Are you struggling with poor water retention and weak bonding in your construction materials? Many builders face these issues, leading to cracking, poor workability, and increased costs. MHEC might be your solution.

Methyl Hydroxyethyl Cellulose (MHEC)1 is a water-soluble cellulose ether that improves water retention, enhances adhesion, and provides thickening effects in construction materials. It's widely used in tile adhesives2, renders, plasters, and self-leveling compounds3 to extend working time and increase bond strength.

I've been working with cellulose ethers4 for over 15 years, and I've seen firsthand how the right MHEC can make or break a construction project. Let's dive into everything you need to know about this versatile construction additive.

What Makes MHEC Different from Other Cellulose Ethers?

Do you know why many professional builders are switching to MHEC instead of traditional HPMC? The answer lies in its unique molecular structure that offers better performance in specific applications.

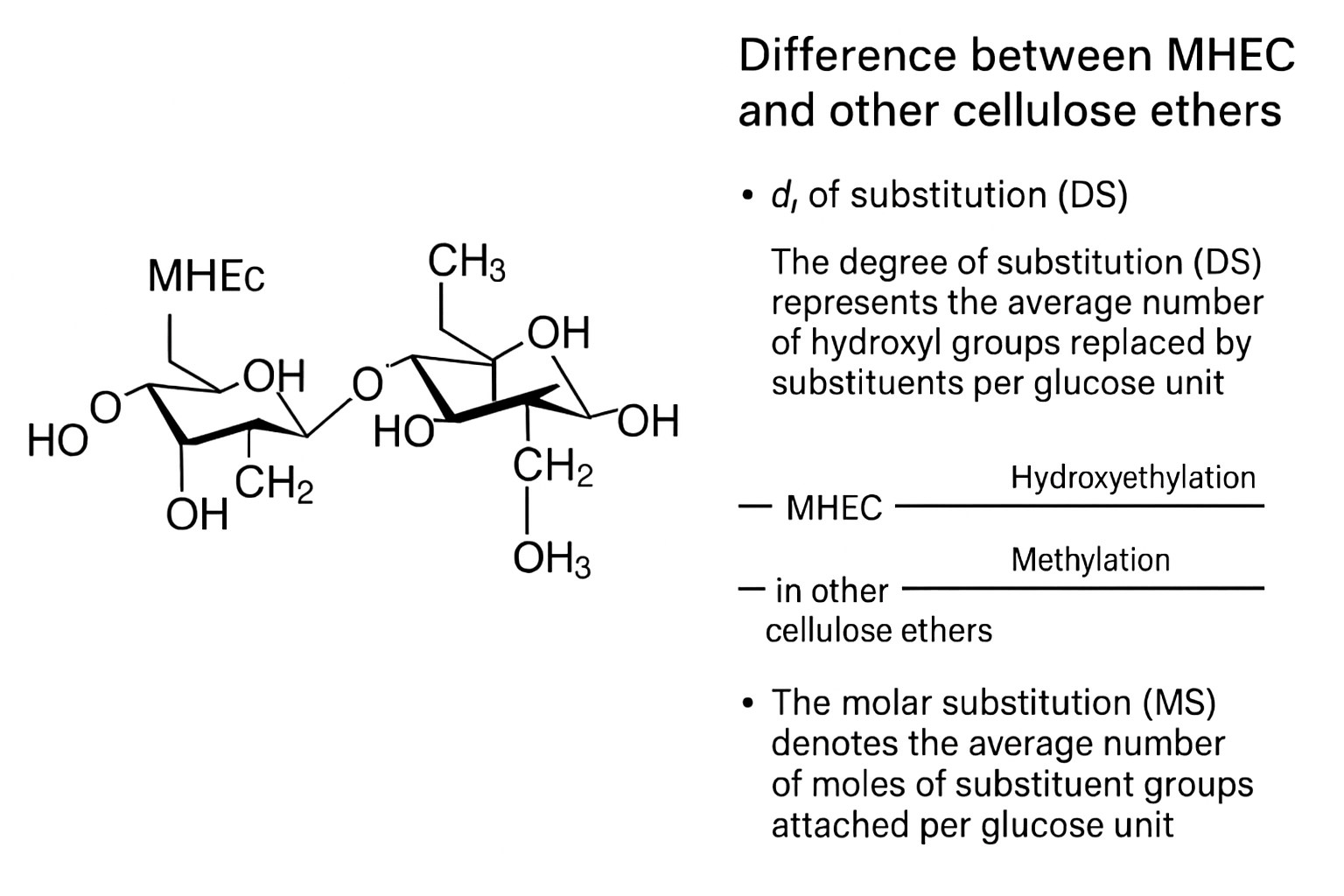

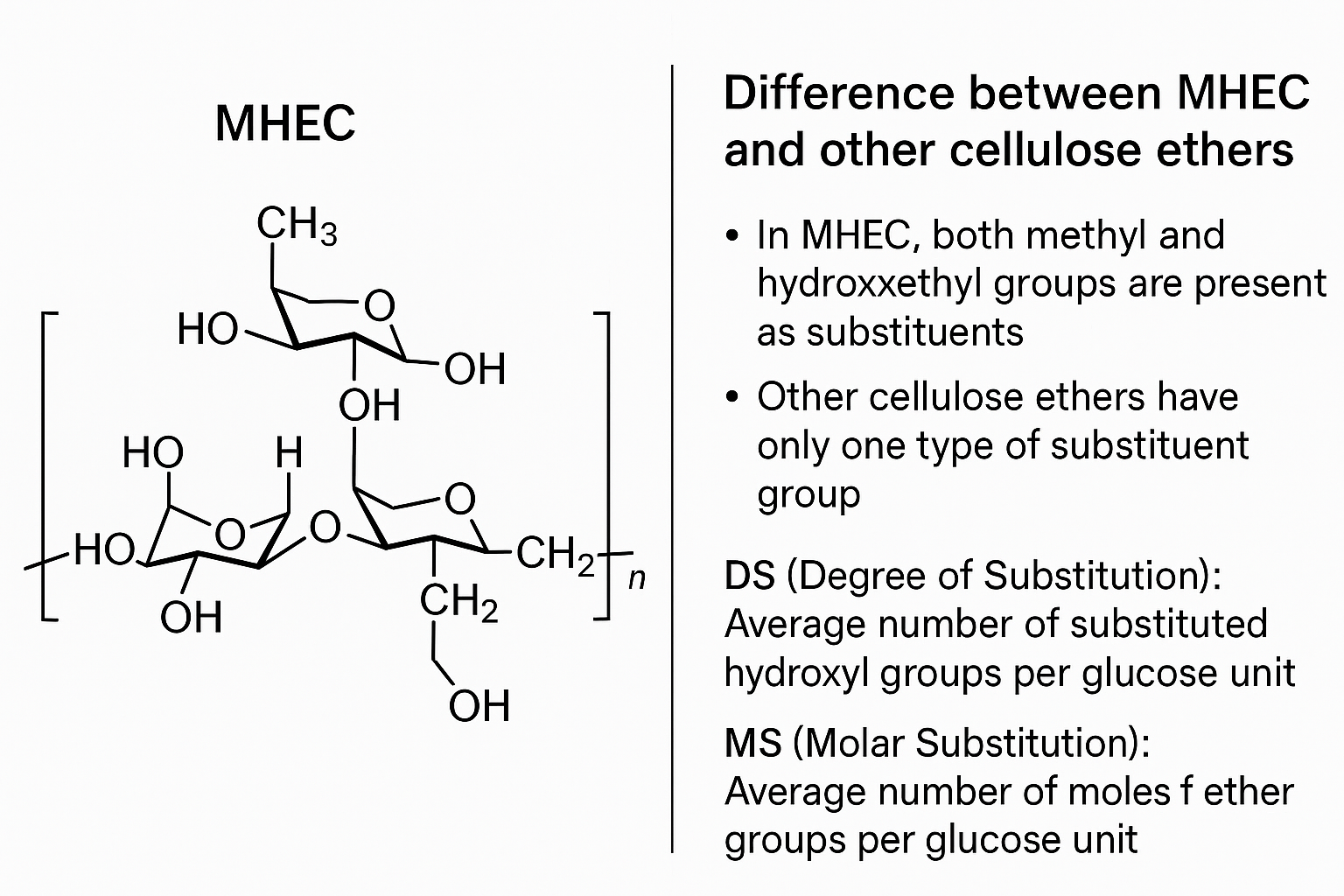

MHEC combines methyl and hydroxyethyl groups on a cellulose backbone, creating a polymer with excellent water retention, controlled viscosity, and enhanced workability. Unlike pure HPMC, it provides superior performance in cement-based applications where higher alkalinity resistance is required.

MHEC stands out because of its balanced substitution pattern. As a manufacturer, I've tested countless formulations to achieve the optimal balance between methyl and hydroxyethyl groups. This balance directly affects how MHEC performs in different construction materials.

The methyl groups provide the basic water retention and thickening properties, while the hydroxyethyl groups enhance solubility and compatibility with cement systems. This dual functionality makes MHEC particularly valuable in dry-mix mortars and renders.

When comparing MHEC to HPMC (Hydroxypropyl Methylcellulose), MHEC typically shows better resistance to enzymatic degradation and more stable viscosity development in alkaline environments. This translates to more consistent performance on the job site, especially in hot or humid conditions where material workability can be challenging to maintain.

MHEC also offers excellent compatibility with other additives commonly used in construction formulations, including redispersible polymer powders5, superplasticizers, and air entrainers. This compatibility allows formulators to create well-balanced products with multiple performance benefits.

What Are the Key Functions of MHEC in Construction Applications?

Have you ever wondered why your mortar dries out too quickly or why your tile adhesive lacks proper strength? These problems often stem from poor water retention and inadequate rheology control.

MHEC serves multiple critical functions in construction materials: it acts as a water retention agent to prevent premature drying, works as a thickener to achieve optimal consistency, improves adhesion to substrates, and enhances workability for easier application. It also helps control sag resistance in vertical applications.

I've helped hundreds of customers optimize their formulations with MHEC, and the results speak for themselves. One customer was struggling with tile adhesive that kept drying out before the tiles could be properly placed. After incorporating our WH-MHEC product at just 0.3% concentration, they extended their open time by over 15 minutes.

The water retention mechanism of MHEC is fascinating from a chemical perspective. The cellulose chains form a three-dimensional network in water, trapping water molecules and releasing them slowly during the cement hydration process. This controlled water release is crucial for proper cement curing and strength development.

Beyond water retention, MHEC dramatically improves the rheology of fresh mortars. It creates a pseudoplastic behavior, meaning the material flows easily when force is applied (like spreading with a trowel) but resists flowing when at rest (preventing sag on vertical surfaces). This property is particularly valuable in tile adhesives2 and renders.

Another key function is the anti-sedimentation effect. MHEC keeps solid particles suspended in the mix, preventing segregation and ensuring consistent performance throughout the application. This is especially important in self-leveling compounds and grouts where particle settling can cause surface defects.

How is WH-MHEC Packaged and Shipped for Optimal Quality?

Are you concerned about product degradation during shipping or storage? Many construction material manufacturers have experienced quality issues due to improper packaging of cellulose ethers4.

WH-MHEC is typically packaged in 25kg moisture-resistant kraft paper bags with PE liners to prevent humidity damage. We also offer jumbo bags (500-1000kg) for larger orders. All packaging is designed for easy handling, optimal product protection, and extended shelf life of up to two years when stored properly.

I personally oversee our packaging processes at Kehao, and we've invested significantly in creating a system that maintains product integrity from our factory to your warehouse. Our multi-layer bags provide excellent moisture protection while still being sturdy enough for international shipping.

Each bag is clearly labeled with product specifications, batch numbers, production dates, and handling instructions in multiple languages. This ensures proper identification and traceability throughout the supply chain. For customers with specific labeling requirements, we offer customized packaging solutions with your branding and specifications.

The standard 25kg bags are palletized and shrink-wrapped for ocean freight shipping. We use reinforced pallets that can withstand the rigors of international transport. For air freight orders, we offer special packaging configurations that maximize space efficiency while maintaining product protection.

Our jumbo bags feature lifting loops for easy handling with forklifts and are constructed with extra reinforcement at stress points. These bulk packages are ideal for customers with automated dosing systems or high-volume production needs. We can also provide FIBC bags with different discharge options depending on your specific handling equipment.

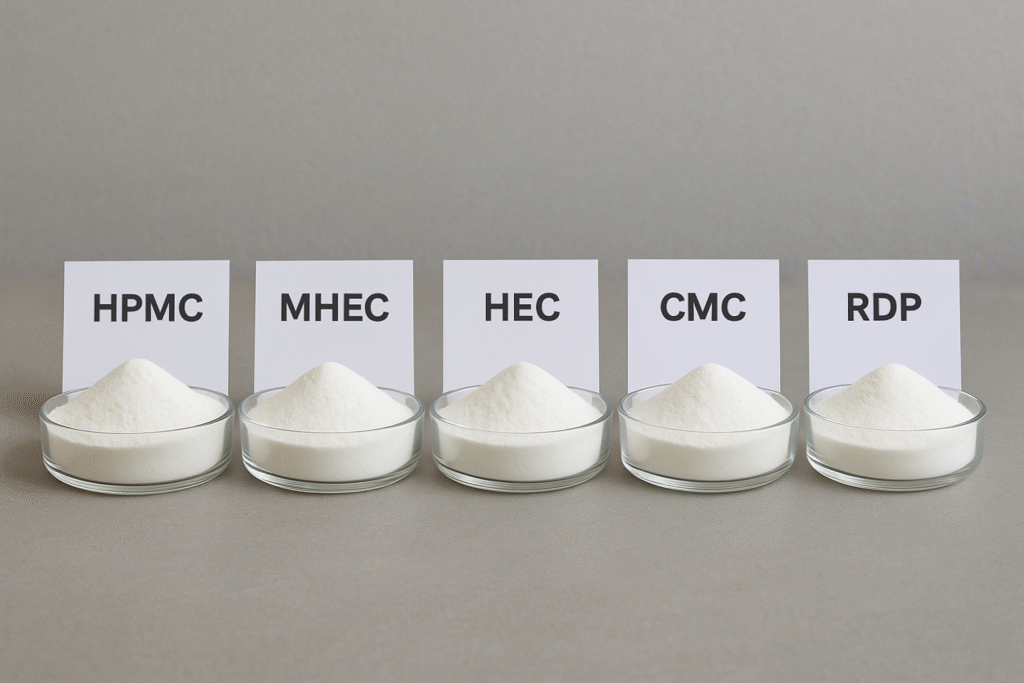

What Other Cellulose Ethers Complement MHEC in Construction Formulations?

Have you been struggling to create the perfect formulation for your specific application? The right combination of cellulose ethers4 and complementary additives can make all the difference in performance outcomes.

MHEC works well with other cellulose derivatives like CMC for improved workability, HPMC for enhanced water retention, and HEC for increased thickening. Each combination offers unique performance benefits. Redispersible powder, superplasticizers, and retarders are also commonly used alongside MHEC to create comprehensive construction solutions.

In my years of formulating with cellulose ethers, I've found that combining MHEC with other additives often creates synergistic effects that enhance overall performance. For example, when we pair MHEC with our redispersible polymer powder, the adhesion strength of tile adhesives increases by up to 40% compared to using either additive alone.

The choice of complementary cellulose ethers depends largely on the specific application requirements. For tile adhesives requiring exceptional open time, combining MHEC with high-viscosity HPMC creates a powerful water retention system. For self-leveling compounds, MHEC pairs well with low-viscosity CMC to achieve the perfect flow characteristics without segregation.

Here's a helpful comparison of common cellulose ethers used alongside MHEC:

| Cellulose Type | Primary Function | Best Paired with MHEC for |

|---|---|---|

| HPMC | Water retention | Tile adhesives, Renders |

| CMC | Binding, Water retention | Paints, Joint compounds |

| HEC | Thickening, Anti-sagging | Ceiling applications, Patching compounds |

| MC | Thickening, Water retention | General mortars, Basic plasters |

Beyond cellulose ethers, we often recommend pairing MHEC with our redispersible polymer powder for applications requiring enhanced flexibility and adhesion. The combination creates a powerful system that addresses both the fresh state properties (through MHEC) and the hardened state properties (through the polymer powder).

What Are the Most Frequently Asked Questions About MHEC?

Are you new to working with cellulose ethers and feeling overwhelmed by technical specifications? You're not alone – I receive dozens of questions every week about MHEC applications and usage.

Common MHEC questions involve dosage rates (typically 0.2-0.5% for most applications), dissolution methods (pre-dispersion in hot water is recommended), compatibility with other additives (generally excellent with most construction chemicals), and storage conditions (cool, dry place in original packaging).

After supplying MHEC to customers worldwide for years, I've compiled answers to the most frequent questions to help you get started quickly and effectively with this versatile additive.

The most common question is about proper dosage. While general recommendations are helpful, the optimal dosage depends on your specific application. For tile adhesives, we typically recommend 0.25-0.35% MHEC by weight of the dry mix. For renders and plasters, 0.20-0.30% is usually sufficient. Self-leveling compounds may require 0.15-0.25%. We always recommend starting with small test batches to fine-tune the dosage for your exact requirements.

Another frequent concern is proper dissolution. MHEC performs best when fully dissolved, which requires the right technique. The most effective method is to disperse MHEC in hot water (above 70°C) while stirring vigorously, then add cold water to reduce the temperature and allow the MHEC to fully dissolve. This "hot-cold" technique prevents lumping and ensures consistent performance.

Many customers ask about shelf life and storage. When stored in its original, unopened packaging in a cool, dry place, MHEC maintains its properties for up to two years. Once opened, the package should be tightly resealed to prevent moisture absorption, which can cause clumping and reduced efficiency.

Compatibility questions are also common. MHEC works well with most construction additives, but the order of addition in your mixing process can be important. We typically recommend adding MHEC to your dry components first, mixing thoroughly, and then adding any liquid additives. This sequence optimizes the performance of all components in the final formulation.

Conclusion

MHEC offers exceptional water retention, thickening, and adhesion enhancement for construction materials. By choosing the right grade and combining it with complementary additives, you can create high-performance formulations that stand out in the market.

-

Explore the benefits of MHEC in construction materials and how it can enhance your projects. ↩

-

Find out how to enhance tile adhesive performance with the right additives and techniques. ↩ ↩

-

Explore the advantages of self-leveling compounds in construction and how to use them effectively. ↩

-

Gain insights into cellulose ethers and how they can enhance construction material formulations. ↩ ↩ ↩

-

Learn how redispersible polymer powders can improve the performance of construction materials. ↩