Builders face daily challenges with traditional site-mixed mortars1: inconsistent quality, material waste, and labor inefficiency. These problems directly impact project timelines and budgets, creating unnecessary stress.

Dry-mix mortar is a factory-produced mixture of sand, binders (like cement), and special additives pre-blended in specific proportions, requiring only water addition at the construction site. It offers superior consistency, quality, reduced waste, and significant time and labor savings compared to traditional site-mixed alternatives.

I've been in the construction materials industry for over 15 years, and I've witnessed firsthand the remarkable shift toward dry-mix mortar2s. Customers who initially resisted the change now wouldn't consider going back to traditional mixing methods. Let's explore why dry-mix mortars have become so popular and how they might benefit your projects too.

What Are the Benefits of Dry Mix?

Many contractors struggle with unpredictable material performance, excessive waste, and high labor costs. These issues directly affect project profitability and reputation in an increasingly competitive market.

Dry-mix mortar benefits include consistent quality, reduced material waste, lower labor costs, extended shelf life (6-12 months when properly stored), improved worksite cleanliness, and precise performance characteristics tailored to specific applications.

The advantages of dry-mix mortar2 extend far beyond simple convenience. As a factory owner who produces these materials, I've had countless conversations with customers about the specific benefits they've experienced after switching from traditional site-mixing.

Material Consistency and Quality Control

The factory production of dry-mix mortar2s involves strict quality control protocols that site-mixing simply cannot match. Every batch undergoes testing to ensure it meets exact specifications for strength, workability, and performance. Our production facility uses computer-controlled systems to measure ingredients with precision down to the gram, eliminating human error.

This consistency is particularly valuable for large-scale projects where even minor variations can lead to significant problems. One of our customers, a major commercial developer, reported that switching to our dry-mix products reduced their callback issues by nearly 40% by eliminating inconsistencies between batches.

Time and Labor Savings

Traditional mortar mixing is incredibly labor-intensive. Workers must measure separate components, operate mixing equipment, and manually transport materials around the site. With dry-mix, the process is dramatically simplified:

| Traditional Site-Mixed Process | Dry-Mix Process |

|---|---|

| Source individual materials (cement, sand, additives) | Order pre-blended dry-mix |

| Transport and store multiple materials | Store single product |

| Measure components for each batch | Open bag and add to mixer |

| Mix to achieve proper consistency | Add specified amount of water |

| Clean up multiple material storage areas | Minimal cleanup required |

This streamlined process can reduce labor costs by 20-30% on many projects. For time-sensitive jobs, this efficiency can be the difference between meeting deadlines and facing penalty clauses.

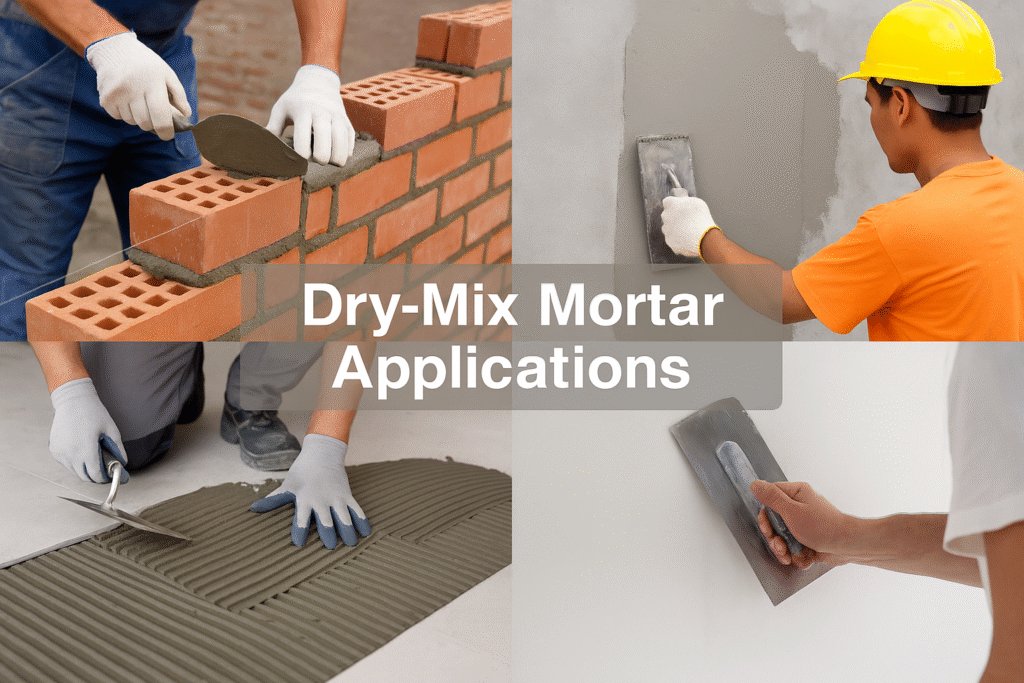

What Is Dry Mix Mortar Used For?

Contractors often waste time and resources using generic mortars for specialized applications, leading to premature failures and expensive repairs. This mismatch between material and purpose undermines project quality and client satisfaction.

Dry-mix mortars are specially formulated for specific applications including masonry (brick/block laying), rendering (wall finishing), flooring (leveling/screeding), tiling (ceramic/stone installation), plastering (interior finishing), and repair work (concrete rehabilitation) - each with tailored properties.

The versatility of dry-mix mortar2s makes them invaluable across virtually all construction sectors. We produce specialized formulations for dozens of specific applications, each with properties engineered for optimal performance in their intended use.

Application-Specific Formulations

Modern dry-mix mortars aren't one-size-fits-all products. They're highly specialized formulations designed with specific performance characteristics. For example:

- Masonry mortars: Enhanced bond strength and water retention

- Rendering mortars: Improved workability and crack resistance

- Floor screeds: Self-leveling properties and rapid hardening

- Tile adhesives: High initial grab and extended open time

- Repair mortars: Low shrinkage and high adhesion to existing substrates

I recently visited a restoration project where contractors were using our specialized repair mortar for a historic building. The architect specifically praised how the color-matched formulation blended seamlessly with the 100-year-old existing mortar while providing modern performance characteristics.

Performance Enhancements

Modern dry-mix mortars often contain specialized additives that would be difficult or impossible to incorporate in site-mixed materials:

- HPMC (Hydroxypropyl methylcellulose) for improved water retention

- Redispersible polymer powders for flexibility and adhesion

- Fibers for crack reduction and improved tensile strength

- Superplasticizers for workability without excess water

- Retarders or accelerators to control setting time

These additives allow for performance characteristics that traditional mortars simply cannot achieve. One of our customers in Saudi Arabia has been using our polymer-modified tile adhesive for outdoor installations in extreme heat conditions (45°C+) with an impressive zero-failure rate over five years.

What Is the Difference Between Wet and Dry Mortar?

Construction professionals often face confusing terminology and unclear distinctions between mortar types, leading to incorrect product selection, application problems, and project delays. This confusion costs time and money.

Wet mortar (ready-mix/site-mixed) comes already mixed with water, requiring immediate use (typically within 1-2 hours), while dry mortar is a powder mixture without water that remains usable for months when properly stored, offering greater flexibility and eliminating waste.

The distinction between wet and dry mortars represents fundamentally different approaches to construction efficiency. Having supplied both products throughout my career, I've observed how each serves different project needs and constraints.

Production and Delivery Methods

Wet mortars (often called ready-mix mortars) are typically produced at batching plants and delivered to construction sites in a ready-to-use state. This approach offers immediate usability but creates significant logistical challenges:

- Limited working time: Once mixed, wet mortar begins setting immediately, typically allowing only 1-2 hours of working time

- Scheduling complexity: Deliveries must be precisely timed to match application schedules

- Waste management: Unused portions must be disposed of, creating environmental concerns

- Weather sensitivity: Rain or extreme temperatures can delay deliveries and affect onsite storage

By contrast, dry-mix mortar2s offer much greater flexibility in scheduling and application. A construction manager from a large housing development told me they reduced material waste by over 60% after switching to our dry-mix products, as they could prepare exactly what they needed for each day's work.

Quality Control and Consistency

The quality control processes for wet and dry mortars differ significantly:

| Aspect | Wet Mortar | Dry Mortar |

|---|---|---|

| Mixing control | Dependent on batching plant | Factory-controlled under laboratory conditions |

| Batch consistency | May vary between deliveries | Highly consistent across production runs |

| Quality testing | Limited pre-delivery testing | Extensive testing of dry components |

| Shelf life | Hours | Months (when properly stored) |

| Adaptability | Fixed properties | Can be adjusted with water ratio |

This enhanced control translates directly into better performance. We regularly test our dry-mix products against site-mixed alternatives, consistently demonstrating superior strength development, adhesion, and durability in standardized tests.

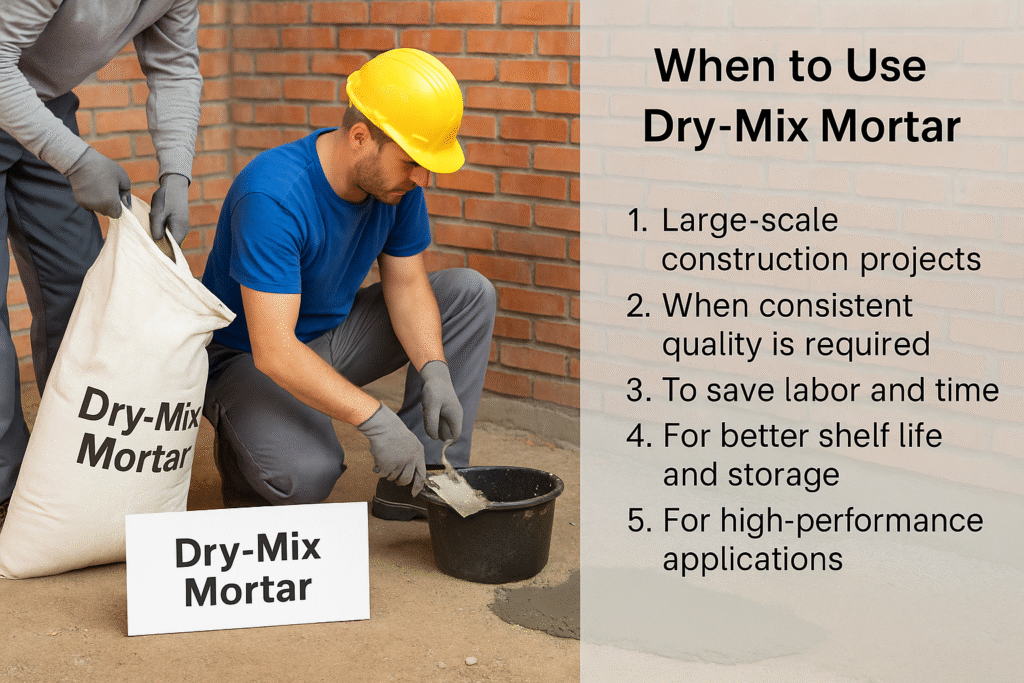

When to Use Dry Mortar Mix?

Project managers often struggle with material selection decisions that balance quality, cost, schedule, and logistical constraints. Making the wrong choice leads to application problems, delays, and budget overruns.

Dry mortar mix is ideal for projects requiring high-quality consistency, sites with limited mixing space, remote locations with difficult delivery access, projects with intermittent mortar needs, and applications demanding specialized performance characteristics impossible to achieve with site-mixed alternatives.

After supplying construction materials to thousands of projects, I've identified several scenarios where dry-mix mortars provide compelling advantages. The decision to use dry-mix isn't just about convenience—it often represents the most practical solution to specific project challenges.

Project Scale and Duration Considerations

The relationship between project size, duration, and mortar selection is nuanced:

For large-scale projects with continuous mortar needs, both options may be viable, but dry-mix offers advantages in:

- Consistency across the entire project timeline

- Elimination of mixing area requirements

- Reduction in labor costs

- Flexibility to use exact quantities needed

For smaller projects or those with intermittent mortar requirements, dry-mix becomes even more advantageous due to:

- No minimum delivery quantities (unlike ready-mix)

- No waste from unused materials

- Ability to store for future use

- Consistent quality even with time gaps between applications

One of our distributors in the UAE specializes in supplying dry-mix mortars to remote desert construction sites where ready-mix deliveries would be impractical. The long shelf-life and consistent performance regardless of ambient conditions make dry-mix the only viable option in these challenging environments.

Specialized Application Requirements

Some construction applications simply demand the precision and enhanced properties that only factory-produced dry-mix mortars can provide:

- Restoration work where matching historical appearances while providing modern performance is critical

- High-rise construction where pumping mortars to upper floors requires special formulations

- Fast-track projects where rapid-setting mortars can accelerate construction schedules

- Decorative finishes where consistent color and texture are essential

- Extreme weather applications requiring special additives to perform in challenging conditions

A recent example from my experience: a major hospital project specified our antimicrobial-enhanced dry-mix plaster for operating theaters because this specialized formulation provided properties impossible to achieve with conventional site-mixed materials.

Conclusion

Dry-mix mortars deliver superior quality, consistency, efficiency, and specialized performance across construction applications. They minimize waste, reduce labor costs, and offer unmatched flexibility, making them the preferred choice for modern construction professionals worldwide.