Are you struggling with poor workability in your mortar or experiencing paint that doesn't perform as expected? Many construction material manufacturers face these exact issues, leading to costly project delays and customer complaints.

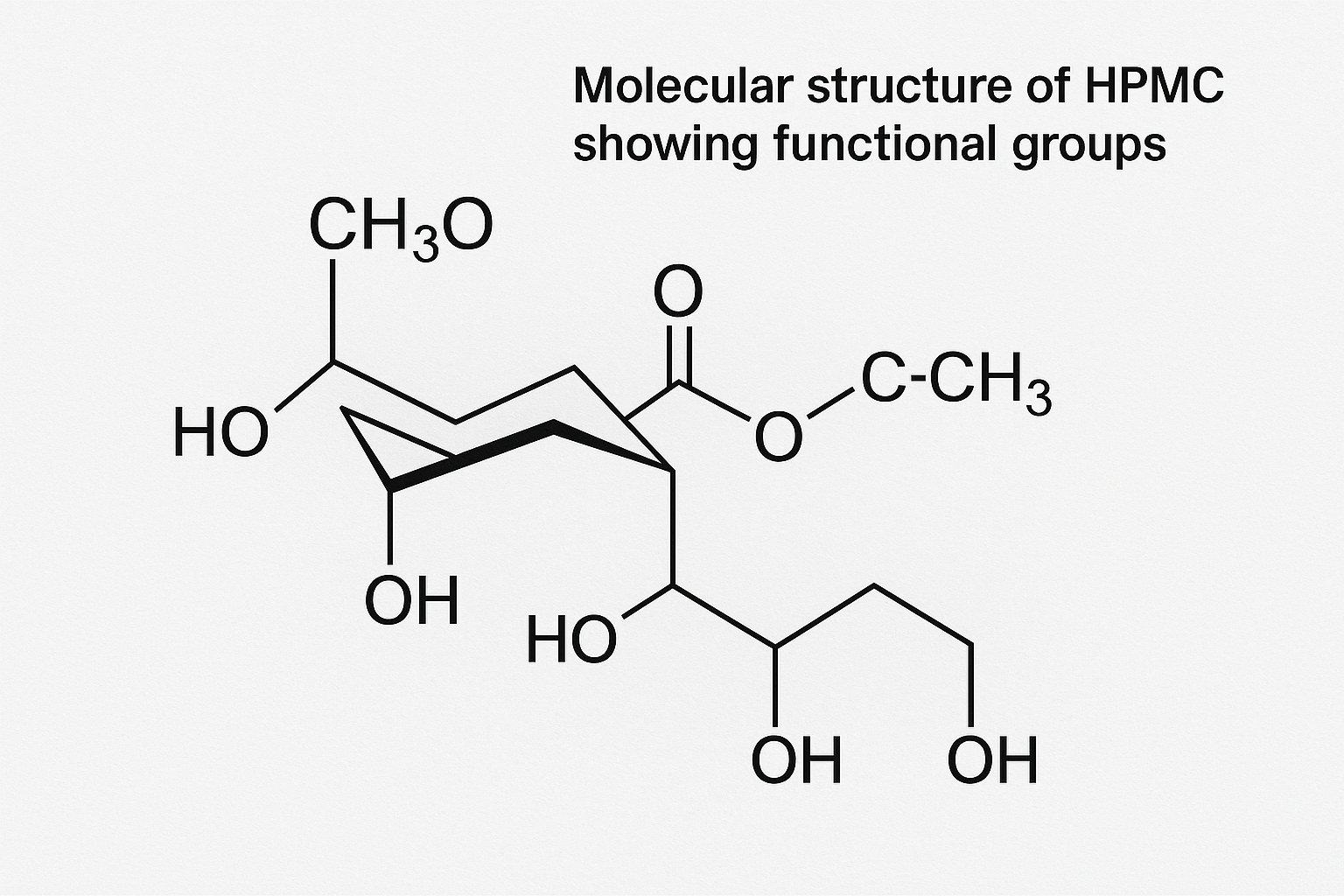

HPMC (Hydroxypropyl Methyl Cellulose)1 is a modified cellulose ether that works as a key additive in construction materials. It improves water retention, enhances workability in mortars, prevents sagging in coatings, and creates stable viscosity in various applications, making it essential for quality building products.

In my 15+ years working with construction material additives, I've seen firsthand how the right HPMC formulation2 can transform product performance. Our factory has helped hundreds of customers across Saudi Arabia, UAE, and throughout Asia achieve better results with their mortars and paints. Let me share what makes our HPMC special and how it might help your manufacturing process.

What Product Details Should You Know About HPMC Before Purchasing?

When clients visit our factory, they often feel overwhelmed by technical specifications and don't know which HPMC grade suits their needs. This confusion can lead to purchasing the wrong product and wasting valuable resources.

HPMC is available in different viscosity ranges (from 5 to 200,000 mPa·s), methoxyl content (19-30%), and hydroxypropyl content (4-12%), determining its performance characteristics. The optimal selection depends on your specific application, with higher viscosity types providing stronger water retention and binding properties.

When I first started supplying HPMC to international markets, I noticed many customers were using inappropriate grades for their applications. For example, one large mortar manufacturer in Saudi Arabia was using low-viscosity HPMC for external wall insulation systems, resulting in poor adhesion and material sliding off walls. After switching to our medium-viscosity HPMC with optimized hydroxypropyl content, their product performance improved dramatically.

HPMC comes in various forms to meet different industry needs. Our most common specifications include:

| Viscosity (2%, 20°C) | Methoxyl Content | Hydroxypropyl Content | Recommended Application |

|---|---|---|---|

| 5-20 mPa·s | 28-30% | 7-12% | Paint thickener, low-viscosity requirement |

| 50-80 mPa·s | 27-30% | 7-12% | General tile adhesive, self-leveling compounds |

| 100-150 mPa·s | 19-24% | 4-12% | Rendering mortars, EIFS (External Insulation Systems) |

| 150-200+ mPa·s | 19-24% | 4-12% | High-performance adhesives, demanding water retention |

The particle size also matters significantly - our HPMC is available in 80-mesh and 100-mesh options, affecting dissolution rate and final application properties. For specialized applications like 3D printing construction materials, we can customize particle size distribution to ensure optimal performance.

What Standards Does Quality HPMC Need to Meet?

Many buyers have purchased HPMC that claimed to meet international standards but delivered poor results. This inconsistency causes production delays, quality problems, and unhappy customers.

Quality HPMC must comply with ASTM C13963 for building materials applications, meet ISO 9001 manufacturing standards, and pass specific performance tests for water retention (≥95%), workability time (>30 minutes), and ash content (<5%). Reliable suppliers provide full test certificates and consistent batch-to-batch performance.

In our Kehao laboratory, we've developed rigorous testing protocols that go beyond standard industry requirements. Every batch undergoes comprehensive testing to ensure consistency. This attention to quality has helped us maintain long-term relationships with major mortar producers across the Middle East and Asia.

Our quality control standards include:

- Moisture content: ≤5.0%

- Ash content: ≤5.0%

- pH value: 5.5-8.0

- Heavy metals: ≤10ppm

- Gel temperature: 65-90°C (depending on grade)

We maintain strict compliance with international standards including:

- REACH registration

- RoHS compliance

- ISO 9001:2015 quality management system

- ISO 14001:2015 environmental management system

For our customers in regulated markets, we provide comprehensive documentation packages including material safety data sheets (MSDS), technical data sheets (TDS), and certificates of analysis (COA) with each shipment. This comprehensive approach to quality assurance has helped our customers meet their regulatory requirements while maintaining consistent production quality.

What Advantages and Features Make Kehao HPMC Stand Out?

The market is flooded with HPMC suppliers making similar claims. This makes it hard to identify truly superior products, and you might end up with inferior materials that compromise your final product quality.

Kehao HPMC features exceptional dissolution speed (2-5 minutes versus industry average 10+ minutes), superior anti-sagging properties, and enhanced water retention (>98%). Our production process uses premium wood pulp and maintains precise molecular weight distribution, resulting in more consistent performance than competitors.

I remember when a large paint manufacturer in Pakistan was struggling with batch-to-batch consistency issues using a competitor's HPMC. Their production efficiency dropped as technicians had to constantly adjust formulations. After switching to our HPMC, they reported 30% faster mixing times and virtually eliminated batch variations.

Our HPMC offers several unique advantages that directly translate to better performance in your applications:

-

Enhanced dissolution properties: Our specialized production technology creates HPMC that dissolves quickly and completely, eliminating "fish-eyes" and lumping issues common with other products. This saves mixing time and ensures consistent final properties.

-

Superior thermal gel stability: Kehao HPMC maintains optimal viscosity across a wider temperature range (5-80°C), making it ideal for applications in varying climate conditions. This is particularly valuable for our customers in regions with extreme temperature variations like Saudi Arabia and the UAE.

-

Customized surface treatment: We can provide HPMC with different surface treatments to match your specific mixing equipment and formulation requirements:

- Hot water soluble (dissolves only in hot water above 85°C)

- Cold water soluble (dissolves readily in cold water)

- Delayed solubility (controlled dissolution rate)

-

Exceptional lot-to-lot consistency: With six dedicated production lines and advanced quality control systems, we maintain a coefficient of variation below 3% across batches - significantly better than the industry standard of 5-10%.

How Can HPMC Be Applied in Different Construction Materials?

Construction material formulators often struggle to balance performance and cost. They may use too much or too little HPMC, leading to either excessive expenses or poor material performance that damages their reputation.

HPMC serves as a multi-functional additive in construction materials. In dry-mix mortars, use 0.2-0.5% for water retention and workability. In tile adhesives, incorporate 0.3-0.6% for extended open time. For paints, add 0.3-1.0% to prevent sagging and improve application properties. Gypsum-based products benefit from 0.1-0.3% for smooth finishing.

During a technical seminar I conducted for customers in Dubai last year, many were surprised to learn they were using HPMC inefficiently. One customer was using a generic HPMC at 0.8% in their tile adhesive formulation but still experiencing poor open time. By switching to our specialized grade at just 0.4%, they achieved better performance while reducing additive costs by nearly 50%.

HPMC functions differently depending on the specific construction application. Here's a detailed breakdown of how to optimize usage across various materials:

For dry-mix mortars:

- Plastering mortars: 0.2-0.4% HPMC (50-100 mPa·s) improves workability and prevents water loss to porous substrates

- Render mortars: 0.3-0.5% HPMC (80-150 mPa·s) enhances weather resistance and reduces cracking

- EIFS basecoats: 0.4-0.6% HPMC (100-150 mPa·s) provides essential sag resistance and bonding strength

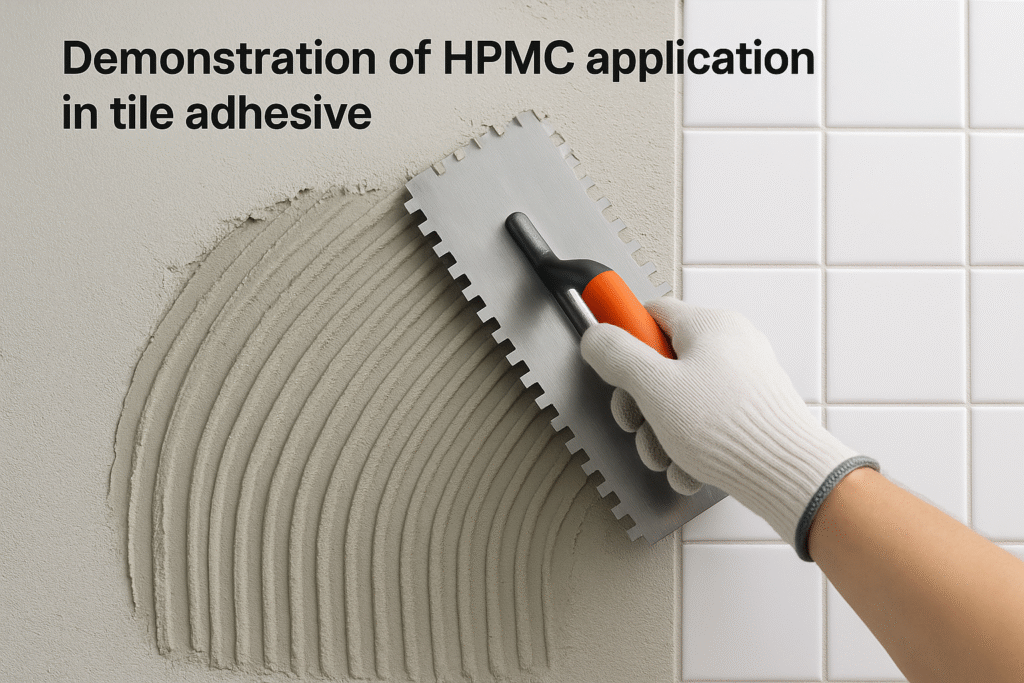

For tile adhesives:

- Standard C1 adhesives: 0.2-0.3% HPMC (40-60 mPa·s) provides basic water retention

- Premium C2S1 adhesives: 0.3-0.5% HPMC (60-100 mPa·s) combined with redispersible powder enhances flexibility and bonding

- Special application adhesives: 0.4-0.6% HPMC (80-150 mPa·s) with specialized additives for vertical applications and natural stone

For gypsum-based products:

- Joint compounds: 0.15-0.3% HPMC (15-30 mPa·s) improves workability and crack resistance

- Self-leveling compounds: 0.1-0.2% HPMC (5-15 mPa·s) combined with other rheology modifiers enhances flow properties

For paint and coating applications:

- Interior paints: 0.3-0.6% HPMC (15-40 mPa·s) improves viscosity stability and application properties

- Exterior paints: 0.4-0.8% HPMC (30-60 mPa·s) enhances weather resistance and durability

- Textured coatings: 0.5-1.0% HPMC (40-100 mPa·s) provides essential sag resistance and pattern stability

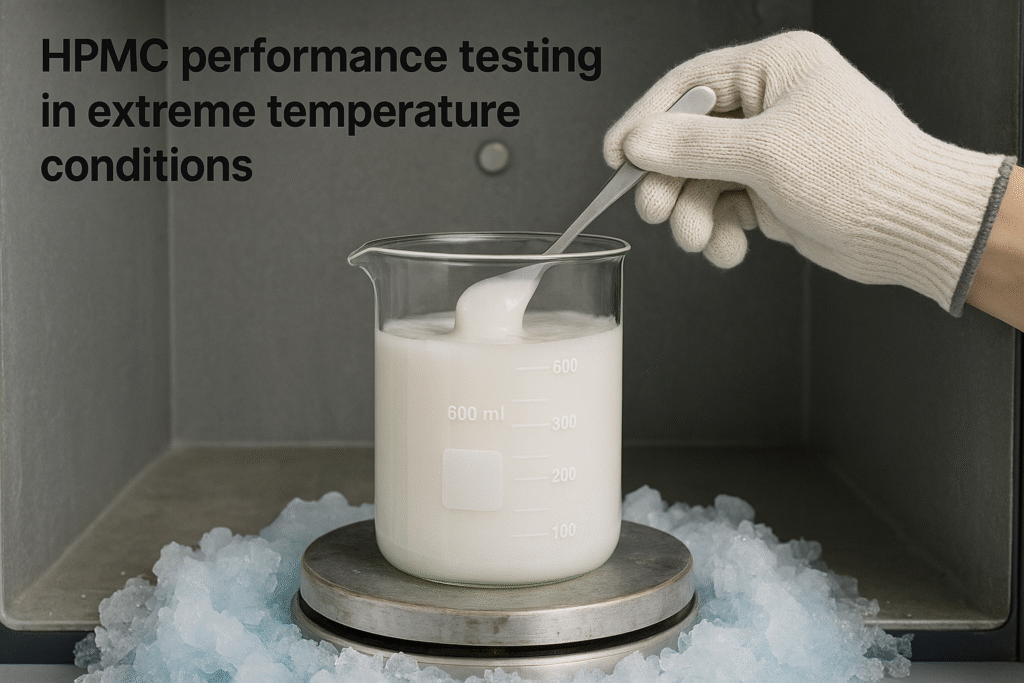

How Does HPMC Perform in Different Application Scenarios?

Material manufacturers often face inconsistent performance across different climate conditions and application methods. This unpredictability can damage their brand reputation and increase customer complaints.

HPMC performs differently based on application conditions. In hot climates (>30°C), higher viscosity grades (100+ mPa·s) maintain workability. For machine application, specialized low-dust HPMC improves equipment longevity. In cold conditions (<10°C), cold-water soluble grades ensure proper dissolution. Proper grade selection for specific scenarios ensures optimal performance.

I remember visiting a customer's construction site in Riyadh during summer, where temperatures exceeded 45°C. Their standard mortar was drying too quickly, causing application problems. After implementing our high-viscosity HPMC with enhanced water retention properties, they were able to maintain a workable mortar for over 30 minutes even in extreme heat.

Application conditions significantly impact HPMC performance, and understanding these variables is crucial for product success:

Climate Considerations

Temperature and humidity dramatically affect how HPMC performs in construction applications:

| Climate Condition | HPMC Recommendation | Dosage Adjustment |

|---|---|---|

| Hot & Dry (>35°C, <30% RH) | Higher viscosity (100-150 mPa·s), specialized hot-climate grade | Increase by 20-30% |

| Hot & Humid (>30°C, >70% RH) | Medium-high viscosity (80-120 mPa·s) with enhanced anti-sag | Standard dosage |

| Cold & Dry (<10°C, <40% RH) | Cold-water soluble grades, medium viscosity | Increase by 10-15% |

| Cold & Humid (<10°C, >70% RH) | Low-medium viscosity with anti-fungal properties | Standard dosage |

Application Method Considerations

Different application techniques require specialized HPMC properties:

For manual application:

- Trowel application: Medium-viscosity HPMC (60-100 mPa·s) provides optimal workability and open time

- Spray application: Low-medium viscosity HPMC (30-60 mPa·s) with specialized surface treatment prevents nozzle clogging

- Roller application: Low-viscosity HPMC (15-40 mPa·s) enhances flow and leveling properties

For machine application:

- Mixing machines: Low-dust HPMC reduces maintenance issues and improves worker conditions

- Pumping equipment: HPMC with controlled particle size distribution prevents equipment clogging

- Automated spray systems: Specialized grades with consistent viscosity under shear conditions

Through our six dedicated production lines, we can customize HPMC properties to match your specific application scenarios, ensuring optimal performance regardless of climate challenges or application methods.

What Should You Know About HPMC Packaging and Shipping?

Improper packaging and shipping arrangements can lead to product degradation, contamination, or delivery delays. These issues disrupt production schedules and can cause significant financial losses.

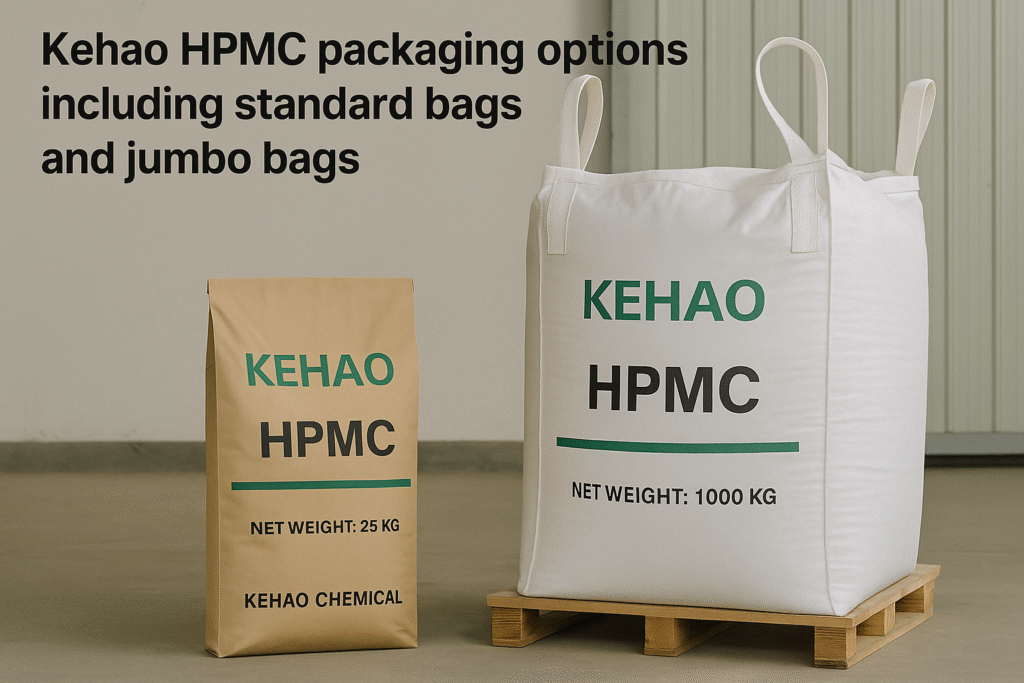

HPMC requires moisture-proof packaging in multi-layer kraft paper bags with PE liners (25kg standard) or jumbo bags (500-1000kg) for bulk orders. Proper container loading (typically 17-18MT per 20ft) prevents damage. Storage conditions must maintain <65% humidity and 10-35°C temperature. Delivery times range from 15-30 days depending on destination.

Based on my experience shipping HPMC to over 20 countries, I've developed specific protocols to ensure product arrives in perfect condition. Last year, we had a customer in Brazil who faced repeated moisture contamination issues with a previous supplier. By implementing our specialized moisture-barrier packaging and proper container preparation guidelines, their problems were eliminated completely.

Our packaging and shipping procedures are designed to maintain HPMC quality from our factory to your production facility:

Packaging Options

We offer several packaging solutions tailored to different customer needs:

-

Standard packaging: 25kg multi-layer kraft paper bags with PE liner

- Dimensions: 50cm × 40cm × 15cm

- Palletized option: 40 bags per pallet, shrink-wrapped and banded

- Container capacity: 680-720 bags (17-18MT) in 20ft container

-

Bulk packaging options:

- 500kg jumbo bags with discharge spout for bulk handling

- 1000kg jumbo bags for large-volume users

- Container capacity: 18-20MT in 20ft container

-

Customized packaging:

- Private labeling available for distributors

- Custom bag sizes (20kg, 50kg) available upon request

- Special moisture-resistant packaging for tropical destinations

Shipping and Logistics

Our logistics department specializes in efficient worldwide delivery:

- FCL (Full Container Load): 15-20 days to Middle East, 25-30 days to South America

- LCL (Less than Container Load): Available for smaller orders

- Express samples: 3-5 days worldwide via DHL/FedEx for urgent testing needs

Storage Requirements

To maintain optimal HPMC quality, we recommend:

- Store in cool, dry place (10-35°C)

- Maintain relative humidity below 65%

- Keep away from direct sunlight and heat sources

- Practice FIFO (First In, First Out) inventory management

- Typical shelf life: 2 years when properly stored

Our comprehensive approach to packaging and logistics ensures your HPMC arrives in perfect condition and maintains its performance properties throughout its shelf life.

Conclusion

HPMC is essential for quality construction materials, offering water retention, workability, and improved performance across various applications. With Kehao's premium HPMC, you get superior dissolution, consistent quality, and expert support to optimize your formulations for any climate or application method.