Rough, uneven walls create an unprofessional finish in construction projects. Builders face challenges achieving smooth surfaces quickly and affordably. Gypsum putty1 offers a solution that transforms problematic walls into perfectly finished surfaces.

Building gypsum putty is a pre-mixed compound made primarily of gypsum, polymers, and additives used to create smooth wall and ceiling surfaces before painting. It fills imperfections, dries quickly, and provides better adhesion than traditional cement-based putties while ensuring excellent workability.

I started using gypsum putty in my projects about five years ago when a client needed quick interior finishing before an important event. The results were so impressive that I've made it a staple material in my construction supply inventory. Let me share what makes this material so valuable for construction professionals.

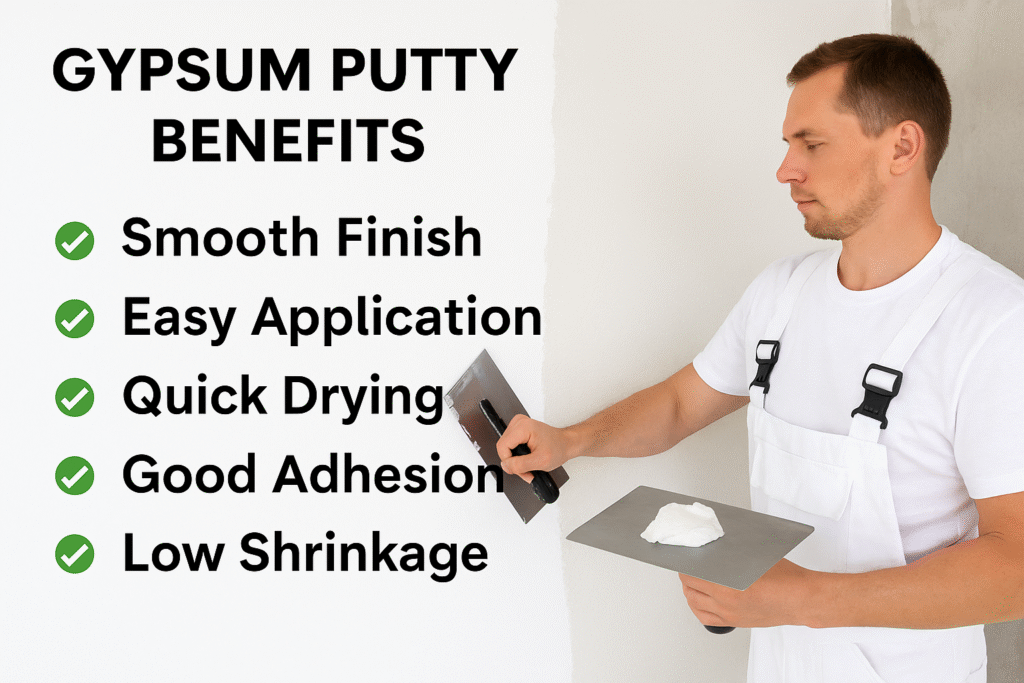

What Are the Main Advantages of Gypsum Putty?

Every construction manager I know struggles with balancing quality and project timelines. Traditional wall finishes often force you to choose one or the other, creating stress and potential client dissatisfaction.

Gypsum putty1 offers several advantages including faster drying time (2-3 hours versus 24+ hours for cement putty), better workability, crack resistance, lower shrinkage, superior adhesion to various substrates, and environmentally friendly properties as it contains no harmful VOCs.

Having worked with various wall finishing materials throughout my career, I've noticed significant differences in project outcomes depending on the putty type chosen. Gypsum putty stands out in several key areas that make it increasingly popular among professionals.

Time Efficiency Comparison

| Property | Gypsum Putty | Cement-Based Putty | Lime Putty |

|---|---|---|---|

| Drying Time | 2-3 hours | 24+ hours | 48+ hours |

| Workable Time | 60-90 minutes | 30-45 minutes | 120+ minutes |

| Layers Required | 2-3 | 3-4 | 3-5 |

| Sandability | Excellent | Poor | Moderate |

The time savings alone make gypsum putty worth considering. On a recent 1,500 square meter office project, we reduced the wall finishing timeline by nearly 40% by switching to gypsum putty. This allowed other trades to begin work earlier, compressing the overall project schedule significantly.

Additionally, the reduced number of layers needed saves on labor costs. While the material itself might cost slightly more than traditional options, the total project economics often favor gypsum putty when accounting for labor, time value, and reduced material waste.

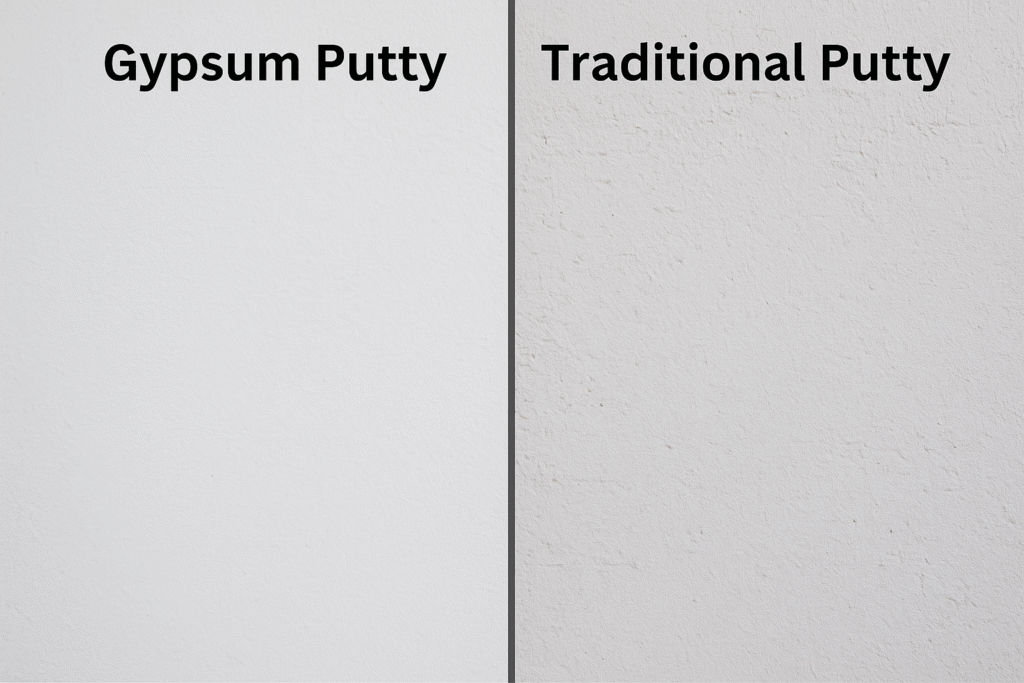

How Does Gypsum Putty Compare with Traditional Wall Putty?

I've seen many contractors waste time and money on wall repairs when using traditional putties. Cracks, bubbles, and poor adhesion lead to callbacks and damaged reputations that no business can afford.

Compared to traditional cement-based putties, gypsum putty is lighter (1.4kg/L vs 2.1kg/L), more flexible (reducing crack formation), creates less dust when sanding, has better moisture regulation properties2, and provides superior workability allowing for thinner application layers and smoother finishes.

The differences between gypsum and traditional putties become most apparent in challenging installation conditions. I recall a project in a high-humidity environment where cement putty consistently failed due to moisture issues. After switching to gypsum putty with its better moisture regulation capabilities, the problems disappeared entirely.

Performance Comparison Table

| Feature | Gypsum Putty | Cement-Based Putty | Acrylic Putty |

|---|---|---|---|

| Weight | Light (1.4kg/L) | Heavy (2.1kg/L) | Medium (1.8kg/L) |

| Flexibility | High | Very Low | Medium |

| Crack Resistance | Excellent | Poor | Good |

| Sanding Properties | Easy, Low Dust | Difficult, High Dust | Moderate |

| Water Resistance | Moderate | Good | Excellent |

| Cost | Medium-High | Low | High |

I've found that while gypsum putty costs approximately 15-20% more than traditional cement putty, the reduction in labor time and improved finish quality easily justifies this difference. Additionally, gypsum putty's lighter weight reduces structural load and transportation costs, a factor often overlooked in material selection decisions.

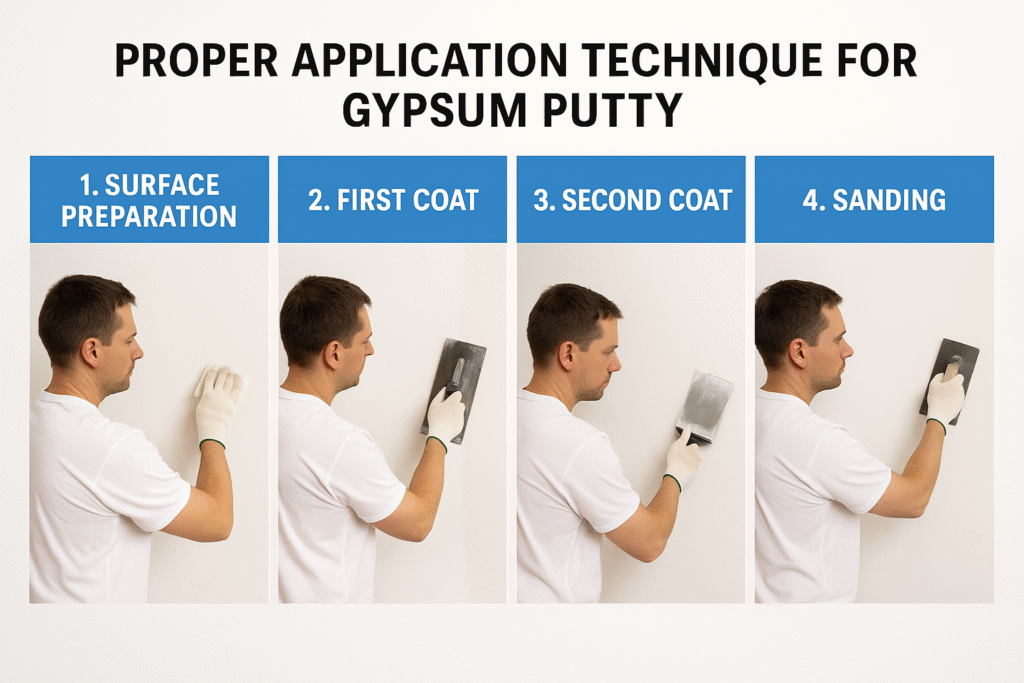

What is the Proper Application Process for Gypsum Putty?

Many contractors apply wall finishes incorrectly, leading to poor results and customer complaints. Without proper technique, even the best materials fail to deliver their promised benefits.

The proper gypsum putty application process involves surface preparation (cleaning and priming if necessary), mixing the putty to the right consistency, applying 2-3 thin layers with a trowel or putty knife, allowing 2-3 hours drying time between coats, and final sanding before painting or wallpapering.

Throughout my years working with construction materials, I've developed a systematic approach to gypsum putty application that maximizes its benefits while minimizing common issues.

Detailed Application Steps:

-

Surface Preparation: Begin by removing all dust, loose material, and oil from the substrate. For highly absorbent surfaces, apply a primer to ensure proper adhesion. I typically use a diluted PVA solution as it's cost-effective and performs well.

-

Putty Preparation: Mix the gypsum putty thoroughly before use. If the consistency is too thick, add water gradually (no more than 5-10% by volume) while mixing until reaching a smooth, creamy consistency. Using a low-speed drill mixer produces the best results.

-

First Coat Application: Apply a thin initial layer using a wide stainless steel trowel, working from bottom to top with smooth, even strokes. The first layer should fill major imperfections but remain relatively thin (1-2mm maximum).

-

Intermediate Layer: After the first coat dries (typically 2-3 hours depending on climate conditions), apply a second, thinner layer perpendicular to the first application. This cross-application technique helps eliminate trowel marks and creates a more uniform surface.

-

Finishing: Apply a final thin layer if necessary, focusing on achieving a perfectly smooth finish. Once dry, sand lightly with 180-220 grit sandpaper for an ultra-smooth result.

Following this methodical approach consistently yields professional results that satisfy even the most demanding clients.

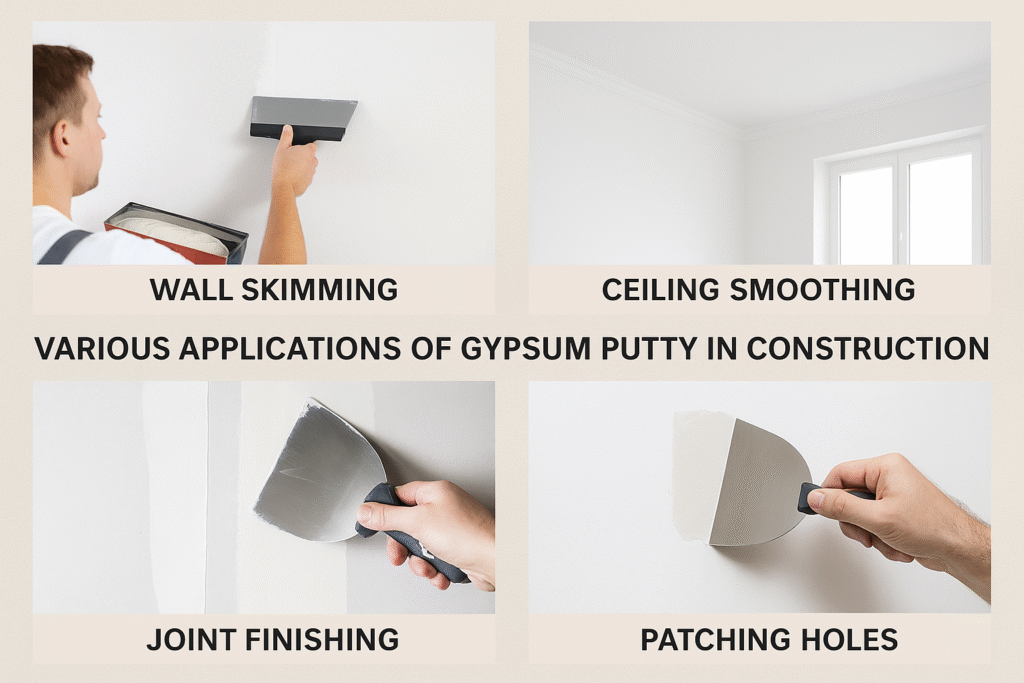

What Are the Main Use Cases and Market Position for Gypsum Putty?

Finding the right materials for specific projects can be confusing. Using inappropriate products wastes money and creates substandard results that damage your professional reputation.

Gypsum putty is primarily used for interior wall and ceiling finishing in residential, commercial, and institutional buildings. It's particularly valuable for fast-track projects, renovation work, and high-end finishes where surface quality is critical. The global market size exceeds $1.2 billion with 7.8% annual growth.

The versatility of gypsum putty makes it suitable for numerous applications across different market segments. I've supplied this material to customers ranging from small residential contractors to major commercial developers, each finding specific benefits for their particular needs.

Market Segment Analysis

| Segment | Adoption Rate | Growth Trend | Key Benefits |

|---|---|---|---|

| Residential | High | Steady | Easy DIY application, quick project completion |

| Commercial | Medium-High | Increasing | Fast turnover, superior finish quality |

| Institutional | Medium | Rapid Growth | Durability, low VOC for sensitive environments |

| Renovation | Very High | Strong | Compatible with existing surfaces, minimal disruption |

| Luxury Properties | High | Strong | Premium finish quality, customization options |

In developing markets like Saudi Arabia, UAE, and India, we've seen approximately 150% increase in gypsum putty adoption over the past five years. This growth is driven by increased awareness of its benefits and gradual professionalization of the construction sector. Even in price-sensitive markets, the total value proposition of gypsum putty is compelling enough to drive market share gains versus traditional materials.

What Technical Specifications Should You Look For in Quality Gypsum Putty?

Many construction projects suffer from using substandard materials. Without understanding the key technical specifications3, buyers often make costly mistakes selecting products that fail prematurely.

Quality gypsum putty should have a pH value of 7-8, setting time of 60-90 minutes, compressive strength >2.5 N/mm², adhesion strength >0.3 N/mm², water retention >95%, and VOC content <10g/L. Products should comply with standards like ASTM C475 and carry proper certification for local building codes.

In my experience supplying construction materials, I've learned that the technical aspects of gypsum putty significantly impact performance. Not all products in the market meet these specifications, which explains the variable results contractors sometimes experience.

Critical Performance Indicators

| Parameter | Acceptable Range | Premium Quality | Impact on Performance |

|---|---|---|---|

| Setting Time | 60-120 minutes | 60-90 minutes | Affects workflow efficiency and project timing |

| Compressive Strength | >2.0 N/mm² | >2.5 N/mm² | Determines durability and resistance to impacts |

| Adhesion Strength | >0.25 N/mm² | >0.3 N/mm² | Prevents delamination and failure over time |

| Water Retention | >92% | >95% | Ensures proper curing and prevents premature drying |

| Particle Size | <200 μm | <150 μm | Affects smoothness of finish and workability |

| Whiteness | >85% | >90% | Impacts final appearance and paint coverage requirements |

When we formulate our kehao gypsum putty products, we pay particular attention to the polymer content and additives that enhance workability. Through extensive testing, we've found that incorporating specific hydroxypropyl methylcellulose derivatives at 0.3-0.5% concentration significantly improves water retention and provides the ideal working window for applicators.

The addition of redispersible polymer powder at 1-2% concentration dramatically increases adhesion strength and flexibility, reducing the risk of cracking that plagues many conventional putties. These technical advantages translate directly to better field performance and higher contractor satisfaction.

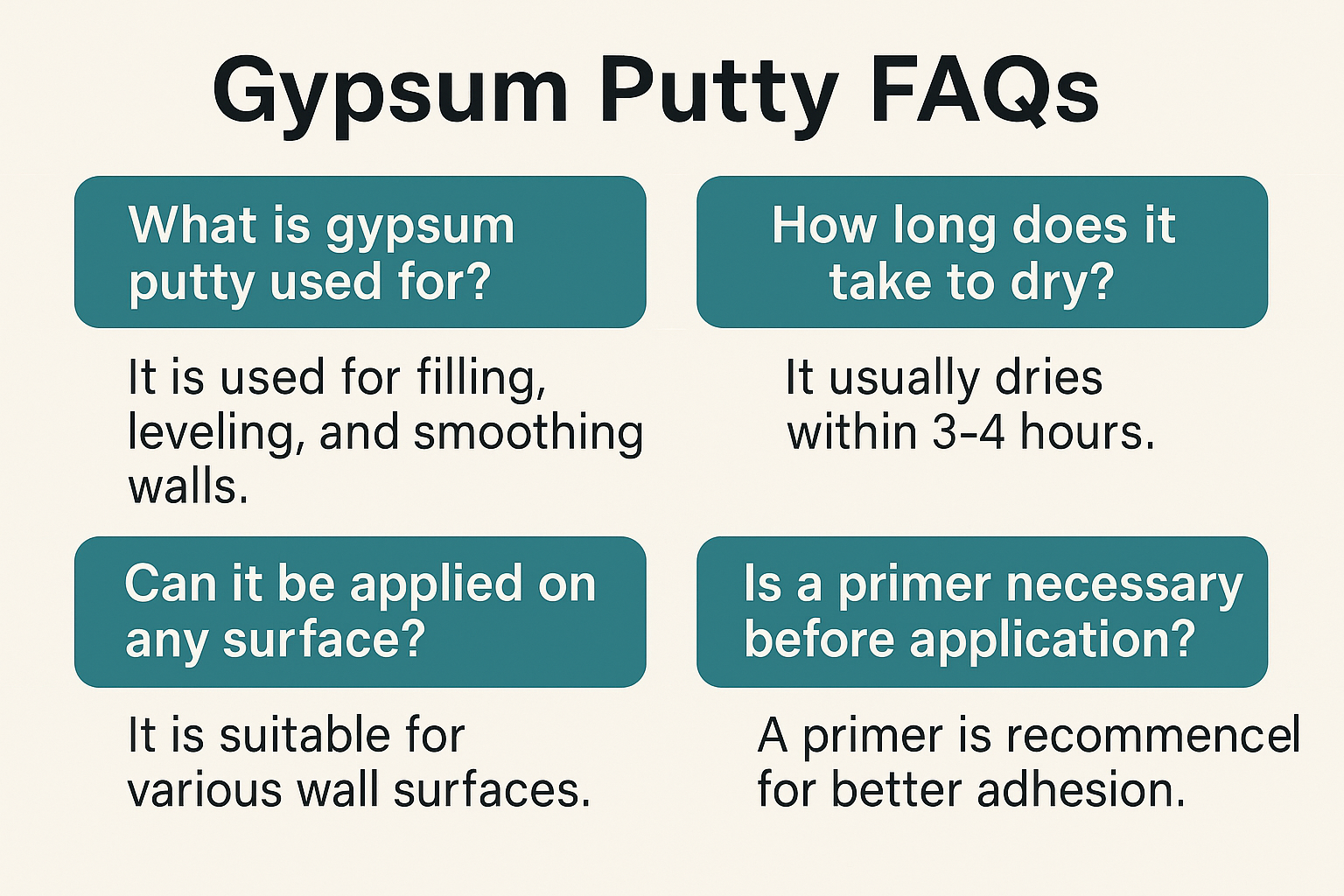

❓ Frequently Asked Questions (FAQ)

Many customers contact me with similar questions about gypsum putty. These uncertainties often delay decision-making and prevent them from experiencing the benefits of modern materials.

The most common questions include whether gypsum putty can be used in bathrooms (yes, with proper sealing), if it can be applied over painted surfaces (yes, after light sanding), how long before painting (minimum 24 hours), shelf life (typically 12 months in sealed containers), and compatibility with various paint types (compatible with all common interior paints).

Having worked directly with customers across multiple markets, I've compiled these frequently asked questions based on real concerns from professionals and DIY users alike.

Expanded FAQ Responses:

Can gypsum putty be used in high-moisture areas?

While basic gypsum putty is not recommended for direct water exposure, many modern formulations include moisture-resistant additives. For bathrooms and kitchens, I recommend our moisture-resistant grade that incorporates hydrophobic components. Additionally, always seal the finished surface with appropriate primers and moisture-resistant paints.

What is the coverage rate per kilogram?

Coverage varies based on surface conditions and application thickness. On average, expect 0.8-1.0 square meters per kilogram at 1mm thickness. Rough surfaces may require up to 30% more material. For accurate project estimation, I always recommend calculating based on 1.2kg/m² to account for wastage and surface variations.

How does temperature affect application?

Optimal application temperature ranges between 10°C and 35°C. Below 10°C, drying time extends significantly and may affect final strength. Above 35°C, working time decreases dramatically, making application difficult. In extreme conditions, I recommend adding our specific retarding agents to maintain workability in hot climates or accelerators for cold weather applications.

Through these detailed answers, I hope to address the common concerns that might prevent you from experiencing the benefits of high-quality gypsum putty in your construction projects.

Conclusion

Gypsum putty delivers superior results through faster drying, better workability, and excellent finish quality. By understanding its proper application and specifications, you'll achieve professional wall finishes that satisfy even your most demanding clients.