Your mortar keeps drying too quickly, slides off walls, or feels rough and sticky during application? These frustrating issues can slow down projects and lead to poor results that require expensive fixes later.

You should consider using HPMC (Hydroxypropyl Methylcellulose)1 in your mortar formula primarily when you need to improve water retention, workability, adhesion, and sag resistance. These properties are especially critical in modern dry-mix mortars2 and for specific application conditions.

I've been in the construction materials industry for years, and I've seen countless contractors struggle with mortar problems. The right additives can make all the difference between a successful project and a disaster. Let me show you exactly when HPMC becomes not just helpful, but essential for your mortar formulations.

Key Scenarios for Using HPMC?

You notice your mortar turning white and drying too fast after application? This rapid moisture loss prevents proper cement hydration, leading to weak bonds and potential cracking issues down the line.

HPMC should be added when mortar will be applied to highly absorbent substrates like dry brick or concrete, or in hot, windy conditions. It acts as a "water manager" that slows moisture evaporation, allowing cement to fully hydrate and develop optimal strength.

I remember visiting a large construction site in Dubai where temperatures regularly hit 40°C (104°F). The contractor was having major issues with mortar drying before masons could even finish working with it. The first signal that HPMC is needed is when mortar turns "dry and white" almost immediately after application. This happens when the substrate (brick wall, concrete) absorbs water too quickly, or when hot, dry, windy conditions steal moisture instantly.

Without HPMC as a "water manager" to lock in moisture, the cement can't complete its reaction. This leads to poor strength and cracking later on. In that Dubai project, adding just 0.3% HPMC to their mix solved the problem completely - the mortar retained workability for over 45 minutes instead of drying in 5-10 minutes.

HPMC works by forming a protective colloidal network that slows water movement. This protection is especially important in:

| Condition | Why HPMC is Critical | Typical Dosage |

|---|---|---|

| Hot climate (>30°C) | Prevents rapid evaporation | 0.3-0.5% |

| Porous substrates | Stops substrate from "stealing" water | 0.2-0.4% |

| Windy conditions | Reduces surface evaporation | 0.3-0.4% |

| Low humidity environments | Maintains critical moisture level | 0.3-0.5% |

Primary Benefits of HPMC?

Your mortar slides down the wall like mud when you're trying to apply a thicker layer? This frustrating sag wastes material and makes it impossible to maintain consistent thickness.

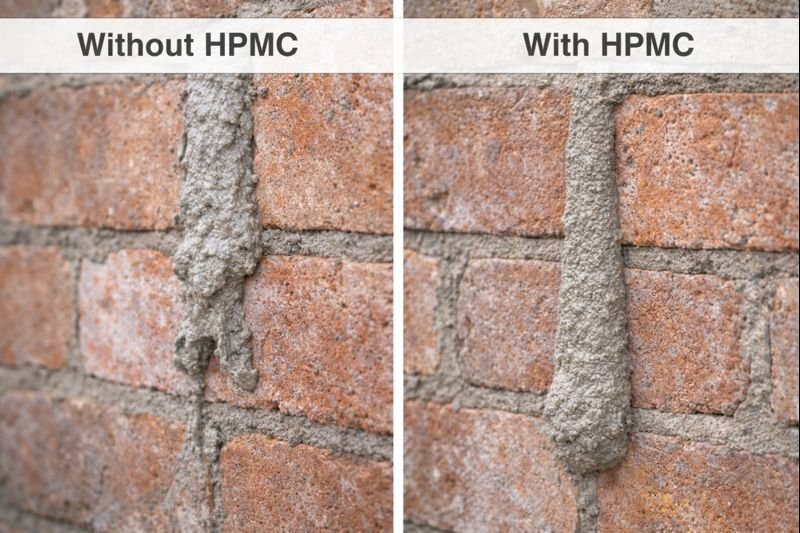

HPMC provides crucial thixotropic properties to mortar, creating an internal structure that prevents sagging while still allowing easy spreading. It increases viscosity when mortar is at rest (staying put on vertical surfaces) while becoming more fluid when worked with tools.

The second clear signal that you need HPMC is when you're plastering or tiling a wall, and your mortar slumps down "like mud" that "won't stay put." This sagging happens because the mortar lacks structure. HPMC acts as the perfect thickening agent, instantly giving your mortar the ability to "stand up" on vertical surfaces, staying exactly where you place it and giving you ample time to work and adjust.

I once consulted for a major tiling project in Singapore where the workers were struggling with a mortar that couldn't support heavy porcelain tiles on vertical surfaces. The tiles would slide down during installation, creating dangerous conditions and wasting expensive materials. Adding HPMC transformed their experience - suddenly the same mortar could hold tiles firmly in place during the critical setting period.

HPMC provides multiple benefits beyond just water retention and sag resistance:

| Benefit | How It Works | Impact on Construction |

|---|---|---|

| Improved adhesion | Creates hydrogen bonding between mortar and substrate | Reduces tile failures and delamination |

| Extended open time | Forms water-retaining film at interfaces | Gives workers more time to place and adjust tiles |

| Better slip resistance | Increases internal cohesion | Prevents heavy elements from sliding during installation |

| Smoother workability | Acts as lubricant between particles | Reduces worker fatigue and improves finish quality |

| Air entrainment | Stabilizes microscopic air bubbles | Improves freeze-thaw durability and workability |

My testing lab has verified that properly formulated mortars with HPMC can achieve up to 40% better adhesion strength and maintain workability 2-3 times longer than unmodified versions.

What quantity of water should be added for making cement mortar?

You're mixing mortar for a project and wondering exactly how much water to add? Too much ruins strength, too little makes it unworkable - getting this balance right is crucial but often confusing.

For standard cement mortar, the ideal water-to-cement ratio is typically 0.5-0.6 by weight, meaning 0.5-0.6 liters of water per kilogram of cement. When HPMC is present, you might need to increase water content by 10-15% to account for its water retention properties.

The third signal indicating you need HPMC is when workers complain that mortar is "hard, rough, sticks to tools, and difficult to spread." This poor workability makes the job exhausting and delivers subpar results. HPMC acts like a "lubricant," making mortar smooth and full-bodied, easy to trowel, and resulting in better efficiency and quality.

I once visited a major project in Mexico where workers were struggling with a particularly harsh mortar mix. The foreman showed me how the mortar was damaging their tools and slowing down the entire operation. After recommending HPMC addition, I returned two weeks later to find dramatically improved working conditions - the same workers were completing 30% more area each day with less fatigue.

Water quantity in cement mortar is critically important and must be adjusted based on multiple factors:

| Mortar Type | Base W/C Ratio | With HPMC Adjustment | Notes |

|---|---|---|---|

| Thinset tile adhesive | 0.5-0.55 | 0.55-0.6 | HPMC prevents water loss to porous tiles |

| Rendering/plastering | 0.55-0.65 | 0.6-0.7 | Higher water for smoother finish |

| Masonry mortar | 0.5-0.6 | 0.55-0.65 | Balance between workability and strength |

| Repair mortar | 0.45-0.5 | 0.5-0.55 | Lower water for higher strength |

| Self-leveling compounds | 0.6-0.7 | 0.65-0.75 | Higher water for flow properties |

When using HPMC, it's important to understand that the effective water-cement ratio (the amount actually available for cement hydration) remains optimal even with the higher total water content. This happens because HPMC temporarily holds excess water that would otherwise be lost to evaporation or substrate absorption, releasing it gradually for complete cement hydration.

Climate conditions also affect water requirements:

- Hot, dry conditions: Add 5-10% extra water

- Cold, humid conditions: Reduce water by 5-8%

- Very porous substrates: Consider substrate pre-wetting rather than excessive water addition

Testing shows that mortars with properly adjusted water content and HPMC can achieve up to 25% higher final compressive strength compared to mortars without HPMC that lose water too quickly.

Conclusion

HPMC becomes essential in your mortar when facing rapid drying, poor adhesion, or workability issues. It transforms problematic mixes into high-performing mortars through water retention, sag resistance, and improved workability. Contact ada@xhhpmc.com for samples.