I see many contractors struggle with failed tile installations. Using the wrong mortar leads to cracked tiles, loose bonds, and costly repairs. The right mortar choice can make all the difference in your tiling project.

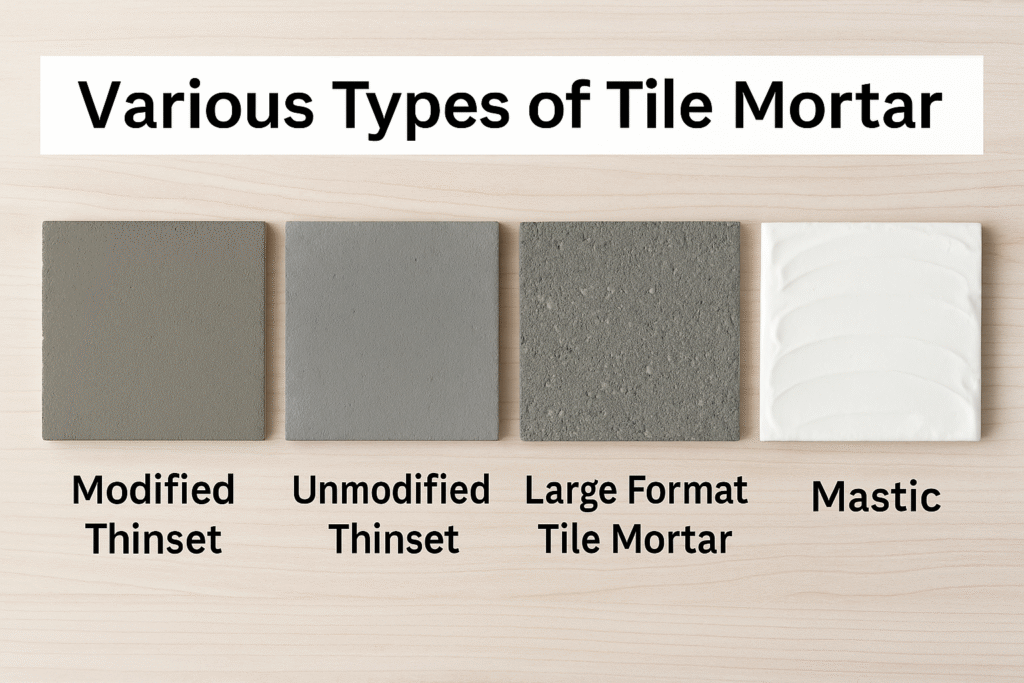

The best mortars for professional tile installation are thin-set mortar for most applications, tile mastic for walls in dry areas, epoxy mortar for chemical resistance, and large-format mortar1 for bigger tiles. Each type contains specific formulations of cement, polymers, and additives like hydroxypropyl methylcellulose2 that affect working time, strength, and flexibility.

After 15 years in the building materials industry, I've seen countless tile jobs fail from using inappropriate mortar. Let's explore all the mortar options so you can make the right choice for your project and ensure beautiful, long-lasting tile installations.

What Makes Thin-Set Mortar the Popular Choice for Most Tile Installations?

Every time I visit a job site, I notice professionals struggling with traditional mortar beds. They're heavy, time-consuming, and require extensive preparation. Thin-set mortar solves these problems instantly.

Thin-set mortar is a blend of Portland cement, fine sand, water-retention agents like HPMC, and latex additives that creates a strong bond in a thin layer (typically 3/32" to 1/4"). It works on most surfaces, including concrete, backer board, and existing tile, making it the versatile standard for both floor and wall tile installation.

Thin-set's popularity comes from its excellent combination of performance and convenience. When I supply thin-set mortar to factories, I always explain its core components and how each affects performance. HPMC (hydroxypropyl methylcellulose2) plays a crucial role by improving water retention, extending working time, and enhancing adhesion strength.

How Does HPMC Improve Thin-Set Performance?

| HPMC Property | Benefit in Thin-Set Mortar |

|---|---|

| Water retention | Prevents water from being absorbed too quickly by porous substrates |

| Workability | Creates a creamy, easy-to-trowel consistency |

| Extended open time | Gives installers more time to place and adjust tiles |

| Sag resistance | Prevents tiles from slipping on vertical surfaces |

| Air entrainment | Improves freeze-thaw durability |

The quality of HPMC directly affects the performance of the thin-set. Higher viscosity grades (around 100,000 mPa·s) work best for vertical applications where sag resistance is crucial, while medium viscosity HPMC (around 50,000-75,000 mPa·s) is ideal for floor applications.

I often recommend modified thin-set containing latex polymers for most installations. These polymers significantly improve flexibility, bond strength, and water resistance. For exterior installations or areas with heavy traffic, modified thin-set is practically essential.

When Should You Use Tile Mastic Instead of Traditional Mortar?

I've heard many contractors complain about the mess and preparation time with traditional mortars. They want something quick and clean for simple wall installations. Tile mastic addresses this frustration perfectly.

Tile mastic is a ready-to-use adhesive made from acrylic resins and fillers that requires no mixing and provides instant grab for wall tiles. It's ideal for bathroom and kitchen backsplashes in dry areas but shouldn't be used in showers, tub surrounds, floors, or exterior applications due to poor water resistance.

Mastic offers convenience that many installers find appealing, especially for small projects. I've noticed that many DIYers and professional installers use mastic for kitchen backsplashes and other vertical installations where high moisture isn't a concern. The premixed formula eliminates measuring and mixing, saving time and reducing cleanup.

However, I always caution customers about mastic's limitations. The organic adhesives in mastic remain somewhat water-soluble even after curing, which makes them susceptible to deterioration in wet environments. Additionally, mastic doesn't have the heat resistance of cementitious mortars.

Comparing Mastic and Thin-Set Applications

| Feature | Tile Mastic | Thin-Set Mortar |

|---|---|---|

| Working time | 10-15 minutes | 20-60 minutes (with HPMC) |

| Dry time | 24-48 hours | 24-72 hours |

| Water resistance | Poor | Excellent |

| Tile size limit | Generally under 8"×8" | No limit with proper formulation |

| Heat resistance | Poor | Excellent |

| Application areas | Dry wall areas | Floors, walls, wet areas, exterior |

| Cost | Higher per sq. ft. | Lower per sq. ft. |

When I discuss mastic with mortar manufacturers, I explain that while mastic has its place in the installer's toolkit, it's not a replacement for a high-quality thin-set. For any application involving moisture, larger tiles, or floors, thin-set with quality HPMC and appropriate additives is the only reliable choice.

Why Is Epoxy Grout Essential for Specialized Tile Applications?

During manufacturing consultations, I frequently encounter clients frustrated with grout staining and deterioration in commercial settings. Standard grouts fail quickly in harsh environments, creating ongoing maintenance headaches and costs.

Epoxy grout is a high-performance alternative that combines epoxy resins with fillers and hardeners to create extremely durable, stain-resistant, and chemical-resistant joints between tiles. It's essential for commercial kitchens, laboratories, pools, and areas exposed to harsh chemicals where traditional cement grout would deteriorate.

Epoxy mortars and grouts represent the premium tier in tile installation materials. Unlike traditional cement-based products, they don't rely on hydraulic bonding but instead create a chemical bond that's virtually impervious to water and chemicals. This makes them ideal for specialized applications where performance is critical.

The formulation of epoxy mortars is quite different from cement-based mortars. Instead of HPMC and other cellulose ethers, they use specialized additives to control flow properties and working characteristics. This results in different handling properties that installers need to understand.

Key Differences Between Epoxy and Cement-Based Systems

| Feature | Epoxy Systems | Cement-Based Systems |

|---|---|---|

| Chemical resistance | Excellent | Limited |

| Stain resistance | Excellent | Poor to moderate |

| Water absorption | Nearly zero | 3-10% typically |

| Flexibility | Moderate to high | Low to moderate |

| Installation difficulty | More complex | Simpler |

| Cost | 3-5× more expensive | More economical |

| Working time | Often shorter | Longer with HPMC |

| Curing time | Chemical cure (independent of environment) | Hydraulic cure (affected by temperature/humidity) |

One thing I always emphasize to my mortar manufacturing clients is that epoxy systems require precise mixing ratios and thorough blending. Even small deviations can dramatically affect performance. This is one reason why cement-based systems containing our HPMC continue to dominate the market—they're more forgiving during mixing and installation while still providing excellent performance for most applications.

How Does Large Format Mortar Differ From Regular Mortar?

I've witnessed countless frustrations with large tiles cracking or lippage issues because standard mortars simply can't handle the weight and stress. Large tiles have unique requirements that standard mortars can't meet.

Large format mortar contains higher polymer content, specialized aggregates, and enhanced water retention3 additives like HPMC that create a thicker bed while maintaining non-sag properties. This allows for better load distribution under heavier tiles and compensates for substrate irregularities4, preventing cracks and lippage in tiles larger than 15"×15".

The trend toward larger tiles has revolutionized the mortar industry. When I first started supplying HPMC to mortar manufacturers, most tiles were 4"×4" or 8"×8". Today, 24"×48" tiles or even larger are common, creating new challenges for mortar formulations.

Large format mortars must balance seemingly contradictory properties: they need to be fluid enough to ensure complete coverage under large tiles while remaining stable enough to prevent sagging on walls and lippage on floors. This is where advanced cellulose chemistry becomes critical.

Technical Requirements for Large Format Mortars

| Property | Requirement | Role of HPMC |

|---|---|---|

| Workability | Extended | High molecular weight HPMC increases viscosity for better workability |

| Open time | 30+ minutes | HPMC retains water longer, extending working time |

| Sag resistance | Less than 0.5mm sag | HPMC provides thixotropic properties |

| Adjustability | 15-20 minutes | Controlled water retention allows repositioning time |

| Coverage ability | 90%+ contact | Improved flow properties ensure complete coverage |

| Thickness capability | Up to 1/2" | Enhanced stability at greater thickness |

| Deformability | Higher S1 or S2 classification | Works with polymers to enhance flexibility |

When formulating large format mortars, we typically recommend using HPMC with higher viscosity (80,000-150,000 mPa·s) and optimized particle size distribution. This creates the ideal balance of non-sag properties and flow characteristics. Additionally, we often suggest incorporating redispersible polymer powders at a higher percentage (usually 4-6%) compared to standard thin-sets (typically 2-3%).

The technical challenge of creating a mortar that can support these massive tiles without slumping or creating lippage is substantial, but with the right formulation, large-format installations can be just as durable and beautiful as traditional tile work.

What Are the Secrets to Properly Mixing Mortar for Maximum Performance?

Through countless factory visits, I've observed inconsistent mixing leading to weak bonds, short working times, and failed installations. Even the best mortar formulation can fail when mixed incorrectly.

Proper mortar mixing requires clean water at 70-75°F, precise water-to-powder ratios (typically 5-6 quarts per 50lb bag), initial mixing for 2-3 minutes followed by a 5-minute slaking period, then re-mixing for 1-2 minutes. This process fully activates the HPMC and other additives, maximizing bond strength and working properties.

The mixing process has a profound impact on mortar performance. I've conducted numerous demonstrations for clients showing how the same formulation can yield dramatically different results based on mixing technique. The full hydration of HPMC and proper dispersion of polymers are particularly sensitive to mixing methodology.

One critical aspect many installers overlook is the slaking period. This 5-minute rest after initial mixing allows the HPMC to fully hydrate and develop its water retention and rheological properties. Skipping this step often leads to reduced working time and decreased bond strength.

Mixing Variables That Affect Performance

| Variable | Impact | Recommendation |

|---|---|---|

| Water temperature | Affects hydration speed | Use 70-75°F water (21-24°C) |

| Water quality | Impurities can affect setting | Use clean potable water |

| Mixing speed | Too fast causes air entrainment | Mix at 300-500 RPM |

| Mixing time | Insufficient mixing = poor dispersion | 2-3 minutes initial mix |

| Slaking period | Critical for HPMC hydration | Mandatory 5-minute rest |

| Re-mixing | Ensures homogeneous properties | 1-2 minutes before use |

| Partial mixing | Inconsistent performance | Always mix full bags |

The paddle design also affects mixing efficiency. For most thin-sets, I recommend using a square or rectangular paddle that creates significant shear forces to break up agglomerates and fully disperse the HPMC and latex polymers. Avoid paint-style paddles that don't create enough shear.

When I train mortar manufacturers' technical teams, I emphasize that the instructions they provide on packaging should be specific and detailed regarding mixing. Many installation failures occur not because the formulation was inadequate, but because the installer didn't understand the critical importance of proper mixing technique5.

Conclusion

Choosing the right mortar—thin-set for versatility, mastic for simple wall applications, epoxy for special conditions, or large-format for bigger tiles—and mixing it properly ensures professional results. Understanding these options will enhance your tile installation success.

-

Understand the unique properties of large-format mortar for handling bigger tiles effectively. ↩

-

Find out how HPMC enhances water retention and adhesion in various mortar types. ↩ ↩

-

Explore the importance of water retention in achieving strong tile bonds and preventing failures. ↩

-

Learn how to address substrate issues to ensure a successful tile installation. ↩

-

Learn the essential steps to ensure proper mixing for maximum mortar effectiveness. ↩