Are you experiencing inconsistent mortar performance or reduced workability? Poor understanding of HPMC viscosity1 properties could be costing you time and money on construction projects, leading to application failures.

HPMC (Hydroxypropyl methylcellulose2) viscosity is a measure of its resistance to flow when mixed in water. It directly influences workability, water retention, and adhesion in construction materials. Proper viscosity selection ensures optimal application performance and finished project quality.

Understanding HPMC viscosity1 is not just about numbers on a specification sheet. It's about knowing how this property transforms your construction materials from basic ingredients into high-performance building solutions. Let me show you why this matters to your bottom line.

What Does the Formula V = Kdt Tell Us About HPMC Viscosity?

Have you noticed that HPMC solutions behave differently under varying application conditions? This inconsistency stems from the complex relationship between viscosity and shear rate, often causing unexpected performance issues.

The formula V = Kdt represents the volume (V) of HPMC solution flowing through a capillary tube, where K is a constant factor, d is the tube diameter, and t is time. This fundamental relationship helps us understand how HPMC solutions flow under different pressures and through various openings during application.

This fundamental equation guides much of our product development at kehao. When we examine how HPMC solutions flow through different openings and under various pressures, we're essentially exploring the practical implications of this formula.

The K constant in this equation varies depending on the specific grade of HPMC. In our factory testing, we've found that K values correlate strongly with molecular weight distribution and substitution patterns. Higher-viscosity grades show significantly different K values than lower-viscosity ones, which explains why they perform so differently in applications like spray-applied renders versus hand-applied mortars.

The diameter (d) factor is particularly important for understanding how HPMC solutions will perform in specific application equipment. This is why we work closely with our customers in Saudi Arabia and UAE who use mechanical pumping systems for large-scale projects. We've created a reference chart for our sales team to help customers select the optimal viscosity grade based on their application method:

HPMC Flow Performance by Application Method

| Application Method | Tube/Opening Diameter | Recommended HPMC Viscosity |

|---|---|---|

| Fine spray | < 1mm | Low (4,000-15,000 mPa·s) |

| Mechanical pumping | 5-15mm | Medium (15,000-50,000 mPa·s) |

| Manual trowel | N/A (open air) | High (50,000-100,000 mPa·s) |

The time factor (t) in the equation helps us understand how quickly material will flow through systems under consistent pressure. I recall helping a major mortar manufacturer in Georgia troubleshoot inconsistent pumping rates in their production line. By analyzing their system using this flow equation, we identified that seasonal temperature changes were affecting the viscosity enough to significantly alter their production rates.

How Does the Formula η = Kα Explain HPMC's Special Properties?

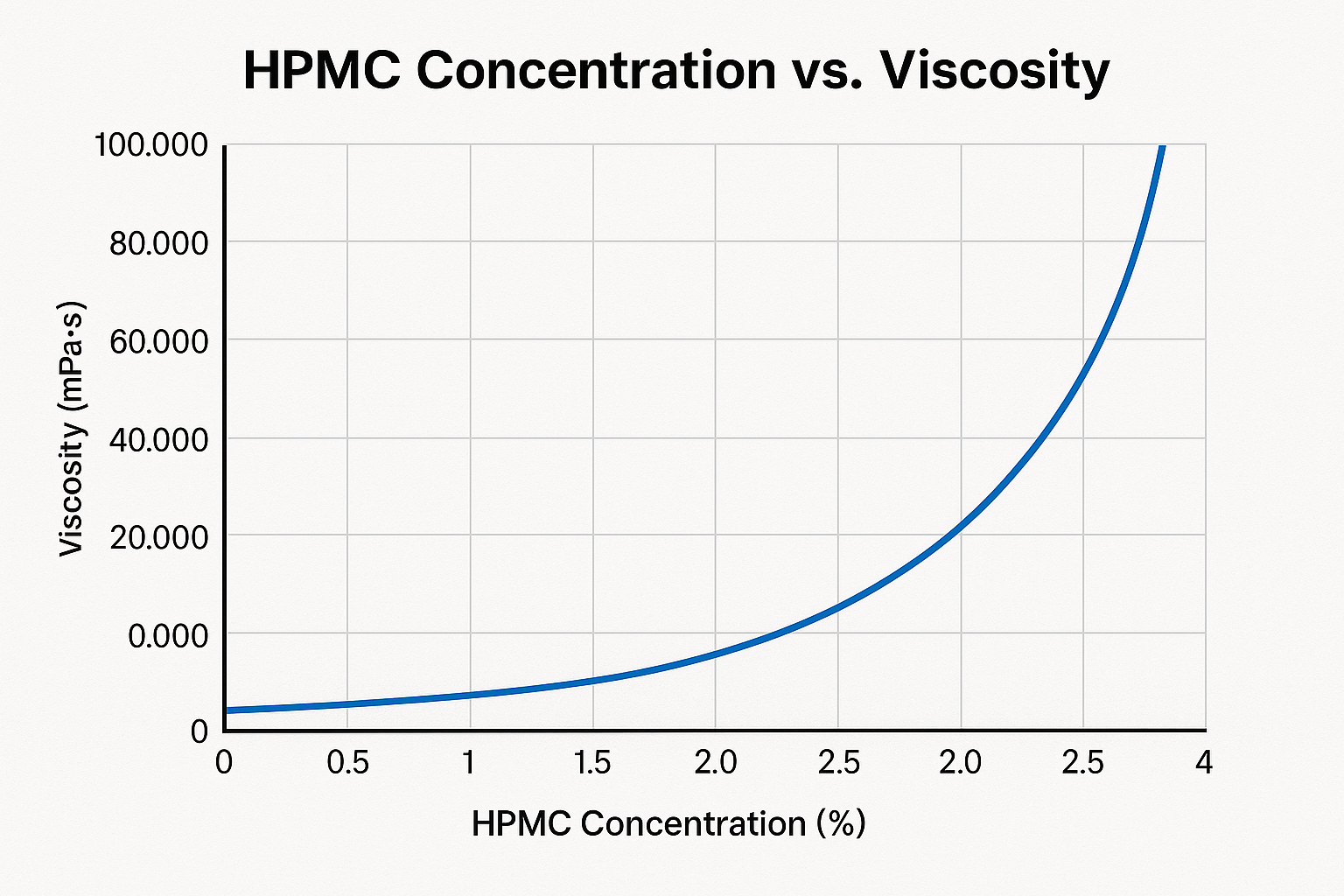

Is your mortar showing poor consistency or sag resistance? The power-law relationship3 between HPMC concentration and viscosity might explain why small formulation changes create big performance problems.

The equation η = Kα represents the relationship between HPMC viscosity1 (η) and its concentration (α), where K is a constant. This power-law relationship shows that viscosity increases exponentially with concentration, not linearly, explaining why small formulation changes can dramatically alter performance.

This exponential relationship between concentration and viscosity is something I emphasize when training new customers about HPMC usage. Many formulation problems occur when customers treat HPMC as if it follows a linear relationship like many other additives.

At kehao, we've conducted extensive laboratory testing to precisely map this relationship for each of our HPMC grades. The exponent in this power law typically ranges from 3.0 to 4.5 depending on the specific molecular structure of the HPMC. This means that doubling the concentration doesn't just double the viscosity—it increases it by 8 to 22 times!

This relationship explains why precise dosing is critical in mortar and paint manufacturing. I visited a customer's factory in Pakistan where they were experiencing batch-to-batch inconsistency. Their mixing procedure allowed for a ±5% variation in HPMC content, which they considered minor. Using our power-law models, I showed them this small variation could cause up to a 40% change in viscosity, explaining their consistency problems.

The K constant in this equation varies based on:

Factors Influencing the Concentration-Viscosity Relationship

| Factor | Effect on K Value | Practical Impact |

|---|---|---|

| Molecular weight | Higher MW = Higher K | Stronger thickening effect |

| Substitution degree | Higher substitution = Lower K | More efficient at lower dosages |

| Particle size | Finer = Higher K | Faster dissolution, quicker viscosity development |

| Temperature | Higher temperature = Lower K | Reduced thickening efficiency in hot climates |

Understanding this relationship has helped us develop specialized grades for customers in hot climates like Saudi Arabia and Iran, where the temperature effect on this power law is particularly important. By adjusting the molecular structure, we've created grades that maintain more consistent viscosity across varying temperatures.

What Fluid Type Does HPMC Create When Mixed With Water?

Ever mixed HPMC and found it behaving differently than expected? This happens because HPMC creates a unique fluid system that doesn't follow simple viscosity rules, causing application problems.

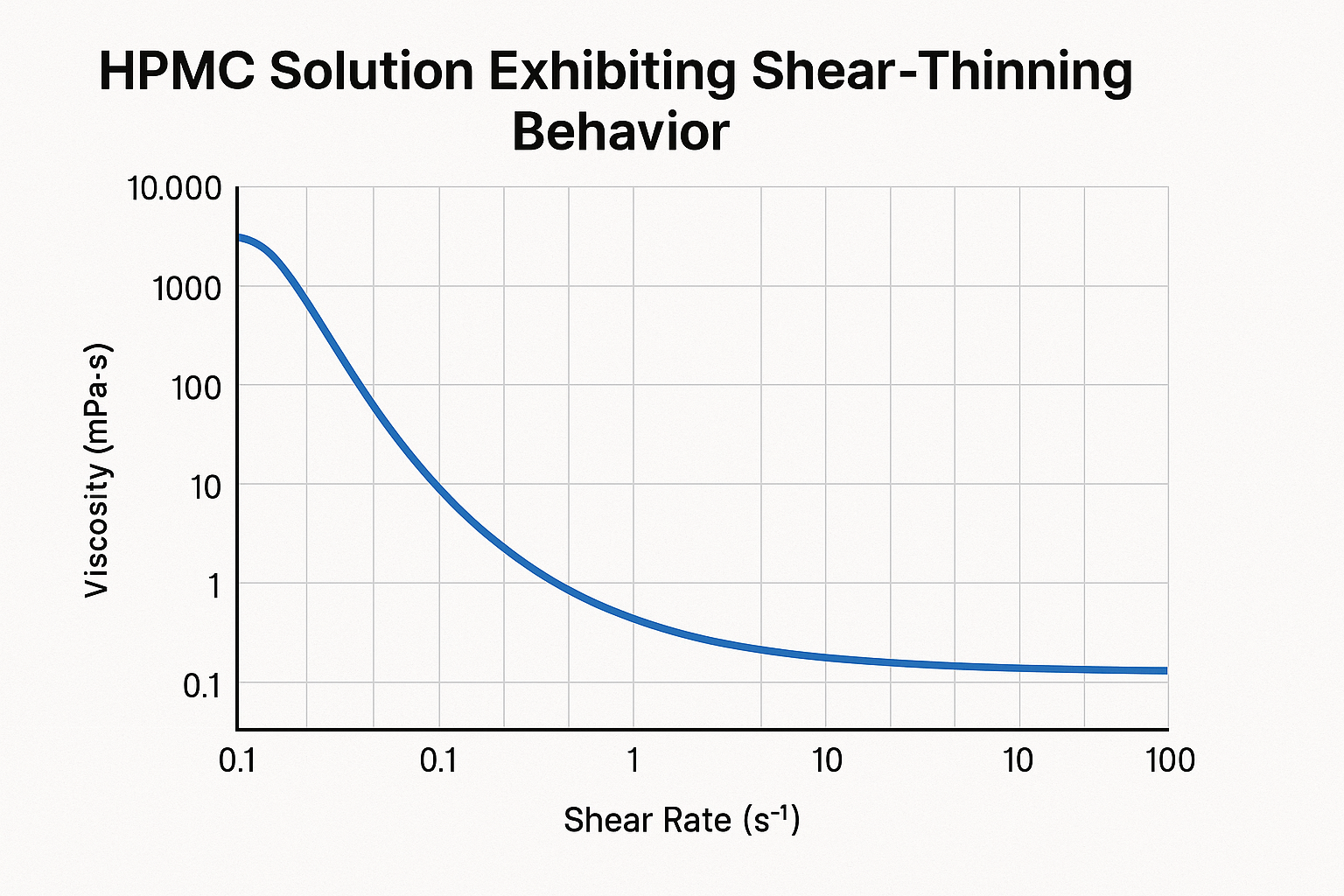

HPMC forms a non-Newtonian pseudoplastic fluid when dissolved in water. Unlike water or oil, its viscosity decreases when force is applied (shear-thinning), making it ideal for construction applications where easy application under pressure but good sag resistance at rest is required.

The fluid type created by HPMC gives construction materials their unique working properties. As a factory owner with six production lines, I've conducted thousands of tests on our HPMC solutions to understand their behavior under different conditions.

HPMC solutions display what we call thixotropic properties - they become more fluid when stirred or applied with pressure (like spreading mortar with a trowel) but regain viscosity when left to stand. This is why our customers in Saudi Arabia and the UAE particularly value our high-quality HPMC for exterior renders that must resist sagging in hot climates.

The pseudoplastic nature of HPMC can be visualized through what we call a flow curve. At our kehao factory, we measure this using specialized rheometers:

HPMC Flow Behavior Characteristics

| Shear Rate | Low-viscosity HPMC | Medium-viscosity HPMC | High-viscosity HPMC |

|---|---|---|---|

| Low | Moderate resistance | High resistance | Very high resistance |

| Medium | Low resistance | Moderate resistance | High resistance |

| High | Very low resistance | Low resistance | Moderate resistance |

This characteristic makes HPMC perfect for tile adhesives - applying force with a notched trowel makes it spread easily, but once applied, it holds its position without sagging. I recall a customer from Pakistan who switched to our HPMC specifically because the competitive product lacked this precise balance of flow properties.

How Is HPMC Viscosity Properly Tested And Measured?

Have you received HPMC shipments with inconsistent viscosity values? Unreliable testing methods can mask product quality issues, leading to production problems and wasted materials.

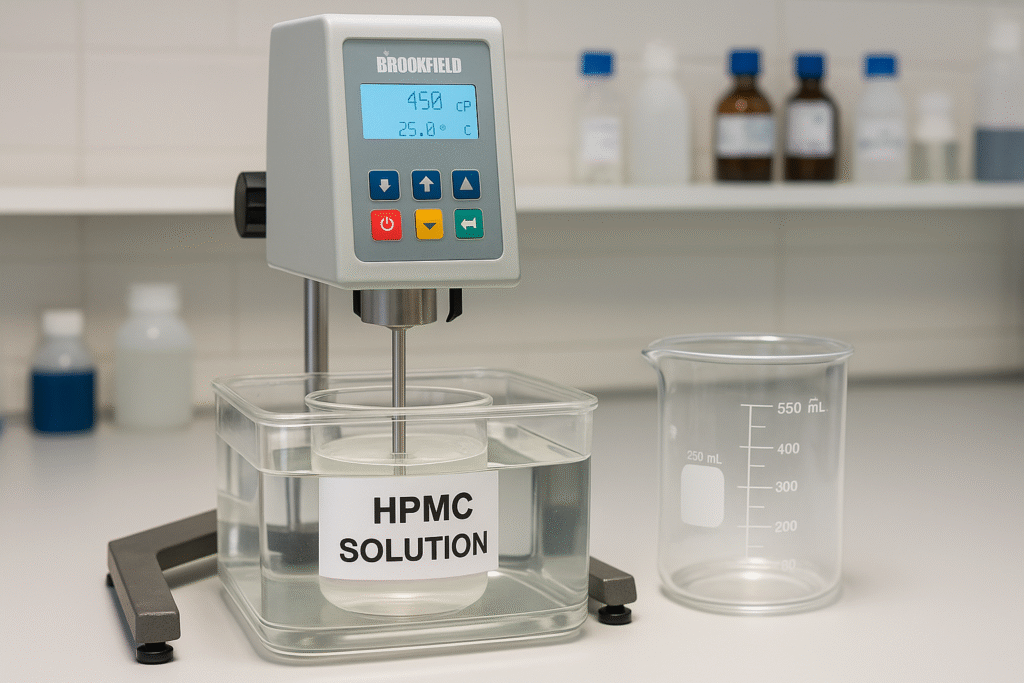

HPMC viscosity1 is professionally measured using rotational viscometers like Brookfield or Haake instruments at specific concentrations (typically 2%) and temperatures (20°C). The results are expressed in millipascal-seconds (mPa·s) or centipoise (cP), with measurements taken at defined rotational speeds to account for non-Newtonian behavior.

When it comes to testing HPMC viscosity, precision is everything. In our kehao factory laboratories, we follow strict testing protocols that exceed industry standards. I've personally trained our quality control team to understand not just how to take measurements, but why each step matters.

The standard test method involves preparing a 2% solution by weight of HPMC in distilled water. The preparation process itself is crucial - we use a "hot/cold" technique where HPMC is first dispersed in hot water (about 80°C) and then cold water is added to achieve complete dissolution. This prevents the formation of lumps that would affect viscosity readings.

After preparation, the solution must be properly conditioned:

HPMC Solution Testing Protocol

| Step | Process | Critical Parameters |

|---|---|---|

| 1. Preparation | Hot/cold dispersion method | Temperature control ±1°C |

| 2. Conditioning | Solution rest period | 24 hours at 20°C |

| 3. Measurement | Rotational viscometer | Specific spindle, RPM setting |

| 4. Verification | Standard solution comparison | Within ±5% of standard |

We've found that many quality issues reported by customers trace back to improper testing methods. A mortar manufacturer in Brazil once complained about inconsistent performance within the same batch. When I visited their facility, I discovered they were testing viscosity at different temperatures throughout the day as their lab heated up. After implementing temperature-controlled testing, their perceived quality issues disappeared.

What Factors Can Affect The Viscosity Of HPMC Solutions?

Are unexpected viscosity variations causing product failures? Multiple factors can alter HPMC performance, making your carefully formulated products behave unpredictably during application.

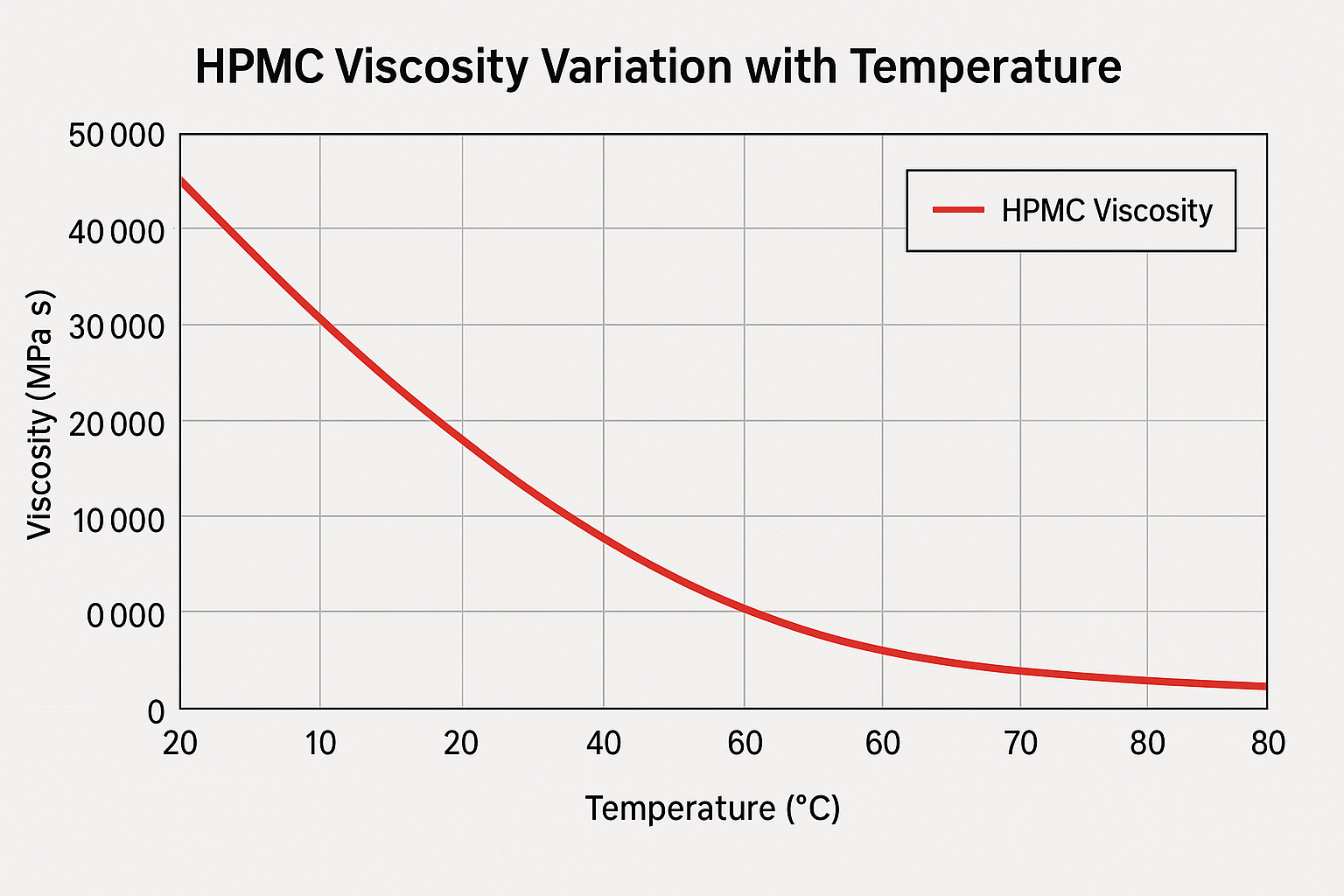

HPMC viscosity is affected by concentration, temperature, pH level, molecular weight, degree of substitution, and presence of additives. Temperature has an inverse relationship with viscosity - as temperature rises, viscosity decreases. Higher concentrations and molecular weight increase viscosity, while extreme pH values can reduce it.

Managing HPMC viscosity in real-world applications requires understanding how multiple factors interact. At kehao, we've developed customized HPMC grades for specific regional needs based on these interactions.

Temperature sensitivity is perhaps the most critical factor in practical applications. Our HPMC exhibits what's called a "thermal gelation" property - when heated above a certain temperature (usually 60-80°C depending on the grade), it forms a temporary gel structure. This property is valuable in cement-based systems as it controls water movement during the critical hydration phase.

The concentration effect is non-linear - doubling the HPMC concentration more than doubles the viscosity. This relationship follows a power law function that we've mapped extensively for each of our product grades:

HPMC Concentration Effects on Viscosity

| Concentration (%) | Relative Viscosity Increase |

|---|---|

| 1% | Baseline |

| 2% | 3-4× baseline |

| 3% | 7-10× baseline |

| 4% | 15-25× baseline |

The molecular structure of HPMC also affects viscosity. Higher molecular weight products (indicated by higher viscosity grades like HPMC 100,000 cP) provide stronger thickening but slower dissolution. The substitution pattern (ratio of hydroxypropyl to methyl groups) affects water interaction and thermal gelation temperature.

I remember working with a customer in Vietnam whose exterior render was failing in the rainy season. Their formulation used standard HPMC that lost viscosity in high humidity conditions. By switching to our specially modified grade with controlled hydroxypropyl/methyl ratio, they achieved consistent performance year-round.

Salt tolerance is another factor we've optimized in our products. In coastal regions like the Philippines, mortar often contains higher salt levels. Standard HPMC can "salt out" in these conditions (precipitate from solution), but our specially engineered grades maintain stability even in high-salt environments.

Conclusion

Selecting the right HPMC viscosity grade is crucial for successful construction applications. Understanding its mathematical relationships, flow behavior, proper testing methods, and influencing factors ensures consistent performance in your products across varying environmental and application conditions.