Many construction projects fail because of improper material selection. Builders struggle with inconsistent mixtures, poor water retention, and reduced workability in mortars and concrete. Cellulose ether solves these problems.

Cellulose ether1 is a modified cellulose derivative that works as a thickener, binder, water retention agent, and stabilizer in construction materials. It improves workability of mortars, extends open time, enhances adhesion, and provides consistent performance in various building applications.

I've been in the cellulose ether manufacturing business for over 15 years, and I've seen how this additive transforms construction materials. The right cellulose ether can make or break a project's success. Let me explain what makes this powder so important for modern construction.

What Is Cellulose Ether?

Do you know what makes your mortar2 stick properly to the wall? Many contractors face issues with poor adhesion and rapid water loss. These problems lead to cracks and weak bonds between materials.

Cellulose ether1 is a white powdered chemical derived from natural cellulose through chemical modification. It dissolves in water to form a clear solution that increases viscosity, improves water retention, and enhances the workability of construction mixtures.

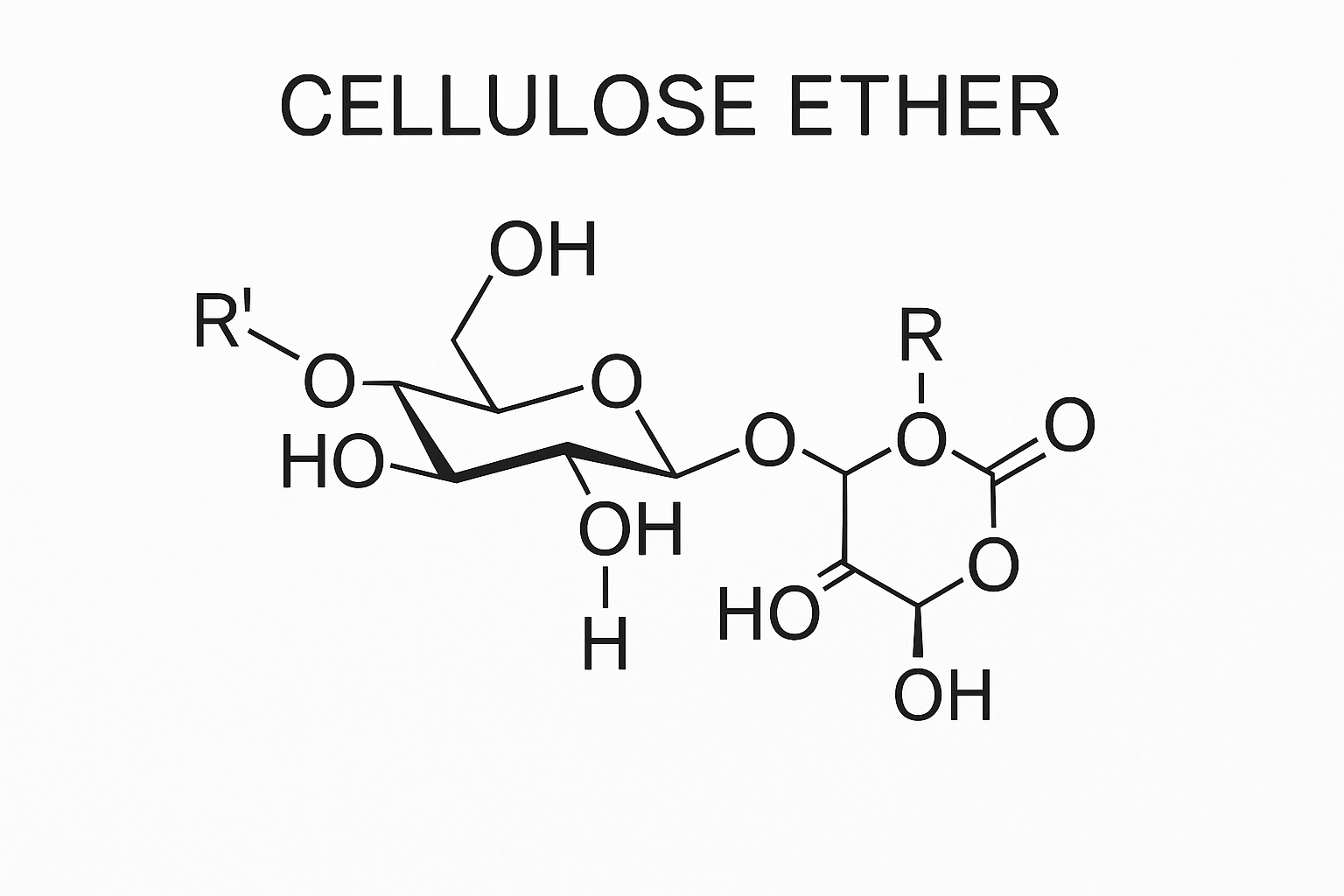

Cellulose ether starts as pure cellulose from cotton or wood pulp. The cellulose undergoes etherification, where hydroxyl groups in the cellulose molecules are replaced with alkyl or hydroxyalkyl groups. This chemical modification changes cellulose from an insoluble fiber to a water-soluble polymer.

The transformation gives cellulose ether its valuable properties. The molecule size (polymerization degree) determines viscosity, while the substitution pattern affects water solubility and thermal gelation. At our factory, we carefully control reaction conditions to ensure consistent quality.

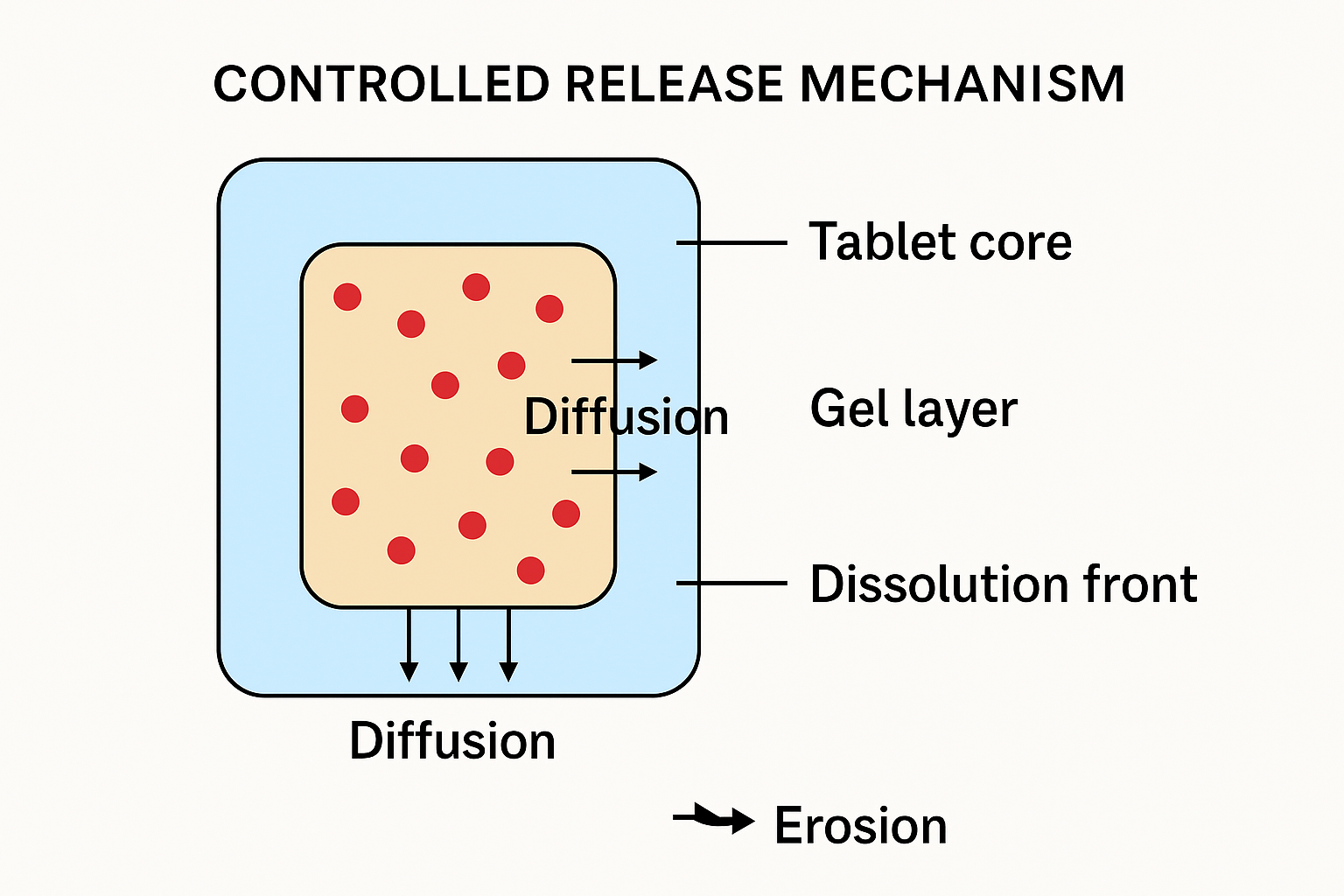

When added to water, cellulose ether forms hydrogen bonds with water molecules, creating a three-dimensional network that thickens the solution. This thickening effect happens at very low concentrations (typically 0.1-2%), making cellulose ether an economical additive for construction materials.

Production Process of Cellulose Ether

Have you wondered how a natural material like cellulose transforms into such a powerful construction additive? Many users don't realize the complex process behind creating consistent, high-quality cellulose ether products.

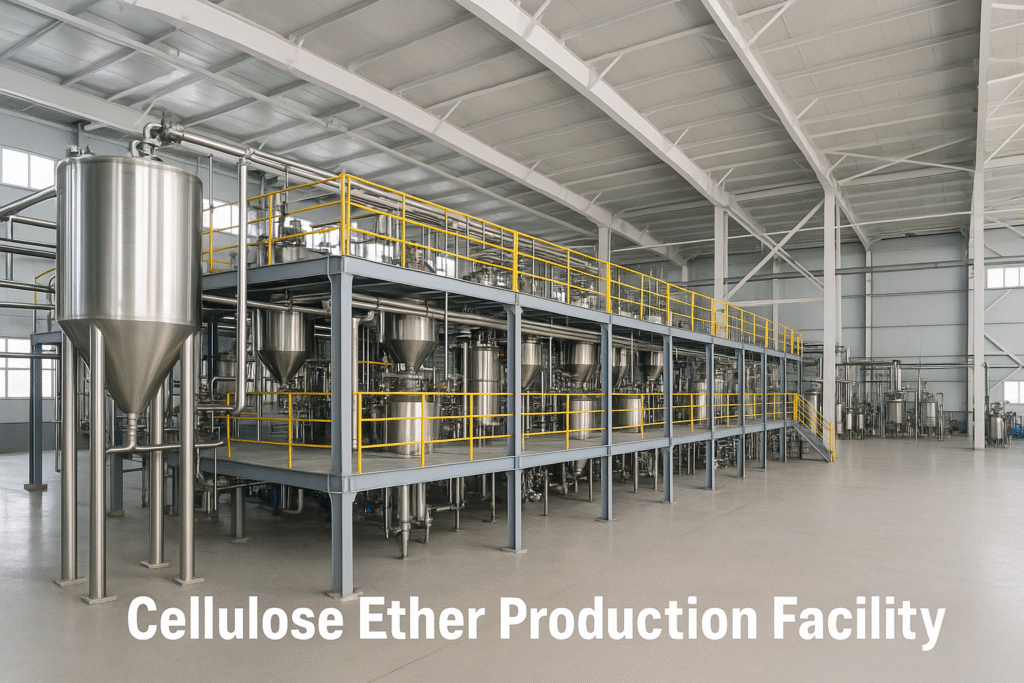

Cellulose ether1 production involves alkalization of purified cellulose with sodium hydroxide, followed by etherification using reagents like chloromethane or propylene oxide. The reaction mixture is then neutralized, purified, dried, and milled to specific particle sizes for different applications.

The production of cellulose ether begins with selecting the right raw materials. At Kehao, we primarily use cotton linters or high-quality wood pulp as our cellulose source. The purity of this starting material directly impacts the final product quality.

The first manufacturing step is alkalization, where we treat cellulose with concentrated sodium hydroxide (caustic soda). This breaks hydrogen bonds in the cellulose structure and makes it more reactive. The alkali cellulose is then reacted with etherifying agents - chemicals that determine the specific type of cellulose ether produced.

For HPMC (hydroxypropyl methylcellulose3), we use chloromethane and propylene oxide. For CMC (carboxymethyl cellulose4), we use chloroacetic acid. The reaction conditions - temperature, pressure, reaction time, and reagent ratios - must be precisely controlled to achieve desired substitution degrees and viscosity.

After the chemical reaction, the crude product undergoes multiple purification steps to remove byproducts and unreacted materials. The purified cellulose ether is then dried in specialized dryers, milled to specific particle sizes, and tested for quality parameters like viscosity, substitution degree, moisture content, and purity.

Our six production lines operate with advanced automation systems that ensure batch-to-batch consistency. This manufacturing excellence is why customers like Mark from Saudi Arabia have trusted our products for their construction applications for years.

Types of Cellulose Ether

Are you confused about which cellulose ether type fits your specific application? Many builders use the wrong type and face issues like poor workability, inconsistent setting times, or inadequate water retention.

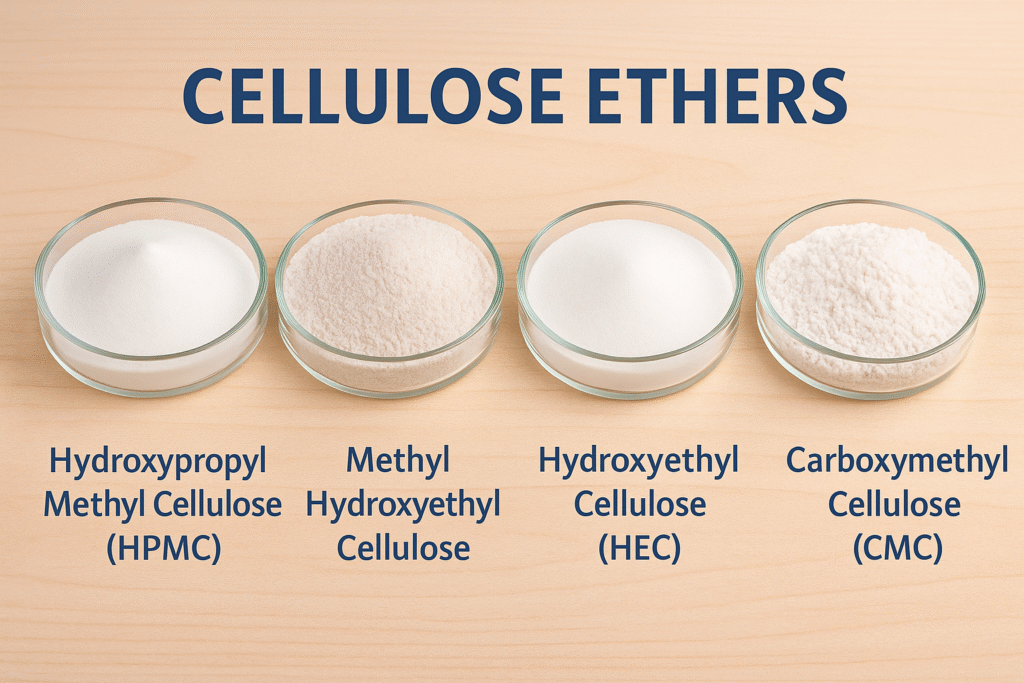

There are several types of cellulose ethers, including methylcellulose (MC), hydroxypropyl methylcellulose3 (HPMC), hydroxyethyl methylcellulose (HEMC), carboxymethyl cellulose4 (CMC), and hydroxyethyl cellulose (HEC). Each type has unique properties suited for specific applications in construction materials.

At Kehao, we produce multiple cellulose ether varieties to meet different application requirements. Each type has unique molecular structures and properties that make them suitable for specific uses. Here's a breakdown of the main types we manufacture:

| Type | Full Name | Key Properties | Main Applications |

|---|---|---|---|

| HPMC | Hydroxypropyl Methylcellulose | High water retention, thermal gelation, good workability | Tile adhesives, renders, EIFS, dry-mix mortars |

| HEMC | Hydroxyethyl Methylcellulose | Balanced water retention and thickening, good compatibility | Gypsum plasters, self-leveling compounds |

| CMC | Carboxymethyl Cellulose | Strong thickening, good stability in alkaline conditions | Paints, ceramic extrusion, drilling muds |

| HEC | Hydroxyethyl Cellulose | Fast dissolution, good compatibility with latex | Paints, gypsum products, cosmetics |

| MC | Methylcellulose | Strong surface activity, good film-forming | Construction adhesives, textile sizing |

The substitution degree (DS) and molar substitution (MS) values determine how the cellulose ether will interact with water and other ingredients in the formulation. Higher DS values typically indicate better water solubility but may affect other performance aspects.

Viscosity is another critical parameter we control during production. We offer products ranging from 5 mPa·s to 200,000 mPa·s to meet different application requirements. Lower viscosity grades dissolve faster and provide good workability, while higher viscosity grades offer superior water retention and sag resistance.

Particle size also matters - we produce fine powder grades for rapid dissolution and coarser grades for delayed dissolution, useful in preventing lumping in dry-mix applications.

Applications of Cellulose Ether in Construction

Have you struggled with mortar that dries too quickly or tiles that don't stick properly? These common construction problems often result from improper additives. The right cellulose ether can transform your construction materials' performance.

Cellulose ethers are extensively used in construction for tile adhesives5, renders, EIFS systems, joint compounds, self-leveling flooring, and cement-based mortars. They improve water retention, enhance adhesion, extend open time, prevent sagging, and provide consistent workability across various environmental conditions.

In my years running Kehao's production facility, I've seen how our cellulose ethers transform construction applications across different markets. The versatility of these additives makes them essential in modern building materials.

Tile adhesives represent one of the largest applications for our HPMC products. The cellulose ether provides critical water retention that prevents premature drying, especially in hot climates like Saudi Arabia or the UAE. It extends open time, allowing installers to adjust tiles properly. Our customer Mark reported a 40% improvement in tile adhesion strength after switching to our HPMC products.

In exterior insulation and finish systems (EIFS), cellulose ethers contribute to consistent workability and prevent sagging during application. The basecoat needs to maintain uniform thickness when applied vertically, and our higher viscosity HPMC grades provide excellent sag resistance while ensuring good adhesion to insulation boards.

For self-leveling compounds, we typically recommend our HEMC products. These provide the right balance of flow properties and water retention. The cellulose ether delays water evaporation, giving the cement enough time to hydrate properly while maintaining flowability.

Here's how dosage affects performance across applications:

| Application | Recommended Cellulose Ether | Typical Dosage | Key Benefits |

|---|---|---|---|

| Tile Adhesives | HPMC 100,000-150,000 mPa·s | 0.2-0.5% | Extended open time, excellent water retention |

| Renders/Plasters | HPMC/HEMC 30,000-80,000 mPa·s | 0.1-0.3% | Improved workability, reduced sagging |

| Self-leveling Compounds | HEMC 15,000-40,000 mPa·s | 0.05-0.15% | Enhanced flow, controlled setting time |

| Joint Compounds | HEC/HPMC 20,000-50,000 mPa·s | 0.2-0.4% | Good workability, crack resistance |

| EIFS Basecoats | HPMC 15,000-30,000 mPa·s | 0.2-0.4% | Sag resistance, improved adhesion |

In developing countries where we export most of our products, cellulose ethers help compensate for variable environmental conditions and worker skill levels by providing more consistent material performance.

Why Cellulose Ether Matters

Are you wondering if cellulose ether is worth the investment for your construction projects? Many manufacturers try to cut costs by using cheap alternatives or eliminating additives altogether, often resulting in product failures and customer complaints.

Cellulose ether1 significantly improves construction material quality by enhancing water retention, workability, adhesion strength, and overall consistency. It reduces material waste, improves installation efficiency, extends product shelf life, and contributes to meeting building standards and regulations.

The importance of cellulose ether extends far beyond simple thickening. In my experience supplying to major mortar and paint manufacturers, I've seen how this additive becomes a critical quality differentiator in finished products.

Water retention capability stands as perhaps the most valuable property cellulose ether brings to construction materials. When a mortar or adhesive is applied to an absorbent substrate like concrete or brick, water can quickly be drawn out of the mixture. This premature water loss prevents proper cement hydration, resulting in weak bonds and potential failure. Our tests show that adding just 0.3% HPMC can increase water retention from 75% to over 95%.

The economic impact is substantial. Contractors using cellulose ether-enhanced products report up to 30% less material waste due to improved workability and longer pot life. Installation time decreases significantly because the material remains workable longer and adheres better to surfaces. One customer in Mexico found that switching to our HPMC-enhanced tile adhesives6 reduced installation time by 25% while improving overall quality.

In hot climates like the Middle East, where many of our customers operate, cellulose ether7 becomes even more critical. The rapid evaporation in these environments can make standard mortars nearly unusable without proper water retention additives. Our specialized grades designed for extreme temperatures have helped customers in UAE and Saudi Arabia maintain consistent quality year-round.

Environmental conditions during application vary widely, and cellulose ether helps buffer these variations:

| Environmental Factor | Problem Without Cellulose Ether | Solution With Cellulose Ether |

|---|---|---|

| High Temperature | Rapid drying, poor hydration | Extended open time, better water retention |

| Low Temperature | Slow setting, susceptibility to frost | Improved cohesion, better water management |

| High Humidity | Slow drying, running or sagging | Enhanced consistency, controlled water mobility |

| Low Humidity | Premature drying, cracking | Superior water retention, controlled hydration |

The regulatory landscape increasingly demands better-performing building materials. Cellulose ether helps manufacturers meet these standards while maintaining profitability.

FAQ: Frequently Asked Questions About Cellulose Ether

Do you have questions about using cellulose ether in your products? Many new customers are unsure about proper dosage, storage requirements, and performance differences between grades. These uncertainties can lead to improper use and suboptimal results.

Cellulose ethers typically dose at 0.1-0.5% by weight in dry mixtures. They should be stored in cool, dry conditions, have a 2-year shelf life, and may require specific mixing procedures. Different grades offer varied viscosity, water retention, and dissolution rates tailored for specific applications.

Based on my experience answering customer questions daily, here are the most common concerns about cellulose ether use in construction applications:

Proper incorporation technique is critical for optimal cellulose ether performance. Unlike some additives, cellulose ether can't simply be added directly to wet mixtures. The correct procedure involves dry-blending it with other powder components before adding water. This prevents lumping and ensures even distribution throughout the mixture.

Many customers ask about compatibility with other additives. Cellulose ethers generally work well with most construction chemicals, but there are exceptions. For example, some highly ionic compounds can reduce effectiveness. We recommend compatibility testing when combining with new additives.

Storage conditions significantly impact cellulose ether quality. Even though the powder appears stable, exposure to high humidity can cause partial hydration and clumping, reducing dissolution efficiency. We recommend storing in original sealed packaging in dry conditions below 30°C.

Here's a troubleshooting guide for common issues:

| Problem | Possible Cause | Solution |

|---|---|---|

| Lumps during mixing | Direct addition to water | Use dry-blend method or pre-disperse in hot water |

| Insufficient thickness | Too low viscosity grade | Switch to higher viscosity product or increase dosage |

| Material slides/sags | Incorrect cellulose ether type | Use HPMC with higher methoxyl content |

| Slow dissolution | Large particle size | Select finer grade or improve mixing process |

| Reduced open time | Insufficient water retention | Increase cellulose ether dosage or use higher quality grade |

Another frequent question concerns differences between manufacturers. While the basic chemistry is the same, manufacturing expertise matters greatly. Our advanced production methods and quality control result in more consistent substitution patterns and fewer impurities than competitors.

Dosage optimization is critical for cost-effectiveness. Starting with manufacturer recommendations and then fine-tuning based on specific formulations and application conditions yields the best results. Our laboratory offers free formulation assistance to help determine optimal cellulose ether type and dosage for your specific application.

Conclusion

Cellulose ether transforms ordinary construction materials into high-performance products. By choosing the right type and quality for your application, you'll achieve better workability, stronger bonds, and more consistent results in any environmental condition.

-

Explore the transformative role of cellulose ether in enhancing construction materials' performance. ↩ ↩ ↩ ↩

-

Find out how to address common mortar problems for better construction outcomes. ↩

-

Explore the versatile applications of HPMC in various construction materials. ↩ ↩

-

Learn about the unique properties and applications of CMC in construction. ↩ ↩

-

Get insights into effective tile adhesive applications for better results. ↩

-

Learn about HPMC-enhanced tile adhesives and how they can reduce installation time and improve quality. ↩

-

Explore how cellulose ether enhances construction materials, improving performance and sustainability. ↩