I've seen too many construction projects fail because of weather. Your masonry work doesn't have to be one of them. Let me show you how to protect your investment.

Weather affects mortar1 in three main ways: it changes setting time, impacts strength development, and can cause complete failure. You need different additives for cold weather (like antifreeze agents) and hot weather (like retarders). Protection methods include covering, heating, and moisture control.

I learned this the hard way. Last year, a customer from Saudi Arabia called me in panic. His mortar wasn't setting properly in 45°C heat. We solved it together, and now I want to share what works.

Understanding the Impact of Temperature on Mortar in Masonry Work?

Temperature can make or break your mortar. Too hot, and it dries before gaining strength. Too cold, and it might never set properly.

Mortar works best between 5°C and 35°C. Below 5°C, chemical reactions slow down dramatically. Above 35°C, water evaporates too fast. Both extremes reduce final strength by up to 50%.

I work with mortar1 additives every day at our factory. Temperature affects everything we do. In cold weather, mortar needs more time and special care. Water in the mix can freeze and expand. This creates tiny cracks that weaken the entire structure. I've tested mortar samples at -10°C, 20°C, and 40°C. The differences are shocking.

Temperature Effects on Mortar

| Temperature | Setting Time | Strength at 28 days | Main Risk |

|---|---|---|---|

| Below 5°C | 3-5x longer | 40-60% of normal | Freezing damage |

| 5-25°C | Normal | 100% | None |

| 25-35°C | 20-40% faster | 80-90% of normal | Too fast drying |

| Above 35°C | 50% faster | 50-70% of normal | Flash setting |

Hot weather brings different problems. The mortar loses water through evaporation. This happens before the cement can use it for hydration. Without enough water, cement can't form strong bonds. Your mortar becomes weak and crumbly.

Setting Expectations: How Long Does Mortar Take to Set?

Every customer asks me this question. The answer depends on weather, mix design, and additives. Let me break it down for you.

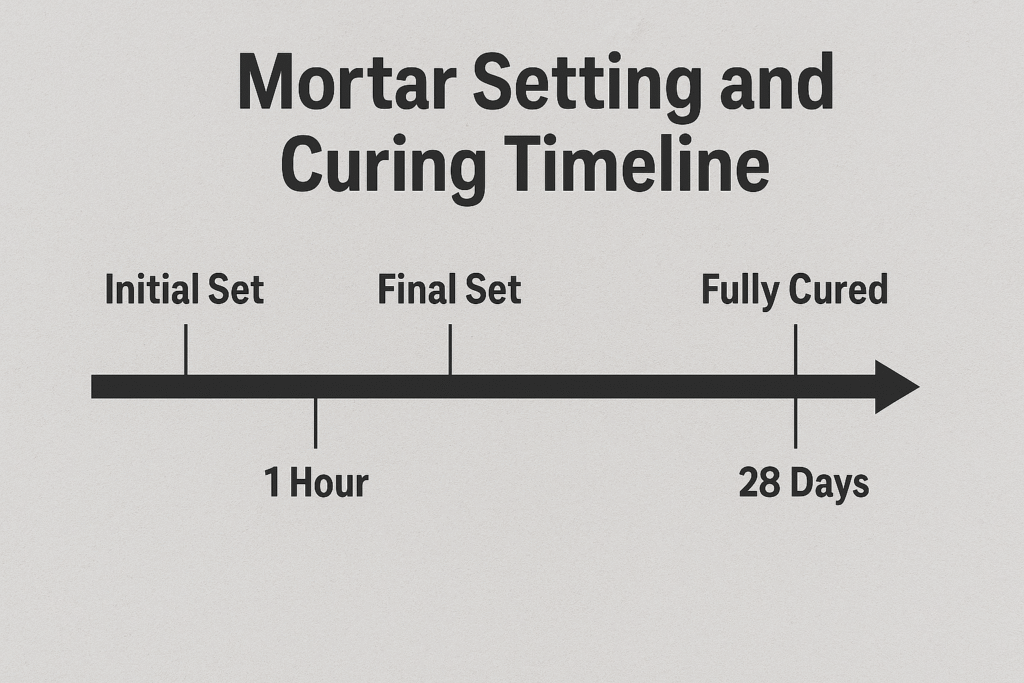

Standard mortar takes 24-48 hours for initial set and 28 days for full cure. Cold weather doubles these times. Hot weather can cut initial set to 12 hours but may reduce final strength.

I remember working with a contractor in Mexico. He needed fast-setting mortar1 for a tight deadline. We adjusted his mix with our cellulose ethers. The mortar set in 6 hours instead of 24. But we had to be careful. Fast setting doesn't mean fast curing. The mortar still needed proper moisture for 28 days to reach full strength. Many people confuse setting with curing. Setting is when mortar becomes hard to touch. Curing is the long process of gaining strength. Both need the right conditions.

Mortar Timeline Under Different Conditions

| Stage | Normal Weather | Cold Weather (5°C) | Hot Weather (35°C) |

|---|---|---|---|

| Initial Set | 2-4 hours | 6-12 hours | 1-2 hours |

| Final Set | 24-48 hours | 48-96 hours | 12-24 hours |

| 7-day Strength | 65% | 30-40% | 50-60% |

| 28-day Strength | 100% | 70-80% | 70-85% |

The type of mortar also matters. Type N mortar1 sets faster than Type S. Adding our hydroxypropyl methylcellulose can extend workability2 without affecting final set time. This gives workers more time to place blocks perfectly.

What Happens If Mortar Freezes?

Frozen mortar is every mason's nightmare. I've seen entire walls fail because of one cold night. Let me explain what happens inside.

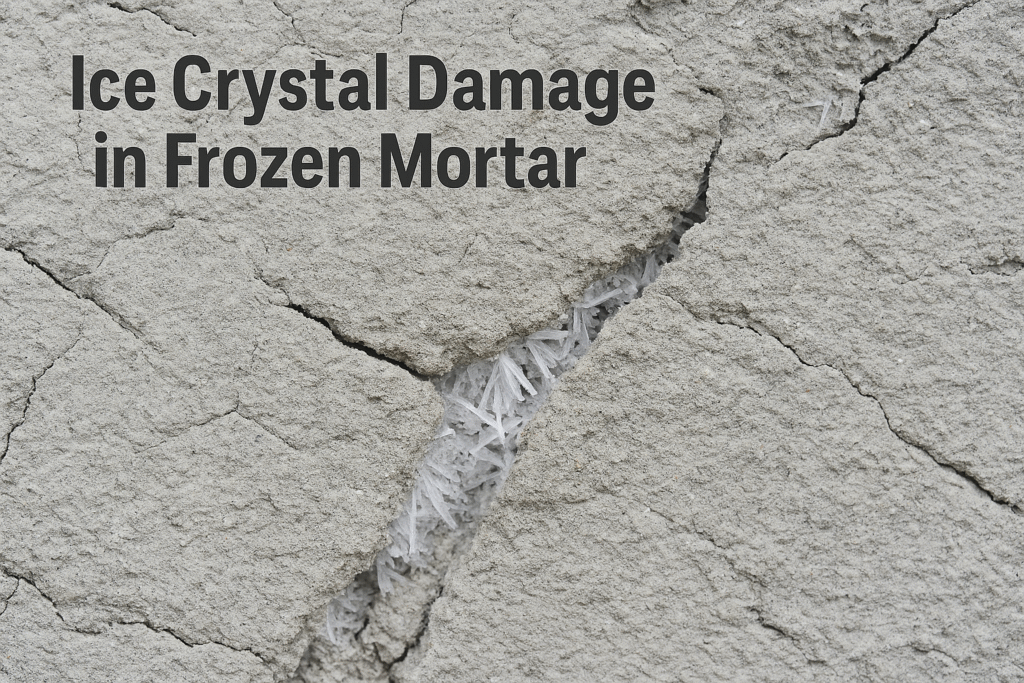

When mortar freezes before setting, ice crystals form and expand by 9%. This destroys the cement paste structure permanently. The mortar loses up to 80% of its potential strength and must be removed and replaced.

A customer from Russia taught me a valuable lesson. He mixed mortar at -5°C without protection. The next day, the mortar looked fine. But when spring came, it crumbled like sand. The ice had destroyed all internal bonds. Fresh mortar contains about 15-20% water. When this water freezes, it expands. The expansion pushes cement particles apart. Even after thawing, these particles can't reconnect properly. The damage is permanent and invisible at first.

Signs of Freeze Damage

| Time After Freezing | Visual Signs | Strength Loss | Action Needed |

|---|---|---|---|

| Immediately | Frost on surface | Unknown | Protect and warm |

| After thawing | Soft, flaky surface | 20-40% | Test strength |

| 7 days | Crumbling edges | 50-70% | Consider removal |

| 28 days | Visible deterioration | 60-80% | Must remove |

I always tell customers: prevention costs less than repair. Once mortar freezes during initial setting, you can't save it. The only solution is complete removal and replacement. This wastes time, materials, and money.

How Cold Can You Work with Mortar?

Working in cold weather requires careful planning. I help customers in cold climates every winter. Here's what you need to know.

You can work with mortar down to 4°C (40°F) with proper precautions. Below this temperature, you need heated materials, insulation, and cold-weather admixtures. Never lay mortar below -4°C (25°F) without a heated enclosure.

Last winter, I visited a job site in northern China. The temperature was 2°C. The crew heated their sand and water. They covered fresh masonry with insulated blankets. The mortar set perfectly. But they had to maintain temperature above 4°C for 48 hours. Cold weather masonry needs three things: warm materials, protection, and time. Start by storing materials indoors. Heat mixing water to 60°C maximum. This gives you a head start. The mortar temperature should be 10-15°C when placed.

Cold Weather Working Limits

| Temperature | Feasibility | Required Measures | Success Rate |

|---|---|---|---|

| 4-10°C | Good | Cover work, warm materials | 95% |

| 0-4°C | Moderate | Heat materials, insulated covers | 85% |

| -4-0°C | Difficult | Heated enclosure, admixtures | 70% |

| Below -4°C | Not recommended | Full heating system | 50% |

Our cellulose products help in cold weather. They retain water and improve workability. This gives masons more time to work before the cold affects the mortar. We also supply special additives3 that lower the freezing point of mixing water.

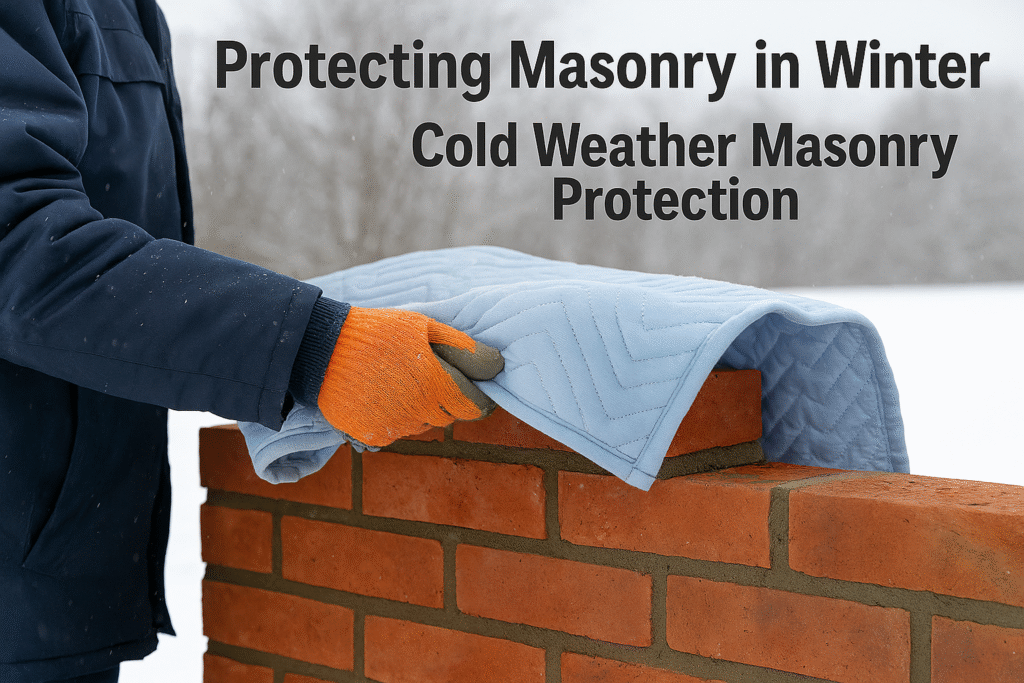

How to Protect Masonry Work in Cold Weather?

Protection starts before you mix the mortar. I've developed a system that works for our coldest customers. Let me share it with you.

Cold weather protection includes: preheating materials, using insulated blankets, creating windbreaks, and maintaining temperature above 4°C for 48 hours. Add cold-weather admixtures and never use frozen materials.

A contractor in Canada showed me his method. He builds temporary shelters around his work. Inside, he uses propane heaters. The masonry stays warm for days. His failure rate dropped from 15% to less than 1%. The key is maintaining consistent temperature. Sudden temperature changes cause more damage than steady cold. Cover fresh masonry immediately after laying. Use insulated blankets rated for your climate. In extreme cold, add supplemental heat under the blankets.

Cold Weather Protection Checklist

| Protection Method | When to Use | Effectiveness | Cost |

|---|---|---|---|

| Insulated blankets | Always below 10°C | High | Low |

| Windbreaks | Windy conditions | Medium | Low |

| Heated enclosures | Below 0°C | Very High | High |

| Admixtures | All cold weather | High | Medium |

| Material preheating | Below 4°C | High | Medium |

I recommend starting protection 24 hours before work begins. Store all materials in heated areas. Mix mortar in small batches to prevent cooling. Work during the warmest part of the day. Most importantly, plan for protection to continue 48-72 hours after placement.

Mortar Additives for Cold Weather?

Cold weather additives save projects. I formulate these products at our factory. Each type serves a specific purpose.

Cold weather mortar additives include: accelerators (calcium chloride), antifreeze agents (calcium nitrite), and water reducers. Use 1-2% by cement weight. These additives can reduce setting time by 50% and prevent freeze damage4 down to -5°C.

We developed a special blend for a project in Russia. The temperature was -10°C. Our additive package included accelerators and antifreeze agents. Combined with our HPMC for workability, the mortar performed perfectly. The building stands strong after five winters. Accelerators speed up cement hydration. This generates heat and reduces freezing risk. Calcium chloride is most common but can cause corrosion. Non-chloride accelerators are safer for reinforced masonry. Antifreeze agents lower the freezing point of water in mortar. They don't prevent freezing completely. Instead, they allow strength gain at lower temperatures.

Cold Weather Additive Guide

| Additive Type | Temperature Range | Dosage | Benefits | Limitations |

|---|---|---|---|---|

| Calcium chloride | 0 to -5°C | 1-2% | Fast, cheap | Corrosive |

| Calcium nitrite | -5 to -10°C | 2-4% | Non-corrosive | More expensive |

| Non-chloride accelerators | 0 to -5°C | 1-3% | Safe for steel | Slower than chloride |

| Antifreeze agents | -10 to -15°C | 3-5% | Very low temps | Reduces strength |

Always test additives3 with your specific materials. Some cements react differently. Our technical team helps customers optimize their mix designs for local conditions.

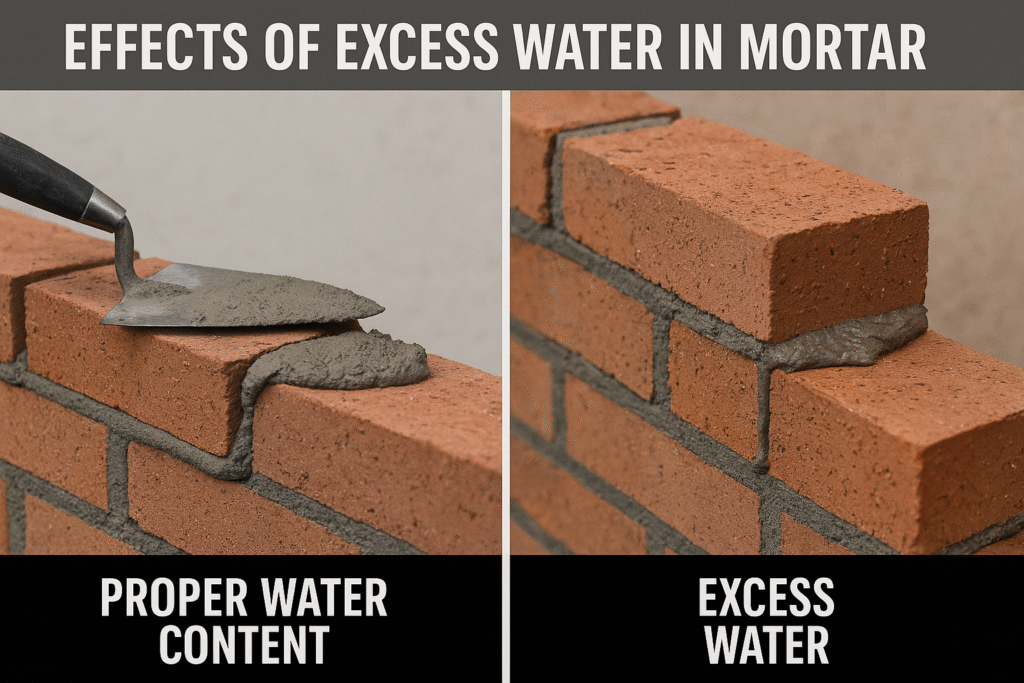

What Happens if Mortar Is Too Wet?

Too much water ruins mortar just like freezing. I see this problem often in rainy climates. Let me explain the science.

Excess water in mortar causes segregation, reduces strength by 50%, and increases shrinkage cracks. Water-cement ratio above 0.6 creates porous, weak mortar. Rain during setting washes out cement paste and leaves sand behind.

A customer in India faced monsoon season. Rain soaked his fresh masonry daily. The mortar1 turned white and powdery. We tested samples and found only 30% of design strength. He had to rebuild entire sections. Water serves two purposes in mortar1: workability and hydration. Cement needs water to form crystals. But too much water spreads cement particles too far apart. They can't bond properly. The result is weak, porous mortar that absorbs more water.

Effects of Excess Water

| Water-Cement Ratio | Workability | 28-day Strength | Durability | Problems |

|---|---|---|---|---|

| 0.4-0.5 | Stiff | 100% | Excellent | Hard to work |

| 0.5-0.6 | Normal | 90-100% | Good | None |

| 0.6-0.7 | Wet | 70-80% | Fair | Some segregation |

| Above 0.7 | Soupy | 40-60% | Poor | Severe problems |

Our water-reducing additives help maintain proper consistency without excess water. HPMC improves workability at lower water content. This gives you strong, workable mortar even in humid conditions.

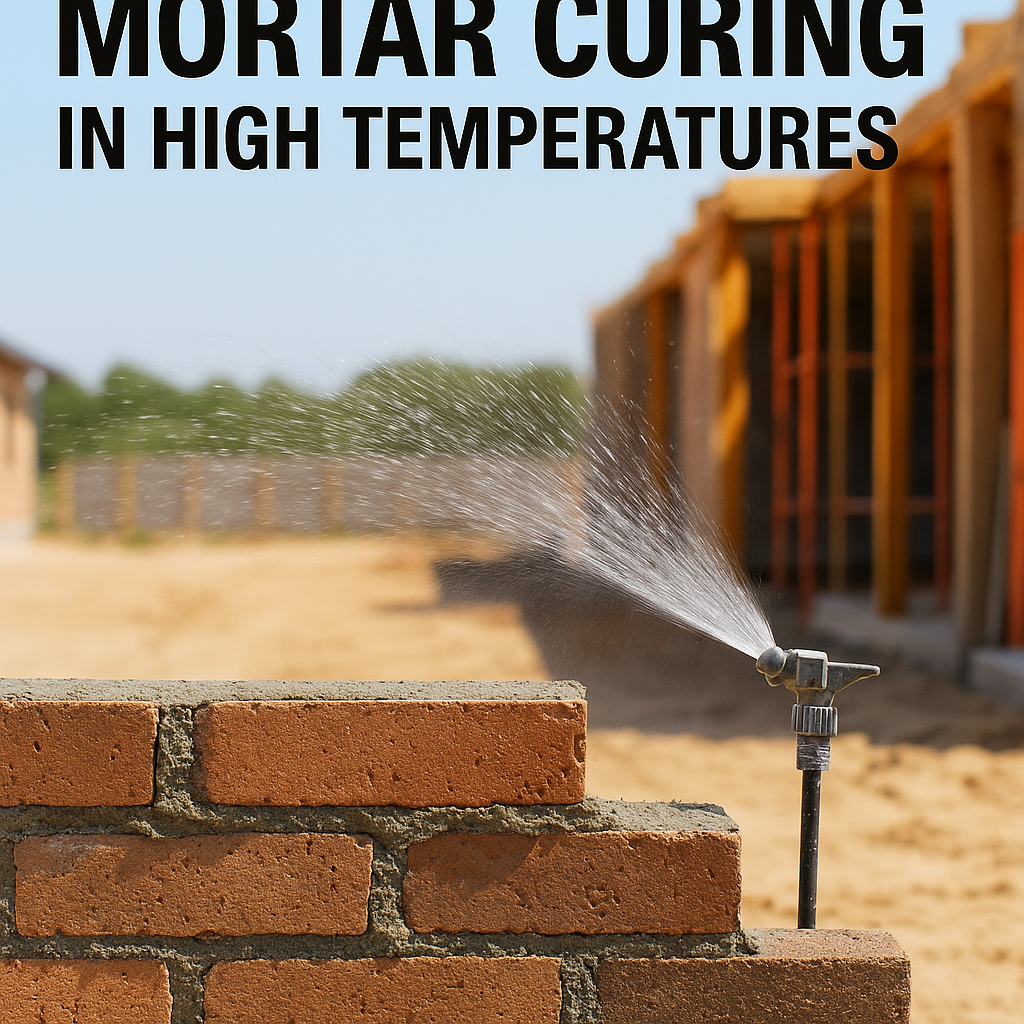

How Long Does Mortar Take to Cure in Hot Weather?

Hot weather creates opposite problems from cold. I work with many customers in desert regions. Their challenges are unique.

In hot weather above 35°C, mortar can reach initial set in 1-2 hours but needs 28 days for full cure. Rapid drying prevents proper hydration. Keep mortar moist for at least 7 days through misting or wet coverings.

My customer in Saudi Arabia taught me about desert construction. Daytime temperatures reach 50°C. His mortar would set in 30 minutes. But it never reached full strength. We solved this with retarders and a strict curing regime. Hot weather accelerates evaporation. Water leaves before cement can use it. This creates a hard but weak surface. Inside, the mortar remains soft and undercured. Proper curing in hot weather requires keeping moisture in the mortar.

Hot Weather Curing Schedule

| Day | Action Required | Frequency | Purpose |

|---|---|---|---|

| 1-3 | Mist spray | Every 2 hours | Prevent rapid drying |

| 4-7 | Wet covering | Twice daily | Maintain moisture |

| 8-14 | Damp covering | Once daily | Continue hydration |

| 15-28 | Periodic wetting | Every 2-3 days | Complete curing |

The first 24 hours are critical. Start curing as soon as mortar firms enough to prevent washout. Use fine mist to avoid disturbing the surface. Cover with wet burlap or curing5 blankets between mistings.

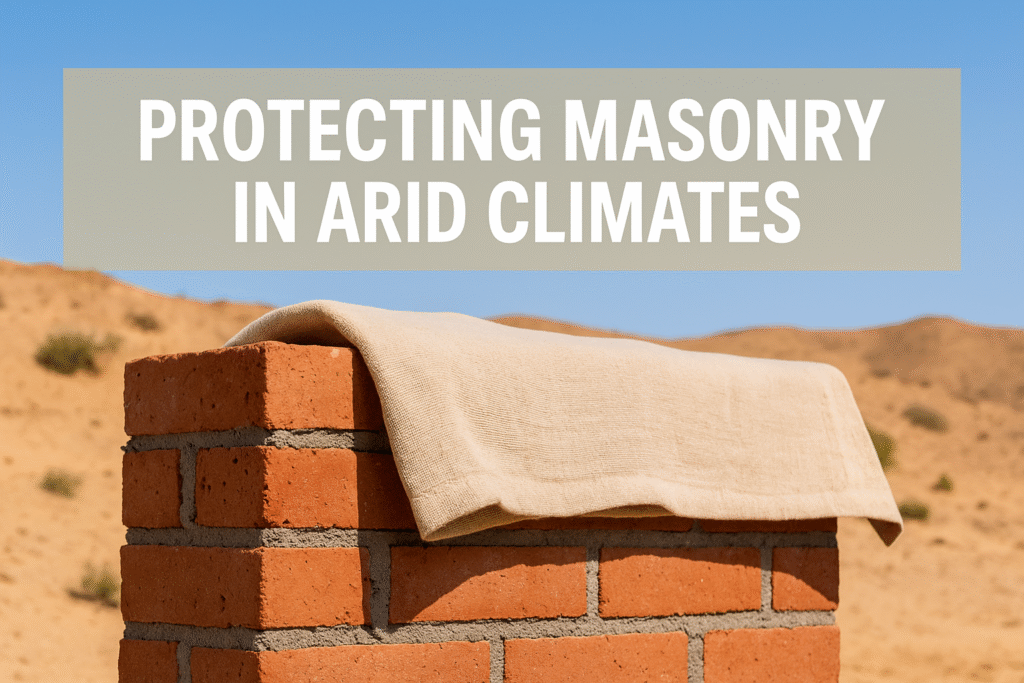

Protecting Masonry Work in Arid Regions?

Desert construction requires special techniques. I've helped projects from Saudi Arabia to Arizona. Here's what works.

Arid region protection focuses on moisture retention6. Use white plastic sheeting to reflect heat, mist regularly, and work during cooler hours. Add hydration stabilizers and extend curing to 14 days minimum.

A project in UAE changed how I think about desert masonry. The contractor worked only at night. He covered everything with white sheets during the day. His mortar strength exceeded specifications by 20%. The secret was controlling temperature and moisture together. Arid regions combine three challenges: high temperature, low humidity, and intense sun. Each factor steals moisture from mortar. Wind makes it worse. I've measured moisture loss rates of 2 liters per square meter per hour in desert conditions.

Arid Climate Protection Strategy

| Time of Day | Temperature | Protection Method | Work Activity |

|---|---|---|---|

| 5-8 AM | 25-30°C | Light covering | Active work |

| 8-11 AM | 30-40°C | White sheets + misting | Limited work |

| 11 AM-4 PM | 40-50°C | Full cover + shade | No work |

| 4-7 PM | 35-40°C | Misting + covers | Resume work |

| Night | 20-30°C | Damp covers | Best working time |

Our HPMC products7 excel in arid conditions. They form a film that reduces evaporation. Combined with proper curing, this ensures complete hydration. We also recommend prewetting masonry units. Dry blocks suck moisture from mortar immediately.

How Long Does It Take Mortar to Cure in Rainy Weather?

Rain poses different challenges. I help customers in tropical regions manage constant moisture. Balance is key.

Mortar needs 24-48 hours of dry conditions for initial set. Light rain after this won't harm properly mixed mortar. Full cure still takes 28 days, but excess moisture can delay strength gain by 20-30%.

A contractor in the Philippines showed me his rain management system. He uses temporary roofs over all work areas. Fresh mortar stays dry for 48 hours minimum. His rejection rate dropped to near zero despite daily rainfall. Rain timing matters most. Fresh mortar washes out easily. But after 24-48 hours, light rain actually helps curing. The problem is heavy rain or standing water. These can leach cement and weaken mortar permanently.

Rain Impact Timeline

| Time After Laying | Rain Intensity | Damage Risk | Required Action |

|---|---|---|---|

| 0-4 hours | Any rain | Very high | Full protection |

| 4-24 hours | Heavy rain | High | Cover immediately |

| 24-48 hours | Light rain | Medium | Monitor closely |

| 48+ hours | Light rain | Low | Beneficial for curing |

| Any time | Washout rain | High | Always protect |

Our water-resistant additives help mortar shed excess water after initial set. But nothing replaces physical protection during the critical first 48 hours. Plan work around weather forecasts. Have covers ready before you start.

Mortar Additives for Hot Weather?

Hot weather additives prevent rapid drying and maintain workability. I formulate these products for extreme conditions.

Hot weather additives include retarders (citric acid, sugars), hydration stabilizers (HPMC), and evaporation reducers. Use 0.1-0.5% retarder and 0.2-0.3% HPMC. These extend workability from 30 minutes to 2-3 hours at 40°C.

We developed a special hot weather package for a customer in Iran. Summer temperatures reached 48°C. Standard mortar became unworkable in 15 minutes. Our additive blend extended this to 2.5 hours while maintaining strength development. Retarders slow cement hydration temporarily. This gives workers time to place mortar properly. Too much retarder delays strength gain. The right amount balances workability with performance.

Hot Weather Additive Selection

| Additive Type | Dosage Range | Effect at 40°C | Cost Impact |

|---|---|---|---|

| Citric acid | 0.05-0.2% | +1-2 hours workability | Low |

| Sugar-based | 0.1-0.3% | +2-3 hours workability | Medium |

| HPMC | 0.2-0.3% | Better water retention | Medium |

| Combined package | As specified | Optimal performance | High |

HPMC serves double duty in hot weather. It retains water and improves workability. Our grades are specially modified for high-temperature stability. Standard cellulose ethers lose effectiveness above 35°C. Ours maintain performance to 50°C.

Conclusion

Weather doesn't have to ruin your masonry. Use the right additives, protect your work, and adjust your methods. Quality materials make the difference between success and failure.

At KEHAO, we manufacture cellulose ethers and additives for every climate. Our HPMC improves workability and water retention. Our technical team helps optimize your mortar for local conditions. Contact us at ada@xhhpmc.com for samples and support. Visit www.xhhpmc.com to learn more about our products. Together, we can make your masonry weather-resistant and strong.

-

Understanding mortar's properties and applications can significantly enhance your construction quality. ↩ ↩ ↩ ↩ ↩ ↩

-

Improving workability can enhance construction efficiency; discover techniques to achieve this. ↩

-

Explore different additives that can enhance mortar performance under various weather conditions. ↩ ↩

-

Identifying freeze damage early can save time and resources; learn what to look for. ↩

-

Curing is essential for mortar strength; explore best practices to ensure proper curing. ↩

-

Explore techniques for moisture retention to improve construction outcomes in arid regions. ↩

-

Discover how HPMC products can significantly improve your construction projects, especially in challenging climates. ↩