Many cement manufacturers struggle with consistency, workability, and water retention issues. These problems lead to lower quality products, wasted materials, and compromised structural integrity.

HPMC (Hydroxypropyl Methylcellulose)1 is a vital additive in cement that improves water retention, enhances workability, increases adhesion, and extends open time. It functions as a thickener, binder, and water-retaining agent, typically used at 0.1-0.5% concentration in cement formulations.

As a manufacturer with six production lines at Kehao, I've seen firsthand how HPMC transforms ordinary cement into a superior building material. Let me explain what makes this cellulose ether so valuable in construction and why selecting the right grade matters for your projects.

What Is Hydroxypropyl Methylcellulose (HPMC) and Its Basic Properties?

Contractors often face cement mixtures that dry too quickly or lack proper adhesion. This leads to cracking, poor bonding, and ultimately project delays and increased costs.

HPMC is a non-ionic cellulose ether derived from natural cellulose through chemical modification. It comes as a white to off-white powder that dissolves in cold water to form a clear solution with viscosities ranging from 100 to 200,000 mPa·s, depending on its molecular weight.

The fundamental properties of HPMC make it invaluable in cement applications. At Kehao, we manufacture HPMC with various viscosity grades (from 100,000 to 200,000 mPa·s) and methoxyl content (19-24%), which directly affects its performance in cement.

Key Properties of HPMC for Cement Applications

| Property | Description | Benefit in Cement |

|---|---|---|

| Water Retention | Holds water within the cement matrix | Ensures proper hydration of cement particles |

| Viscosity | Thickens aqueous solutions | Controls consistency and sag resistance |

| Surface Activity | Reduces surface tension | Improves wetting and adhesion to substrates |

| Thermal Gelation | Forms gel at elevated temperatures | Prevents material separation during application |

| pH Stability | Stable in alkaline environments | Compatible with cement's high pH |

I've tested numerous HPMC grades in our laboratory and found that the methoxyl substitution level significantly impacts water retention. Higher methoxyl content (22-24%) typically provides better water retention, which is crucial for cement applications in hot climates like Saudi Arabia and UAE, where many of our customers operate.

How Does HPMC Improve the Performance of Cement Mixtures?

Construction professionals often struggle with cement that's difficult to spread, quick to dry, and prone to cracking. These issues waste time, increase labor costs, and compromise the final build quality.

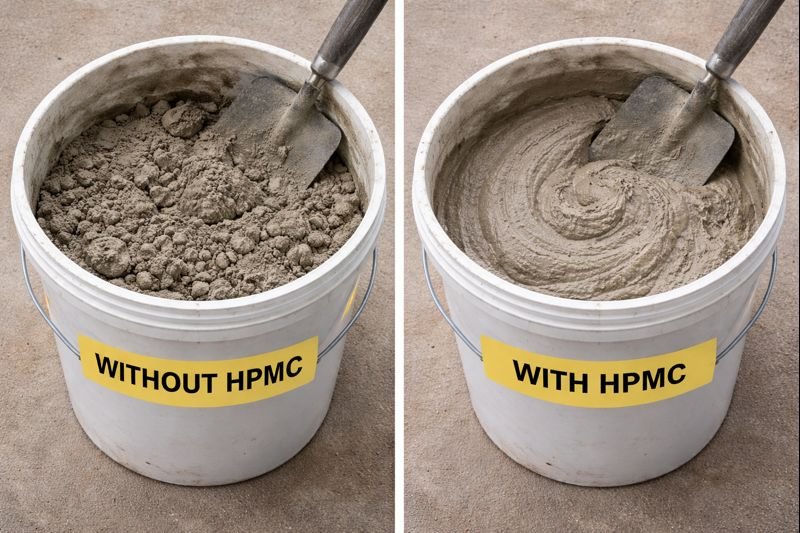

HPMC improves cement performance by forming a protective colloid in the mixture that retains water, enhances workability, prevents segregation, extends open time, and strengthens adhesion. This results in easier application, better consistency, and improved structural integrity of the finished cement product.

The role of HPMC in cement extends far beyond basic water retention. Based on my experience at Kehao's testing facilities, I've observed multiple mechanisms through which HPMC transforms ordinary cement into high-performance building material.

Mechanism of Action in Cement

HPMC creates a three-dimensional network structure within the cement matrix. When water is added to cement containing HPMC, the polymer chains of HPMC begin to unfold and hydrate. This process forms a gel-like structure that physically entraps water molecules, slowing their evaporation and migration.

Our research shows that HPMC with viscosity around 150,000 mPa·s works best for general cement applications. However, for specialized uses like self-leveling compounds2, lower viscosity grades (40,000-60,000 mPa·s) provide better flow characteristics while still maintaining adequate water retention.

The hydroxypropyl groups in HPMC interact with cement particles, creating a lubricating effect that reduces internal friction. This is why cement mixtures with HPMC feel "buttery" and spread more easily, reducing the physical effort required during application—something our customers in the construction industry particularly value.

What Are the Main Benefits of Using HPMC in Cement Formulations?

Construction professionals face increasing demands for more sustainable, efficient, and durable building materials. Traditional cement formulations often fall short, resulting in wasted resources and compromised building integrity.

HPMC provides multiple benefits in cement including improved workability, enhanced water retention, increased bond strength, reduced sagging on vertical surfaces, extended working time, and better crack resistance. These advantages result in smoother application, stronger structures, and reduced material waste.

At Kehao, we've documented substantial improvements in cement performance through careful HPMC selection and dosage optimization. Our research and customer feedback have highlighted several significant benefits that directly impact construction efficiency and outcomes.

Quantifiable Improvements with HPMC

The benefits of incorporating HPMC extend beyond theoretical advantages—they translate to measurable improvements in construction practice. In controlled tests at our laboratory, we've observed that adding just 0.3% HPMC to cement mortar can increase water retention from approximately 72% to over 95%.

| Benefit | Without HPMC | With HPMC (0.3%) | Improvement |

|---|---|---|---|

| Water Retention | 70-75% | 95-98% | ~25% increase |

| Open Time | 20-30 minutes | 60-90 minutes | 2-3× longer |

| Adhesion Strength | 0.3-0.5 MPa | 0.8-1.2 MPa | 2-3× stronger |

| Sag Resistance | 1-2 mm | <0.5 mm | 2-4× less sag |

| Workability Time | 15-20 minutes | 45-60 minutes | 3× longer |

One of our customers in Saudi Arabia reported that switching to our HPMC-modified cement reduced their material waste by approximately 15% and increased their project completion speed by nearly 20%. These efficiency gains resulted from the extended working time and improved adhesion properties that allowed for smoother application with fewer mistakes and less rework.

Additionally, HPMC contributes to more sustainable construction practices by allowing for reduced cement content in certain applications while maintaining strength requirements. Some formulations can reduce cement content by 5-10% when properly optimized with HPMC, leading to lower carbon footprints without sacrificing performance.

How Is HPMC Applied in Different Cement-Based Systems?

Many manufacturers struggle to determine the right amount of HPMC for different applications. This leads to wasted expensive additives, inconsistent product performance, and frustrated end-users who experience varying results.

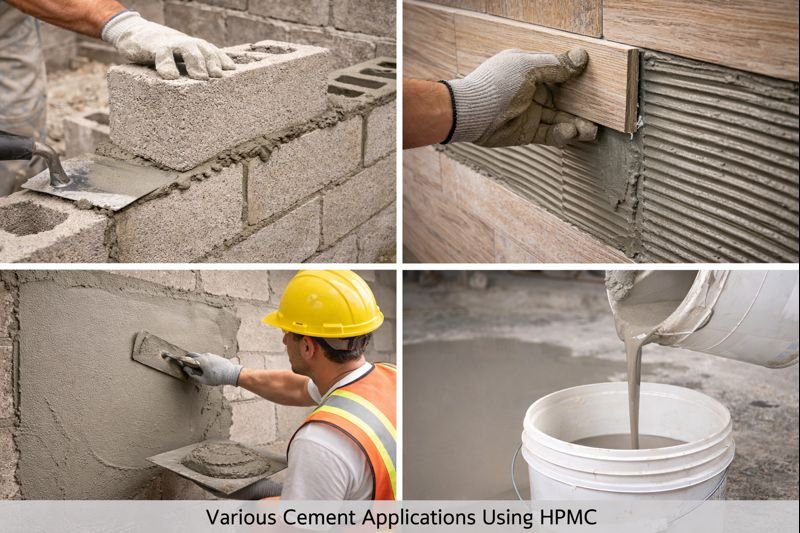

HPMC is incorporated into cement-based materials during the dry-mixing stage at concentrations of 0.1-0.5% depending on the application. It's used in diverse systems including tile adhesives3 (0.2-0.3%), self-leveling compounds2 (0.1-0.2%), rendering mortars4 (0.2-0.4%), and EIFS systems5 (0.3-0.5%) with dosage adjusted for specific performance requirements.

Through my years at Kehao, I've worked closely with customers across different construction sectors to optimize HPMC usage in their specific cement applications. The key to success lies in understanding how different concentrations and grades affect performance in various systems.

Application-Specific HPMC Usage

The versatility of HPMC makes it valuable across numerous cement applications, each requiring specific considerations for optimal results. Based on our research and customer implementations, I've compiled this detailed breakdown:

| Application | HPMC Concentration | Recommended Viscosity | Key Benefits |

|---|---|---|---|

| Tile Adhesives | 0.2-0.3% | 100,000-150,000 mPa·s | Extended open time, slip resistance |

| Self-Leveling Compounds | 0.1-0.2% | 40,000-80,000 mPa·s | Flow control, bleeding prevention |

| Rendering Mortars | 0.2-0.4% | 80,000-150,000 mPa·s | Workability, water retention |

| EIFS Systems | 0.3-0.5% | 100,000-200,000 mPa·s | Adhesion, cohesion strength |

| Joint Compounds | 0.3-0.4% | 60,000-100,000 mPa·s | Crack resistance, sandability |

| Repair Mortars | 0.2-0.3% | 80,000-120,000 mPa·s | Thixotropy, reduced shrinkage |

The incorporation method is equally important as the dosage. For best results, HPMC should be thoroughly pre-mixed with other dry ingredients before adding water. This ensures uniform distribution throughout the cement matrix. During a recent factory visit to a customer in Mexico, I observed that changing their mixing sequence improved HPMC efficiency by nearly 15%, allowing them to reduce their dosage while maintaining the same performance level.

Climate considerations also play a significant role in HPMC selection. For our customers in hot, dry regions like the Middle East, we recommend slightly higher HPMC concentrations (increase of 0.05-0.1%) and higher viscosity grades to compensate for accelerated water evaporation. Conversely, in humid climates like Southeast Asia, lower concentrations often suffice.

Conclusion

HPMC transforms ordinary cement into a high-performance building material by improving water retention, workability, and adhesion. By selecting the right grade and concentration for your specific application, you can achieve superior results while reducing waste and improving efficiency.

-

Explore how HPMC enhances cement performance, ensuring better workability and water retention. ↩

-

Learn about self-leveling compounds and their benefits in creating smooth surfaces. ↩ ↩

-

Discover effective methods for applying tile adhesives to ensure strong bonds. ↩

-

Explore the uses of rendering mortars in construction and their benefits. ↩

-

Learn about Exterior Insulation and Finish Systems and their advantages. ↩