Getting a smooth, flawless wall finish seems simple until you try it yourself. Poor-quality wall putty leads to cracks, bubbling, and peeling that costs time and money to fix.

Quality wall putty1 and skim coat2 create smooth, durable surfaces by filling imperfections and providing an ideal base for paint. The right additives prevent cracking, enhance adhesion, improve workability, and extend shelf life while maintaining cost-effectiveness.

I've spent years working with contractors across developing markets, and one thing remains constant: the foundation of beautiful walls starts with quality putty. Let me share what makes truly exceptional wall putty and how the right additives transform ordinary formulations into superior products.

What Are the Essential Additives for Wall Putty and Skim Coat?

Have you ever wondered why some wall putties crack after drying while others remain perfect for years? The difference isn't luck - it's chemistry.

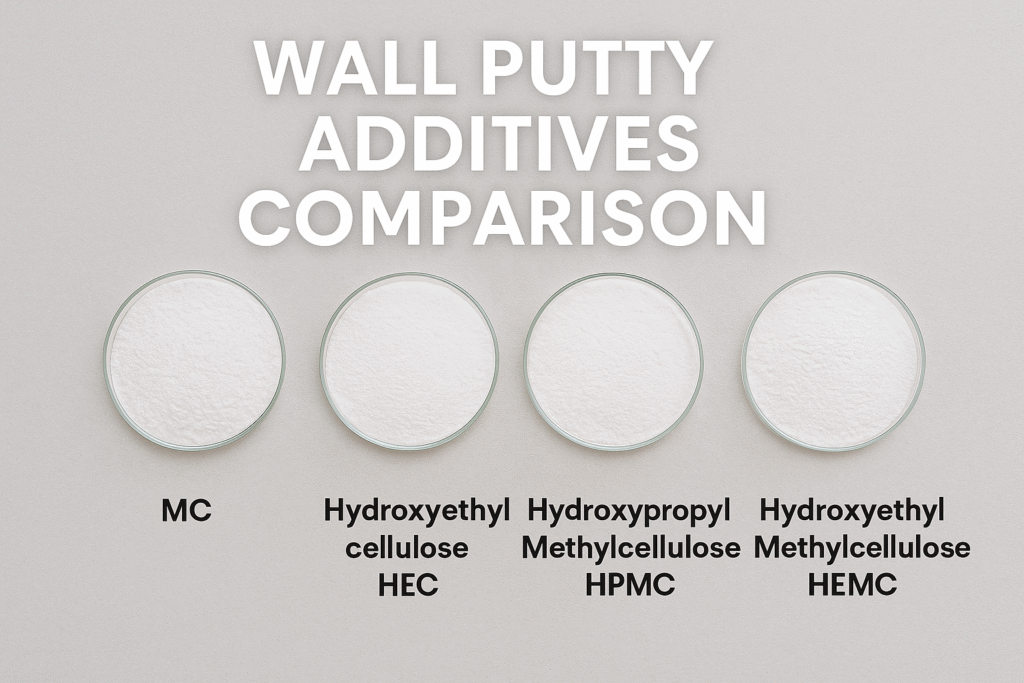

The essential additives for quality wall putty include cellulose ethers (HPMC)3, redispersible polymer powders4, thickeners, water retention agents, and anti-sagging compounds. These ingredients work together to provide workability, adhesion, flexibility, and durability to the finished surface.

When I first started supplying additives to paint factories in Saudi Arabia, I noticed many manufacturers struggled with batch consistency. Their wall putty would perform differently depending on temperature, humidity, and even the specific batch of raw materials they received. This inconsistency led to customer complaints and wasted product.

The key to consistent wall putty performance lies in using the right cellulose ethers. Hydroxypropyl methylcellulose (HPMC)5 is the backbone of quality putty formulations. It provides water retention that prevents too-rapid drying, which causes cracking. It also gives the putty its smooth, workable consistency that applicators love.

But not all HPMC is created equal. The viscosity, substitution degree, and particle size all affect performance. For example, HPMC with 100,000 mPa·s viscosity creates putty that hangs well on vertical surfaces without sagging, while lower viscosity grades around 15,000-30,000 mPa·s work better in spray applications. Mesh size matters too - finer mesh HPMC dissolves faster, reducing lumps in the final product.

Beyond HPMC, redispersible polymer powders4 add crucial flexibility and adhesion. In hot climates like the UAE or Saudi Arabia, putty needs extra flexibility to handle thermal expansion without cracking. RDP provides this flexibility while also enhancing adhesion to difficult substrates like smooth concrete.

What Are the Advantages of KEHAO Additives for Wall Putty Skim Coat?

My mortar factory produced excellent products, but constant quality issues from our additive suppliers drove costs up and reliability down. Could there be a better way?

KEHAO additives offer superior consistency, customized solutions for specific climate conditions, comprehensive technical support, cost-effective formulation optimization, and enhanced product performance compared to standard market offerings.

Working with manufacturers across developing countries has taught me that the real value of additives goes far beyond their chemical properties. When I visit putty manufacturers in places like Pakistan, India or Saudi Arabia, I often see them struggling with the same problems: quality consistency, application issues in extreme climates, and finding the right balance between cost and performance.

KEHAO's advantage starts with consistency. Our six production lines maintain strict quality control measures that ensure every batch performs identically. This consistency is crucial for putty manufacturers who need predictable results. We've invested in advanced testing equipment that monitors viscosity profiles across temperature ranges - something particularly important for products headed to markets with extreme temperature fluctuations.

The real game-changer is our customization approach. Rather than offering one-size-fits-all products, we analyze specific needs based on climate conditions. For example, our HPMC for the Middle East market has enhanced water retention properties to prevent flash-drying in hot conditions. For humid tropical environments like the Philippines or Vietnam, we adjust the formulation to include anti-fungal properties and improved workability in high humidity.

Our technical support extends beyond simply selling additives. When a major customer in Brazil was experiencing sagging issues with their putty, our team didn't just recommend a higher viscosity grade - we sent technical experts who worked alongside their formulators to develop a customized solution that considered all factors, from local aggregates to typical application techniques in their market.

Cost optimization remains a priority without sacrificing quality. By finely tuning the balance between HPMC, redispersible powders, and other ingredients, we help manufacturers reduce overall formulation costs while maintaining or even improving performance characteristics.

How Do Cellulose Ethers Impact Wall Putty Performance?

Ever applied putty only to watch it slide down the wall or dry too quickly, leaving cracks? The problem wasn't your technique - it was missing or poor-quality cellulose ethers.

Cellulose ethers like HPMC and HEMC control water retention, improve consistency and workability, prevent sagging on vertical surfaces, and ensure proper curing time. They create the ideal balance between application ease and final strength.

During my visits to construction sites across developing markets, I've witnessed firsthand how cellulose ethers transform the application experience. In India, I watched workers struggling with a locally-produced putty that dried almost immediately after application in the hot climate. The quick water loss made proper smoothing impossible and resulted in a weak, crack-prone surface. After switching to a formulation with our KEHAO HPMC, the difference was remarkable.

Water retention is the most critical function of cellulose ethers in wall putty. They form a protective gel structure that regulates how quickly water evaporates from the mixture. Think of it as a time-release mechanism for moisture. In practical terms, this means applicators have the optimal working time to spread and smooth the putty before it begins to set. In hot climates like Saudi Arabia or UAE, this property becomes even more crucial.

The viscosity profile of cellulose ethers also directly impacts application behavior. HPMC with optimal viscosity creates putty that spreads easily under trowel pressure but regains structure once the pressure is removed. This thixotropic behavior prevents sagging on vertical surfaces - a common problem with inferior formulations.

Different grades of cellulose ethers produce varied effects:

| HPMC Viscosity | Best Application | Performance Characteristics |

|---|---|---|

| 15,000-30,000 mPa·s | Spray applications | Flows easily, levels well |

| 40,000-60,000 mPa·s | General purpose | Good balance of workability and sag resistance |

| 100,000+ mPa·s | Vertical surfaces | Excellent sag resistance, longer working time |

Beyond viscosity, the substitution degree (how hydroxypropyls and methyl groups are arranged in the molecule) affects water retention and dissolution speed. Our KEHAO HPMC is engineered with optimal substitution patterns for wall putty applications, ensuring consistent performance across temperature ranges.

Conclusion

Quality wall putty depends on the right additives, particularly cellulose ethers like HPMC. KEHAO's consistent, customized solutions offer superior performance across different climates, helping manufacturers deliver flawless finishes that stand the test of time.

-

Explore the advantages of quality wall putty for achieving smooth, durable surfaces in your projects. ↩

-

Learn about skim coats and their role in creating flawless wall finishes. ↩

-

Discover how cellulose ethers enhance the performance of wall putty for better results. ↩

-

Find out how these powders contribute to flexibility and adhesion in wall putty formulations. ↩ ↩

-

Discover the unique properties of HPMC that make it essential for quality wall putty. ↩