Are you struggling with mortars that slide down walls or crack after drying? Your materials might be to blame. The right additives make all the difference between project success and costly failures.

Hydroxypropyl Methylcellulose (HPMC)1 serves as the "main force" in mortar, primarily retaining water to ensure cement has sufficient moisture for solidification and strength development. Meanwhile, Hydroxypropyl Starch (HPS)2 functions as a "special forces" additive, specifically addressing anti-sagging and improving workability.

I've worked with countless mortar formulations over my years at Kehao, and I've noticed many contractors and even manufacturers often confuse these two additives. Understanding their distinct characteristics isn't just technical trivia – it directly impacts your project's quality and cost-effectiveness. Let me break down these differences in practical terms.

What is Hydroxypropyl Starch (HPS)2 and How Does it Work in Construction?

Have you ever applied mortar to a wall only to watch it sag or slide down? This frustrating experience points to a missing ingredient in your mix.

Hydroxypropyl Starch (HPS) is a modified starch that provides excellent anti-sagging properties in mortars. It creates a gel-like structure that holds materials in place on vertical surfaces while maintaining workability, with typical dosage rates of 0.05-0.15% in dry mortar formulations.

Key Properties of Hydroxypropyl Starch ether (HPS)

When I first started recommending HPS to our customers at Kehao, many were skeptical about adding another component to their formulations. But the results speak for themselves. HPS transforms how mortar behaves during application, especially on vertical surfaces.

Unlike HPMC, HPS has a unique thixotropic behavior – it's fluid under pressure (when you're applying it) but becomes gel-like at rest, preventing sagging. This creates that buttery, smooth feel that professional masons and plasterers prize so highly.

HPS typically has lower water retention capabilities than HPMC but excels in providing immediate viscosity and anti-sagging properties. It's particularly valuable in thicker applications where gravity becomes a significant challenge.

From a technical perspective, HPS molecules are significantly larger than HPMC molecules, which gives them different interaction profiles with cement particles. This larger molecular structure helps create a more pronounced scaffold within the mortar, supporting it against gravity's pull.

| Here's how HPS performs on key characteristics: | Property | HPS Performance |

|---|---|---|

| Anti-sagging | Excellent | |

| Workability | Very good | |

| Water retention | Moderate | |

| Open time | Moderate | |

| Cost | Lower than HPMC | |

| Typical dosage | 0.05-0.15% |

This particular set of properties makes HPS invaluable for specific applications but not a complete replacement for HPMC in most formulations.

What is Hydroxypropyl Methylcellulose (HPMC)1 and Why is it Essential in Construction?

Is your mortar drying too quickly, resulting in poor bonding and eventual cracking? Water retention problems may be the culprit.

Hydroxypropyl Methylcellulose (HPMC) is a cellulose derivative that significantly enhances water retention in mortars and grouts. It ensures cement has sufficient water for complete hydration, typically dosed at 0.2-0.5% in dry mortar mixtures to improve consistency, workability, and final strength.

Key Properties of Hydroxypropyl Methylcellulose (HPMC)

I often tell my customers that if mortar is like a well-functioning team, HPMC is the captain. While visiting construction sites across Saudi Arabia and the UAE, I've witnessed firsthand how HPMC transforms basic cement mixtures into professional-grade materials.

HPMC's primary function is water retention – it forms a protective colloid around water molecules, releasing them slowly during the cement hydration process. This ensures proper curing even in challenging conditions like high temperatures or absorbent substrates.

Beyond water retention, HPMC contributes significantly to workability, providing lubrication between aggregate particles. This creates a smoother application experience and reduces physical effort during installation.

The viscosity of HPMC (typically measured in mPa·s) is a crucial specification that determines its performance. Different construction applications require specific viscosity ranges to achieve optimal results. For example, tile adhesives generally benefit from higher viscosity HPMC grades (60,000-100,000 mPa·s), while renders might use medium viscosity grades (40,000-60,000 mPa·s).

HPMC also influences open time – the period during which the mortar remains workable after application. This property is particularly critical for large-area applications like tiling, where installers need sufficient time to make adjustments.

| Here's a comparison of HPMC performance characteristics: | Property | HPMC Performance |

|---|---|---|

| Water retention | Excellent | |

| Workability | Good | |

| Anti-sagging | Moderate | |

| Open time | Long | |

| Cost | Higher than HPS | |

| Typical dosage | 0.2-0.5% |

These characteristics make HPMC indispensable in virtually all cementitious formulations, though its anti-sagging properties may not be sufficient for all applications.

How Do HPS and HPMC Differ in Construction Applications?

Are you struggling to decide which additive is right for your specific project? The differences go beyond simple substitution.

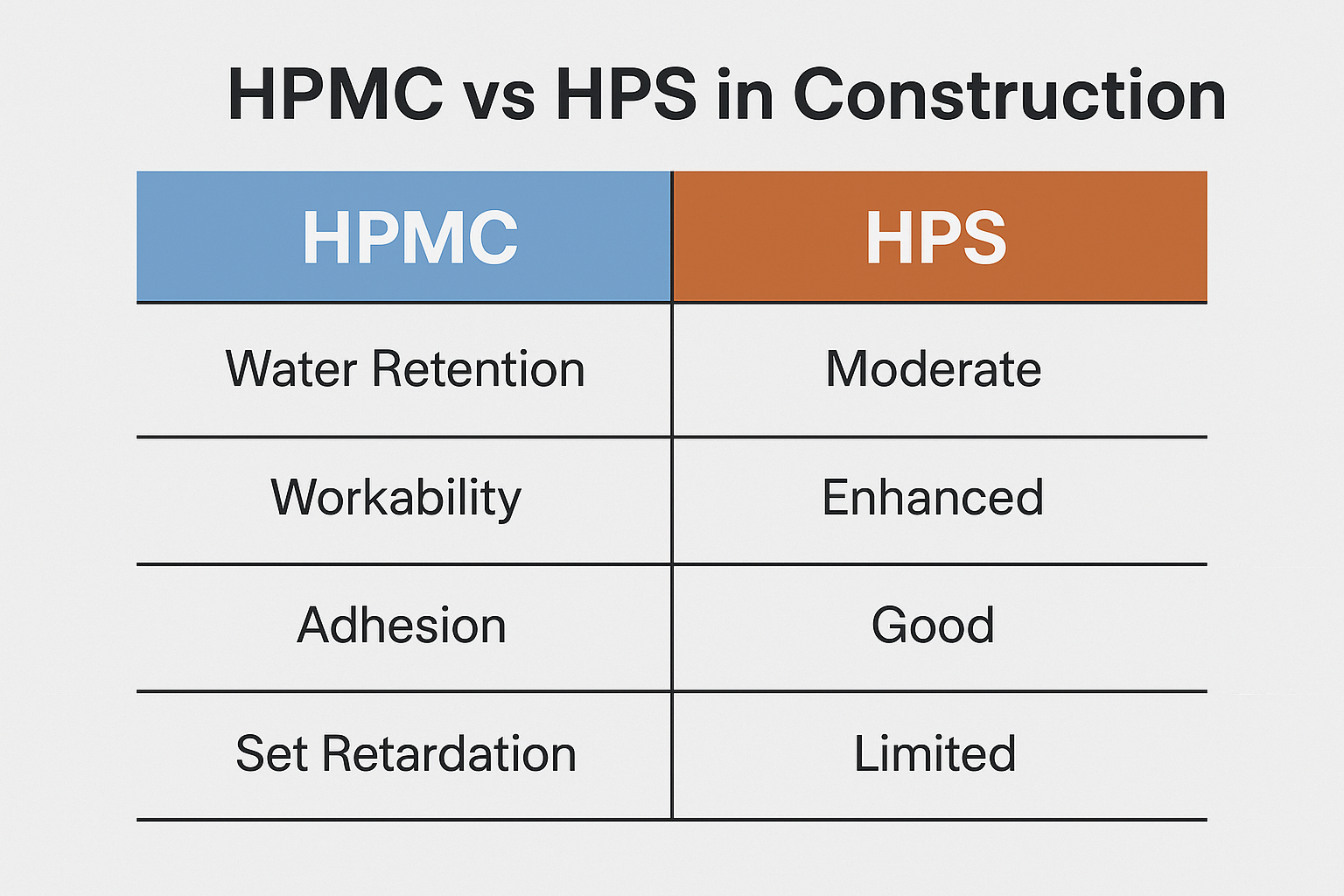

HPS excels at anti-sagging and provides smooth application feel but offers moderate water retention. HPMC provides superior water retention and open time but moderate anti-sag properties. They complement rather than replace each other, with optimal construction formulations often containing both additives for balanced performance.

Differences between HPS and HPMC in Construction

In my 15 years of formulating construction additives3 at Kehao, the most common misconception I encounter is that HPS and HPMC are interchangeable or competing products. This couldn't be further from the truth.

These two additives actually form what I call a "golden partnership" in effective mortar formulations. While they share some overlapping functions, their primary mechanisms and strengths are distinct and complementary.

HPMC operates primarily as a water retention agent, forming hydrogen bonds with water molecules to create a protective colloid that slows evaporation and cement hydration. Its molecular structure allows it to dissolve gradually, releasing water over time. This function is absolutely critical for cement strength development – insufficient water retention leads to incomplete hydration and weak final strength.

HPS, by contrast, works through a different mechanism. Its larger molecular structure creates an immediate scaffold within the fresh mortar mixture, providing resistance to flow while still allowing for easy manipulation. This creates that distinctive "buttery" feel that professional applicators prize, while preventing the material from sagging on vertical surfaces.

From a formulation perspective, the key difference becomes apparent in their cost-performance relationship:

| Aspect | HPS | HPMC |

|---|---|---|

| Primary function | Anti-sagging | Water retention |

| Secondary benefits | Improved workability | Extended open time |

| Mechanism | Physical scaffold | Chemical water binding |

| Cost impact | Lower (less expensive) | Higher (more expensive) |

| Dissolution speed | Faster | Slower |

| Temperature sensitivity | Higher | Lower |

The optimization strategy I recommend to our clients involves using both additives strategically. By incorporating HPS alongside a potentially lower-grade HPMC, formulators can actually achieve better overall performance at reduced cost. The HPS compensates for any reduction in viscosity from using a lower-grade HPMC, while maintaining the critical water retention properties needed for proper curing.

Where Should You Use HPS and HPMC in Construction Projects?

Confused about which products need which additives? Different applications have distinct requirements that determine the ideal formulation.

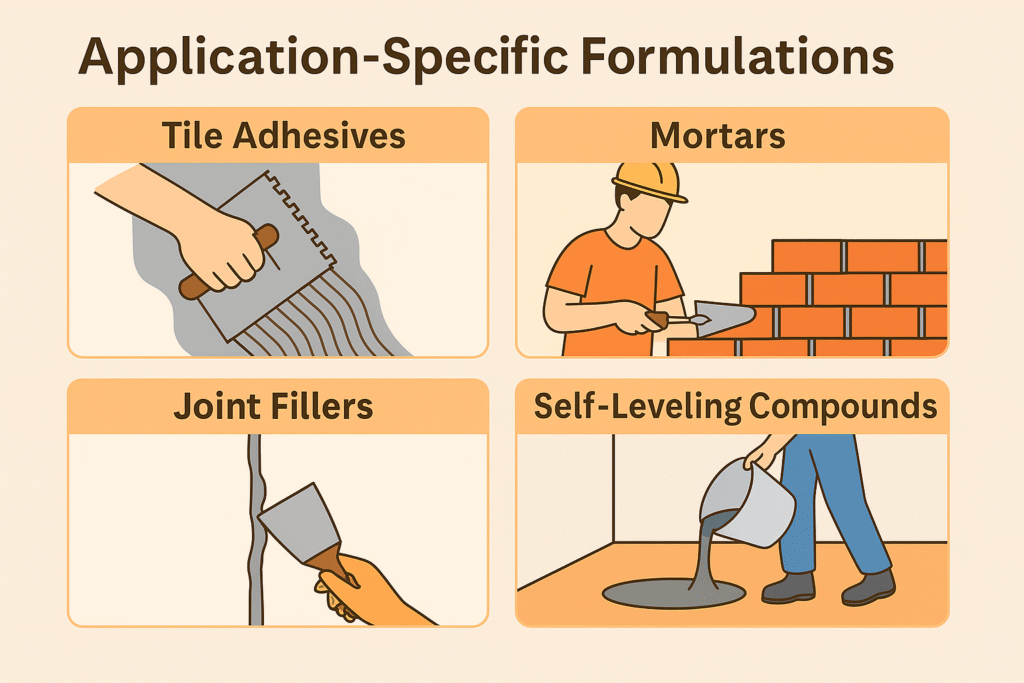

Use HPMC-dominant formulations for thin-set applications requiring extended working time like tile adhesives and joint compounds. Use HPS-enhanced formulations for thick-layer vertical applications like renders and plasters where anti-sagging is critical. Many professional formulations combine both for balanced performance.

Applications in Construction

Through my work supporting construction material manufacturers across developing markets, I've gathered practical insights about which formulations work best for specific applications. The optimal additive combination varies significantly based on application method, thickness, and performance requirements.

Tile adhesives represent a perfect example of application-specific formulation needs. These products typically require excellent water retention for proper cement hydration and strong bonding, making HPMC essential. However, with larger format tiles becoming increasingly popular, anti-sagging properties have grown in importance. A standard formulation might include 0.3% HPMC as the primary additive, with 0.05-0.1% HPS added specifically to improve anti-sagging without significantly increasing costs.

Wall renders and plasters demonstrate different requirements. Applied in thicker layers on vertical surfaces, these products face significant gravitational challenges. Here, HPS plays a more prominent role, often at dosages of 0.1-0.15%, while HPMC might be included at 0.2-0.3% to ensure proper curing. This combination creates a render that both stays in place during application and develops proper strength during curing.

Self-leveling underlayments represent yet another distinct formulation challenge. These products need to flow easily to create flat surfaces but must resist segregation of components. In this case, HPMC remains important for water retention, but HPS might be reduced or eliminated since anti-sagging is not a priority.

External thermal insulation composite systems (ETICS) require particularly careful formulation. The adhesive layer must bond heavy insulation panels to vertical surfaces without sagging during the crucial initial setting period. For these demanding applications, higher dosages of both additives might be necessary – typically 0.3-0.4% HPMC and 0.1-0.15% HPS.

The regional climate significantly impacts optimal formulations as well. In my work with clients in the Middle East, where high temperatures accelerate drying, I often recommend increasing HPMC content to extend open time. Conversely, in humid tropical environments like Vietnam or the Philippines, the emphasis might shift toward HPS to prevent sagging issues exacerbated by slower drying.

Conclusion

HPMC and HPS work as complementary partners rather than competitors in construction formulations. HPMC serves as the "main force" for water retention, while HPS acts as "special forces" for anti-sagging and workability. Using them together creates superior mortars at optimized costs.

-

Explore how HPMC enhances water retention and strength in mortars, crucial for successful construction projects. ↩ ↩

-

Learn about HPS's anti-sagging properties and how it improves workability in construction materials. ↩ ↩

-

Discover various construction additives and how they enhance the performance of building materials. ↩