Tile installation can be frustrating with traditional methods. I've seen countless projects ruined by cracking, loosening, and efflorescence that appear weeks after installation, leaving customers angry and contractors scrambling to fix costly mistakes.

Traditional tile pasting typically involves applying a cement-sand mortar mix1 directly onto prepared surfaces, pressing tiles into this bed, and allowing it to cure. This method requires skilled labor, creates substantial mess, and often results in inconsistent adhesion strength compared to modern adhesives.

When I first started in the construction industry, these traditional methods were all we knew. But as buildings have evolved and customer expectations have risen, the shortcomings of these approaches have become impossible to ignore. Let's look at the specific problems that make traditional tile pasting methods increasingly obsolete in modern construction.

What Exactly Is the Traditional Tile Pasting Method?

The traditional way of pasting tiles gives me headaches just thinking about it. I've watched workers spend days mixing cement and sand on-site, creating dust clouds that affect everyone nearby and leave worksites in complete chaos.

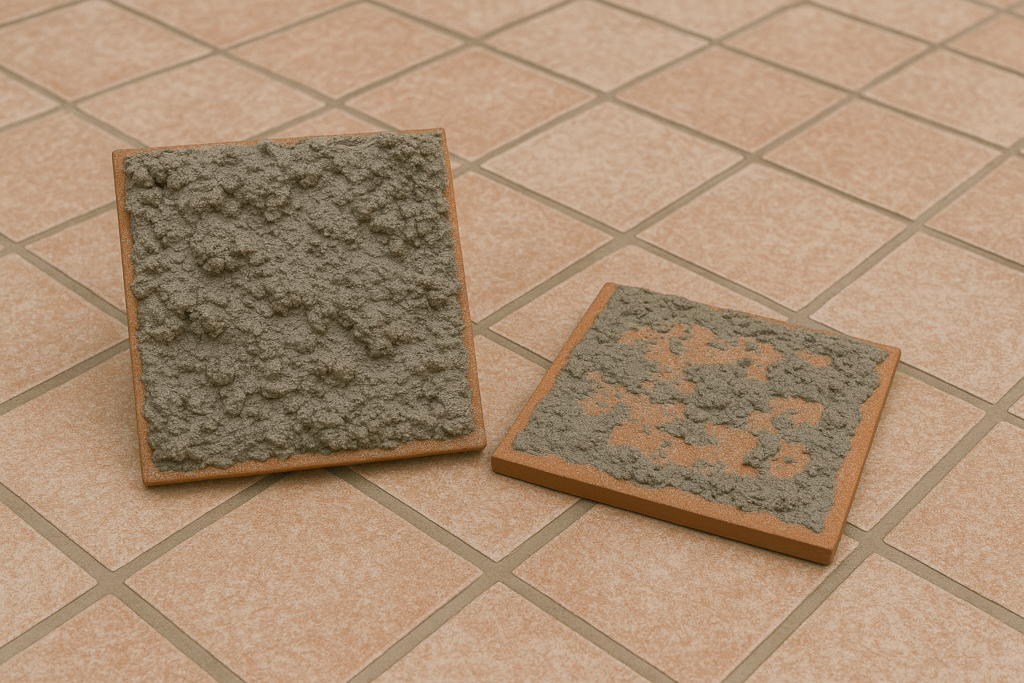

Traditional tile pasting uses a thick bed method where cement, sand and water are manually mixed on-site to create a mortar with approximately 1:3 cement-to-sand ratio. This wet mixture is applied 10-15mm thick directly to a pre-soaked substrate, with tiles embedded while the mortar is still workable.

The traditional thick-bed method dates back centuries and remains common in many developing regions. This approach requires skilled craftsmen who develop a feel for proper consistency through years of experience. The process typically starts with surface preparation - cleaning, leveling, and roughening the substrate. Workers then mix Portland cement with sand and water to create a workable paste.

This mortar must be applied at just the right consistency - too dry and tiles won't adhere properly; too wet and the mortar slumps and creates uneven surfaces. The installation process is labor-intensive, with workers spreading mortar across sections of floor or wall, then placing tiles one by one, tapping them level with rubber mallets.

The entire system relies on the chemical bonding between cement and substrate, as well as the mechanical grip created by the mortar's thickness. In many regions, this method continues to be preferred because of low labor costs and minimal equipment requirements, despite its many technical limitations.

Traditional Method Materials:

| Component | Typical Ratio | Purpose |

|---|---|---|

| Portland Cement | 1 part | Primary binding agent |

| River Sand | 3-4 parts | Provides bulk and stability |

| Water | As needed | Activates cement hydration |

| Lime (optional) | 0.5 parts | Improves workability |

Why Does Traditional Tile Pasting Lead to Quality Problems?

I've seen countless projects where beautiful tiles were installed, only to have them pop off walls or crack within months. These failures aren't random - they're built into the limitations of traditional methods that can't handle modern building stresses.

Traditional tile pasting suffers from inconsistent mix ratios, poor water retention, limited flexibility, and inadequate adhesion to non-porous tiles. These limitations cause tiles to detach, crack, or develop efflorescence as buildings settle or temperature changes occur, particularly in modern construction with varied materials.

The fundamental issue with traditional tile pasting methods lies in their inability to accommodate the realities of contemporary construction. Modern buildings experience significant movement due to thermal expansion, structural settling, and vibration - conditions that rigid cement-sand mortars simply cannot withstand. This inflexibility creates stress points that eventually lead to failure.

Traditional mortars also struggle with water management. Without proper additives like hydroxypropyl methylcellulose (HPMC)2, these mortars release water too quickly, resulting in incomplete cement hydration and reduced bonding strength. I've tested traditional mortars alongside modern thin-set adhesives containing HPMC, and the difference in water retention capability is dramatic - often 30-50% improvement with properly formulated products.

Another critical issue is the variability in mix preparation. On-site mixing inevitably leads to inconsistencies between batches. One section might have perfect adhesion while another fails prematurely. Modern manufactured tile adhesives eliminate this variability through precise factory formulation.

The thickness of traditional mortar beds also creates problems - slower drying times increase the risk of efflorescence as dissolved salts migrate to the surface during extended curing periods. Additionally, the heavyweight nature of these installations places greater structural load on buildings and increases labor costs substantially.

Common Failure Points in Traditional Methods:

| Problem | Cause | Consequence |

|---|---|---|

| Delamination | Poor substrate bonding | Tiles detaching from walls/floors |

| Hollow spots | Inconsistent mortar application | Cracked tiles when pressure applied |

| Efflorescence | Dissolved salts migrating to surface | White powder deposits ruining appearance |

| Uneven surfaces | Inadequate leveling technique | Visually unappealing installations |

| Long curing times | Thick mortar beds | Project delays and extended site disruption |

How Do Modern Alternatives Overcome Traditional Shortcomings?

I've watched the transformation in my customers' faces when they switch to modern tile adhesives. The relief is immediate - cleaner worksites, faster completion, and most importantly, significantly fewer callbacks for repairs.

Modern tile adhesives incorporate cellulose ethers like HPMC and redispersible polymer powders3 that dramatically improve water retention, flexibility, and adhesion strength. These factory-formulated products create consistent results with thinner application layers, reducing weight, speeding installation, and preventing common failures of traditional methods.

The science behind modern tile adhesives represents a quantum leap over traditional methods. These engineered products combine multiple specialized ingredients to address specific performance requirements. Hydroxypropyl methylcellulose (HPMC) serves as a critical water retention agent, ensuring cement particles have sufficient time to fully hydrate and develop maximum bonding strength. This single component solves multiple traditional problems - preventing too-rapid drying, improving workability, and enhancing adhesion.

Redispersible polymer powders (RDP) introduce flexibility that was impossible with traditional rigid mortars. These polymers create microscopic bridges between the adhesive and both the substrate and tile, maintaining bonds even as buildings move and flex. During my factory visits, I've observed stress tests where properly formulated adhesives maintain integrity under deformation that would immediately fracture traditional mortars.

The thin-bed application method made possible by these modern formulations dramatically reduces material consumption - typically using only 3-5mm thickness versus the traditional 10-15mm. This reduction decreases overall installation weight by up to 70%, significantly benefiting structural loading in multi-story buildings. The thinner layer also accelerates drying time, allowing faster project completion and earlier grouting.

Quality control represents another major advancement. Factory-produced adhesives undergo rigorous testing to international standards like EN 12004 or ISO 13007, ensuring consistent performance impossible with site-mixed materials. Modern adhesives are also specially formulated for specific applications - waterproof formulations for bathrooms, highly flexible products for exterior facades, and rapid-setting varieties for time-sensitive projects.

Key Components in Modern Tile Adhesives:

| Component | Function | Benefit over Traditional Methods |

|---|---|---|

| Cellulose Ethers (HPMC)4 | Water retention | Ensures complete cement hydration |

| Redispersible Polymer | Flexibility, adhesion | Prevents cracking and detachment |

| Special Cements | Controlled setting | Consistent cure times |

| Lightweight Fillers | Weight reduction | Easier handling, less structural load |

| Rheology Modifiers | Non-slip properties | Better vertical installation performance |

Conclusion

Traditional tile pasting methods rely on basic cement mortars that lack the flexibility, consistency and adhesion strength needed for modern construction. Today's specialized adhesives with HPMC and polymers deliver superior performance while reducing installation time and long-term failures.

-

Learn about the preparation process of cement-sand mortar mix and its implications for tile adhesion. ↩

-

Discover the benefits of HPMC in modern tile adhesives and its role in improving adhesion. ↩

-

Learn how redispersible polymer powders enhance the performance of tile adhesives. ↩

-

Exploring the role of HPMC in adhesives will provide insights into their benefits and applications in construction. ↩