the cellulose backbone, directly affecting its hydrophilic-hydrophobic balance and consequently its water retention properties.

The substitution degree is perhaps the most technically complex aspect of HPMC, but understanding it has transformed how I help clients select the right product. In the chemical structure of HPMC, there are two key substitution parameters: methoxyl content (typically 28-30%) and hydroxypropoxyl content (7-12%).

The balance between these two groups determines how the HPMC interacts with water molecules.

From my work with factories across developing markets, I've found that a higher hydroxypropoxyl substitution typically improves water retention capability because these groups are more hydrophilic. However, the methoxyl groups play an equally important role in controlling dissolution temperature and gel formation.

The perfect balance creates an HPMC that forms a strong gel structure at the right time during the mortar's setting process.

This balance is particularly important when dealing with extreme climate conditions. For instance, when I advised a large mortar producer in Iran who was experiencing inconsistent results between summer and winter applications, adjusting the HPMC substitution degree resolved their seasonal performance variations.

Consider these substitution patterns for different applications:

| Application | Recommended Methoxyl (%) | Recommended Hydroxypropoxyl (%) | Benefit |

|---|---|---|---|

| Hot climate mortars | 28-29 | 9-12 | Enhanced thermal stability |

| Cold climate mortars | 29-30 | 7-9 | Lower dissolution temperature |

| Tile adhesives | 28-30 | 7-8 | Balanced water retention and adhesion |

How Does Viscosity Affect Water Retention Properties?

Is your mortar drying too quickly despite using HPMC? The viscosity grade you're using might not match your application needs.

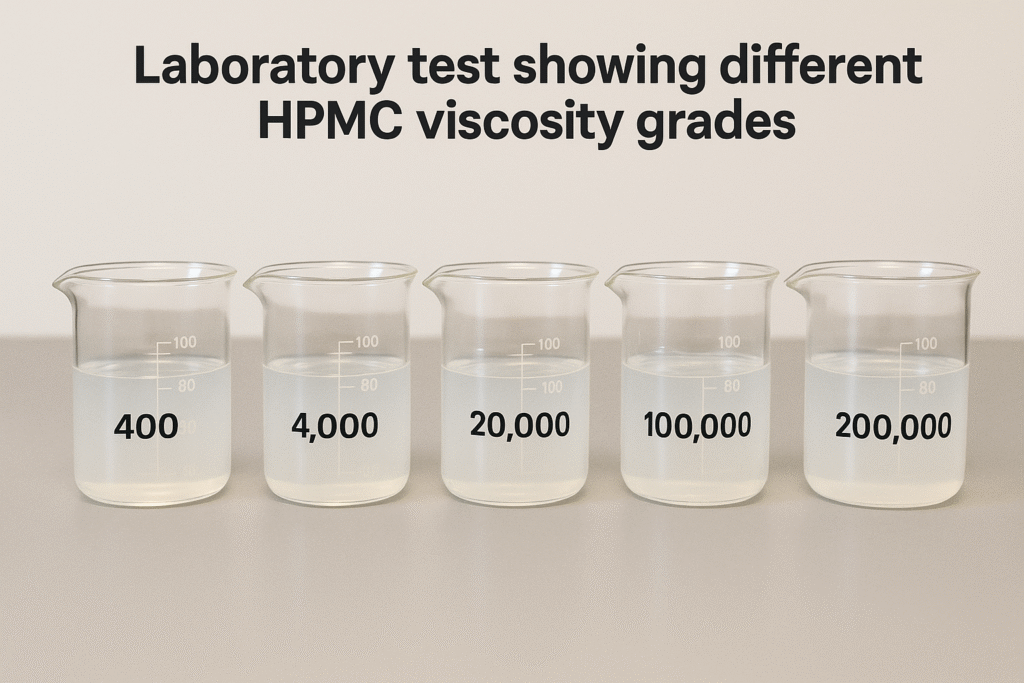

HPMC viscosity3 directly correlates with water retention capabilities – higher viscosity grades generally provide better water retention by creating thicker gel structures that more effectively prevent water evaporation and migration.

As the technical director at Kehao, I've conducted extensive testing on how viscosity affects water retention across different mortar formulations. Viscosity is measured in mPa·s (millipascal-seconds) and ranges from ultra-low (5-20 mPa·s) to extremely high (100,000+ mPa·s).

This property reflects how effectively the HPMC solution resists flow, which directly impacts its ability to hold water within the mortar system.

Through our laboratory testing with clients in Pakistan and India, we've consistently observed that higher viscosity HPMC creates a more structured gel network that physically traps water molecules. A 100,000 mPa·s HPMC typically achieves 95%+ water retention compared to 85-90% for a 15,000 mPa·s product in identical mortar formulations.

However, selecting the appropriate viscosity involves more than maximizing water retention. Higher viscosity HPMC generally reduces workability and increases cost. From my experience serving over 200 mortar manufacturers, I've developed this practical guide for viscosity selection:

| Mortar Type | Recommended Viscosity Range (mPa·s) | Optimal Water Retention (%) |

|---|---|---|

| Self-leveling compounds | 5,000-15,000 | 80-85 |

| Standard tile adhesives | 15,000-30,000 | 85-90 |

| Renders/Plasters | 40,000-80,000 | 90-95 |

| High-performance mortars | 80,000+ | 95-98 |

Additionally, viscosity requirements may vary based on application method. For spray-applied mortars, I typically recommend lower viscosity grades to ensure proper flowability through equipment while still maintaining adequate water retention.

What Is the Optimal HPMC Dosage for Effective Water Retention?

Using too much or too little HPMC? Find the sweet spot that balances cost and performance for your specific mortar formulation.

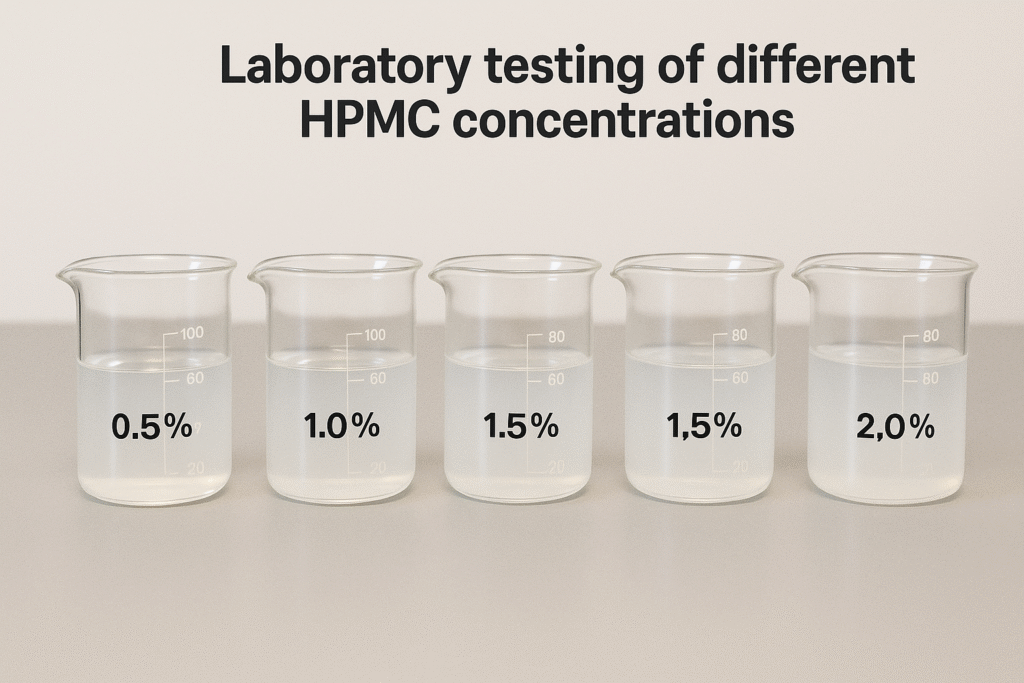

HPMC dosage significantly impacts water retention, with optimal concentrations typically ranging between 0.2-0.5% of the dry mortar weight, though the exact percentage depends on the specific grade and application requirements.

Finding the optimal HPMC dosage4 has been a critical part of my consultation work with mortar manufacturers across Vietnam, Philippines, and Brazil.

While molecular weight, substitution degree, and viscosity are inherent properties of the HPMC itself, dosage is the factor that you as a manufacturer have the most direct control over during formulation.

Through extensive testing in our R&D center, we've established that water retention increases with HPMC dosage, but this relationship isn't linear. There's typically a plateau point beyond which adding more HPMC yields diminishing returns while significantly increasing cost and potentially creating other issues like excessive air entrainment or delayed setting.

For most standard cement-based mortars, I recommend starting with these dosage guidelines:

| HPMC Viscosity | Starting Dosage (% of dry mix) | Expected Water Retention | Adjustment Factors |

|---|---|---|---|

| 5,000-15,000 mPa·s | 0.25-0.35% | 80-85% | +0.05% for porous substrates |

| 15,000-40,000 mPa·s | 0.2-0.3% | 85-90% | +0.05% for hot/dry conditions |

| 40,000-100,000 mPa·s | 0.15-0.25% | 90-95% | -0.05% for cool/humid conditions |

| >100,000 mPa·s | 0.1-0.2% | 95%+ | Adjust based on workability needs |

It's worth noting that the optimal dosage is highly dependent on your specific formulation. For instance, when I worked with a major mortar producer in Mexico, we found that the presence of other additives like redispersible polymer powder reduced the HPMC requirement by approximately 0.05-0.1% while maintaining the same water retention properties.

Conclusion

Understanding the four key factors of HPMC water retention—molecular weight, substitution degree, viscosity, and dosage—will help you select the right grade for your specific mortar applications, ensuring optimal performance and cost-effectiveness.

-

Explore this link to understand how HPMC enhances water retention in mortars, crucial for construction quality. ↩

-

Discover the significance of substitution degree in HPMC, which can greatly influence mortar performance and consistency. ↩

-

Understanding HPMC viscosity is crucial for optimizing water retention in mortars. Explore this link to learn more about its effects. ↩

-

Understanding the optimal HPMC dosage can significantly enhance your mortar formulations, ensuring better performance and cost-effectiveness. ↩