I've seen many construction projects fail because of wet concrete. Too much water ruins the strength. Let me show you how to avoid this costly mistake.

When concrete has too much water, it becomes weak and cracks easily. The excess water creates voids and reduces the concrete's strength by up to 50%, leading to structural failure.

I remember a client from Saudi Arabia who lost thousands of dollars because his contractor added too much water. The entire floor had to be redone. This happens more often than you think, especially in hot climates where workers add extra water to make pouring easier.

What's the Role of Water in Concrete Mix?

Water seems simple, but getting it wrong destroys your concrete. I learned this the hard way when I started in construction materials1. Your project depends on this balance.

Water makes concrete workable and starts the chemical reaction with cement. The right amount creates strong bonds between cement particles. Too little makes mixing impossible, too much weakens everything.

Understanding Water-Cement Ratio

The water-cement ratio controls everything in your concrete. I use this simple table with my customers:

| Concrete Use | Water-Cement Ratio | Strength Result |

|---|---|---|

| Foundations | 0.40-0.45 | High strength |

| Driveways | 0.45-0.50 | Medium strength |

| Sidewalks | 0.50-0.55 | Standard strength |

Water does three main jobs in concrete. First, it makes the mix workable so you can pour and shape it. Second, it starts hydration - the chemical process that hardens cement. Third, it helps distribute all ingredients evenly. But here's what many people miss: only about 25% of the water actually reacts with cement. The rest just takes up space and evaporates, leaving tiny holes that weaken your concrete. That's why we use water reducers like our HPMC products2 at KEHAO to get workability without excess water.

What Happens If You Put Too Much Water in Concrete?

Your concrete turns into a disaster waiting to happen. I've tested thousands of batches, and excess water always causes the same problems. Your money goes down the drain.

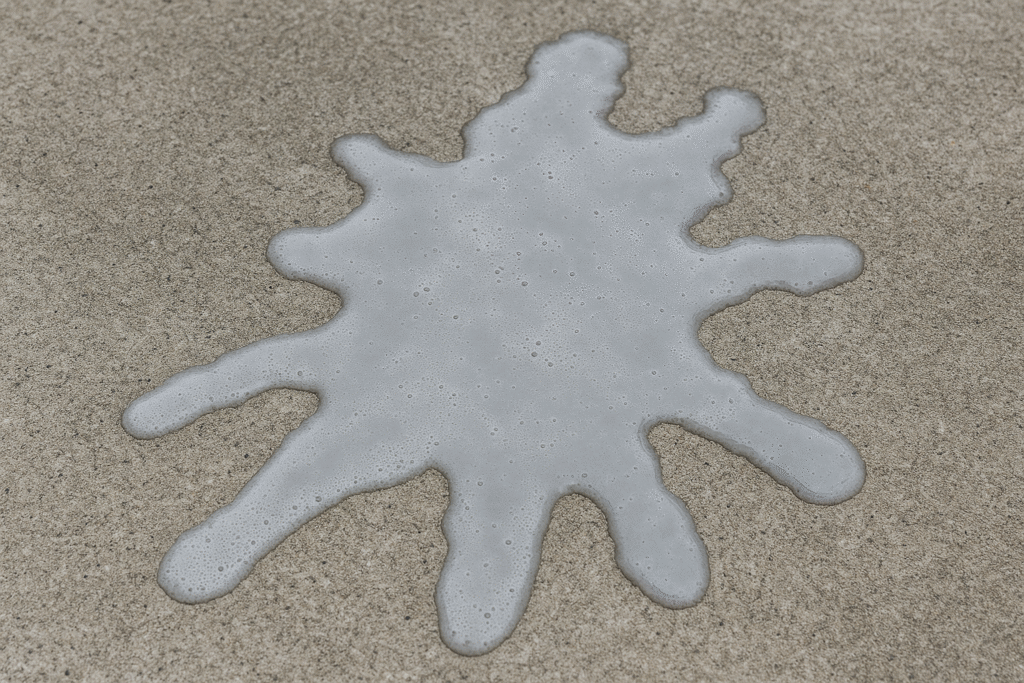

Too much water causes segregation, excessive bleeding, shrinkage cracks, and strength loss. The concrete becomes porous and weak, failing to meet building codes and requiring expensive repairs or complete replacement.

Common Problems from Wet Concrete

When you add too much water, several things go wrong at once. The cement paste becomes diluted and can't hold the aggregates properly. Heavy stones sink to the bottom while water rises to the top - we call this segregation. Then bleeding starts, where water pools on the surface. As this water evaporates, it leaves channels and voids throughout your concrete. The surface becomes dusty and weak. Shrinkage cracks appear everywhere as the excess water dries out. Your concrete might look fine at first, but it will fail early. I've seen 28-day strength tests show only 40% of the required strength because someone added "just a little more water" to make pouring easier.

How To Fix Too Much Water in Concrete?

Don't panic if your mix is too wet. I've helped many contractors save their projects. Quick action makes the difference between minor fixes and total failure.

For wet concrete, immediately add more cement and aggregates to restore the proper ratio. Use accelerators to speed curing, apply surface treatments, and consider using water-reducing admixtures like HPMC for future batches.

Emergency Repair Steps

Here's my proven method for fixing wet concrete:

| Step | Action | Time Frame |

|---|---|---|

| 1 | Stop adding water immediately | Instant |

| 2 | Calculate how much extra water was added | 5 minutes |

| 3 | Add proportional cement and sand | 10 minutes |

| 4 | Mix thoroughly | 5 minutes |

| 5 | Add accelerator if needed | 2 minutes |

The key is acting fast. Once concrete starts setting, you can't fix the water problem. If the mix is already poured, focus on surface treatments. Apply a dry shake hardener to absorb excess moisture. Use fans to speed evaporation. Consider grinding and resealing the surface later. For future pours, I recommend our hydroxypropyl methylcellulose (HPMC) products. They let you reduce water while keeping excellent workability. Many of my customers in hot countries like Saudi Arabia and UAE use HPMC to prevent this exact problem.

How To Tell If Concrete Is Too Wet?

Spotting wet concrete early saves your project. After 20 years in this business, I can tell by looking. Let me teach you the signs.

Wet concrete shows clear signs: it bleeds water on top, aggregates sink leaving paste on surface, edges slump and won't hold shape, and the mix looks soupy rather than cohesive.

Visual and Physical Tests

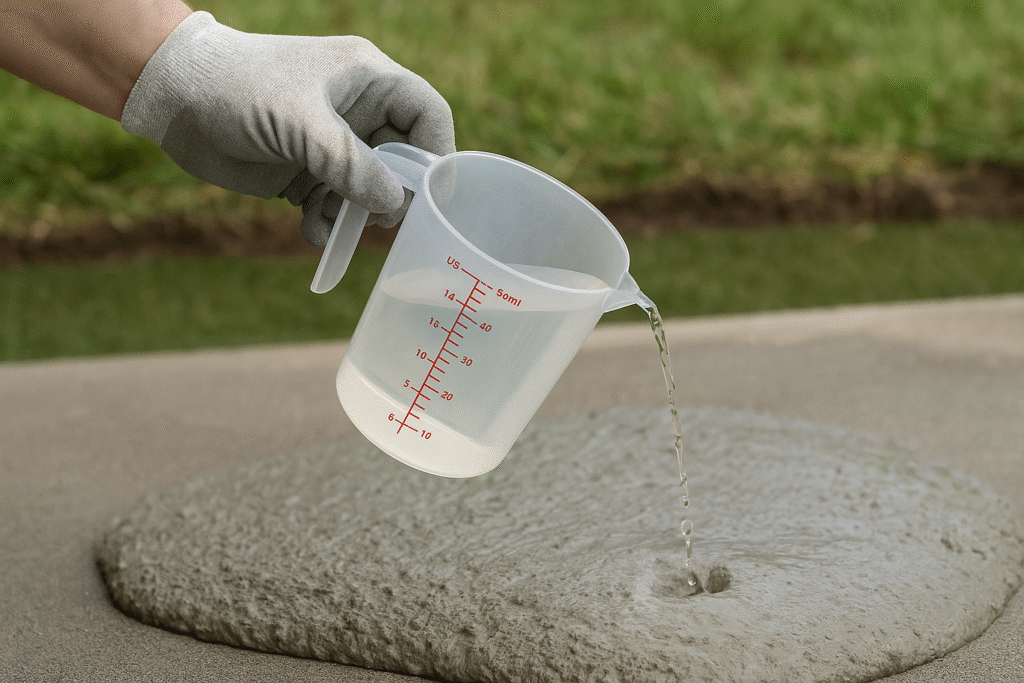

The slump test gives you exact measurements. Fill the cone, lift it, and measure how much the concrete drops. Normal concrete slumps 2-4 inches. Wet concrete collapses completely. But you don't always need formal tests. Watch the surface - if water appears within minutes, you have too much. Try making a pile with a shovel. Good concrete holds its shape. Wet concrete flows like thick soup. Listen to the mixer too. Wet concrete makes a sloshing sound instead of the normal tumbling noise. Check the edges of your forms. Water bleeding through joints means trouble. Feel the mix with your hands (wear gloves). It should feel like thick cookie dough, not runny cake batter.

How Much Water To Put in Concrete Mix?

Getting water right makes or breaks your project. I teach this formula to every new customer. Simple math prevents expensive mistakes.

Use 0.4 to 0.6 pounds of water per pound of cement for most applications. This equals about 4-6 gallons per 94-pound bag. Always start with less and add gradually.

Calculating Your Water Needs

Here's my easy calculation method that works every time:

| Cement Bags | Minimum Water | Maximum Water | Best For |

|---|---|---|---|

| 1 bag (94 lbs) | 4 gallons | 6 gallons | General use |

| 5 bags | 20 gallons | 30 gallons | Driveways |

| 10 bags | 40 gallons | 60 gallons | Foundations |

Start with the minimum amount. Mix thoroughly. Add small amounts until you reach the right consistency. Remember, you can always add more water, but you can't take it out. Weather affects your water needs too. Hot, dry days need slightly more water because of evaporation. Cold days need less. Wind increases evaporation. Always adjust based on conditions. Write down your exact measurements for consistent results. Many contractors guess and get different strength every time. That's why I recommend using our water reducers - they give you consistent results regardless of weather.

High-Performance Water Reducer Solution

Water reducers changed everything in modern concrete. I've supplied these products to major projects worldwide. They solve the water problem completely.

KEHAO's hydroxypropyl methylcellulose (HPMC) reduces water needs by 15-30% while improving workability. It prevents segregation, reduces bleeding, and increases final strength. Perfect for hot climates and challenging pours.

Why Choose KEHAO Water Reducers

Our HPMC products2 work differently than basic plasticizers. They modify the cement paste structure at a molecular level. This creates better particle distribution without excess water. You get flowing concrete that's actually stronger than stiff mixes. Our customers in Saudi Arabia love this because workers can pour easily in 45°C heat without adding extra water. The concrete stays workable longer too. Normal concrete starts setting in 30 minutes in hot weather. With our HPMC, you get 90 minutes of workability. This prevents cold joints and rushed work. We customize the formula based on your climate and cement type. Our lab tests every batch to ensure consistency. With 6 production lines, we never run out of stock. Fast shipping to Middle East and Asia means you get products when you need them.

Get in Touch with KEHAO

Your concrete deserves the best materials. I personally handle every inquiry to ensure you get the right solution. Let's solve your water problems together.

Contact Ada at ada@xhhpmc.com or visit www.xhhpmc.com for immediate assistance. We offer free samples, technical support, and customized solutions for your specific concrete challenges.

Partner with Confidence

We understand your business because we've worked with companies like yours for years. Our customers range from small ready-mix plants to massive construction companies. We speak your language - both technically and literally, with support in English, Arabic, and Spanish. Our certifications meet international standards. We provide full documentation for every shipment. Payment terms are flexible, including LC for large orders. Most importantly, we guarantee consistent quality. Every batch matches our specifications exactly. No surprises, no failed tests, no project delays. We ship to Saudi Arabia in 15 days, UAE in 12 days, and most Asian countries within 10 days. Our packaging prevents moisture damage during transport. Custom branding available for distributors. Join hundreds of satisfied customers who trust KEHAO for their concrete admixture needs.

Conclusion

Too much water destroys concrete strength and wastes money. Use proper ratios, test your mix, and consider HPMC water reducers for best results. Contact us today at ada@xhhpmc.com.