Concrete cracking costs builders millions annually. Without proper reinforcement, even quality concrete develops weaknesses, compromising structural integrity and leading to expensive repairs. Polypropylene fiber1 offers a surprisingly simple solution.

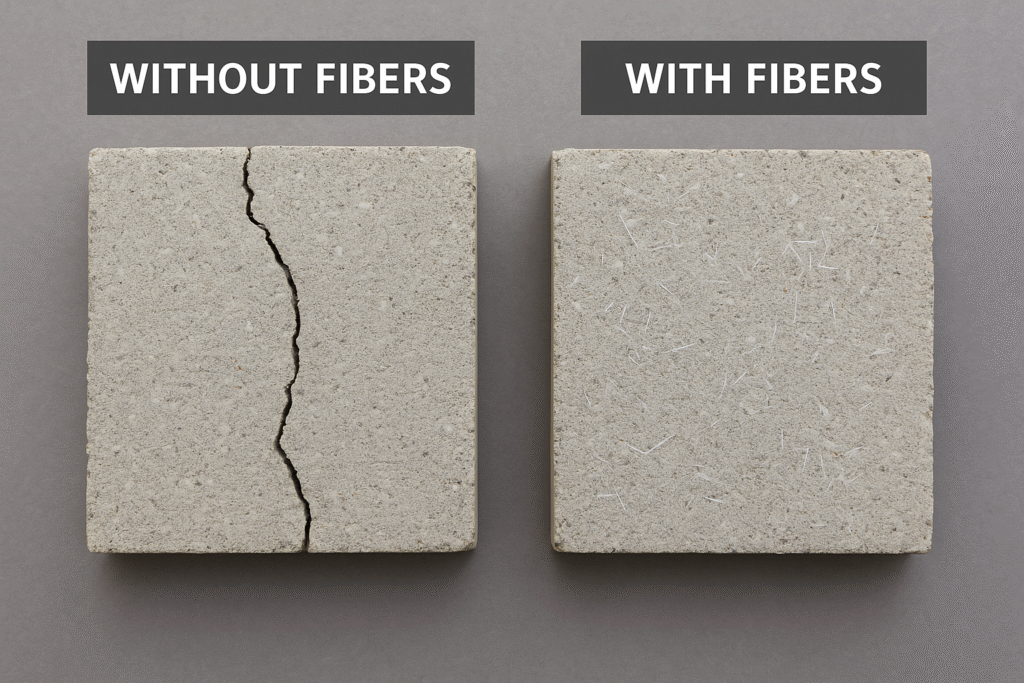

Polypropylene fiber1 prevents cracking in concrete by creating a three-dimensional network that holds microcracks in place before they develop into larger structural cracks. Unlike steel reinforcement which addresses structural strength, these fibers specifically target early-stage plastic shrinkage cracking that occurs during curing.

At Kehao, we've seen countless customers struggle with concrete durability issues before discovering the remarkable benefits of polypropylene fiber. This lightweight synthetic material has revolutionized construction practices worldwide, making structures more resilient and longer-lasting. Let me walk you through why this unassuming material deserves your attention.

How Does Polypropylene Fiber Transform Construction Projects?

Pain point: Traditional concrete is prone to early shrinkage cracks, leading to water penetration, structural weakening, and costly repairs. Standard solutions often fail to address the root problem during the critical curing stage.

Polypropylene fiber1 works by distributing thousands of tiny fibers throughout the concrete matrix. As concrete cures and water evaporates, these fibers create a multidirectional support system that resists the tensile forces causing microcracks, particularly during the first 24 hours when concrete is most vulnerable.

The Science Behind Crack Prevention

Concrete cracking occurs primarily during the plastic state - when the material is still curing. This is where polypropylene fiber truly shines. Unlike structural reinforcements like steel rebar that handle major loads, polypropylene fibers target a different problem entirely.

When water evaporates from concrete, it creates tension forces that the fresh concrete cannot withstand. I've observed this countless times at construction sites - without proper protection, microscopic cracks form and quickly spread. Polypropylene fibers create what we call a "three-dimensional random network" throughout the concrete matrix.

Think of it as thousands of tiny anchors holding the concrete together at the microscopic level. These fibers physically bridge across potential crack planes and prevent them from widening. The key distinction here is timing - polypropylene fiber works during that critical early period before concrete fully hardens, when it's most susceptible to cracking.

| Crack Type | Traditional Solution | How Polypropylene Fiber Helps |

|---|---|---|

| Plastic Shrinkage | Proper curing techniques | Creates fiber network preventing microcrack formation |

| Settlement Cracks | Proper consolidation | Reduces bleeding and water migration |

| Thermal Cracking | Control joints | Distributes stress across multiple tiny fibers |

In our laboratory testing, concrete samples with polypropylene fiber consistently showed 70-90% reduction in early-age cracking compared to conventional mixes. This isn't about making concrete stronger - it's about making it more resilient during its most vulnerable phase.

What Advantages Does Polypropylene Fiber Offer Beyond Crack Prevention?

Problem: Construction materials often force trade-offs between performance, durability, and cost. Engineers struggle to find solutions that deliver across multiple requirements without significant drawbacks.

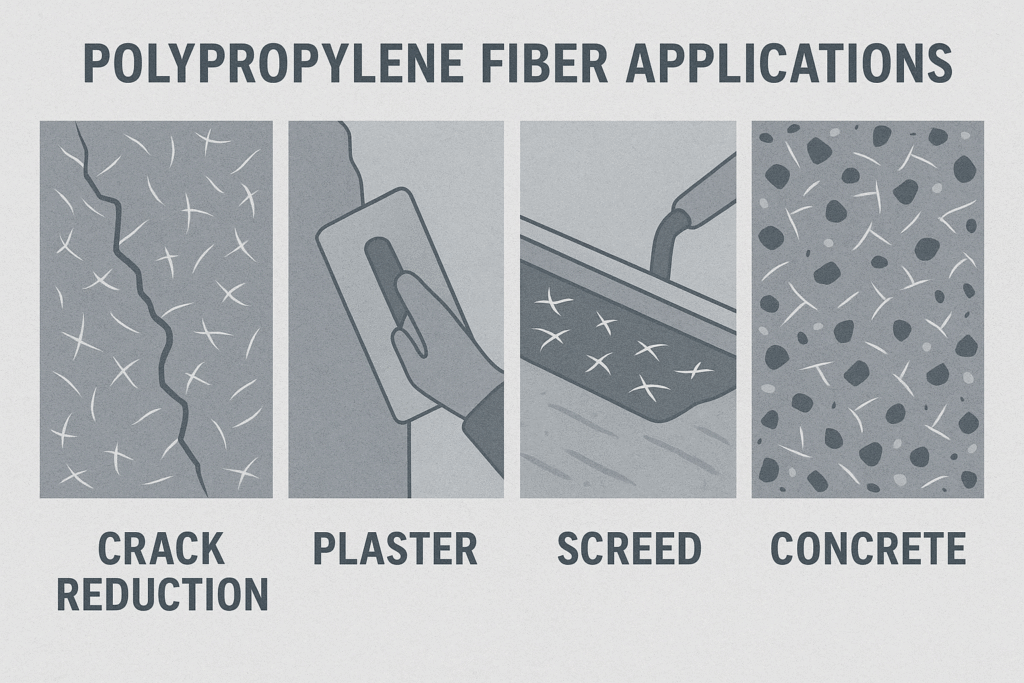

Polypropylene fiber1 improves concrete durability by enhancing impact resistance (up to 80%), reducing permeability, increasing freeze-thaw resistance, and improving abrasion resistance - all while being alkali-resistant, non-corrosive, and cost-effective compared to alternatives like glass fiber or steel mesh.

Enhanced Performance Characteristics

When I first started recommending polypropylene fiber to our clients, many were skeptical about the range of benefits beyond crack control. However, the performance improvements have consistently impressed even the most experienced engineers in our network.

Impact resistance is perhaps the most visibly improved property. In testing, fiber-reinforced concrete withstands repeated impacts without spalling or fragmenting. This makes it ideal for applications like industrial floors, roads, and precast elements that experience dynamic loading or potential impacts. I've witnessed fiber-reinforced concrete panels survive impacts that would shatter conventional concrete.

Water permeability reduction is another critical advantage. The same fiber network that prevents cracking also creates a more tortuous path for water molecules, significantly reducing permeability. This translates directly to improved durability in wet environments and resistance to chemical attack. Our projects in coastal areas have shown remarkable resistance to salt water intrusion when properly reinforced with polypropylene fiber.

| Property | Improvement vs. Standard Concrete | Real-World Benefit |

|---|---|---|

| Impact Resistance | 70-80% increase | Reduced maintenance, longer service life |

| Permeability | 60-70% reduction | Enhanced durability in harsh environments |

| Freeze-Thaw Durability | 50-60% improvement | Extended lifespan in cold climates |

| Abrasion Resistance | 40-50% increase | Lower maintenance costs for high-traffic surfaces |

Furthermore, polypropylene fiber is alkali-resistant, meaning it doesn't degrade in the highly alkaline environment of concrete. Unlike steel reinforcement, it never corrodes, eliminating the risk of rust staining or expansion cracking. We've found this particularly valuable in projects with exposure to de-icing salts or marine environments.

At approximately 0.1-0.2% by volume in typical applications, polypropylene fiber delivers these benefits without significantly increasing material costs. The fiber distributes evenly during mixing without clumping (when properly dosed), making it contractor-friendly without specialized equipment or training.

Conclusion

Polypropylene fiber1 doesn't replace structural reinforcement but works alongside it as a specialized solution for concrete's "skin-deep" problems. By creating a three-dimensional network that holds microcracks in place during curing, it delivers more durable, impact-resistant and waterproof concrete structures that last longer with less maintenance.