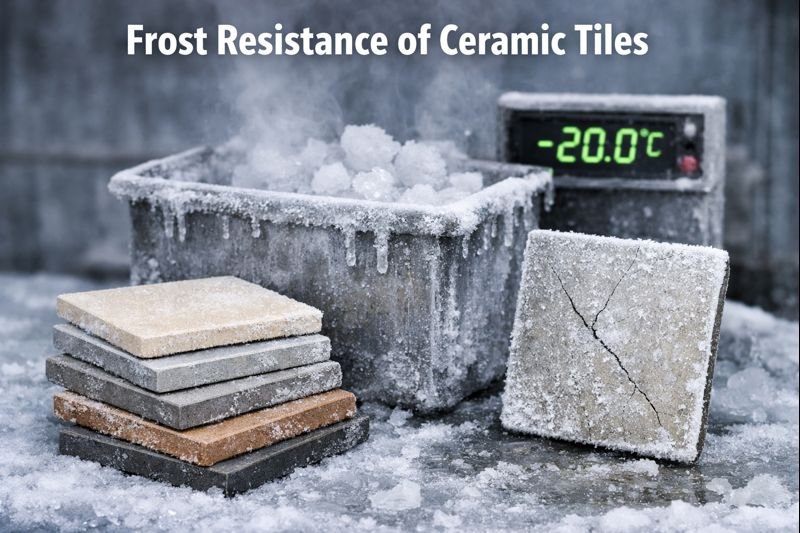

Water seeping into ceramic tiles can freeze in cold weather, causing cracks and damage. Many homeowners discover this problem too late, leading to costly repairs and replacements in outdoor installations.

Frost-resistant ceramic tiles1 are specifically manufactured to withstand freezing temperatures without cracking or breaking. These tiles have low porosity (water absorption rate below 3%) and are fired at high temperatures, creating a dense body that prevents water penetration and subsequent freeze-thaw damage.

When choosing tiles for outdoor spaces or areas exposed to freezing temperatures, understanding frost resistance becomes crucial. Let me walk you through everything you need to know about this important tile characteristic.

Types of Grout for Ceramic Tile - Which Works Best in Freezing Conditions?

Freezing temperatures don't just affect tiles themselves. Poor grout choices can crack, deteriorate and compromise your entire installation, leaving you with an unsightly, damaged surface.

Epoxy grout is the best option for frost-prone areas as it's virtually non-porous, highly water-resistant, and maintains flexibility during temperature fluctuations. Unlike cement-based grouts, epoxy won't crack or deteriorate when exposed to freeze-thaw cycles, offering superior protection against moisture penetration.

Let's examine the different grout types and their suitability for areas exposed to freezing temperatures:

Cement-Based vs. Epoxy Grouts for Frost Resistance

Cement-based grouts2 are the traditional choice but have limitations in frost-prone areas. These grouts are porous and can absorb water, which expands when frozen, leading to cracking. Even with sealers, they require regular maintenance to maintain water resistance.

Epoxy grouts, on the other hand, are inherently waterproof and don't need sealing. They maintain flexibility during temperature changes and resist staining, making them ideal for outdoor applications. While more expensive initially, their durability in freezing conditions provides better long-term value.

| Grout Type | Water Resistance | Freeze-Thaw Durability | Cost | Maintenance |

|---|---|---|---|---|

| Cement-Based | Low to Moderate (requires sealing) | Poor to Fair | $ | High |

| Epoxy | Excellent | Excellent | $$$ | Low |

| Modified Cement | Moderate | Good | $$ | Moderate |

For the best frost resistance performance, I recommend pairing epoxy grout with properly rated frost-resistant tiles to create a complete system that will withstand winter's harshest conditions.

What is Meant by Frost Resistance for Ceramic Tile? Technical Explanation

The anxiety of watching your beautiful outdoor tile installation deteriorate after just one winter can be overwhelming. Many customers come to me after experiencing this heartbreaking and expensive lesson.

Frost resistance in ceramic tiles refers to their ability to withstand repeated freeze-thaw cycles without cracking, spalling, or deteriorating. This property is achieved through specific manufacturing processes that create tiles with low water absorption rates (typically below 3% for outdoor use) and high structural integrity.

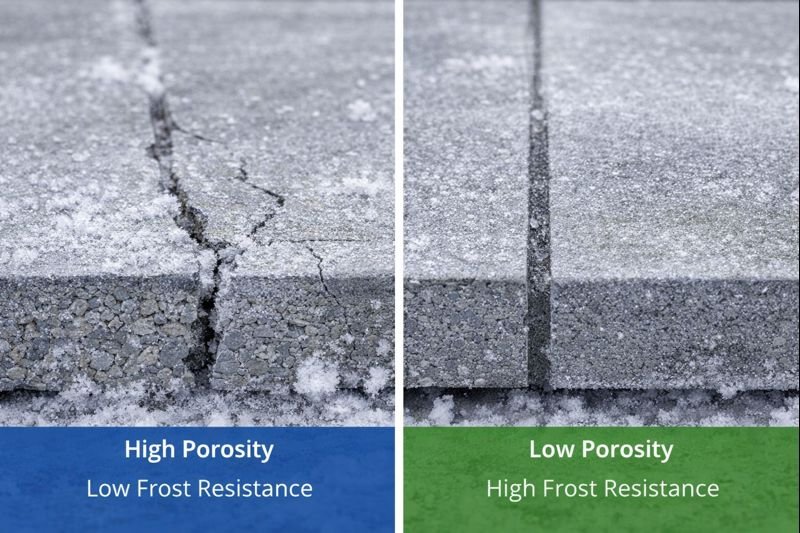

Understanding the science behind frost resistance helps explain why not all ceramic tiles are suitable for outdoor use in cold climates. When water penetrates a porous tile and freezes, it expands by approximately 9%, creating internal pressure. In tiles with high porosity, this pressure causes microfractures that worsen with each freeze-thaw cycle.

Frost-resistant tiles are manufactured using high-quality clays and minerals that are fired at extremely high temperatures (often over 1200°C). This vitrification process creates a dense, non-porous structure that prevents water infiltration. Many manufacturers also add specific materials to enhance frost resistance, creating stronger molecular bonds within the tile body.

The European standard EN 202 or ISO 10545-12 tests define the methodology for determining frost resistance, subjecting tiles to multiple freeze-thaw cycles before examining them for damage. Tiles that pass these rigorous tests earn frost resistance certification, making them suitable for outdoor applications in cold regions.

Frost Resistance Ratings Explained

| Rating | Water Absorption | Suitable Environments | Typical Applications |

|---|---|---|---|

| Non-frost resistant | >3% | Indoor only | Interior floors, walls |

| Moderately frost resistant | 1-3% | Limited outdoor use | Covered patios, transitional areas |

| Fully frost resistant | <1% | All outdoor areas | Uncovered patios, pool surrounds, driveways |

When selecting tiles for outdoor projects in areas that experience freezing temperatures, I always recommend checking the specific frost resistance rating rather than relying on general product categories.

Important Considerations - What Affects a Tile's Frost Resistance?

I've seen many beautiful outdoor installations ruined by winter, leaving homeowners frustrated and facing unexpected replacement costs. Choosing the right tile for freezing environments requires understanding several critical factors.

Frost resistance in ceramic tiles is affected by multiple factors: water absorption rate, tile thickness, installation method, and substrate preparation. The most crucial factor is water absorption - tiles rated "impervious" (less than 0.5% absorption) offer the highest frost resistance, while those with higher absorption rates are more vulnerable to freeze-thaw damage.

When evaluating ceramic tiles for frost-resistant applications, consider these important factors:

Water Absorption Rate and Frost Resistance Relationship

Water absorption rate is the most critical indicator of a tile's frost resistance. This percentage represents how much water a tile absorbs relative to its dry weight. The lower this number, the better the tile will perform in freezing conditions.

Porcelain tiles, a subset of ceramic tiles, typically have the lowest water absorption rates (below 0.5%) due to their dense composition and high firing temperatures. This makes them excellent choices for outdoor installations in cold climates. Standard ceramic tiles, by contrast, can have absorption rates ranging from 3% to 15%, making many unsuitable for frost-prone areas.

Most manufacturers classify their tiles according to these absorption rates:

| Classification | Water Absorption Rate | Frost Resistance | Common Applications |

|---|---|---|---|

| Non-vitreous | >7% | None | Indoor use only |

| Semi-vitreous | 3-7% | Limited | Indoor or covered areas |

| Vitreous | 0.5-3% | Moderate to Good | Most outdoor applications |

| Impervious | <0.5% | Excellent | Any outdoor application |

Beyond water absorption, proper installation plays a crucial role in frost resistance performance. Even the most frost-resistant tile can fail if installed incorrectly. Ensure proper drainage, use appropriate setting materials designed for outdoor use, and create adequate expansion joints to accommodate thermal movement. The substrate must also be prepared correctly to prevent water accumulation beneath the tiles, which can cause damage during freeze-thaw cycles.

Can ceramic tile be used for a fireplace?

The threat of damage from extreme temperature fluctuations makes many homeowners wonder if ceramic tiles are suitable for fireplace surrounds. This concern is valid since improper materials can crack, discolor, or even create unsafe conditions.

Ceramic tile can be used for fireplace surrounds and hearths when properly selected for heat resistance. Porcelain tiles, with their low porosity and high firing temperatures, are particularly suitable. Always verify the manufacturer's specifications regarding heat resistance and avoid using frost-resistant outdoor tiles, which may contain different additives.

When selecting ceramic tiles for fireplace applications, heat resistance becomes as important as frost resistance is for outdoor applications. While the mechanisms of damage differ, both involve the tile's ability to withstand thermal stress.

For fireplace surrounds, I recommend porcelain tiles with Class A fire ratings. These tiles have been tested to withstand high temperatures without releasing toxic fumes or contributing to flame spread. Installation around fireplaces requires special attention to expansion joints and appropriate heat-resistant setting materials.

Some manufacturers produce specialized ceramic tiles specifically designed for high-temperature applications. These tiles often contain refractory materials similar to those used in kilns and industrial furnaces, making them extremely resistant to thermal shock.

| Area | Recommended Tile Type | Special Considerations |

|---|---|---|

| Fireplace surround | Porcelain or specialized ceramic | Heat-resistant setting materials, expansion joints |

| Hearth | Dense, thick porcelain or natural stone | Additional substrate insulation, heat-resistant grout |

| Far surrounds | Standard ceramic acceptable | Standard installation methods |

It's worth noting that while frost-resistant tiles might seem suitable for fireplaces due to their durability, they're engineered for different stresses. Always confirm with the manufacturer that your selected tile is appropriate for fireplace use.

What type of tile is best for outdoor use?

I've had customers spend thousands on outdoor tile installations only to find their beautiful patios damaged after one winter. This heartbreaking scenario is completely avoidable with the right tile selection.

Porcelain tiles are best for outdoor use, particularly in areas with freezing temperatures, due to their extremely low water absorption rate (under 0.5%), high density, and excellent frost resistance. They also resist fading from UV exposure, withstand temperature fluctuations, and require minimal maintenance compared to natural stone or standard ceramic.

When selecting outdoor tiles, frost resistance is just one of several important characteristics to consider. Outdoor installations face multiple challenges including UV exposure, temperature fluctuations, moisture, and in some cases, chemical exposure from pool water or deicing salts.

Comparing Outdoor Tile Options

Porcelain tiles lead the market for outdoor applications, but other options exist. Let's compare the most common outdoor tile materials:

| Tile Type | Frost Resistance | Slip Resistance | UV Resistance | Maintenance | Relative Cost |

|---|---|---|---|---|---|

| Porcelain | Excellent | Good to Excellent | Excellent | Low | $$ - $$$ |

| Natural Stone | Varies by type | Varies by finish | Good | Moderate to High | $$$ - $$$$ |

| Quarry Tile | Good | Excellent | Good | Low | $$ |

| Terracotta | Poor to Fair | Good | Fair | High | $ - $$ |

| Concrete Tile | Moderate | Good | Moderate | Moderate | $ - $$ |

Beyond material selection, other characteristics of outdoor tiles should include:

-

Slip resistance: Outdoor tiles need adequate traction, especially when wet. Look for tiles with R9-R13 ratings (with R13 providing the highest slip resistance).

-

Wear resistance: Measured using the PEI scale (Porcelain Enamel Institute), outdoor tiles should ideally have ratings of IV or V to withstand heavy traffic.

-

Thickness: For outdoor applications, thicker tiles (at least 10mm, preferably 20mm for patios) provide better durability and resistance to breakage.

-

Color stability: UV-resistant tiles will maintain their appearance without fading, even with constant sun exposure.

For extreme conditions, such as areas with harsh winters where deicing salts might be used, I recommend through-body porcelain tiles. Unlike glazed tiles, these maintain their color throughout the entire tile body, making any chips or scratches less noticeable and ensuring lasting performance even in the most challenging conditions.

Conclusion

Frost-resistant ceramic tiles1 must have low water absorption rates (under 3%), be properly installed with suitable grout, and meet specific testing standards. Choose porcelain for the best outdoor performance and ensure proper installation for lasting durability in freezing conditions.