Many contractors face cracked, peeling floors after installation despite paying premium prices for "high-strength" self-leveling compounds. The frustration of project failures and costly repairs can be overwhelming.

The secret to quality self-leveling compounds1 isn't primarily in the cement content but in the expensive chemical additives, particularly redispersible latex powder2 (RDP). This polymer acts like thousands of "flexible springs" within the rigid cement matrix, determining whether your floor will crack or detach over time.

I've been in the building materials industry for over 15 years, and I've seen countless projects fail because buyers focused solely on compressive strength (MPa) ratings. Let me show you what industry professionals actually look for when selecting a reliable self-leveling compound that will stand the test of time.

What Exactly Is a Cement Self-Leveling Compound?

Many contractors struggle with uneven floors that lead to installation failures and customer complaints. Traditional leveling methods are labor-intensive and often inconsistent.

Cement self-leveling compound is a specially formulated dry powder mixture containing Portland cement, fine aggregates, and chemical additives that when mixed with water creates a free-flowing, self-smoothing floor topping that automatically levels itself while requiring minimal finishing work.

Self-leveling compounds have revolutionized floor preparation in both residential and commercial construction. Unlike traditional cement screed that requires extensive troweling and skilled labor, these advanced formulations do most of the work themselves.

At its core, a quality self-leveling compound contains:

- Portland cement (the base binder)

- Fine-graded silica sand (providing structure)

- Polymer modifiers (primarily RDP)

- Flow agents (creating self-leveling properties)

- Setting retarders or accelerators (controlling workability time)

- Various performance enhancers (for specific applications)

What most manufacturers don't emphasize is the polymer content, particularly the amount and quality of redispersible latex powder2. This component typically represents 3-8% of the formulation by weight but can account for up to 40% of the raw material cost. This explains why some compounds are twice the price of others, even when they appear similar on the surface.

Formulation Comparison: Economy vs. Premium Self-Leveling Compounds

| Component | Economy Grade (%) | Premium Grade (%) | Function |

|---|---|---|---|

| Portland Cement | 30-35 | 25-35 | Primary binder |

| Fine Aggregates | 55-65 | 45-55 | Structure and volume |

| RDP (Polymer) | 1-3 | 5-8 | Flexibility, adhesion, crack resistance |

| Flow Agents | 0.5-1 | 1-2 | Self-leveling properties |

| Performance Additives | 0.5-3 | 3-8 | Specialized enhancements |

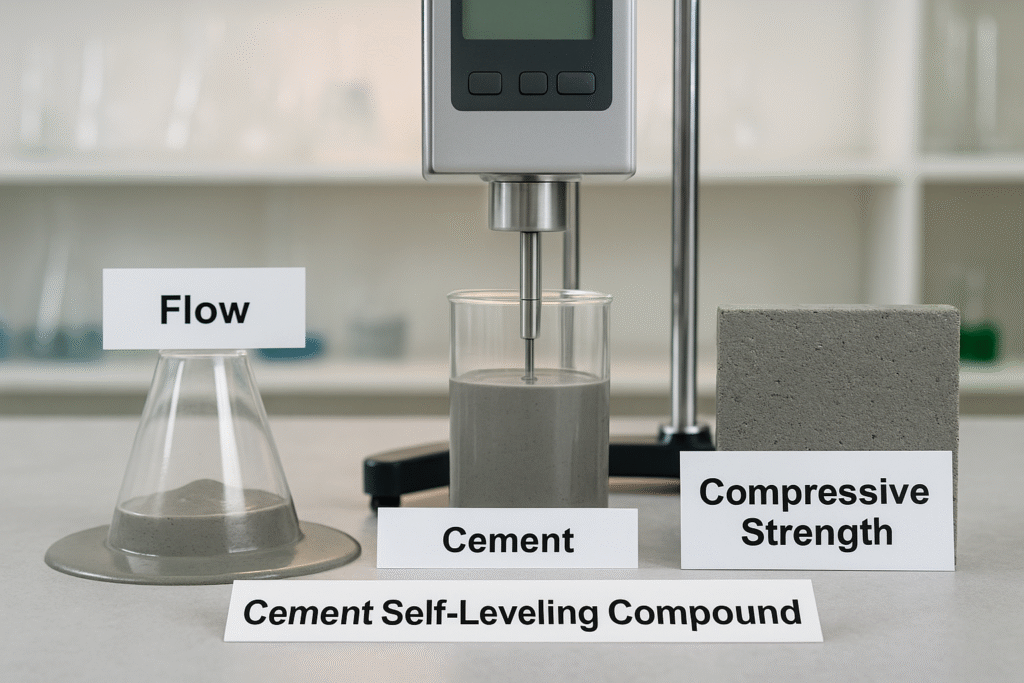

How Do Cement Self-Leveling Compound Specifications Impact Performance?

Contractors often face specification confusion with technical datasheets loaded with impressive numbers but little practical guidance on which values matter most for project success.

The most critical specifications for self-leveling compounds1 are compressive strength (15-40 MPa), flexural strength (5-10 MPa), polymer content (3-8%), flow rating (>140mm), and bond strength (>1.0 MPa). Among these, flexural strength and polymer content are the best indicators of long-term performance.

https://placehold.co/600x400 "Technical specifications of cement self-leveling compound")

https://placehold.co/600x400 "Technical specifications of cement self-leveling compound")

When I consult with larger mortar factories and distributors, I always emphasize looking beyond the compressive strength numbers that dominate marketing materials. While compressive strength (resistance to downward pressure) is important, flexural strength (resistance to bending) is actually the more valuable predictor of real-world performance.

The relationship between specifications and performance becomes clear when we examine how floors actually fail. Rarely do they collapse from excessive downward pressure (compressive failure). Instead, they typically crack from differential movement (flexural failure) or detach from the substrate (bond failure) - both issues that proper polymer modification addresses.

Key specifications to evaluate include:

Technical Specifications Comparison

| Property | Standard Grade | Industrial Grade | Ultra-Premium Grade | Why It Matters |

|---|---|---|---|---|

| Compressive Strength | 15-20 MPa | 25-35 MPa | >35 MPa | Load-bearing capacity |

| Flexural Strength | 3-5 MPa | 6-8 MPa | >8 MPa | Crack resistance |

| Polymer Content | 1-3% | 3-5% | 5-8% | Flexibility and durability |

| Working Time | 15-20 min | 20-30 min | 30-45 min | Installation ease |

| Flow Rating | 120-140mm | 140-160mm | >160mm | Self-leveling capability |

| Bond Strength | 0.5-1.0 MPa | 1.0-1.5 MPa | >1.5 MPa | Adhesion to substrate |

| Set Time | 2-4 hours | 3-6 hours | 4-8 hours | Project timeline |

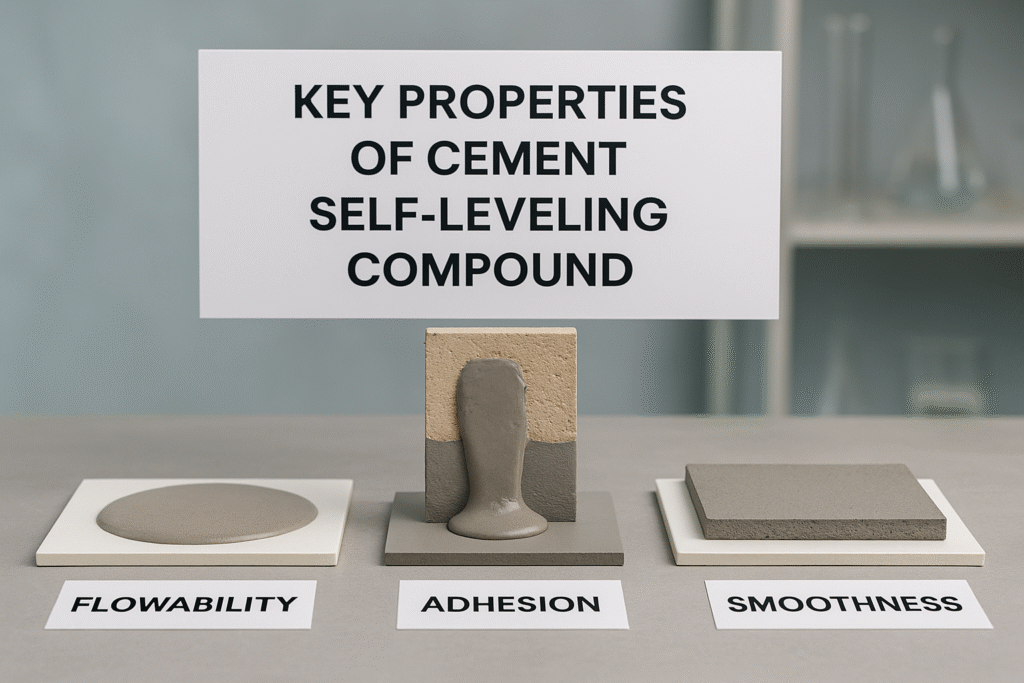

What Are The Key Properties That Make Cement Self-Leveling Compounds Effective?

Construction managers often discover that a self-leveling compound that worked perfectly in one project fails in another, leading to expensive repairs and project delays.

Quality cement self-leveling compounds must balance five key properties: flow ability, set time, surface finish, crack resistance, and substrate adhesion. These properties are primarily controlled by the type and amount of polymer modification, not just cement content.

I've visited countless job sites where contractors were struggling with products that either set too quickly to work with effectively or remained soft for days, delaying the entire project timeline. In most cases, these issues trace back to improper formulation rather than application errors.

The redispersible polymer powder (RDP) content plays a crucial role in balancing these properties. When water is added to the dry mix, these polymers redisperse into tiny latex particles throughout the cement matrix. As the compound cures, these particles form flexible polymer films that bridge micro-cracks and enhance adhesion to the substrate.

Different polymer types deliver different benefits:

- VAE (Vinyl Acetate Ethylene): Excellent flexibility and adhesion

- VA/VeoVa: Superior water resistance

- Acrylic: Enhanced durability and chemical resistance

The highest-performing self-leveling compounds often contain blends of these polymers to optimize performance across multiple properties. This is why experienced buyers always inquire about the polymer system used in the formulation.

Polymer Impact on Performance

| Performance Attribute | Low Polymer Content (1-2%) | Optimal Polymer Content (4-7%) | Excessive Polymer (>8%) |

|---|---|---|---|

| Flow Ability | Adequate but may segregate | Excellent, consistent | Can become sticky |

| Crack Resistance | Poor, brittle | Excellent | Very good but costly |

| Surface Hardness | High but brittle | Balanced hardness/flexibility | May be too soft |

| Water Resistance | Poor | Good to excellent | Excellent |

| Cost Efficiency | Low initial cost, high repair cost | Balanced cost/performance | Unnecessarily expensive |

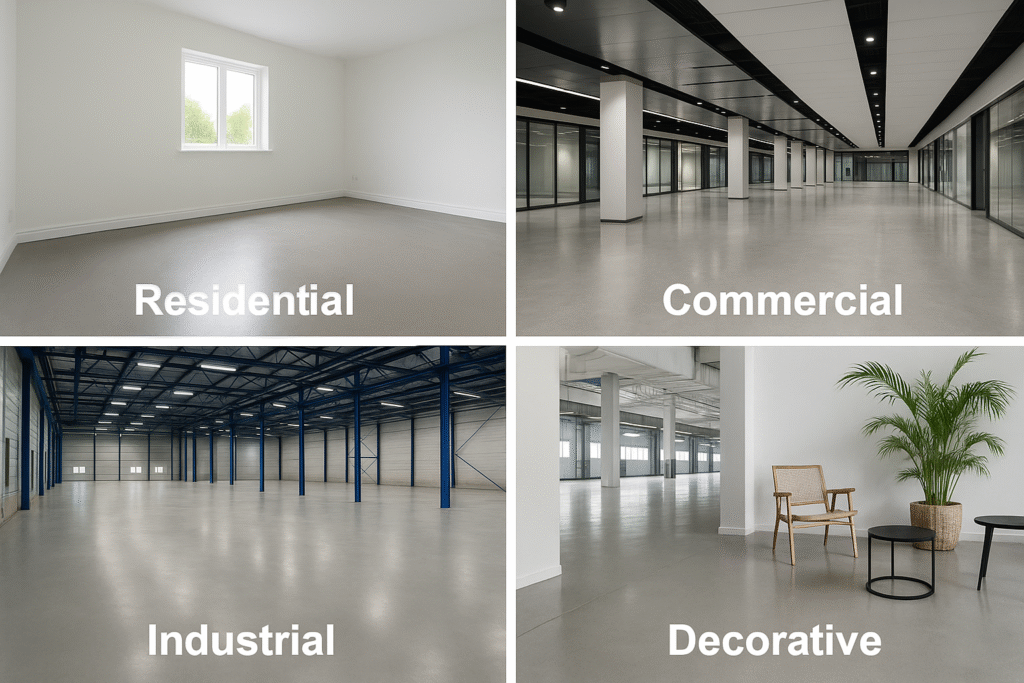

Where Can Cement Self-Leveling Compounds Be Applied?

Flooring installers frequently use products without understanding their application limitations, leading to premature failures in environments where the product was never designed to perform.

Cement self-leveling compounds1 can be applied over concrete, ceramic tile, terrazzo, metal, and wood substrates. They're suitable for residential, commercial, and light industrial settings, with specialized formulations available for extra-heavy duty applications, outdoor use, or rapid-setting requirements.

Different environments demand different formulations, which is why one-size-fits-all products often disappoint. In my experience consulting with larger industrial clients, I've found that understanding the specific end-use environment is crucial for selecting the right product.

The RDP content and type significantly influence application suitability. For instance, industrial environments exposed to heavy machinery require compounds with higher compressive strength but still need adequate flexibility from quality polymer modification to withstand vibration.

Common application environments include:

Application Environment Requirements

| Environment | Thickness Range | Key Requirements | Recommended Polymer |

|---|---|---|---|

| Residential | 2-10mm | Smooth finish, crack-free | VAE (4-5%) |

| Commercial | 3-15mm | Durability, quick return to service | VAE/VeoVa blend (5-6%) |

| Light Industrial | 5-20mm | Chemical resistance, abrasion resistance | Acrylic/VAE blend (5-7%) |

| Heavy Industrial | 10-30mm | Impact resistance, vibration dampening | Specialized acrylic (6-8%) |

| Exterior | 5-20mm | Freeze/thaw stability, moisture resistance | Hydrophobic types (6-8%) |

Different substrates also require specific preparation techniques and primer systems. Concrete substrates typically need mechanical preparation and a suitable primer to ensure proper adhesion. Wood substrates need reinforcement with fiberglass mesh and specialized primers to prevent moisture transfer.

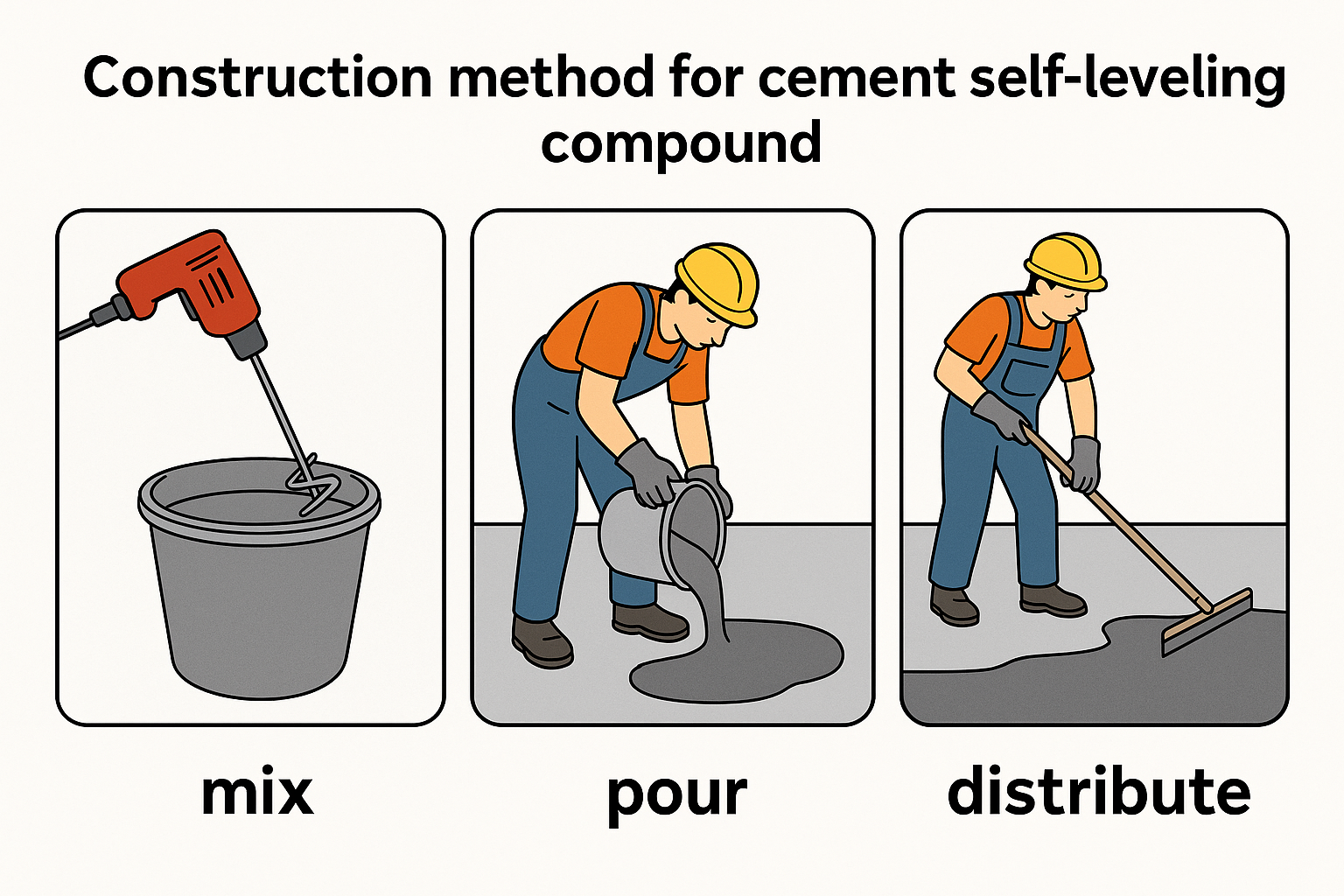

How Should Cement Self-Leveling Compounds Be Applied Correctly?

Many contractors face expensive failures due to improper application techniques, even with top-quality materials. The technically demanding nature of these products requires precise methodology.

Proper application of cement self-leveling compounds requires thorough substrate preparation, appropriate priming, mechanical mixing with exact water ratios, systematic pouring techniques, and adequate curing conditions. Skipping any step can result in debonding, cracking, or surface defects.

I've witnessed countless flooring failures that had nothing to do with product quality and everything to do with application errors. Self-leveling compounds are technically advanced products that demand strict adherence to manufacturer guidelines.

The application process typically involves:

-

Substrate Assessment and Preparation:

- Concrete moisture testing (must be <3% moisture content or use moisture barriers)

- Surface profiling (typically CSP 3-5 for concrete)

- Crack and joint treatment

- Perimeter isolation strip installation

-

Priming:

- Selection of appropriate primer based on substrate

- Proper application rate and technique

- Adequate drying time

-

Mixing:

- Strict adherence to water-to-powder ratios

- Mechanical mixing with appropriate equipment (300-600 RPM drill with mixing paddle)

- Proper mixing time (typically 2-3 minutes)

-

Application:

- Systematic pouring techniques (maintain a wet edge)

- Use of gauge rakes, smoothing tools, or spiked rollers as needed

- Working within the material's open time

-

Curing:

- Protection from rapid drying

- Temperature and humidity control

- Adequate curing time before foot traffic or flooring installation

For optimal performance, especially with premium products containing higher polymer content, maintaining ideal environmental conditions3 is essential. The temperature should be between 10-30°C (50-86°F) with relative humidity between 40-70% during application and initial curing.

What Key Precautions Should Be Taken When Using Cement Self-Leveling Compounds?

Many contractors discover problems only after installation when the material fails to perform as expected, leading to costly rework and project delays.

Critical precautions include checking substrate moisture content (<3%), maintaining proper ambient conditions (10-30°C), using only clean mixing equipment, respecting minimum thickness requirements, and providing adequate ventilation during application and curing.

Throughout my years in the industry, I've compiled a list of the most common mistakes that lead to self-leveling compound failures. By far, the most frequent issue is inadequate substrate preparation, followed closely by improper mixing and poor environmental controls during application.

The polymer content4 significantly affects a product's sensitivity to application conditions. Higher-quality products with optimal polymer modification (4-7% RDP) tend to be more forgiving of minor application variations, which explains why professional installers often prefer these despite the higher initial cost.

Key precautions include:

Critical Attention Points:

| Phase | Common Mistakes | Prevention Measures |

|---|---|---|

| Preparation | Insufficient surface profiling | Mechanical preparation to CSP 3-5 |

| Ignoring substrate moisture | Conduct moisture testing, use barriers if needed | |

| Priming | Under-application of primer | Follow coverage rates, ensure complete coverage |

| Using incorrect primer type | Match primer to substrate and compound type | |

| Mixing | Incorrect water ratios | Measure water precisely, never estimate |

| Inadequate mixing | Use proper equipment, mix for full recommended time | |

| Environmental | Extreme temperatures | Maintain 10-30°C during application and curing |

| Drafts and direct sunlight | Shield area from air movement and direct sun | |

| Post-Installation | Premature traffic exposure | Follow recommended wait times before allowing traffic |

| Improper cleaning methods | Use only manufacturer-recommended cleaning products |

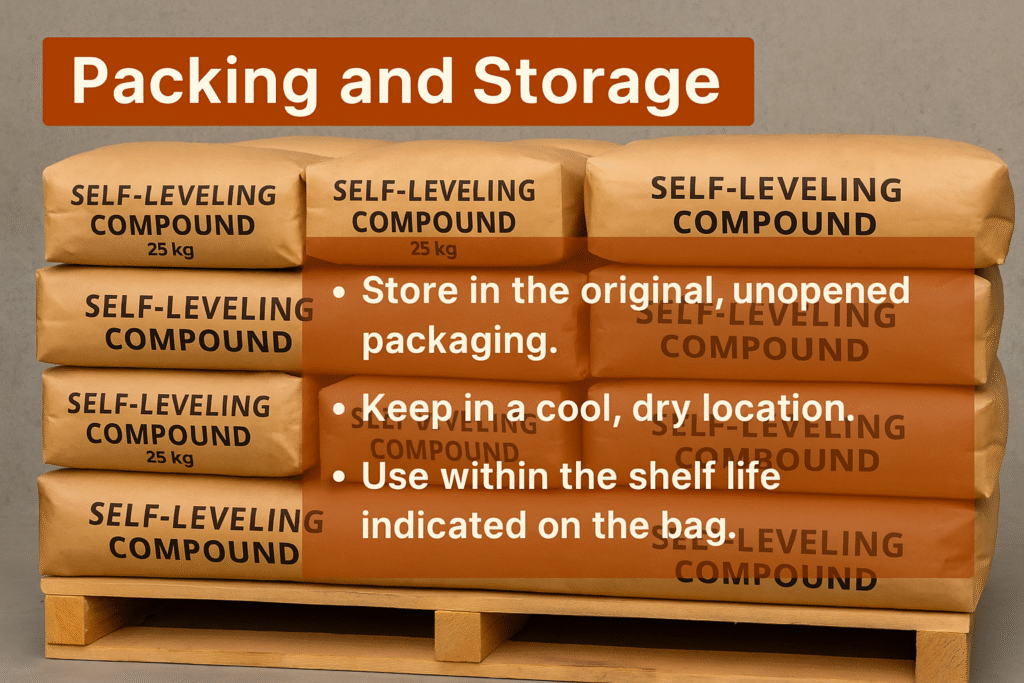

How Should Cement Self-Leveling Compounds Be Packaged and Stored?

Contractors often face product failures due to improper storage conditions or using products past their effective shelf life, wasting materials and causing project delays.

Cement self-leveling compounds are typically packaged in moisture-resistant 20-25kg bags and should be stored in dry conditions at 5-30°C for no more than 6-12 months. The polymer content significantly impacts shelf stability, with higher-quality products generally offering longer usable shelf life.

I've visited warehouses where self-leveling compounds were improperly stored directly on concrete floors or near open doorways, exposing them to moisture that caused partial hydration before use. This led to inconsistent performance despite the product being technically within its shelf life.

Storage conditions significantly impact the polymer component of these formulations. Redispersible polymer powders are sensitive to moisture and extreme temperatures, which can cause the particles to clump or lose their ability to redisperse properly when water is added.

Proper storage and handling include:

-

Packaging Considerations:

- Multi-wall paper bags with polyethylene moisture barrier

- Palletized and shrink-wrapped for bulk transport

- Clear identification of manufacture date and batch number

-

Storage Requirements:

- Elevated storage on pallets (never directly on concrete)

- Indoor storage protected from precipitation and humidity

- Temperature control between 5-30°C (41-86°F)

- First-in, first-out (FIFO) inventory management

-

Shelf Life Factors:

- Standard products: 6-12 months

- Products with specialty additives: May be reduced to 4-6 months

- Products with humidity indicators on packaging

The relationship between polymer content and storage stability isn't straightforward. While higher polymer content products are more expensive and therefore seemingly more affected by waste, they often contain superior stabilizing additives that extend usable shelf life when properly stored.

What Safety Considerations Apply to Cement Self-Leveling Compounds?

Many contractors underestimate the health hazards associated with cement-based products, leading to workplace injuries, compliance issues, and potential long-term health effects.

Safety considerations include respiratory protection against silica dust, skin protection from alkaline irritation, proper ventilation during mixing and application, and compliance with local workplace hazard regulations. Products with higher polymer content typically generate less airborne dust during handling.

Throughout my career, I've emphasized that safety isn't just a regulatory requirement—it's a business necessity. Projects delayed by workplace incidents or health complaints cost far more than proper safety equipment and procedures.

Self-leveling compounds contain Portland cement, which creates strongly alkaline conditions when mixed with water (pH 12-13). This can cause severe skin irritation and potential chemical burns with prolonged contact. Additionally, these products may contain respirable crystalline silica, which poses serious inhalation hazards.

Modern formulations with higher polymer content4 often include dust-reducing additives that minimize airborne particles during handling and mixing, making them safer for applicators and surrounding workers.

Key safety considerations include:

-

Personal Protective Equipment (PPE5):

- Respiratory protection (N95 minimum, P100 recommended for frequent users)

- Chemical-resistant gloves (nitrile or butyl rubber)

- Eye protection (safety glasses with side shields or goggles)

- Protective clothing to prevent skin contact

-

Workplace Controls:

- Adequate ventilation during mixing and application

- Dust control measures (wet mixing, HEPA vacuums)

- Proper cleanup procedures to prevent dust generation

- Handwashing facilities and emergency eyewash stations

-

Training Requirements:

- Hazard Communication training for all users

- Proper application techniques to minimize exposure

- Emergency procedures for spills or exposures

Safety Comparison: Standard vs. Advanced Formulations

| Safety Aspect | Standard Formulation | Advanced (Higher Polymer) Formulation |

|---|---|---|

| Dust Generation | Significant during handling | Reduced due to anti-dust additives |

| Alkalinity | Highly alkaline (pH 12-13) | Still alkaline but improved handling properties |

| Protection Requirements | Full PPE suite essential | Full PPE recommended but higher tolerance margin |

| Cleanup | Requires careful dust control | Easier cleanup with less dust hazard |

Conclusion

The true value of high-strength self-leveling compounds lies not in their cement content but in their polymer modification, particularly the quality and quantity of redispersible latex powder. Experienced buyers look beyond compressive strength to assess flexural strength and polymer content, ensuring they're getting durable industrial-grade products rather than brittle alternatives.

-

Explore this link to discover top-rated self-leveling compounds that ensure durability and performance. ↩ ↩ ↩

-

Learn about the advantages of redispersible latex powder in enhancing the performance of construction materials. ↩ ↩

-

Understand how temperature and humidity can impact the performance of self-leveling compounds. ↩

-

Learn how polymer content influences performance and durability in self-leveling compounds. ↩ ↩

-

Using the right PPE is crucial for safety and preventing workplace injuries. ↩