Are your coatings failing to provide the consistency and performance your customers expect? Many manufacturers struggle with stability issues, poor application properties, and inconsistent finishes that damage their reputation.

Hydroxyethyl cellulose (HEC)1 is a water-soluble polymer that functions as a key thickening agent, stabilizer, and performance enhancer in water-based coatings and paints. It provides ideal viscosity control, prevents pigment settling, and enables smooth application while maintaining excellent film formation properties.

I've been in the cellulose ether business for over 15 years, and I've seen firsthand how the right HEC can transform coating formulations. Our customers often come to us after trying inferior products that caused separation issues and poor shelf stability. Let me show you why HEC has become indispensable in modern coating systems.

What Are the Key Benefits of HEC in Coating Formulations?

Do you struggle with balancing viscosity control and application properties2 in your water-based paints? This is where many coating manufacturers face their biggest formulation challenges.

HEC provides excellent thickening efficiency in water-based systems, delivering pseudoplastic flow behavior that enables high viscosity at rest (preventing settling) while allowing easy application under shear stress (brushing or spraying). Its non-ionic nature makes it compatible with most paint ingredients across pH ranges.

I remember visiting a paint factory in Saudi Arabia where they were having serious issues with pigment settling during storage. Their products were being returned because customers found separated layers when opening the cans. After implementing our high-quality HEC at the proper dosage, their shelf stability improved dramatically, and customer complaints dropped by nearly 80%.

Performance Benefits of HEC in Water-Based Systems

When formulating water-based coatings, viscosity control is just the beginning. HEC offers several crucial advantages:

| Benefit | Description | Impact on Final Product |

|---|---|---|

| Thickening Efficiency | Provides excellent viscosity control with small amounts | More economical formulations |

| Pseudoplastic Behavior | High viscosity at rest, lower when under stress | Prevents settling while enabling smooth application |

| pH Stability | Effective across wide pH range (2-12) | Versatile for various formulations |

| Temperature Resistance | Maintains performance in various conditions | Consistent product behavior in different climates |

| Anti-Sagging | Improves film build on vertical surfaces | More professional-looking finishes |

The most important aspect many formulators overlook is selecting the right HEC viscosity grade. At our factory, we produce multiple grades ranging from 10,000 mPas to 100,000 mPas (2% solution). Low-viscosity grades work well for spray applications, while medium and high-viscosity types better suit brush and roller applications. I always advise customers to test different grades in their specific systems rather than making assumptions based on previous formulations.

Where Can HEC Be Applied in the Coatings Industry?

Are you aware of all the possible applications where HEC could improve your product lineup? Many manufacturers limit themselves by not exploring the full potential of this versatile additive.

HEC can enhance numerous coating types including interior and exterior emulsion paints, primers, textured finishes, wood stains, concrete sealers, and specialty coatings. Its consistent performance across these applications makes it a versatile choice for manufacturers looking to standardize ingredients across product lines.

In our experience working with coating manufacturers across the Middle East and Asia, we've seen the most dramatic improvements when HEC is incorporated into water-based exterior paints. These products face the toughest conditions - high temperatures, UV exposure, and occasional heavy rain. Without proper stabilization, they can fail prematurely.

Application-Specific Benefits of HEC

The versatility of HEC makes it valuable across numerous coating applications, each with unique requirements:

| Application | HEC Function | Customer Benefit |

|---|---|---|

| Interior Wall Paints | Provides sag resistance and improves hiding power | Fewer coats needed, more uniform finish |

| Exterior Emulsions | Enhances weather resistance and reduces dirt pickup | Longer-lasting finishes in harsh conditions |

| Primers | Improves substrate wetting and adhesion | Better topcoat performance and reduced peeling |

| Textured Finishes | Controls rheology for pattern creation | Consistent textures and easier application |

| Wood Stains | Prevents pigment settling while maintaining transparency | Even coloration and enhanced grain visibility |

I recently consulted with a large paint manufacturer in the UAE who was developing a new line of textured finishes. They struggled with consistency issues - some batches would create beautiful patterns while others would sag or flatten. By implementing our medium-viscosity HEC grade and fine-tuning the dosage, they achieved the perfect balance of workability and pattern retention. The technical director later told me this consistency was the key factor in winning a major hotel renovation contract.

Why Should You Choose HEC for Your Coating Formulations?

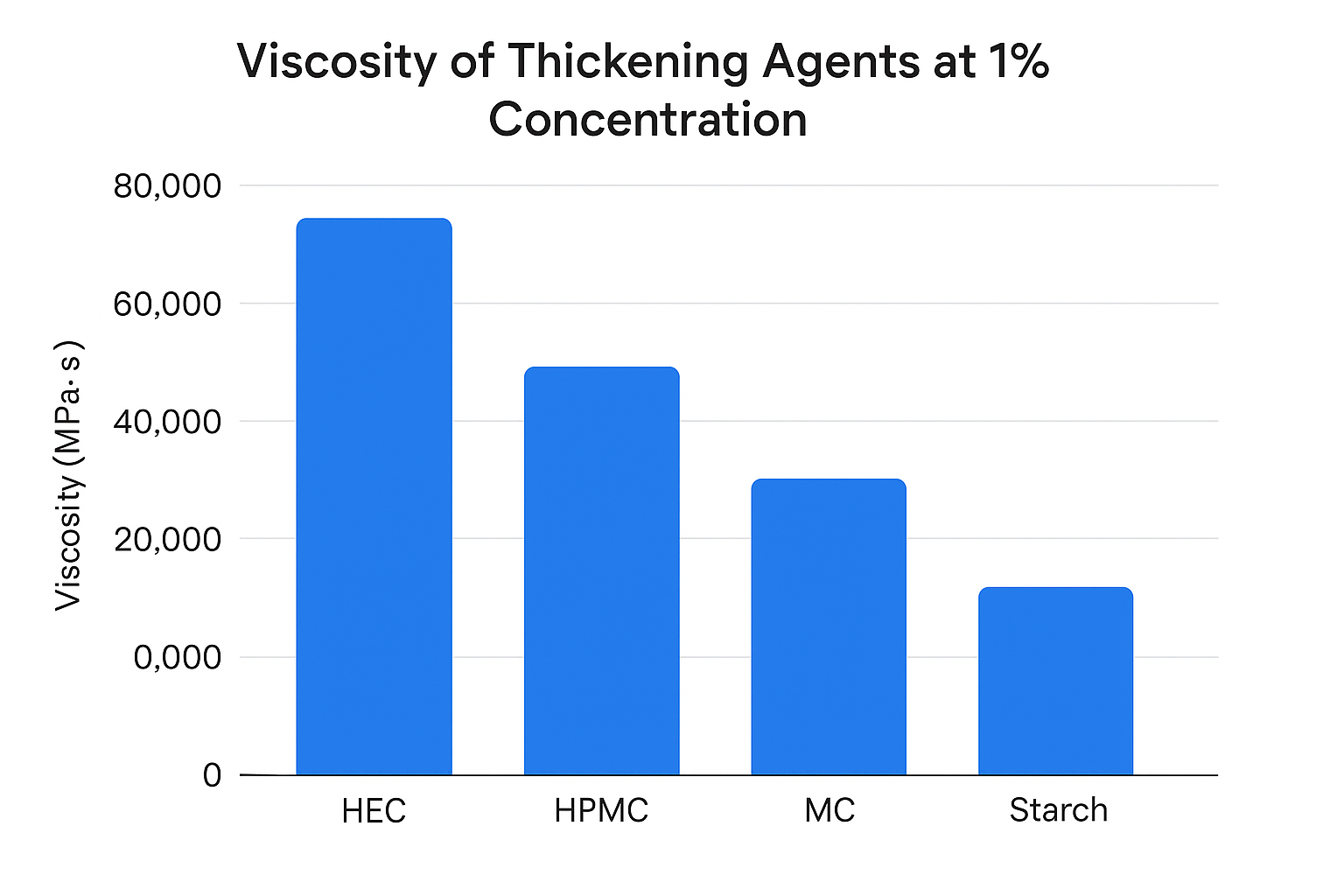

Have you compared HEC with other thickening technologies for your water-based systems? Many manufacturers stick with familiar additives without exploring more efficient alternatives.

HEC offers significant advantages over other thickeners including excellent cost-efficiency, broad compatibility with coating ingredients, minimal impact on water resistance of dried films, and good storage stability. Its non-ionic nature prevents reactions with other formula components that can occur with ionic thickeners.

When I joined the technical team at Kehao, one of my first projects was comparing various thickening technologies in a standard exterior paint formula. We evaluated HEC against cellulosic ethers3, synthetic associative thickeners, and natural gums. While each had strengths, HEC consistently delivered the best balance of performance and cost across multiple criteria.

Comparative Advantages of HEC in Modern Coating Systems

When selecting a rheology modifier for your coatings, understanding how HEC compares to alternatives helps make informed decisions:

| Thickening Agent | Cost Efficiency | Compatibility | Water Resistance | Storage Stability | Ease of Incorporation |

|---|---|---|---|---|---|

| HEC | Excellent | Very Good | Good | Excellent | Good |

| HPMC | Good | Excellent | Moderate | Very Good | Good |

| Associative Thickeners | Moderate | Good | Excellent | Good | Excellent |

| Polyurethane Thickeners | Poor | Very Good | Excellent | Very Good | Very Good |

| Natural Gums | Good | Poor | Poor | Moderate | Poor |

What makes our HEC particularly valuable is the manufacturing process we use. Some manufacturers cut corners by using lower-quality cellulose sources or inadequate purification steps. This results in HEC that may contain residual contaminants that can trigger paint defects or reduced shelf life. At our facility, we use a rigorous multi-stage purification process that results in consistent, high-quality HEC that performs reliably batch after batch.

I've worked with customers who switched to our HEC after experiencing issues with competitors' products. One major paint producer in Pakistan had been experiencing mysterious fish-eye defects in their premium interior paint. After extensive testing, they traced the problem to inconsistent quality in their previous HEC supply. Since switching to our product three years ago, this defect has been completely eliminated, saving them substantial rework and customer complaint costs.

Conclusion

Hydroxyethyl cellulose is a versatile, cost-effective additive that solves multiple coating formulation challenges. By selecting the right HEC grade for your specific applications, you can enhance product performance, ensure consistency, and improve customer satisfaction.

-

Explore how HEC enhances viscosity control and stability in coatings, making it a vital ingredient for manufacturers. ↩

-

Learn about the essential application properties that affect the performance of water-based paints. ↩

-

Learn about the advantages and applications of cellulosic ethers in modern coating systems. ↩