Hand sanitizer production has surged worldwide, but many manufacturers struggle with stability, viscosity, and formulation issues. I've seen countless clients waste resources on failed batches when simple adjustments would have saved their production.

An effective alcohol-based hand sanitizer requires 60-95% alcohol content, proper thickening with hydroxyethyl cellulose1 (HEC) at 0.5-2.0% concentration, pH adjustment to 6.5-7.5, and must follow WHO or FDA guidelines for safety and effectiveness. HEC provides ideal viscosity without stickiness while maintaining alcohol's antimicrobial properties.

Making hand sanitizers isn't simply mixing alcohol with thickeners. I've worked with major sanitizer producers across Saudi Arabia and UAE who initially struggled with separation, consistency, and regulatory compliance—issues that proper formulation knowledge could have prevented. Let me share what I've learned about creating stable, effective sanitizers with hydroxyethyl cellulose1.

What Are The Basics Of Alcohol-Based Hand Sanitizer Production?

Production issues plague many new sanitizer manufacturers. In my factory visits, I see the same mistakes: improper mixing techniques, wrong alcohol concentrations, and unsuitable thickening agents that lead to product failures and costly remakes.

Alcohol-based hand sanitizers work by disrupting microbial cell membranes and denaturing proteins. They require 60-95% alcohol (ethanol or isopropyl), a thickening agent like hydroxyethyl cellulose1, moisturizers, and possibly fragrance. The manufacturing process involves careful mixing under controlled conditions to ensure stability and efficacy.

Producing effective hand sanitizers requires understanding both the science and art of formulation. I remember visiting a client's facility in Pakistan where they struggled with product separation. Their sanitizer would split into layers within days of production. The issue wasn't their alcohol quality—it was their mixing procedure and improper incorporation of the hydroxyethyl cellulose thickener.

The effectiveness of sanitizers depends on several critical factors. First, the alcohol concentration must be precisely controlled—too low, and it won't kill pathogens; too high, and it evaporates before killing germs. Second, viscosity control through proper HEC dispersion determines user experience and dosage control. Third, pH adjustment ensures stability and skin compatibility.

Here's a simplified view of the main components in a typical alcohol-based hand sanitizer:

| Component | Function | Typical Percentage |

|---|---|---|

| Ethanol/Isopropyl Alcohol | Active antimicrobial | 60-95% |

| Hydroxyethyl Cellulose | Thickener | 0.5-2.0% |

| Glycerin | Moisturizer | 1.45% |

| Hydrogen Peroxide | Preservative | 0.125% |

| Purified Water | Solvent | Balance to 100% |

What Is The Recommended Alcohol Concentration For Hand Sanitizers?

I've seen many manufacturers debate alcohol percentages. Some Middle Eastern clients believed higher was always better, while others used too little to cut costs. Both approaches compromise effectiveness and potentially violate regulations.

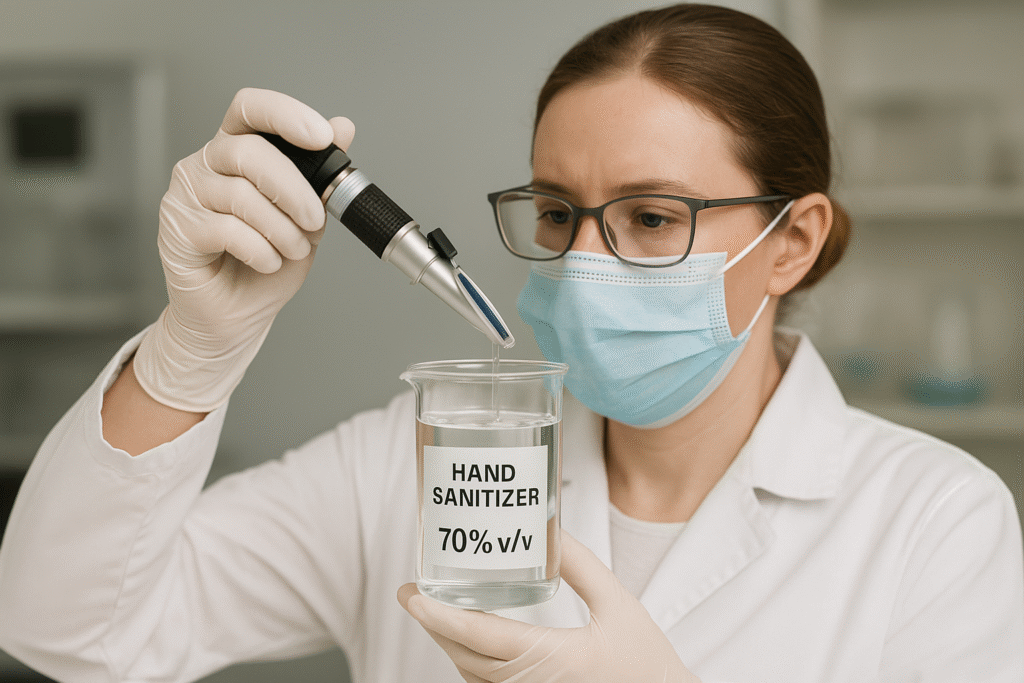

The CDC and WHO recommend 60-95% alcohol concentration for effective hand sanitizers, with optimal antimicrobial activity around 70-75%. Below 60%, sanitizers cannot reliably kill many pathogens; above 95%, the evaporation is too rapid for complete germ kill. Ethanol (ethyl alcohol) or isopropyl alcohol are both acceptable active ingredients.

Finding the right alcohol concentration balance is critical for sanitizer effectiveness. Last year, I advised a large distributor in Iran who was using 50% alcohol content to reduce costs. Their products weren't meeting antimicrobial standards, risking their reputation and regulatory compliance. We reformulated to 70% alcohol with optimized HEC content, which actually reduced overall costs while meeting all effectiveness standards.

Alcohol concentration affects multiple product aspects beyond just germ-killing ability. Higher concentrations create faster-drying products, which can be beneficial for quick use but may provide less contact time for thorough disinfection. Lower (but still effective) concentrations allow longer contact time and often work better with thickeners like hydroxyethyl cellulose.

During the COVID-19 pandemic, I worked with manufacturers who struggled to source high-purity ethanol. We developed alternative formulations using isopropyl alcohol, which required slightly different HEC concentrations due to the different molecular interactions. This highlights the importance of understanding thickener behavior with different alcohols:

| Alcohol Type | Optimal Concentration | HEC Dispersibility | Notes |

|---|---|---|---|

| Ethanol (Ethyl Alcohol) | 70-75% | Good | Standard in most formulations |

| Isopropyl Alcohol | 70-75% | Moderate | Requires careful HEC dispersion |

| n-Propanol | 60-70% | Challenging | Rarely used in commercial products |

How Does Alcohol Actually Kill Germs In Hand Sanitizers?

Manufacturers often don't understand the mechanism, leading to formulation choices that compromise efficacy. I've had to explain this repeatedly when clients ask to lower alcohol content or add incompatible ingredients.

Alcohol kills germs through protein denaturation and cell membrane disruption. When alcohol contacts microbial cells, it penetrates the cell membrane, coagulates essential proteins, and disrupts cellular metabolism. This process requires sufficient contact time (15-30 seconds) and adequate concentration, explaining why both factors are critical to sanitizer effectiveness.

Understanding alcohol's antimicrobial action helps explain why formulation choices matter so much. One of my clients in Saudi Arabia wanted to create a "stronger" sanitizer by mixing different types of alcohols. While well-intentioned, this approach created interaction issues with the hydroxyethyl cellulose and reduced overall effectiveness compared to a properly formulated single-alcohol product.

The efficacy of alcohol against different pathogen types varies significantly. It works extremely well against enveloped viruses like coronavirus but has limitations against certain non-enveloped viruses and bacterial spores. This is crucial knowledge for manufacturers marketing their products for specific applications.

The relationship between alcohol concentration, contact time, and thickener plays a vital role in real-world effectiveness. Too much HEC can actually impede alcohol's antimicrobial action by binding to some of the alcohol molecules and reducing their availability for germ killing. Too little, and the product runs off hands before adequate contact time. The perfect balance looks like this:

| Pathogen Type | Alcohol Effectiveness | Minimum Contact Time | Impact of HEC |

|---|---|---|---|

| Enveloped Viruses (Coronavirus) | Excellent | 20 seconds | Maintains contact time |

| Bacteria (E. coli, S. aureus) | Very Good | 15 seconds | Helps ensure coverage |

| Fungi | Good | 30 seconds | Critical for adequate exposure |

| Bacterial Spores | Poor | Not effective | N/A |

How Does Hydroxyethyl Cellulose Function In Hand Sanitizers?

Many sanitizer producers I've consulted with initially chose the wrong thickener, resulting in products that separated, became cloudy, or felt sticky—problems that proper HEC selection would have prevented.

Hydroxyethyl cellulose (HEC) in hand sanitizers functions as a rheology modifier, creating gel-like consistency without reducing alcohol effectiveness. Unlike some thickeners, HEC remains stable in high alcohol concentrations, doesn't leave sticky residue, improves skin feel, and helps maintain proper application coverage on hands, typically used at 0.5-2.0% concentration.

Selecting the right hydroxyethyl cellulose grade makes a tremendous difference in your sanitizer quality. I've worked with numerous manufacturers in Vietnam and the Philippines who were frustrated with poor product consistency. Their HEC grades had inappropriate molecular weights for alcohol systems, causing formulation issues that were easily solved by switching to alcohol-compatible HEC types.

The successful incorporation of HEC into alcohol systems requires specific techniques that differ from water-based applications. Direct addition to high-concentration alcohol often results in clumping and poor dispersion. Instead, I recommend preparation of an HEC pre-gel in water before alcohol addition, or using specially modified HEC grades designed for alcohol systems.

The molecular structure of hydroxyethyl cellulose provides unique advantages over other thickeners in sanitizer applications:

| Thickening Agent | Alcohol Compatibility | Skin Feel | Stability | Cost-Effectiveness |

|---|---|---|---|---|

| Hydroxyethyl Cellulose | Excellent | Non-sticky | High | Good |

| Carbomer | Good | Slightly sticky | Moderate | Moderate |

| Xanthan Gum | Poor-Moderate | Slimy | Low in high alcohol | Excellent |

| HPMC | Good | Good | Good | Very Good |

| CMC | Poor | Sticky | Poor | Excellent |

What Are The Best DIY Formulation Tips For Alcohol-Based Hand Sanitizers?

Through years of consulting for sanitizer manufacturers, I've seen countless formulation attempts fail due to simple mistakes in ingredient selection, process order, or quality testing. Even experienced chemists can struggle with alcohol-HEC systems.

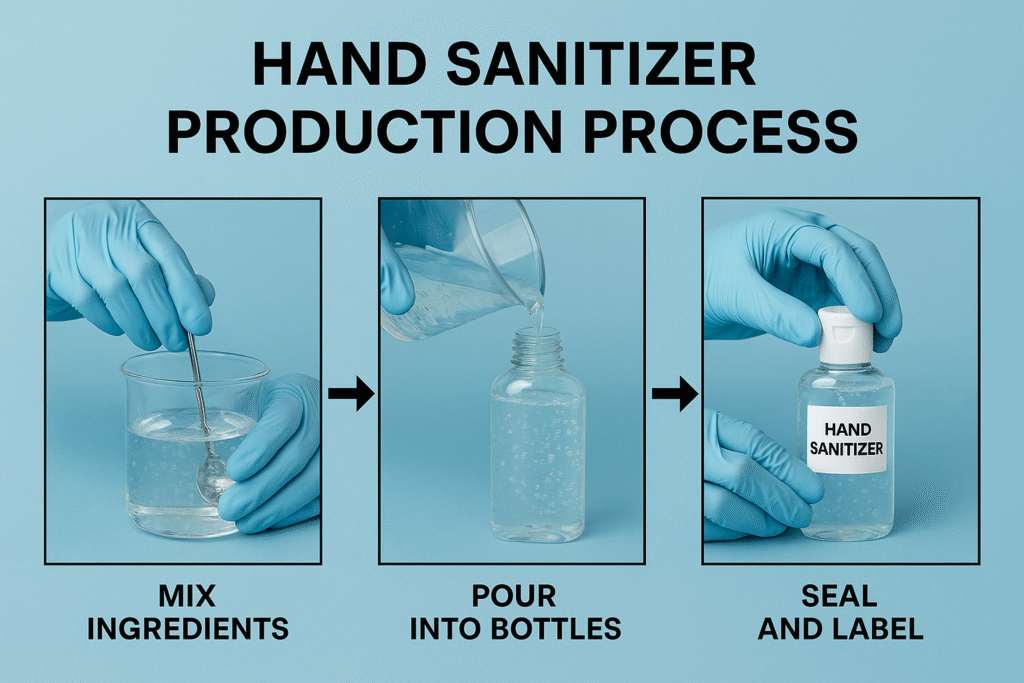

For DIY hand sanitizer formulation, first prepare a pre-gel of HEC (1-2%) in cold water, adjust to pH 6.5-7.5, then slowly add alcohol while mixing. Add glycerin (1-3%) for moisturizing, test final alcohol concentration, and adjust viscosity if needed. Always test antimicrobial efficacy and stability before scaling up production.

Developing effective formulations requires attention to detail and understanding ingredient interactions2. One sanitizer manufacturer in Brazil struggled with HEC dispersion—their product contained undissolved particles and lacked proper viscosity. We solved this by implementing a different dispersion technique using high-shear mixing and proper temperature control during HEC incorporation.

Process order matters tremendously in sanitizer production. Adding components in the wrong sequence can cause incompatibilities, precipitation, or poor thickening. I've developed this standardized procedure for our clients after extensive testing:

- Prepare water phase (about 20% of final formulation)

- Add preservatives and adjust pH to 6.5-7.0

- Slowly add HEC under moderate agitation

- Allow complete hydration (30-60 minutes)

- In a separate vessel, prepare alcohol phase with moisturizers

- Slowly add the HEC solution to the alcohol while mixing

- Add fragrance (if used) and adjust final pH

Quality testing is non-negotiable for ensuring product safety and efficacy. At minimum, manufacturers should test:

| Test Parameter | Acceptable Range | Testing Frequency | Equipment Needed |

|---|---|---|---|

| Alcohol Content | 60-95% | Every batch | Alcoholmeter or GC |

| Viscosity | Product-specific | Every batch | Viscometer |

| pH | 6.0-8.0 | Every batch | pH meter |

| Stability | No separation (4 weeks) | New formulations | Stability chamber |

| Antimicrobial Efficacy | >3 log reduction | New formulations | Microbiology testing |

What Are The Safety And Legal Considerations For Hand Sanitizer Production?

Many new clients underestimate regulatory complexity. I've had to help several manufacturers in Singapore and Mexico completely reformulate their products after regulatory rejections cost them significant time and money.

Hand sanitizer producers must follow FDA regulations (US) or WHO formulation guidelines internationally. This includes adhering to ingredients restrictions, proper facility registration, following Good Manufacturing Practices (GMP), implementing correct labeling with active ingredients, warnings, and manufacturing information, and maintaining batch testing records.

Regulatory compliance isn't optional—it's essential for legal operation and consumer safety. A distributor in Georgia once approached me with a formula containing methanol (toxic when absorbed through skin) instead of ethanol. This dangerous substitution would have caused serious health issues. We immediately developed a proper ethanol-based formula with appropriate HEC thickening and helped them understand the critical safety requirements.

Safety concerns extend beyond just formulation to production facilities. Alcohol-based sanitizers present significant fire hazards during manufacturing. Proper ventilation, explosion-proof electrical equipment, and strict smoking prohibitions are absolute requirements. Here are the key safety measures I recommend to all clients:

- Use explosion-proof mixing equipment

- Ensure proper grounding of all metal equipment

- Maintain adequate ventilation (at least 12 air changes per hour)

- Install appropriate fire suppression systems

- Implement strict smoking and ignition source controls

- Store alcohol in appropriate safety cabinets

Proper labeling is another area where many manufacturers fall short. Requirements vary by country, but generally must include:

| Label Element | Requirement | Common Mistakes |

|---|---|---|

| Active Ingredient | Must list alcohol type and % | Incorrect concentration claims |

| Usage Instructions | "Apply to hands, rub until dry" | Missing proper contact time |

| Warnings | Flammability, external use only | Insufficient warning language |

| Manufacturer Info | Name, address, contact | Incomplete information |

| Batch/Lot Number | Traceable production code | Missing traceability |

How Can You Ensure You're Following FDA And WHO Rules For Hand Sanitizers?

Many manufacturers I've worked with in India and Pakistan initially struggled with international compliance, especially during the pandemic when regulations changed rapidly. Staying current with guidelines is essential.

To comply with FDA and WHO regulations3 for hand sanitizers, manufacturers must use approved ingredients (denatured ethanol, isopropyl alcohol), maintain proper alcohol concentrations (60-95%), follow specific labeling requirements, register manufacturing facilities, and implement batch testing protocols. Non-compliance can result in product recalls, fines, and legal liability.

Regulatory compliance becomes particularly challenging during health emergencies when temporary guidelines may be enacted. During COVID-19, I helped several manufacturers in Sri Lanka navigate the FDA's temporary policies for hand sanitizer production, which permitted certain manufacturing adjustments but still maintained strict quality and safety requirements.

The differences between FDA and WHO formulations can confuse manufacturers. The WHO provides two main formulations that serve as standards worldwide:

- Formulation 1: 80% ethanol, 1.45% glycerol, 0.125% hydrogen peroxide

- Formulation 2: 75% isopropyl alcohol, 1.45% glycerol, 0.125% hydrogen peroxide

Both formulations notably lack thickeners like HEC, as they were designed for liquid sanitizers. Adding HEC requires validation that effectiveness isn't compromised. I typically recommend adding no more than 1.0% HEC to maintain proper antimicrobial activity while achieving desired viscosity.

Documentation requirements are substantial and include:

| Documentation Type | Content Required | Retention Period |

|---|---|---|

| Batch Records | Ingredients, amounts, processing parameters | 1-3 years |

| Testing Reports | Alcohol content, microbiological testing | 1-3 years |

| Supplier Documentation | Ingredient specifications, certificates | Duration of use |

| Process Validation | Evidence that process yields consistent results | Life of product |

| Complaints & Adverse Event Reports | Any reported issues with product | 1-3 years |

Which Thickening Agents Work Best For Alcohol-Based Hand Sanitizers?

The choice of thickener dramatically impacts product quality. I've helped numerous clients in UAE and Mexico switch from problematic carbomers and gums to hydroxyethyl cellulose4, solving stability and aesthetic issues.

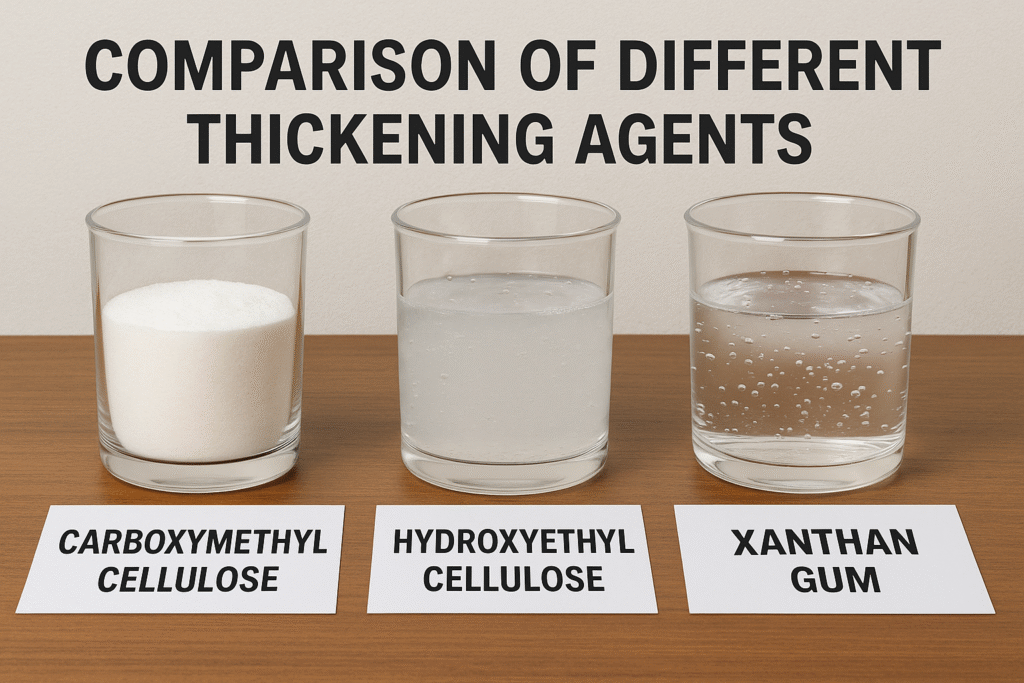

Hydroxyethyl cellulose (HEC) is the preferred thickener for alcohol-based hand sanitizers due to its alcohol stability, clean feel, and cost-effectiveness. Carbomers provide excellent clarity but require neutralization, while xanthan gum has poor alcohol compatibility. HPMC offers good stability but slower hydration, and acrylate copolymers provide luxurious feel but at higher cost.

Selecting the right thickener involves balancing multiple factors. A large sanitizer producer in Vietnam initially used carbomer, which created a beautiful clear gel but required complex pH adjustment and caused production bottlenecks. We switched them to a specialized grade of HEC designed for alcohol systems, which simplified their process and reduced production timeI'll continue writing the blog post where it left off:

The compatibility between thickening agents and alcohol systems varies significantly. Through extensive testing in our laboratory, we've documented the performance of different thickeners across multiple parameters. Here's a comparison based on real-world testing with 70% ethanol formulations:

| Thickener | Clarity | Stability | Skin Feel | Ease of Use | Cost Ratio |

|---|---|---|---|---|---|

| Hydroxyethyl Cellulose | Good | Excellent | Non-sticky | Good | 1.0x |

| Carbomer | Excellent | Good | Slightly tacky | Poor | 1.3x |

| Xanthan Gum | Poor | Poor | Stringy | Moderate | 0.8x |

| HPMC | Good | Good | Smooth | Moderate | 1.1x |

| Acrylate Copolymers | Excellent | Excellent | Premium | Poor | 2.0x |

The molecular weight and substitution level of hydroxyethyl cellulose4 significantly impacts performance in alcohol systems. Lower molecular weight grades disperse more easily but provide less viscosity, while higher molecular weight grades offer robust thickening but require more careful dispersion techniques. I recommend medium viscosity grades (approximately 30,000-40,000 mPa·s in 2% solution) for most hand sanitizer applications.

Temperature sensitivity also varies between thickeners. During a consulting project in Saudi Arabia, we discovered their sanitizer was thinning dramatically during summer shipping. Their carbomer-based system lost viscosity at high temperatures, while a reformulation with HEC maintained consistent viscosity across 20-45°C temperature ranges, solving their stability issues.

What Are The Frequently Asked Questions About Hand Sanitizers With HEC?

During trade shows and client consultations, I receive many recurring questions about hydroxyethyl cellulose4 in sanitizers. These represent common confusion points for manufacturers new to HEC formulation.

FAQ about HEC in sanitizers: HEC won't reduce alcohol effectiveness when properly formulated; typical concentration is 0.5-2.0%; dispersion requires proper technique with pre-hydration; shelf life is typically 2-3 years when properly preserved; and yes, it's compatible with common additives like aloe vera, vitamin E, and essential oils when used in appropriate concentrations.

New manufacturers often struggle with technical aspects of formulation. One client in the Philippines repeatedly encountered cloudy product despite using high-quality HEC. After investigation, we discovered their water contained high mineral content, causing interaction with the HEC. Switching to deionized water immediately solved the problem.

During the COVID-19 pandemic, raw material shortages forced many manufacturers to adapt their formulations. When traditional HEC grades became scarce, I helped several clients in Brazil and Mexico successfully substitute alternative grades by adjusting their dispersion techniques and concentration levels to maintain finished product specifications.

Here are detailed answers to the most common technical questions we receive:

| Question | Detailed Answer |

|---|---|

| How to properly disperse HEC? | Pre-disperse in glycerin or alcohol/water mixture (20:80) before adding to main batch; use high-shear mixing; ensure powder is added slowly to prevent clumping |

| Will HEC reduce antimicrobial efficacy? | No, when used at recommended levels (0.5-2.0%) and properly dispersed, HEC doesn't significantly impact alcohol's germ-killing ability |

| How does water quality affect HEC performance? | Hard water can reduce clarity and stability; deionized or distilled water is recommended for optimal results |

| Can I adjust viscosity after production? | Yes, post-production adjustment is possible by adding diluted HEC solution or alcohol to reach target viscosity |

| What's the impact of pH on HEC stability? | HEC is stable across pH 2-12, making it versatile for various formulations; optimal range for skin compatibility is pH 6-8 |

Conclusion

Effective alcohol-based hand sanitizers require careful formulation with 60-95% alcohol and proper hydroxyethyl cellulose4 thickening. Follow WHO guidelines, ensure quality control, and maintain proper manufacturing practices for a product that's both effective and regulatory-compliant.

-

Learn how hydroxyethyl cellulose enhances sanitizer formulation and stability. ↩ ↩ ↩

-

Understand the significance of ingredient compatibility in effective sanitizer production. ↩

-

Staying informed about FDA and WHO regulations is essential for manufacturers to ensure compliance and product safety. ↩

-

Understanding hydroxyethyl cellulose is key for formulating effective and stable alcohol-based hand sanitizers. ↩ ↩ ↩ ↩