Getting HPMC to dissolve properly is a common challenge for many of our customers. Incorrect dissolution can lead to lumps, reduced effectiveness, and wasted material.

To dissolve HPMC correctly, you need to match your dissolution method to your specific HPMC type. Instant type (surface-treated) HPMC dissolves in cold water with agitation, while hot-soluble type requires dispersion in hot water (above 85°C) followed by cooling for complete dissolution.

As a manufacturer with six production lines, I've seen countless clients struggle with HPMC dissolution. In this guide, I'll share our factory's proven techniques for different HPMC types, helping you achieve perfect dissolution every time.

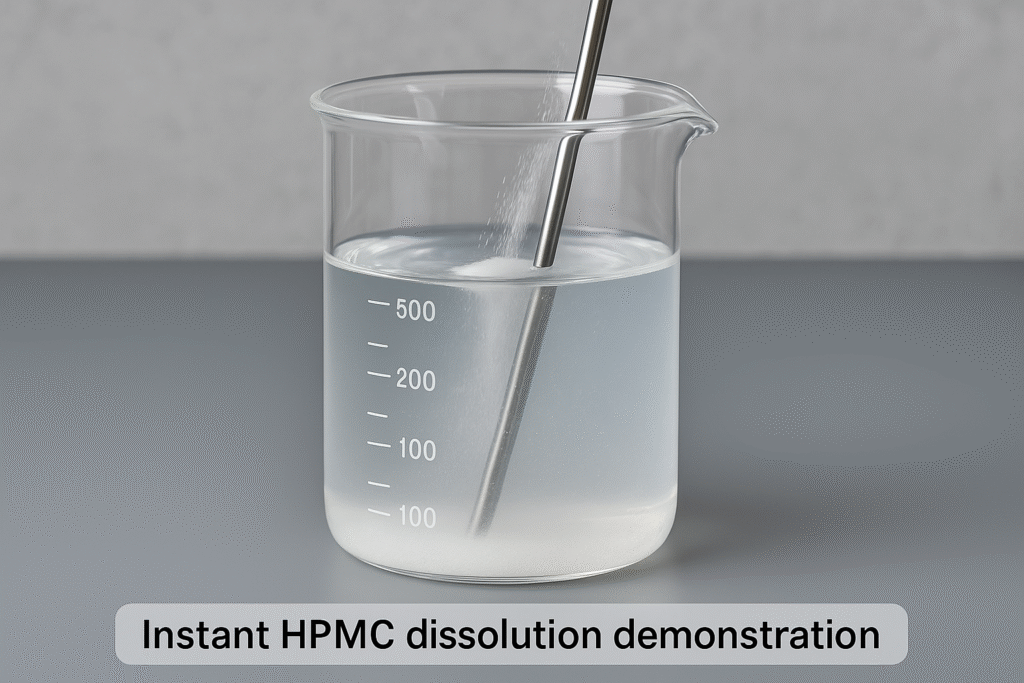

Instant Type (Surface Treated) HPMC: How Does It Dissolve?

Many customers waste time and materials when dissolving surface-treated HPMC. Using the wrong water temperature or inadequate mixing can result in clumps that never fully dissolve.

Instant type HPMC is surface-treated to prevent lumping in cold water. To dissolve it properly, add the powder slowly to cold water (below 40°C) while stirring continuously. Complete dissolution typically occurs within 20-30 minutes depending on grade and concentration.

The key advantage of instant type HPMC is its easy dissolution in cold water, which saves time and energy in production processes. I often recommend this type to clients who need quick incorporation into their formulations.

For best results with instant type HPMC, follow these steps:

- Prepare water at room temperature (20-25°C)

- Create a vortex in the water using a high-speed mixer

- Slowly add the HPMC powder into the vortex, not all at once

- Continue mixing at moderate speed for 20-30 minutes

The surface treatment of instant HPMC involves applying specific surfactants that prevent the particles from sticking together when they contact water. This treatment adds approximately 3-5% to the production cost but significantly improves ease of use.

| Parameter | Recommendation | Reason |

|---|---|---|

| Water Temperature | Below 40°C | Higher temperatures reduce solubility |

| Addition Rate | Slow, gradual | Prevents lumping |

| Mixing Speed | High initially, then moderate | Creates vortex, then ensures complete dissolution |

| Dissolution Time | 20-30 minutes | Ensures complete hydration |

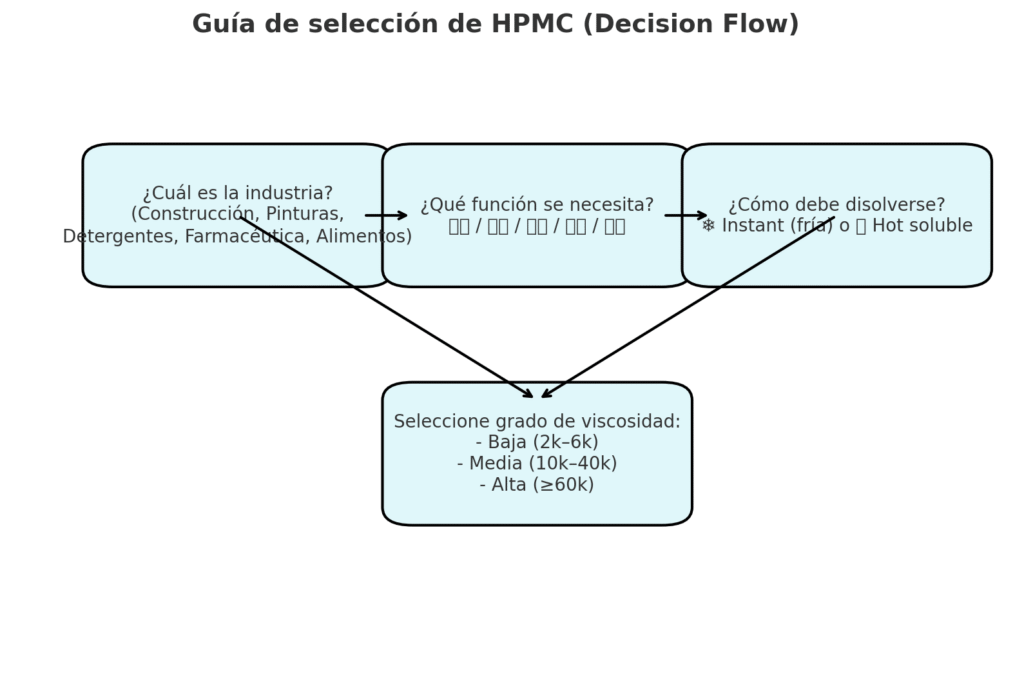

Applications: Where Is Each Type Best Used?

Many first-time users select the wrong HPMC type for their application. This mismatch can lead to processing difficulties, inconsistent results, and production delays.

Instant type HPMC is ideal for dry-mix mortars, tile adhesives, and products where cold-water mixing is preferred. Hot-soluble types excel in processes with heated water availability, like industrial paper production, pharmaceutical manufacturing, and certain construction applications requiring delayed viscosity development.

In my experience working with clients across Saudi Arabia, UAE, and other markets, application needs often dictate which HPMC type is most suitable. For example, our clients in hot climates often prefer instant types for construction applications because water on job sites is already warm, making cold-water dissolution more practical.

The choice between HPMC types significantly impacts production efficiency and final product quality. Many of our clients in the paint industry prefer instant types for their ready-mixed formulations, while our clients producing dry-mix mortars may choose either type depending on their production setup.

Application considerations include:

- Production equipment capabilities

- Available water temperature in manufacturing

- Required dissolution speed

- End-product performance needs

- Cost considerations (instant types typically cost 3-5% more)

We've found that clients who match HPMC type to their specific application requirements experience fewer production issues and achieve more consistent end products. For example, one of our clients in India switched from hot-soluble to instant type for their tile adhesive production, reducing mixing time by 40% and improving batch consistency.

Hot Soluble Type (Non-Surface Treated): What's The Correct Method?

Improper dissolution of hot-soluble HPMC leads to wasted material and compromised product performance. I've seen manufacturers struggle with partially dissolved HPMC creating inconsistent viscosity in their end products.

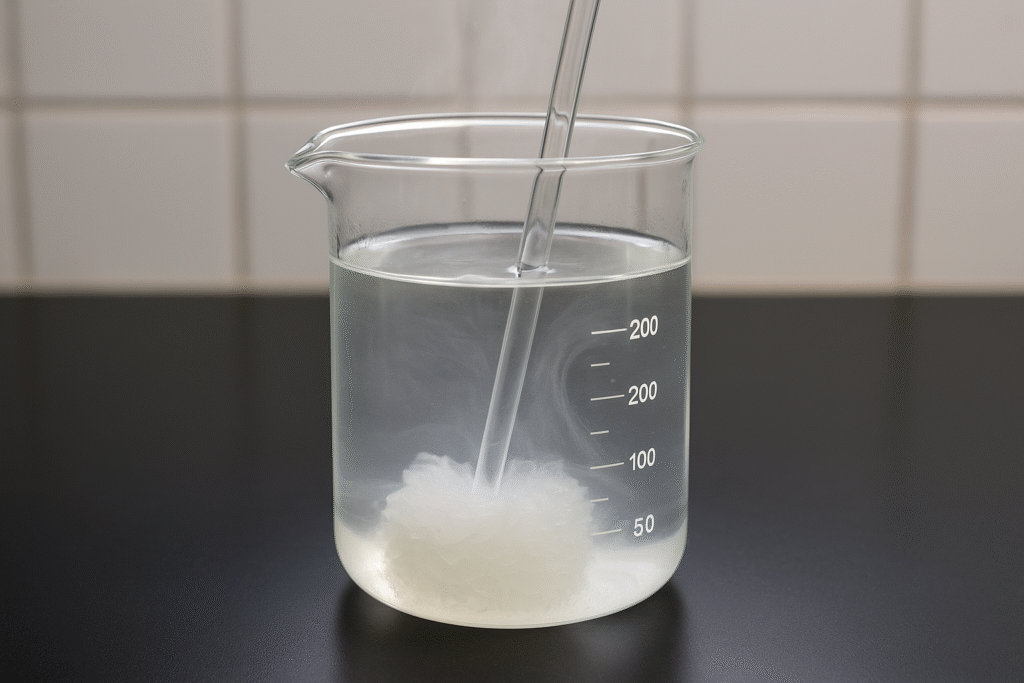

Hot soluble HPMC requires a two-step dissolution process. First, disperse the powder in hot water (85-95°C) to achieve proper wetting without viscosity development. Then, cool the mixture to below 40°C for complete hydration and viscosity development.

The hot dissolution method takes advantage of HPMC's unique thermal properties. At temperatures above 85°C, HPMC particles are wetted but remain insoluble, allowing for even dispersion without immediate viscosity development. This property helps prevent the formation of lumps that are difficult to dissolve later.

For hot-soluble HPMC, I recommend this specific procedure:

- Heat water to 85-95°C

- Add HPMC powder while stirring moderately (not too fast to avoid air incorporation)

- Continue mixing for 5-10 minutes to ensure complete dispersion

- Allow the mixture to cool naturally or with controlled cooling to below 40°C

- Continue mixing during cooling for another 20-30 minutes for complete hydration

This method creates a more homogeneous solution compared to direct cold-water dissolution. In one case, our client in Pakistan reduced defects in their final product by 35% after switching to this proper hot dissolution method.

| Phase | Temperature | Purpose | Duration |

|---|---|---|---|

| Dispersion | 85-95°C | Particle wetting without lumping | 5-10 minutes |

| Cooling | Gradually to <40°C | Allow hydration to begin | Variable |

| Hydration | Below 40°C | Complete dissolution and viscosity development | 20-30 minutes |

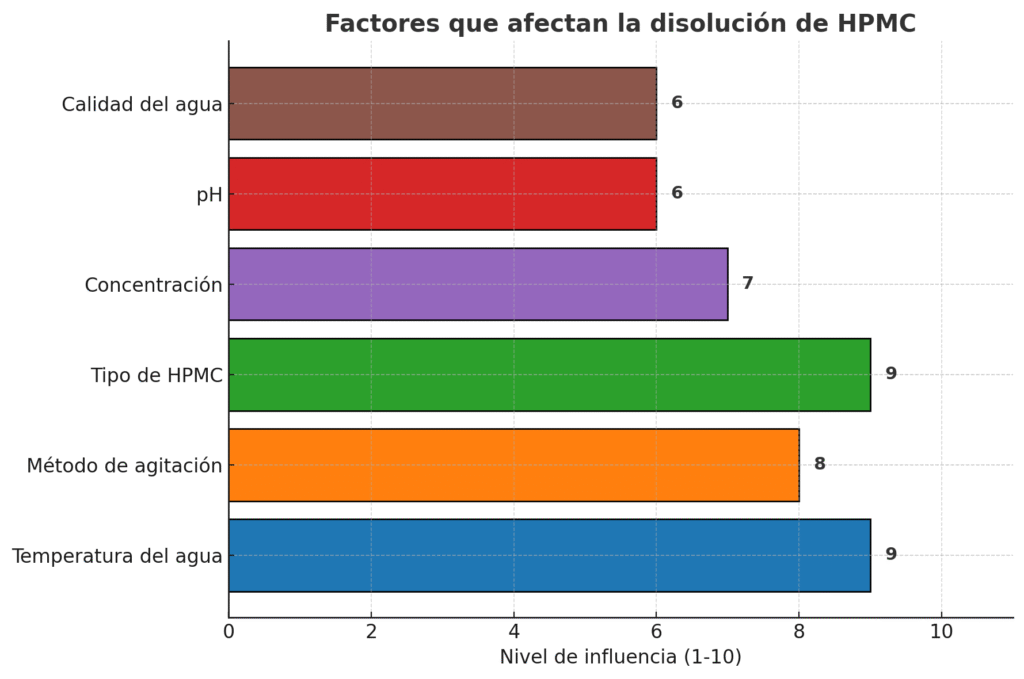

Practical Considerations: What Factors Affect Dissolution?

Many users overlook critical factors that affect HPMC dissolution. These oversights often lead to inconsistent results, even when following standard dissolution procedures.

HPMC dissolution is affected by water quality, viscosity grade, concentration, mixing equipment, and pH. Higher viscosity grades and concentrations require longer dissolution times. Hard water can impair dissolution, while mixing equipment must provide adequate shear force without excessive air incorporation.

In our laboratory testing, we've identified several factors that significantly impact dissolution quality. Water hardness is particularly important – calcium and magnesium ions in hard water can interact with HPMC molecules, affecting dissolution rate and final solution properties.

From my experience working with clients across different industries, I've observed that mixer design plays a crucial role in successful HPMC dissolution. Insufficient shear force leads to incomplete dissolution, while excessive agitation can incorporate air, creating foam and bubbles that are difficult to remove.

The pH of the solution also affects dissolution behavior. HPMC dissolves best in neutral to slightly alkaline conditions (pH 7-9). In acidic environments (below pH 5), dissolution may be slower and require additional attention.

Temperature consistency throughout the dissolution process is critical. Temperature fluctuations can cause partial gelation and uneven dissolution. This is especially important in large-scale production where temperature gradients can exist within large mixing vessels.

Here are practical recommendations based on our factory's experience:

- For water hardness above 200 ppm, consider water treatment or adjustment

- Match mixer type to HPMC grade (higher viscosity grades require more powerful mixing)

- Monitor temperature continuously during dissolution

- For high concentrations (>2%), consider staged addition of HPMC

- Allow for longer dissolution times with higher viscosity grades

Recommended Uses: Which Method Should You Choose?

Selecting the wrong dissolution method wastes time and compromises product quality. I've seen customers struggle with inefficient processes simply because they didn't match the method to their needs.

Choose instant type HPMC for applications requiring quick incorporation, cold-water processing, and when heating equipment is unavailable. Select hot-soluble HPMC for applications demanding higher purity, lower cost, or when hot water is readily available in your production process.

Throughout my years at Kehao, I've guided customers through this selection process based on their specific needs. One client in Mexico was experiencing inconsistent results in their exterior wall putty. After analyzing their production setup, we recommended switching to hot-soluble HPMC with their existing heated mixing tanks, which resolved their consistency issues while reducing raw material costs by 4%.

The decision between dissolution methods should consider several factors:

- Available equipment capabilities

- Production volume and batch size

- Time constraints in production scheduling

- Energy costs (heating water vs. longer mixing times)

- Required final product properties

For small-scale operations or job site mixing, instant types offer convenience despite their slightly higher cost. For large industrial processes with existing heating capabilities, hot-soluble types often provide better economics and can offer advantages in certain applications where delayed viscosity development is beneficial.

Many of our customers in the construction sector prefer instant types for field applications, while our industrial clients often opt for hot-soluble types in their controlled manufacturing environments. The choice ultimately depends on balancing processing requirements with final product performance needs.

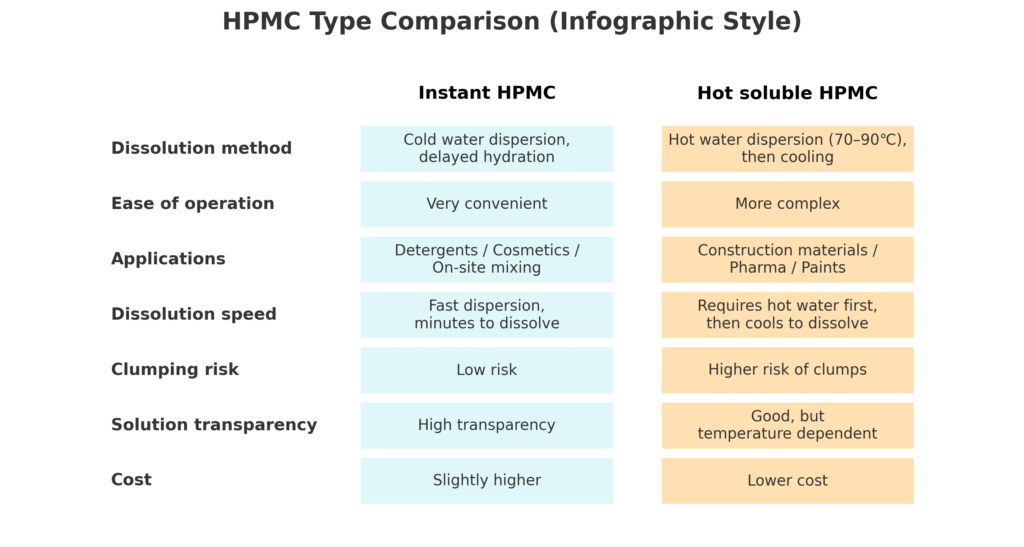

Comparative Analysis: How Do The Methods Stack Up?

Many users struggle to decide between HPMC types because they lack clear information on the pros and cons of each dissolution method. This uncertainty leads to suboptimal choices and process inefficiencies.

Instant type HPMC offers faster dissolution (20-30 minutes), simpler processing, and elimination of heating/cooling but costs 3-5% more. Hot-soluble HPMC is more economical, provides better clarity in solution, and offers controlled viscosity development but requires heating equipment and longer processing time (45+ minutes).

Based on data from our six production lines and feedback from clients across over 15 countries, I've compiled this comprehensive comparison to help you make the right choice for your application.

In our experience working with diverse industries, each method has distinct advantages in specific contexts. The instant type's ease of use makes it popular in construction applications, especially in developing markets where processing equipment may be limited. The hot-soluble type remains the standard for industrial applications where precise control of solution properties is critical.

| Factor | Instant Type | Hot-Soluble Type |

|---|---|---|

| Dissolution Time | 20-30 minutes | 45+ minutes |

| Equipment Needs | Simple mixer | Heater + mixer + cooling capability |

| Energy Consumption | Lower | Higher |

| Initial Cost | 3-5% higher | Standard |

| Solution Clarity | Good | Excellent |

| Particle Dispersion | Very good | Excellent |

| Suitability for Field Use | Excellent | Limited |

| Viscosity Development | Immediate | Controlled, gradual |

Many of our clients have found that the slightly higher cost of instant types is offset by energy savings and simplified processing. However, for large-scale operations where heating systems are already in place, the hot-soluble type often provides better overall economics and solution properties.

One interesting observation from our technical team: solutions prepared using the hot dissolution method often demonstrate slightly better stability and clarity over time, which can be critical for certain applications like pharmaceutical products and specialty coatings.

Conclusion

Choosing the right HPMC type and dissolution method depends on your specific application needs. Instant types offer convenience for cold-water processing, while hot-soluble types provide economic advantages for equipped facilities. Following the proper dissolution procedure for your chosen type ensures optimal performance.