I see it all the time - construction professionals struggling with slow-setting plasters, poor finishes, and high costs. These issues can delay projects and eat into profits when you're managing large-scale construction.

Gypsum plaster1 is a versatile construction material made from calcined gypsum that sets quickly (typically 20-30 minutes), provides excellent fire resistance2, offers superior thermal insulation3, and creates smooth finishes. Unlike cement plaster, it's lighter, easier to work with, and doesn't shrink significantly when drying.

When I first started supplying construction materials to developers across the Middle East and Asia, I quickly realized that understanding material properties isn't just technical knowledge—it's essential business intelligence. Let me share what I've learned about gypsum plaster after years of working with major construction companies in Saudi Arabia, UAE, and beyond.

What Makes Gypsum Plaster Different From Other Construction Materials?

I've seen countless projects delayed because contractors chose the wrong plaster type. Poor material selection can lead to cracking, longer drying times, and difficult application.

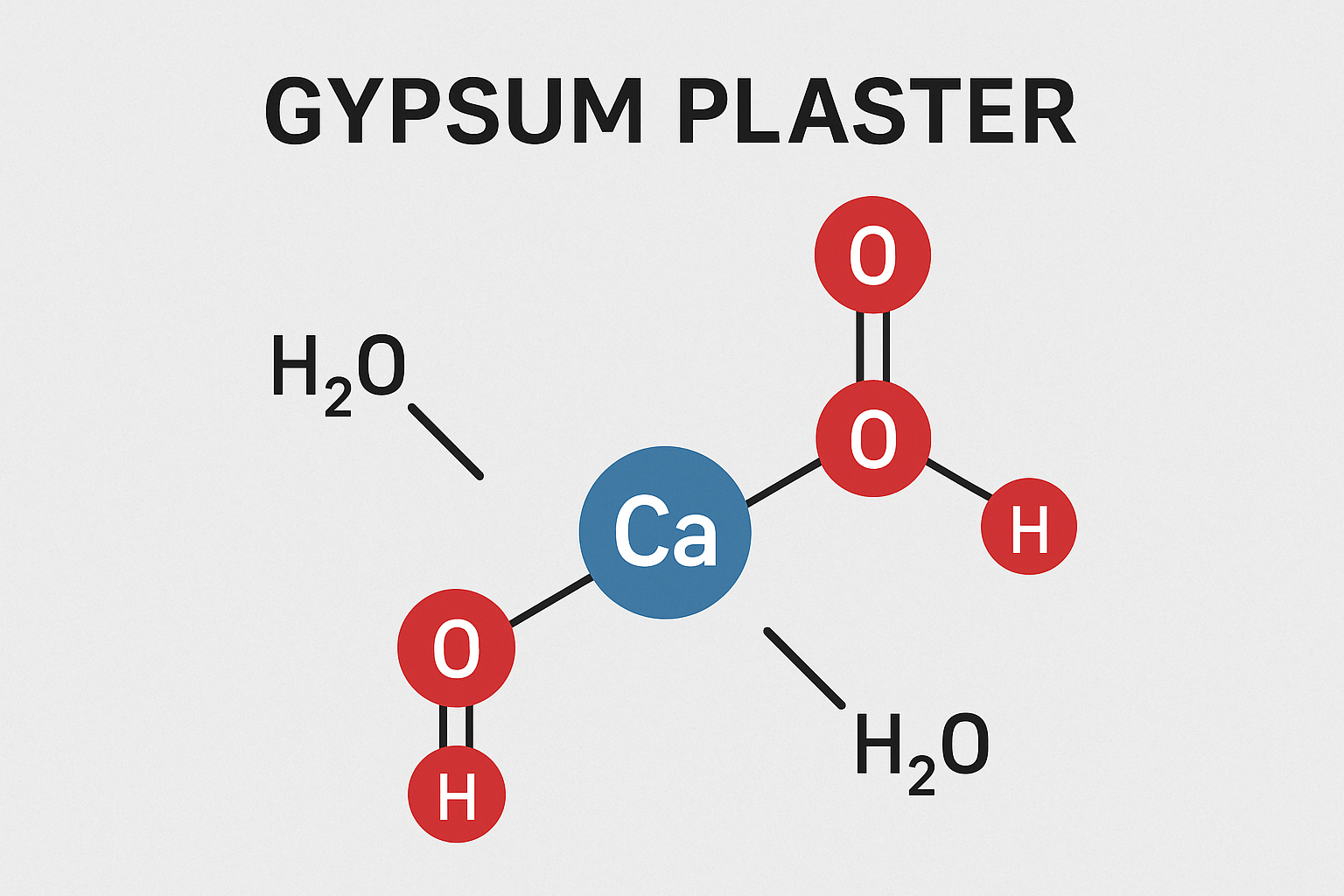

Gypsum plaster1 consists primarily of calcium sulfate hemihydrate4 (CaSO₄·½H₂O) created by heating gypsum at 150°C. When mixed with water, it undergoes a chemical reaction, reverting to gypsum (CaSO₄·2H₂O) and creating a solid, hardened material ideal for interior walls and ceilings.

Gypsum plaster has a fascinating chemistry that gives it unique properties. The setting process involves an exothermic reaction where the material actually heats up as it hardens. This happens because when water is added to the dry plaster powder, the calcium sulfate hemihydrate rehydrates, releasing heat.

This chemical process gives gypsum plaster several advantages:

- Quick Setting Time: The crystallization process typically completes within 20-30 minutes, allowing for faster construction schedules

- Volume Stability: Unlike many materials, gypsum actually expands slightly (about 0.2%) when setting, which helps it fill molds completely

- Workability: The plaster remains workable during its "cream time" before suddenly hardening

- Porosity: The crystalline structure creates microscopic pores that contribute to thermal and acoustic properties

My clients often ask about the different grades of gypsum plaster. Here's a breakdown I typically share:

| Grade | Setting Time | Applications | Special Properties |

|---|---|---|---|

| Regular | 20-30 minutes | General interior walls | Standard strength |

| Slow-set | 60-120 minutes | Large areas, detailed work | Extended working time |

| High-strength | 30-45 minutes | High-traffic areas | Enhanced durability |

| Lightweight | 20-30 minutes | Ceilings, fire protection | 30% lighter than standard |

| Acoustic | 30 minutes | Sound-sensitive spaces | Enhanced sound absorption |

How Does Gypsum Plaster Compare to Cement Plaster in Performance and Cost?

I remember walking through a project in Dubai where one building used gypsum plaster and another used cement. The difference in work pace was striking - the gypsum sections were moving twice as fast.

Gypsum plaster1 offers faster setting (30 minutes vs 24+ hours), lighter weight (12kg/m² vs 20kg/m²), better insulation (0.3 W/mK vs 0.5 W/mK), and superior fire resistance compared to cement plaster. While cement plaster costs 10-15% less initially, gypsum's faster application and reduced labor needs often make it more economical overall.

https://placehold.co/600x400)

The choice between gypsum and cement plaster significantly impacts project timelines, labor requirements, and building performance. From my experience working with large construction firms across developing markets, this decision can make or break a project's profitability.

When comparing these materials in depth, several factors stand out:

-

Application Efficiency: Gypsum plaster can be applied in a single coat at 12-15mm thickness, while cement plaster typically requires multiple coats totaling 15-20mm. This difference alone can reduce application time by 40-50%, as I've documented with clients in Saudi Arabia and the UAE.

-

Structural Impact: Cement plaster adds approximately 20kg/m² to wall loads, nearly double gypsum's 12kg/m². For a 10-story building with 5,000m² of wall space, this translates to 40 additional tons of dead load with cement plaster, potentially requiring costly structural reinforcements.

-

Thermal Performance: With thermal conductivity of 0.3 W/mK versus cement's 0.5 W/mK, gypsum provides better insulation. In hot climates like the Middle East, this can reduce cooling costs by 8-12% annually according to studies I've shared with my clients.

-

Crack Resistance: Cement plaster's shrinkage during curing (up to 0.1%) leads to microcracking, while gypsum's slight expansion during setting (0.2%) minimizes this issue. In a recent project in Pakistan, buildings using gypsum plaster showed 70% fewer surface cracks during the first year.

-

Environmental Impact: Gypsum production requires temperatures of approximately 150°C, compared to 1,450°C for cement, resulting in roughly 80% less CO2 emissions per ton produced - an increasingly important factor as sustainability regulations tighten across global markets.

| Property | Gypsum Plaster | Cement Plaster |

|---|---|---|

| Setting Time | 20-30 minutes | 24-48 hours |

| Weight | ~12 kg/m² | ~20 kg/m² |

| Application | Single coat | Multiple coats |

| Surface Finish | Very smooth | Rougher texture |

| Water Resistance | Limited | Good |

| Cost per m² | $4-6 | $3-5 |

| Labor Cost Index | 1.0 | 1.6 |

Conclusion

Gypsum plaster1 offers faster setting times, better insulation, lighter weight, and superior finishes compared to cement alternatives, making it an excellent choice for modern construction projects despite its slightly higher initial cost.

-

Explore the advantages of Gypsum plaster, including its quick setting time and superior finishes, which can enhance your construction projects. ↩ ↩ ↩ ↩

-

Explore the fire-resistant properties of Gypsum plaster and its importance in building safety. ↩

-

Understand the thermal insulation properties of Gypsum plaster and how it can reduce energy costs in buildings. ↩

-

Discover the chemistry behind calcium sulfate hemihydrate and how it contributes to the properties of Gypsum plaster. ↩